The global market for electronic connectors, including JST 2-pin variants, is experiencing steady expansion driven by rising demand in consumer electronics, automotive systems, and industrial applications. According to Mordor Intelligence, the global electrical connectors market was valued at USD 76.6 billion in 2023 and is projected to reach USD 104.4 billion by 2029, growing at a CAGR of approximately 5.2% during the forecast period. A significant portion of this growth is attributed to compact, reliable connectors such as JST 2-pin types, widely used in battery packs, PCB interconnections, and IoT devices. As product miniaturization and energy efficiency become key design priorities, manufacturers specializing in precision connectors are gaining strategic importance. Based on market presence, product quality, and technical innovation, the following five companies have emerged as leading manufacturers of JST 2-pin connectors.

Top 5 Connector Jst 2 Pin Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 J.S.T. Mfg. Co., Ltd.

Domain Est. 1997

Website: jst-mfg.com

Key Highlights: YL connector (Meets glow wire testing standards) This is a 4.5 mm pitch, wire-to-wire connector that comes with glow-wire compliant housing material and allows ……

#2 PH connector

Domain Est. 1998

Website: jst.com

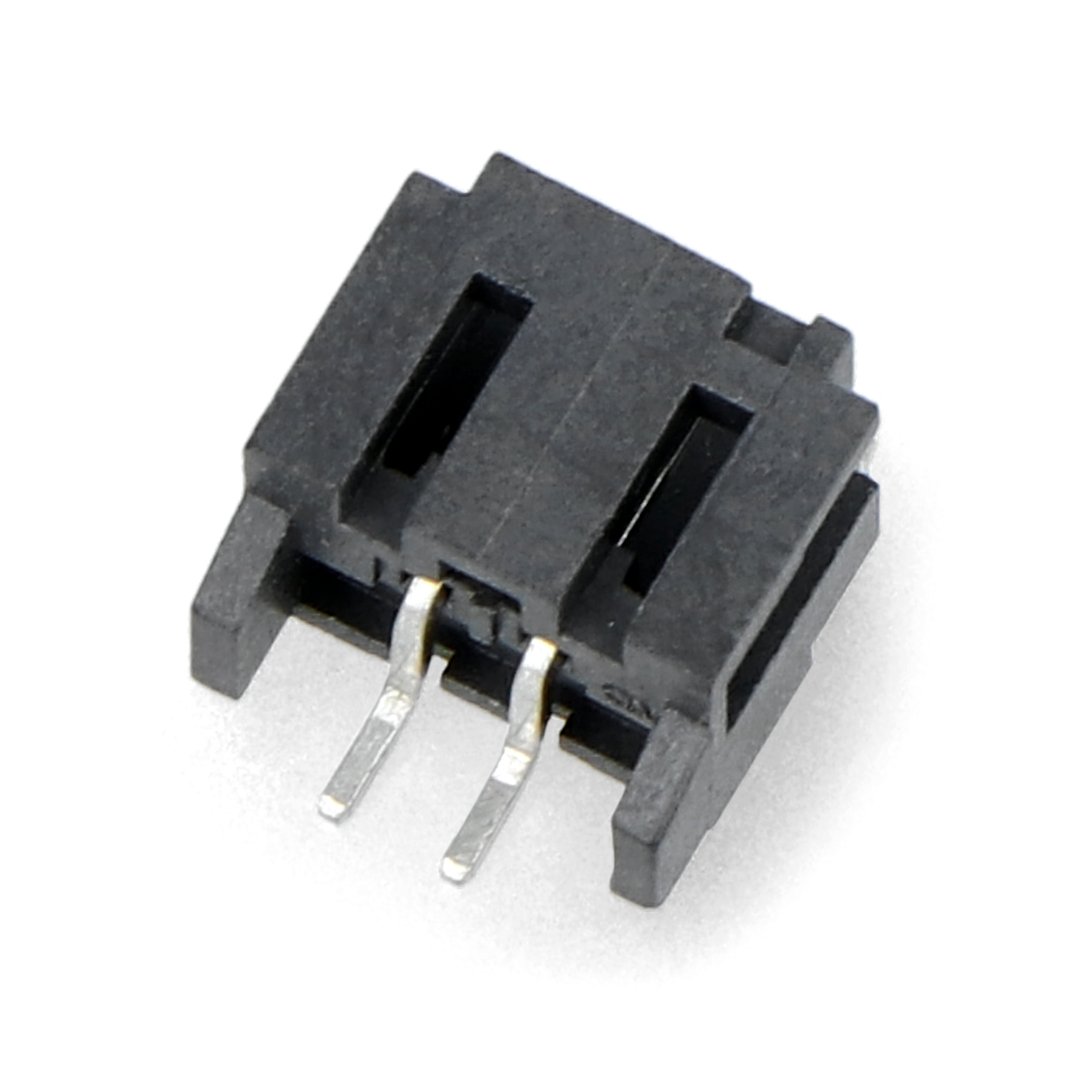

Key Highlights: With a mounting height of 8 mm and a width of only 4.5 mm in the top-entry version, this low-profile wire-to board connector features a pitch of 2.0 mm….

#3 2 Pin JST connector

Domain Est. 2012

Website: optmv.net

Key Highlights: Connector. Model. Length. DiameterD. Min.Bending Radius. Fixed Installation. Motion Installation. 2 Pin JST connector. 1to2. OPT-EX1M-2P-2B….

#4 JST

Domain Est. 2012

#5 JST Connector 2Pin Plug (Male+Female)

Domain Est. 2017

Website: pixelelectric.com

Key Highlights: JST Connector 2Pin Plug (Male+Female) : Facilitate linking power adapters, LED lamps, and controllers, ensuring marked polarity for simple, solder-free use….

Expert Sourcing Insights for Connector Jst 2 Pin

H2: 2026 Market Trends for JST 2-Pin Connectors

The global market for JST 2-pin connectors is poised for steady growth and transformation by 2026, driven by rising demand across multiple high-tech and industrial sectors. As a standardized, compact, and reliable interconnection solution, JST 2-pin connectors are widely used in consumer electronics, automotive systems, medical devices, and Internet of Things (IoT) applications. Several key trends are expected to shape the market landscape in 2026.

-

Expansion of IoT and Smart Devices

The proliferation of IoT devices—ranging from smart home sensors to industrial monitoring systems—will significantly boost demand for compact and reliable connectors. JST 2-pin connectors are favored for their small footprint and secure locking mechanism, making them ideal for low-power signal and power transmission in battery-operated IoT nodes. As smart infrastructure and connected devices scale globally, the need for dependable interconnects like JST 2-pin variants will continue to rise. -

