The global concrete stamps and molds market is experiencing robust growth, driven by rising demand for decorative concrete in residential, commercial, and infrastructure projects. According to Grand View Research, the global decorative concrete market was valued at USD 8.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This surge is fueled by increasing urbanization, architectural innovation, and the preference for cost-effective, durable, and aesthetically pleasing surfacing solutions. As demand for high-quality textured finishes in driveways, patios, walkways, and public spaces grows, manufacturers of concrete stamps and molds are scaling innovation in design realism, material durability, and ease of use. In this evolving landscape, a select group of manufacturers has emerged as leaders, combining advanced manufacturing techniques with extensive design libraries to meet the needs of contractors and DIYers alike. Based on market presence, product range, innovation, and customer reviews, here are the top 9 concrete stamps and molds manufacturers shaping the industry today.

Top 9 Concrete Stamps Molds Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Decorative Concrete

Domain Est. 1997

Website: euclidchemical.com

Key Highlights: A complete line of decorative systems, tools and products used to transform and enhance interior and exterior concrete….

#2 Concrete Stamping System

Domain Est. 1997

Website: brickform.com

Key Highlights: Brickform is the leading name in concrete stamping tools and materials. Find professional grade stamps, coloring products, sealers and more….

#3 Proline Decorative Concrete Systems

Domain Est. 1998

Website: prolinestamps.com

Key Highlights: Our comprehensive product line encompasses Concrete Stamps, Concrete Stamping Tools, Table Molds, Edge and Form liners, Pre-Cast GFRC Material, Color ……

#4 Concrete Stamps, Liners, Molds

Domain Est. 1998

#5 Decorative Concrete Premium Tools

Domain Est. 1999

Website: butterfieldcolor.com

Key Highlights: Our stamping & texturing tools have been designed and precision manufactured to perform to the expectations that our 40 years of field experience provides….

#6 Rockmolds.com

Domain Est. 2005

Website: rockmolds.com

Key Highlights: All the concrete stamping tools now available, used to create driveways, walkways, water features, stepping stones, landscape edging….

#7 Custom Concrete Molds and Stamps

Domain Est. 2008

Website: expressions-ltd.com

Key Highlights: Free delivery · 30-day returnsCustom Concrete Molds and Stamps We can help you EXPRESS your style by creating custom products for you. We make custom stamps and molds!…

#8 Shop Concrete Stamps

Domain Est. 2019

Website: metropolitanmaterials.com

Key Highlights: Free delivery over $2,500Shop concrete stamps online for stamping concrete projects. U.S. shipping & local Detroit delivery. Explore different patterns, sizes, and textures….

#9 Custom Concrete Stamp Molds

Domain Est. 2021

Website: siliconeconcretemolds.com

Key Highlights: With expertise in making the best stamp molds, we are all set to offer the best to the customers. We offer concrete stamp molds for sale as we are aware of the ……

Expert Sourcing Insights for Concrete Stamps Molds

H2: Analysis of 2026 Market Trends for Concrete Stamps and Molds

Market Overview and Growth Drivers

The global market for concrete stamps and molds is projected to experience steady growth leading into 2026, driven by increasing demand in residential, commercial, and infrastructure sectors. As urbanization accelerates and construction activities rise—particularly in emerging economies—architectural concrete finishes are gaining popularity for their aesthetic appeal and cost-effectiveness. Concrete stamps and molds enable contractors to replicate high-end materials such as stone, brick, wood, and tile at a fraction of the cost, making them a preferred choice in decorative concrete applications.

Key growth drivers include:

– Rising investments in infrastructure development across Asia-Pacific, Latin America, and Africa.

– Growing homeowner preference for customized outdoor spaces, such as stamped concrete patios, driveways, and pool decks.

