The global septic tank market is experiencing steady growth, driven by increasing demand for decentralized wastewater treatment solutions, especially in rural and semi-urban areas. According to Grand View Research, the global septic tank market size was valued at USD 10.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This expansion is fueled by rising urbanization, stricter environmental regulations, and infrastructure development in emerging economies. Concrete septic tanks remain a dominant choice due to their durability, longevity, and cost-effectiveness over alternative materials like plastic or fiberglass. As demand intensifies, a select group of manufacturers have emerged as leaders in delivering competitively priced, high-quality concrete septic tanks at scale. Based on market presence, production capacity, pricing competitiveness, and geographic reach, the following six manufacturers represent the top players shaping the current landscape of concrete septic tank pricing and supply.

Top 6 Concrete Septic Tank Price Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Septic Tanks

Domain Est. 1996

Website: jensenprecast.com

Key Highlights: Jensen’s septic tanks feature a variety of robust septic tank solutions designed for industrial and commercial wastewater treatment needs….

#2 Septic Tanks

Domain Est. 1996

Website: lbfoster.com

Key Highlights: Precast concrete septic tanks are underground watertight containers designed to collect, store, treat, and release wastewater from residential homes or other ……

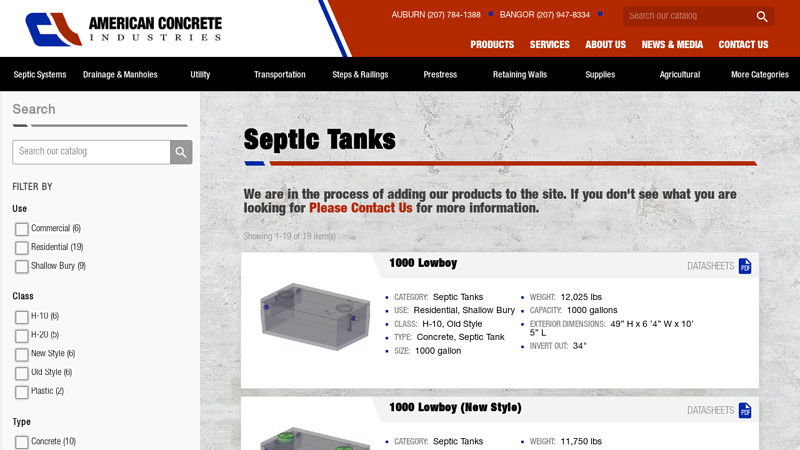

#3 Septic Tanks

Domain Est. 1998

Website: americanconcrete.com

Key Highlights: Weight:23,750 lbs; Capacity:1,500 gallons; Interior Dimensions:46″ H x 6′-0″ W x 12′-0″ L; Exterior Dimensions:61.5″ H x 6′-10″ W x 12′-10″ ……

#4 Precast Concrete Septic Tanks

Domain Est. 1999

Website: crestprecastconcrete.com

Key Highlights: Operating as one of the most efficient Precast facilities in the Midwest, our management and staff have always produced quality and durable septic tank ……

#5 Septic Tanks

Domain Est. 2015

Website: bc-concrete.com

Key Highlights: We manufacture a variety of quality precast septic tanks in various sizes to meet most every application. Related products. Tanks · Grease ……

#6 Septic Tanks for Sale

Domain Est. 2023

Website: tank-superstore.com

Key Highlights: 30-day returnsAs a premier septic tank supplier, we have an extensive selection, including 300-gallon, and up to 1500-gallon plastic septic holding tanks….

Expert Sourcing Insights for Concrete Septic Tank Price

H2: 2026 Market Trends for Concrete Septic Tank Prices

As the global construction and sanitation sectors continue to evolve, the pricing of concrete septic tanks in 2026 is expected to be influenced by a confluence of economic, environmental, and technological factors. Here’s an analysis of key market trends projected to impact concrete septic tank prices by 2026:

-

Rising Raw Material Costs

The price of cement, aggregates, and steel—core materials in concrete septic tank production—is anticipated to remain volatile due to supply chain constraints and increased global demand. Inflationary pressures and energy costs associated with cement manufacturing may drive up production expenses, leading to higher consumer prices for concrete tanks by 2026. -

Increased Demand in Developing Regions

Rapid urbanization and infrastructure development in emerging markets—particularly in Sub-Saharan Africa, South Asia, and Southeast Asia—are expected to boost demand for affordable, durable sanitation solutions. Concrete septic tanks, valued for their longevity and cost-effectiveness, will likely see increased adoption, potentially pushing prices upward due to higher demand volumes. -