Growth in Consumer Electronics and Wearables

The consumer electronics sector remains a primary driver for JST 2-pin connectors. With advancements in wearable technology—such as fitness trackers, smartwatches, and hearables—there is an increasing need for miniaturized, durable connectors that support frequent charging and data transfer. JST’s PH and SH series 2-pin connectors are commonly used in these applications due to their reliability and compact design. -

Electric Vehicles and Automotive Electrification

The automotive industry’s shift toward electrification and advanced driver-assistance systems (ADAS) is creating new opportunities for JST connectors. While larger connector systems dominate powertrain applications, 2-pin JST connectors are increasingly used in auxiliary systems such as sensors, interior lighting, and infotainment modules. As electric vehicle (EV) production scales through 2026, demand for secondary connectors, including JST 2-pin models, is expected to grow. -

Focus on Miniaturization and High Reliability

OEMs across industries are prioritizing component miniaturization without sacrificing performance. JST 2-pin connectors meet this demand with options like the 1.0mm pitch (SH series) and 2.0mm pitch (XH, PH series), enabling integration into densely packed PCBs. In 2026, we anticipate continued innovation in materials and design to improve thermal resistance, mating durability, and vibration resistance—critical for harsh environments. -

Regional Manufacturing Shifts and Supply Chain Resilience

Asia-Pacific remains the dominant region for both manufacturing and consumption of JST connectors, with China, Japan, and South Korea leading production. However, geopolitical factors and the push for supply chain diversification may spur localized manufacturing in India, Vietnam, and Eastern Europe. Distributors and OEMs are expected to prioritize suppliers with robust logistics and quality control by 2026. -

Sustainability and RoHS Compliance

Environmental regulations and corporate sustainability goals are influencing connector design and materials. JST has maintained compliance with RoHS and REACH standards, and by 2026, eco-friendly manufacturing processes and recyclable packaging are likely to become differentiators in the market. Demand for lead-free, halogen-free connectors will remain strong, especially in Europe and North America. -

Increased Competition and Aftermarket Proliferation

While JST (Japan Solderless Terminal) remains the original manufacturer and brand leader, the market has seen a surge in compatible 2-pin connectors from third-party suppliers—especially from China. These alternatives offer cost advantages but vary in quality. In 2026, OEMs will increasingly balance cost-efficiency with reliability, driving demand for certified clones and counterfeit-resistant sourcing channels.

