The global concrete block machine market is experiencing robust growth, driven by rising urbanization, infrastructure development, and the increasing adoption of automated and eco-friendly construction technologies. According to a report by Grand View Research, the global concrete block machine market size was valued at USD 2.1 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030. Another analysis by Mordor Intelligence projects similar momentum, citing growing demand for energy-efficient building materials and advancements in machine automation as key growth accelerators. With manufacturers increasingly investing in high-capacity, low-maintenance, and sustainable production systems, competition among leading concrete block machine producers has intensified. This evolving landscape underscores the importance of identifying top-tier manufacturers that combine innovation, reliability, and global reach—qualities essential for meeting modern construction demands. In this context, the following list highlights the top 10 concrete block machine manufacturers shaping the future of the industry.

Top 10 Concrete Block Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Concrete Electric Pole Machine, China Block Making Machine …

Domain Est. 2004

Website: sdshengya.com

Key Highlights: shengya Machinery Co., ltd is a professional manufacturer with 25years history in concrete pole machine, concrete block machine and clay interlocking brick ……

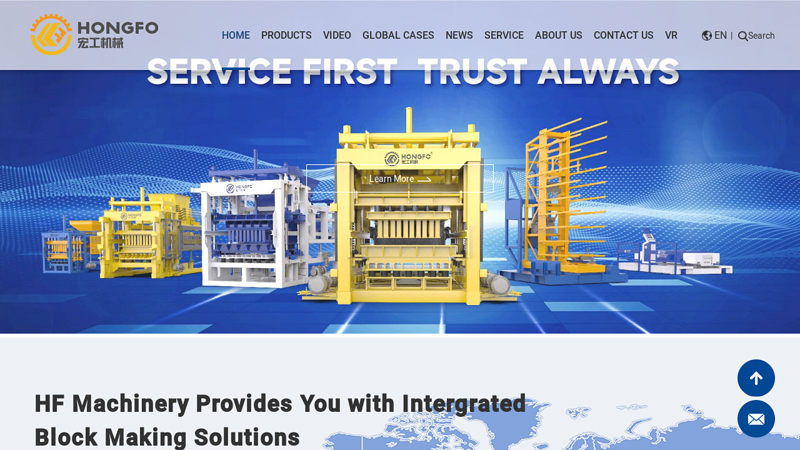

#2 Block Machine Manufacturers,Brick Making Machine Suppliers And …

Domain Est. 2012 | Founded: 1989

Website: hfblockmachine.com

Key Highlights: Qingdao HF Machinery Co., Ltd is the professional manufacturer and exporter for block machine since 1989, providing users in 130 countries and regions…

#3 Columbia Machine

Domain Est. 1997

Website: columbiamachine.com

Key Highlights: Columbia Machine is one of the world’s leading manufacturers of concrete products equipment, serving customers for over 85 years, in over 100 countries….

#4 Page

Domain Est. 2003

Website: presmakina.com

Key Highlights: Pres Makina is a global manufacturer of high-quality automatic concrete block machines, offering fully automated and hydraulic systems for efficient, ……

#5 Rometa®

Domain Est. 2006

Website: concrete-machinery.com

Key Highlights: Design and manufacture of equipment for the concrete industry. Block Making Machines and Batching Plants. See our Block Making Machines….

#6 Concrete Block Machine

Domain Est. 2014

Website: alqimma.com

Key Highlights: We present to you the latest and best concrete block manufacturing machines. These machines combine advanced technology with easy operation….

#7 Besser Company

Domain Est. 1996 | Founded: 1904

Website: besser.com

Key Highlights: Besser Company is a global leader in concrete production equipment, molds, and training. Serving the concrete industry with proven solutions since 1904….

#8 Block Making Machine Supplier

Domain Est. 2019

Website: blockmachine.net

Key Highlights: We also manufacture concrete pipe making machine, concrete batching plant, and AAC block machine. You can get the high-quality machine and best price from us….