Environmental Regulations and Sustainability Standards

Stricter environmental regulations aimed at reducing groundwater contamination are promoting the use of precast concrete septic systems over plastic or on-site constructed alternatives. Compliance with green building standards may lead manufacturers to invest in low-carbon cement or recycled materials, which could affect pricing—either increasing costs short-term or enabling premium pricing for eco-certified products. -

Competition from Alternative Materials

The growing popularity of fiberglass and polyethylene septic tanks—lighter, easier to install, and corrosion-resistant—poses a competitive challenge. To remain competitive, concrete tank manufacturers may optimize production efficiency or offer bundled services, potentially stabilizing or moderating price increases despite rising input costs. -

Labor and Installation Costs

The labor-intensive nature of concrete tank installation, including transportation and on-site handling, contributes significantly to total project costs. As labor wages increase globally, particularly in North America and Europe, the overall cost of concrete septic systems may rise, indirectly influencing market pricing even if the tank unit price remains stable. -

Technological Advancements and Prefabrication

The shift toward prefabricated, modular concrete septic systems is expected to improve quality control and reduce construction time. Investments in automated manufacturing may lower per-unit production costs over time, helping to offset material inflation and potentially stabilizing prices by 2026. -

Government Incentives and Rural Sanitation Programs

Public funding for rural sanitation infrastructure, such as India’s Swachh Bharat Mission or USA’s USDA Rural Development grants, may increase demand while subsidizing costs for end-users. These programs could moderate retail price increases by supporting large-scale procurement and local manufacturing.

Conclusion

By 2026, concrete septic tank prices are expected to experience moderate upward pressure due to rising material and labor costs, though regional variations will persist. Market growth in developing economies, regulatory shifts, and innovations in manufacturing will play crucial roles in shaping pricing dynamics. While competition from alternative materials remains a challenge, the durability and reliability of concrete solutions are likely to sustain their market share, especially in areas prioritizing long-term infrastructure resilience.

Common Pitfalls When Sourcing Concrete Septic Tank Prices (Quality, IP)

Sourcing concrete septic tanks involves more than just comparing prices. Buyers often encounter hidden risks related to quality, intellectual property (IP), and long-term performance. Below are common pitfalls to avoid when evaluating concrete septic tank suppliers and pricing.

Underestimating Quality Variations Despite Similar Price Quotes

One of the most frequent mistakes is assuming that all concrete septic tanks priced similarly offer the same durability and performance. Concrete strength, reinforcement (rebar), curing processes, and manufacturing standards can vary significantly between suppliers. Lower-priced tanks may use substandard concrete mix designs, inadequate steel reinforcement, or poor casting techniques, leading to cracking, leaks, or structural failure over time.

Ignoring Manufacturing Standards and Certifications

Not all manufacturers comply with national or international standards (e.g., ASTM, CSA, or ISO). Purchasers may focus solely on price without verifying whether the tanks meet regulatory requirements for load-bearing capacity, water tightness, and environmental resistance. Choosing a non-compliant tank may result in failed inspections, costly replacements, or environmental violations.

Overlooking Intellectual Property (IP) in Design and Technology

Some advanced septic tank designs incorporate patented technology—such as integrated baffles, filtration systems, or modular connections. Sourcing from unauthorized or counterfeit manufacturers can lead to IP infringement issues, especially in commercial or government projects where compliance with original designs is mandatory. Using IP-protected designs without licensing may result in legal action or project delays.

Failing to Assess Supplier Longevity and After-Sales Support

Low-priced tanks from fly-by-night manufacturers may seem attractive initially, but they often lack warranty coverage, technical support, or spare parts availability. If a tank fails prematurely, the absence of reliable after-sales service can lead to extended downtime and higher lifecycle costs.

Not Accounting for Transportation and Installation Costs

Concrete septic tanks are heavy and bulky. Some suppliers quote low unit prices but do not include shipping, handling, or crane requirements. Failing to factor in logistics can inflate the total cost significantly. Additionally, poor handling due to inadequate packaging or lack of installation guidance may compromise tank integrity before it’s even put into use.

Conclusion

When sourcing concrete septic tanks, prioritizing the lowest price without evaluating quality standards, compliance, and IP rights can lead to long-term financial and operational setbacks. Conduct thorough due diligence on suppliers, request third-party test reports, verify design IP status, and consider total cost of ownership—not just the initial quote.