In conclusion, the 2026 market for JST 2-pin connectors will be characterized by steady demand growth, technological refinement, and expanding applications across emerging industries. As connectivity becomes more embedded in everyday devices and systems, JST 2-pin connectors will remain a critical enabler of reliable, efficient, and compact electronic interconnections.

Common Pitfalls Sourcing JST 2-Pin Connectors (Quality, IP Rating)

When sourcing JST 2-pin connectors, overlooking key quality and Ingress Protection (IP) factors can lead to reliability issues, safety hazards, and product failures. Below are common pitfalls to avoid:

1. Assuming All JST Connectors Are Identical

Many suppliers use “JST” generically, but not all connectors meet genuine JST specifications. Counterfeit or clone connectors may have incorrect pin dimensions, pitch, or housing tolerances, leading to poor mating, intermittent connections, or damage during insertion.

2. Ignoring IP Rating Requirements

Not all JST 2-pin connectors are sealed. Assuming a connector is waterproof or dust-resistant without verifying its IP rating (e.g., IP67, IP68) can result in field failures in harsh environments. Always confirm the IP rating and ensure it matches your application’s environmental demands.

3. Overlooking Contact Resistance and Current Rating

Low-quality connectors may use substandard materials, leading to high contact resistance and overheating under load. Always verify current-carrying capacity and ensure connectors meet required electrical specs to prevent thermal issues.

4. Poor Mating Cycle Durability

Cheap connectors often fail after minimal mating cycles. Genuine JST connectors typically support 500–1,000+ mating cycles. Using inferior parts can result in early mechanical failure, especially in serviceable or frequently disconnected systems.

5. Inadequate Strain Relief and Wire Attachment

Low-quality connectors may lack proper crimp contacts or strain relief, leading to wire pull-out or broken connections under stress. Always inspect crimp quality and housing design to ensure mechanical reliability.

6. Misunderstanding IP Certification Scope

A connector may claim an IP rating only when mated with a specific counterpart or when fully assembled with proper seals. Always check test conditions—some ratings apply only in fully mated configurations, not when unmated or improperly installed.

7. Sourcing from Unverified Suppliers

Purchasing from unauthorized distributors increases the risk of counterfeit or non-compliant parts. Use franchised distributors or directly source from JST or certified partners to ensure authenticity and traceability.

8. Neglecting Temperature and Material Specifications

Low-grade plastics may deform or degrade under high temperatures or UV exposure. Confirm the connector’s material (e.g., nylon, PVC) and operating temperature range to ensure compatibility with your application environment.

Avoiding these pitfalls ensures reliable performance, safety compliance, and long-term durability of your JST 2-pin connector installations.

Logistics & Compliance Guide for JST 2-Pin Connector

This guide outlines key logistics considerations and compliance requirements for the procurement, handling, and use of JST 2-pin connectors in manufacturing and product development environments.

Overview of JST 2-Pin Connectors

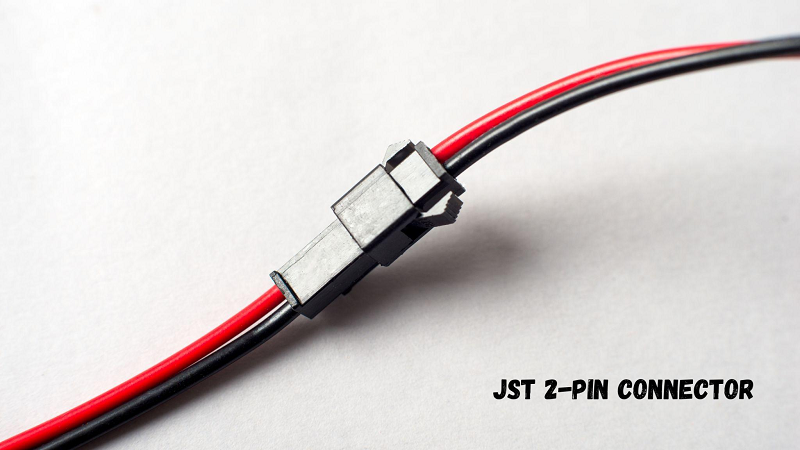

JST 2-pin connectors are compact, polarized electrical connectors commonly used for low-voltage signal and power applications in consumer electronics, IoT devices, and industrial sensors. Manufactured by Japan Solderless Terminal (JST), they feature a reliable locking mechanism and are available in various pitch sizes (commonly 2.5mm or 2.0mm). Proper logistics and compliance practices ensure performance, safety, and regulatory adherence.