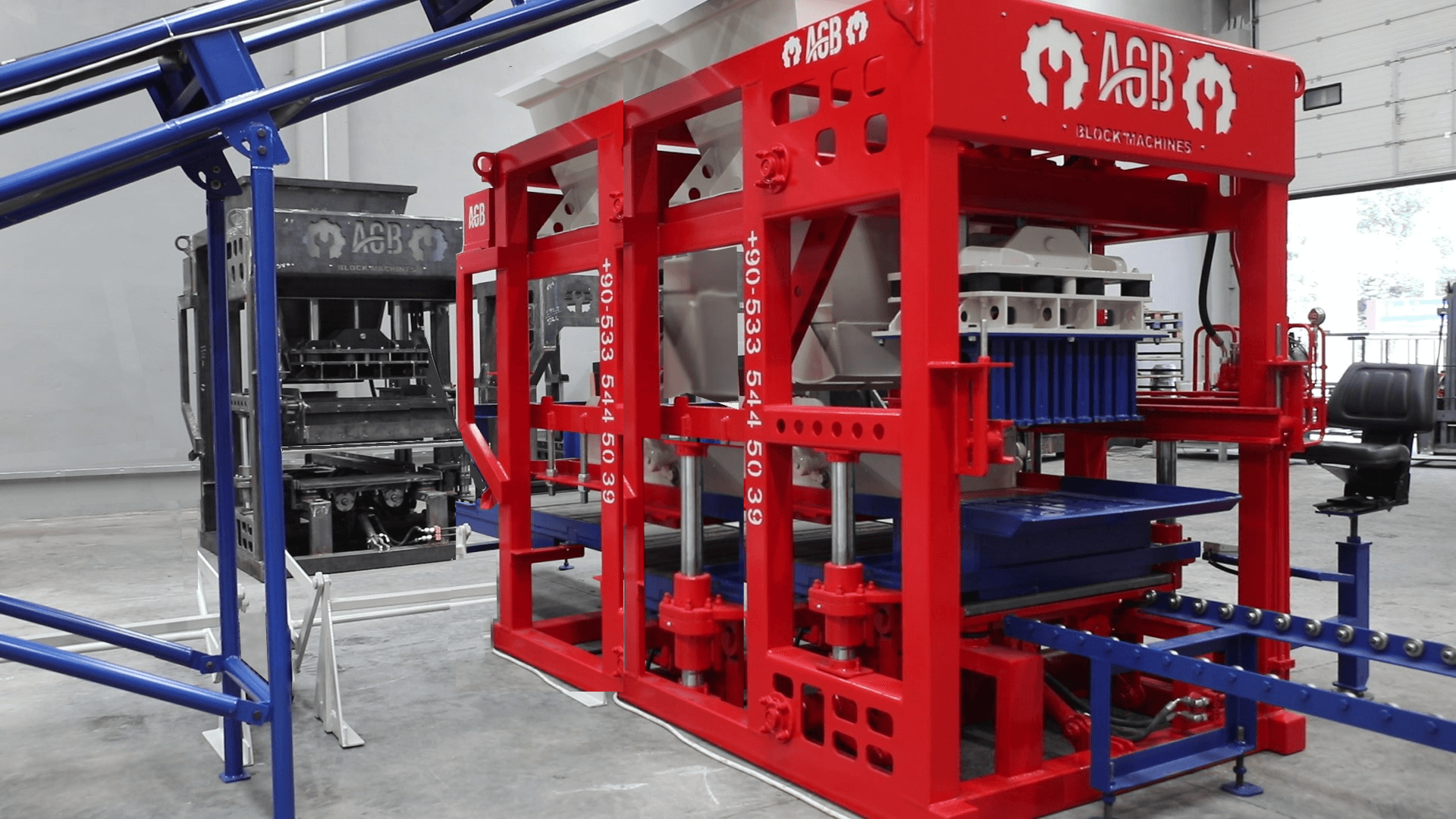

#9 AGB Machine

Domain Est. 2022

Website: agbmachine.com

Key Highlights: AGB Machine a Turkish company specializing in high-performance block and paving machines, suitable for the production of concrete blocks, hollow block ……

#10 American Block Machinery

Domain Est. 2023

Website: americanblockmachinery.com

Key Highlights: We have Concrete Block Machines. They are designed to produce both concrete blocks and paver bricks. Our machines are the best block machine investment, for ……