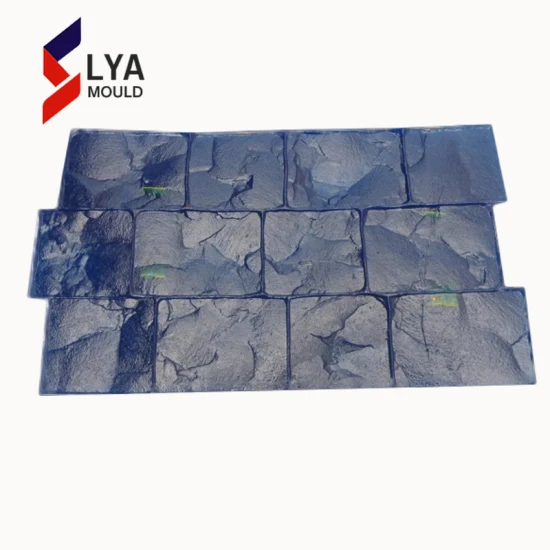

– Advancements in mold materials (e.g., urethane and polyurethane blends) that offer greater durability, detail reproduction, and ease of use.

– Expansion of DIY (do-it-yourself) culture supported by online tutorials and accessible tools.

Technological and Material Innovations

By 2026, technological advancements are expected to redefine the concrete stamps and molds industry. Manufacturers are increasingly adopting 3D scanning and printing technologies to create highly detailed and customizable molds. This innovation allows for intricate patterns and textures that were previously difficult or costly to produce using traditional steel or rubber molds.

Additionally, the development of lightweight, flexible, and wear-resistant urethane molds is enhancing usability and longevity. These materials reduce physical strain during installation and improve the consistency of stamped patterns across large surface areas.

Smart mold systems equipped with alignment guides and registration features are also gaining traction, minimizing human error and improving project efficiency—especially in commercial applications where precision is critical.

Regional Market Dynamics

The North American market is expected to remain dominant in 2026 due to high adoption rates of decorative concrete in residential landscaping and municipal projects. The U.S., in particular, has a mature market for stamped concrete, supported by a robust network of contractors and suppliers.

Meanwhile, the Asia-Pacific region is poised for the fastest growth, fueled by rapid urbanization in countries like India, China, and Indonesia. Government initiatives promoting smart cities and sustainable infrastructure are creating new opportunities for decorative concrete solutions.

Europe shows steady demand, with a focus on eco-friendly construction and heritage replication. Concrete molds are being used to restore historical facades or mimic traditional materials in compliance with preservation standards.

Sustainability and Environmental Considerations

Sustainability is becoming a key factor influencing market trends. By 2026, manufacturers are expected to prioritize eco-conscious production methods, including the use of recyclable mold materials and low-VOC (volatile organic compound) release processes. The integration of recycled aggregates in stamped concrete systems complements green building certifications such as LEED and BREEAM.

Moreover, the long lifespan and low maintenance of stamped concrete contribute to its sustainability profile, further boosting its appeal in environmentally focused construction projects.

Competitive Landscape

The concrete stamps and molds market remains fragmented, with a mix of large manufacturers and regional specialty producers. Key players are investing in R&D, expanding product portfolios, and enhancing distribution channels to gain market share. Strategic partnerships with construction firms and landscape architects are becoming more common to promote integrated design-build solutions.

Brands such as Brickform, Super Stamp, and Ultimate Images continue to lead with innovative product lines and strong brand recognition. However, increasing competition from low-cost manufacturers in Asia may pressure pricing, especially in price-sensitive markets.

Challenges and Outlook

Despite positive growth prospects, the market faces challenges including:

– Fluctuations in raw material prices (e.g., rubber, polyurethane).

– Skilled labor shortages affecting the quality of stamped concrete installations.

– Economic volatility impacting construction spending in certain regions.

Nonetheless, the long-term outlook for concrete stamps and molds remains favorable. With continued innovation, expanding applications, and growing aesthetic expectations in construction, the market is on track to achieve moderate compound annual growth rate (CAGR) of approximately 5–7% through 2026.

In conclusion, the 2026 market for concrete stamps and molds will be shaped by technological progress, regional development disparities, sustainability demands, and evolving consumer preferences—positioning the industry for resilient and adaptive growth.

Common Pitfalls When Sourcing Concrete Stamps and Molds: Quality and Intellectual Property Issues

Logistics & Compliance Guide for Concrete Stamps and Molds

Product Classification and HS Codes

Concrete stamps and molds are typically classified under specific Harmonized System (HS) codes for international shipping and customs purposes. Accurate classification ensures correct duty assessment and regulatory compliance.