Packaging and Storage Requirements

- Original Sealed Packaging: Store connectors in original moisture barrier bags (MBB) if humidity-sensitive, especially for surface-mount (SMD) variants.

- ESD Protection: Handle and store in electrostatic discharge (ESD)-safe containers and environments when applicable.

- Environmental Conditions: Store in a dry, temperature-controlled area (15–30°C, 30–60% RH) to prevent oxidation or material degradation.

- Shelf Life: Observe manufacturer-recommended shelf life; inspect for discoloration or deformation prior to use.

Shipping and Transportation

- Labeling: Clearly label packages with part number (e.g., SM2P-BSS-1-TF), quantity, RoHS status, and ESD sensitivity if applicable.

- Shock and Vibration Protection: Use cushioned packaging to prevent terminal damage during transit.

- Regulatory Documentation: Include commercial invoice, packing list, and compliance certificates for international shipments.

- Hazard Classification: JST connectors are generally non-hazardous; confirm with MSDS (Material Safety Data Sheet) if required.

Regulatory Compliance

Ensure connectors meet regional and international standards:

– RoHS (EU): Restriction of Hazardous Substances – Confirm lead-free compliance (Pb-free).

– REACH (EU): Registration, Evaluation, Authorisation and Restriction of Chemicals – Verify no SVHCs above threshold.

– UL/CSA (North America): For applications requiring safety certification, confirm if the connector is UL Recognized (file number E182837 common for JST).

– IPC/WHMA-A-620: Follow standards for cable and wire harness assembly practices.

– Conflict Minerals (Dodd-Frank Act): Suppliers should provide CMRT (Conflict Minerals Reporting Template) upon request.

Traceability and Documentation

- Batch/Date Code Tracking: Maintain records of received lot numbers and manufacturing dates for traceability.

- Certificates of Conformance (CoC): Require CoC from suppliers stating compliance with specifications and environmental regulations.

- Supplier Qualification: Source from authorized distributors or direct JST partners to avoid counterfeit parts.

Handling and Assembly

- ESD Precautions: Use grounded workstations and wrist straps when handling connectors.

- Correct Mating: Avoid forced insertion; ensure proper alignment of plug and receptacle.

- Crimping Tools: Use JST-recommended crimping tools and terminals (e.g., AWM style wires) to ensure reliable connections.

- Inspection: Perform visual and continuity checks post-assembly.

Disposal and Environmental Responsibility

- Waste Electrical Equipment (WEEE): Dispose of defective connectors through certified e-waste recycling programs.

- Recyclability: Plastic housing (typically PA66 or PBT) and metal contacts (phosphor bronze) are recyclable; separate materials when possible.

Summary

Adhering to proper logistics and compliance protocols for JST 2-pin connectors ensures product reliability, regulatory compliance, and supply chain integrity. Always consult the latest manufacturer datasheets and regional regulations to stay current with requirements.

Conclusion for Sourcing JST 2-Pin Connectors:

After evaluating various suppliers, quality standards, pricing, and availability, sourcing JST 2-pin connectors is best approached by prioritizing reputable distributors such as Digi-Key, Mouser, or Arrow, which offer genuine JST products with guaranteed specifications and reliable performance. These connectors are widely used in low-voltage applications, including battery packs, sensors, and PCB interconnections, where secure mating and compact design are critical.

While lower-cost alternatives from third-party manufacturers or online marketplaces may appear attractive, they often pose risks related to compatibility, durability, and insulation quality. Therefore, it is recommended to source connectors that meet recognized standards (e.g., JST original or authorized equivalents) to ensure long-term reliability and safety in end applications.

In summary, for consistent quality, traceability, and performance, sourcing genuine JST 2-pin connectors through authorized suppliers is the optimal strategy, especially for commercial or safety-critical applications. Establishing a long-term relationship with a trusted supplier can also support inventory stability and reduce lead time risks.