Expert Sourcing Insights for Concrete Block Machine

H2: 2026 Market Trends for Concrete Block Machine

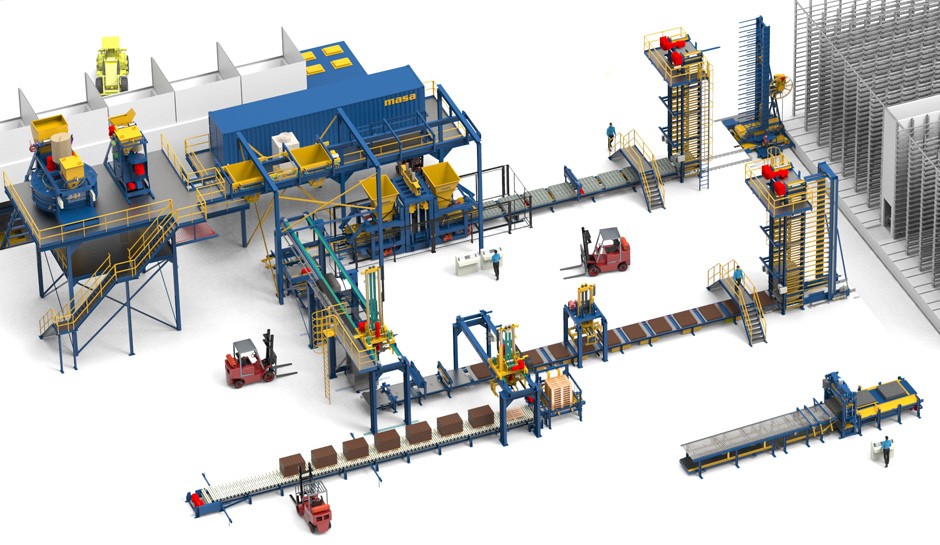

The global concrete block machine market is poised for substantial transformation by 2026, driven by rapid urbanization, technological innovation, and increasing demand for sustainable construction solutions. As governments and private sectors alike prioritize infrastructure development and green building practices, concrete block machines are becoming central to modern construction methodologies. The following trends are expected to shape the market landscape in 2026:

-

Increased Automation and Smart Technology Integration

By 2026, automation will be a dominant trend in the concrete block machine industry. Manufacturers are increasingly incorporating IoT (Internet of Things), artificial intelligence (AI), and advanced sensors into their machines to enhance precision, reduce labor costs, and improve production efficiency. Fully automated systems capable of self-diagnosis, remote monitoring, and predictive maintenance will gain traction, particularly in developed markets and large-scale production facilities. -

Growing Demand for Eco-Friendly and Energy-Efficient Machines

Sustainability is a key driver shaping the industry. Concrete block machines that utilize recycled materials (such as fly ash, slag, or construction waste) and consume less energy are seeing rising demand. Regulatory pressures and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers to innovate with low-emission, energy-efficient models. In 2026, machines with closed-loop water recycling systems and reduced carbon footprints are expected to dominate environmentally conscious markets. -

Expansion in Emerging Economies

Rapid urbanization in Asia-Pacific, Africa, and Latin America is fueling infrastructure growth, leading to increased demand for affordable and durable construction materials. Countries like India, Nigeria, and Indonesia are witnessing a construction boom, creating a surge in demand for cost-effective concrete block machines. Localized manufacturing and the availability of semi-automatic models tailored to small and medium enterprises (SMEs) will be critical success factors in these regions. -

Shift Toward Modular and Customizable Block Designs

Architects and builders are increasingly favoring aesthetically pleasing and functionally versatile concrete blocks. This trend is encouraging the development of machines capable of producing interlocking, hollow, and decorative blocks with high precision. In 2026, modular construction and prefabrication techniques will drive demand for machines that offer flexibility in mold design and block dimensions. -

Rising Adoption of Hydraulic and Servo-Driven Systems

Hydraulic concrete block machines, known for their durability and high output, continue to dominate the market. However, servo-electric systems are gaining ground due to their energy efficiency, lower maintenance needs, and quieter operation. By 2026, hybrid models combining hydraulic power with servo control are expected to become more common, offering an optimal balance between performance and sustainability. -

Consolidation and Strategic Partnerships Among Manufacturers

The competitive landscape is likely to witness consolidation, with key players acquiring smaller firms or forming strategic alliances to expand their technological capabilities and geographic reach. Partnerships with construction technology firms and material suppliers will enable integrated solutions, enhancing value propositions in the marketplace. -

Impact of Government Policies and Infrastructure Spending

Public infrastructure initiatives—such as affordable housing projects, road development, and smart city programs—will significantly influence demand for concrete block machines. In 2026, countries with aggressive public spending plans (e.g., China’s Belt and Road Initiative, India’s Smart Cities Mission) will be key growth markets.

In conclusion, the 2026 concrete block machine market will be defined by innovation, sustainability, and regional expansion. Companies that invest in smart manufacturing, eco-friendly technologies, and localized solutions will be best positioned to capitalize on emerging opportunities across global construction sectors.