Logistics & Compliance Guide for Concrete Septic Tank Price

When evaluating the cost of concrete septic tanks, it’s essential to consider not only the initial purchase price but also logistics and regulatory compliance factors that can significantly impact the final total cost. This guide outlines key considerations to ensure smooth procurement, transportation, installation, and adherence to local and federal regulations.

1. Understanding the Base Price

The base price of a concrete septic tank typically includes manufacturing costs and standard features such as tank size, inlet/outlet fittings, and structural reinforcement. Prices vary based on capacity (ranging from 500 to 2,000+ gallons), with larger tanks costing more due to increased material and labor inputs.

Average price range:

– 1,000-gallon tank: $600 – $1,200

– 1,500-gallon tank: $1,000 – $1,800

Note: These prices exclude delivery, installation, permits, and site preparation.

2. Transportation & Logistics Costs

Transportation is a major factor influencing total cost due to the weight and bulk of concrete septic tanks.

Key logistics considerations:

– Distance from Manufacturer: Longer hauls increase fuel and labor costs. Local suppliers typically offer lower delivery fees.

– Access to Installation Site: Remote or challenging terrain (e.g., steep driveways, narrow roads) may require specialized equipment, increasing costs.

– Weight Restrictions: Concrete tanks can weigh several tons when empty. Ensure local roads and bridges support heavy loads; otherwise, route planning or permits may be necessary.

– Delivery Equipment: Flatbed trucks and cranes may be needed. Rental or included service fees should be factored in.

Expect delivery costs of $100 – $500+, depending on distance and site conditions.

3. Handling and Installation Requirements

Proper handling is critical to avoid cracking or structural damage during unloading and placement.

- Use of a crane or backhoe is standard.

- Ensure the installer follows manufacturer guidelines for setting the tank on a compacted gravel base.

- Improper installation may void warranties and lead to costly repairs.

Installation labor typically costs $1,500 – $4,000, depending on site complexity and regional labor rates.

4. Regulatory Compliance & Permits

Compliance with local, state, and federal regulations is mandatory and affects project cost and timeline.

Common compliance requirements:

– Permitting: Most jurisdictions require a permit for septic system installation. Application fees range from $100 to $1,000.

– Soil Testing: A percolation (perc) test is often required to determine soil suitability. Cost: $100 – $500.

– Design Approval: System design must meet local health department standards, including tank size, drain field layout, and setback distances from wells and property lines.

– Inspections: Mandatory inspections at various stages (excavation, installation, final) ensure compliance. Inspection fees: $150 – $500.

Failure to comply can result in fines, rework, or system rejection.

5. Environmental & Safety Standards

Concrete septic tanks must meet environmental protection and public health standards:

- Manufacturing Standards: Look for tanks compliant with ASTM C913 or equivalent standards for precast concrete.

- Watertight Integrity: Tanks must be leak-proof to prevent groundwater contamination.

- EPA & Local Guidelines: Adherence to EPA Onsite Wastewater Treatment Systems Manual and state-specific codes is essential.

6. Total Cost Estimation Example

For a typical 1,000-gallon concrete septic tank installation:

| Item | Estimated Cost |

|—————————-|———————-|

| Tank (1,000-gallon) | $900 |

| Delivery | $300 |

| Installation Labor | $2,500 |

| Permits & Inspections | $600 |

| Soil Testing & Design | $400 |

| Total | $4,700 |

7. Tips to Optimize Cost and Compliance

- Obtain quotes from multiple local suppliers to compare prices and delivery options.

- Schedule delivery and installation during favorable weather conditions to avoid delays.

- Confirm compliance requirements with your local health department before purchasing.

- Choose a certified installer experienced with concrete systems and local regulations.

By carefully planning logistics and ensuring full compliance, you can avoid unexpected costs and ensure a durable, code-compliant septic system.

In conclusion, sourcing a concrete septic tank requires careful consideration of several factors that influence price, including tank size, local material and labor costs, delivery fees, site accessibility, and compliance with regional regulations. Obtaining multiple quotes from reputable suppliers and contractors ensures competitive pricing and reliable quality. While concrete septic tanks are generally more durable and long-lasting compared to alternative materials, initial costs can vary significantly by location and project requirements. Therefore, a balance between cost-efficiency and long-term performance should guide the decision-making process. Proper research, site evaluation, and professional consultation are essential to secure a fair price and a reliable septic solution that meets both budgetary and regulatory needs.