- Recommended HS Code: 8205.59.50 (Other hand tools n.e.c. of base metal, not elsewhere specified)

- Alternative/Additional Codes: 8479.89.90 (Machines and mechanical appliances having individual functions, not elsewhere specified)

Note: Classification may vary by country; consult local customs authorities for precise code assignment.

Import and Export Regulations

Ensure compliance with import/export laws in both origin and destination countries. Key considerations include:

- Export Controls: Verify if the product is subject to any export restrictions, especially when shipping to sanctioned countries.

- Import Permits: Some countries may require import licenses for industrial tools or manufacturing equipment.

- Customs Documentation: Prepare commercial invoices, packing lists, and bill of lading/air waybills with accurate product descriptions, weights, and values.

Packaging and Handling Requirements

Proper packaging ensures safe transit and reduces damage claims.

- Protective Packaging: Use heavy-duty cardboard or wooden crates with internal foam or bubble wrap to prevent deformation or surface damage.

- Labeling: Clearly label packages with:

- Product name and model number

- “Fragile – Handle With Care”

- Orientation arrows

- Weight and dimensions

- Stackability: Design packaging to support stacking without crushing lower units.

Shipping and Freight Considerations

Choose appropriate shipping methods based on urgency, volume, and destination.

- Freight Options:

- LCL (Less than Container Load): For small shipments to multiple destinations.

- FCL (Full Container Load): Cost-effective for bulk orders.

- Air Freight: For urgent or high-value shipments.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP) in sales contracts.

Regulatory and Safety Compliance

Adhere to regional safety and environmental regulations.

- REACH (EU): Confirm that materials used (e.g., polyurethane, steel) comply with chemical restrictions.

- RoHS (EU): Not typically applicable, but verify if electronic components are included.

- OSHA (USA): Provide safety data sheets (SDS) if molds involve hazardous coatings or release agents.

- Labeling Requirements: Include CE marking (if applicable), warnings, and manufacturer details on product or packaging.

Product Standards and Certification

While concrete stamps are not typically subject to stringent certifications, adherence to quality standards enhances market acceptance.

- ISO 9001: Recommended for quality management systems.

- ASTM Standards: Refer to ASTM C1354 or C1563 for testing procedures related to concrete stamping and surface finishes (indirect relevance).

Returns and Warranty Logistics

Establish clear policies for defective or damaged products.

- Warranty Terms: Define duration (e.g., 1–2 years) and coverage (e.g., manufacturing defects).

- Return Process: Specify return authorization (RMA) procedures, shipping responsibilities, and inspection protocols.

- Reverse Logistics: Partner with freight providers offering return management services.

Recordkeeping and Documentation

Maintain comprehensive records for audit and compliance purposes.

- Retention Period: Keep shipping documents, customs filings, and compliance records for a minimum of 5 years.

- Digital Archiving: Store electronic copies of SDS, test reports, and certification documents.

Summary

Successfully managing the logistics and compliance of concrete stamps and molds requires attention to classification, packaging, shipping, and regional regulations. Proactive planning and documentation minimize delays, reduce costs, and ensure smooth international trade operations.

Conclusion on Sourcing Concrete Stamp Molds

Sourcing high-quality concrete stamp molds is a critical step in achieving professional, durable, and aesthetically appealing stamped concrete results. After evaluating various suppliers, materials, design options, and manufacturing techniques, it is evident that selecting the right molds significantly impacts the final outcome of any hardscaping or architectural concrete project.

Key considerations when sourcing include mold material (typically polyurethane or rubber), design realism, pattern compatibility, durability, and ease of release. It is also important to work with reputable manufacturers or suppliers that offer consistent quality, technical support, and a broad range of patterns and textures to meet diverse project needs.

Additionally, cost-efficiency should not compromise quality—investing in superior molds may involve higher upfront costs but leads to longer service life, fewer replacements, and better impressions over time. Compatibility with existing tools and installation techniques, as well as availability of edge molds and accent pieces, further enhances the overall efficiency and visual continuity of the project.

In conclusion, a strategic approach to sourcing concrete stamp molds—balancing quality, design versatility, supplier reliability, and long-term value—ensures optimal performance and superior results in decorative concrete applications. Making informed choices in mold selection ultimately contributes to the success, professionalism, and longevity of every stamped concrete endeavor.