Common Pitfalls When Sourcing a Concrete Block Machine (Quality and Intellectual Property)

Sourcing a concrete block machine, especially from international suppliers or lesser-known manufacturers, involves several risks related to both product quality and intellectual property (IP). Being aware of these pitfalls can help buyers make informed decisions and avoid costly mistakes.

Poor Build Quality and Substandard Materials

One of the most frequent issues is receiving machines constructed with inferior materials or poor craftsmanship. Low-cost suppliers may use thin steel, subpar motors, or unreliable hydraulic systems to cut costs. This results in frequent breakdowns, reduced machine lifespan, and higher maintenance costs. Buyers should request material certifications, conduct factory audits, or hire third-party inspectors to verify build quality before purchase.

Inadequate or Misleading Technical Specifications

Suppliers may exaggerate machine capabilities such as production speed, block strength, or automation level. Discrepancies between advertised and actual performance can disrupt production planning and increase operational costs. Always verify specifications with real-world references, request test production videos, and, if possible, visit the manufacturer’s facility to see the machine in operation.

Lack of After-Sales Support and Spare Parts Availability

Many suppliers, especially those based overseas, offer limited technical support, training, or spare parts. When a machine breaks down, delays in receiving replacements or expert assistance can halt production for days or weeks. Ensure the supplier provides a clear support plan, available spare parts inventory, and accessible technical service—preferably with local representation.

Non-Compliance with Local or International Standards

Machines may not conform to safety, electrical, or environmental regulations in the buyer’s country. This can lead to legal issues, insurance complications, or operational shutdowns. Confirm that the machine meets relevant standards (e.g., CE, ISO, ANSI) and request compliance documentation before finalizing the purchase.

Intellectual Property Infringement Risks

Some manufacturers produce machines that copy patented designs, software, or automation systems from reputable brands. Purchasing such equipment may expose the buyer to legal liability, especially in jurisdictions with strong IP enforcement. Always inquire about the machine’s design origin and avoid suppliers who are evasive about engineering details or brand partnerships.

Hidden Costs and Lack of Transparency

Initial quotes may exclude shipping, import duties, installation, training, or essential accessories. These hidden costs can significantly increase the total investment. Request a detailed breakdown of all expenses and clarify what is included in the final price.

Limited Customization and Scalability

Off-the-shelf machines may not suit specific production needs, such as unique block sizes or integration into existing workflows. Suppliers with weak engineering capabilities may offer little flexibility. Confirm the manufacturer’s ability to customize the machine and support future upgrades.

By addressing these pitfalls proactively—through due diligence, supplier vetting, and contract safeguards—buyers can reduce risks and ensure a reliable, compliant, and long-term productive investment in their concrete block machine.

Logistics & Compliance Guide for Concrete Block Machine

Overview

This guide provides essential information for the safe, efficient, and compliant transportation, import/export, installation, and operation of a concrete block machine. Adhering to logistics procedures and regulatory requirements ensures timely delivery, avoids penalties, and supports smooth operations.

International Shipping & Transportation

-

Packaging & Crating:

Ensure the machine is securely crated using weather-resistant, ISO-certified wooden or steel crates. Include shock-absorbing materials and lifting points compliant with international freight standards. -

Mode of Transport:

- Sea Freight: Most common for heavy machinery. Use Full Container Load (FCL) or Roll-on/Roll-off (RoRo) based on machine size.

- Air Freight: Only for urgent, small components due to high cost and weight limitations.

-

Overland Transport: For regional delivery; confirm road weight limits, permits, and route clearance.

-

Documentation:

Prepare: Commercial Invoice, Packing List, Bill of Lading/Air Waybill, Certificate of Origin, and Equipment Test Reports. Include machine specifications and HS code.

Import/Export Compliance

-

Harmonized System (HS) Code:

Typically 8474.31 or 8474.32 (Machinery for making concrete products). Confirm with local customs authority. -

Import Duties & Taxes:

Research destination country’s tariff rates, VAT/GST, and any anti-dumping duties. Use a customs broker to ensure accurate classification and duty assessment. -

Export Controls:

Verify if the machine contains components subject to export regulations (e.g., dual-use technology). Check compliance with national export control lists (e.g., U.S. EAR, EU Dual-Use Regulation).

Regulatory & Safety Standards

-

Electrical Compliance:

Ensure the machine meets voltage, frequency, and electrical safety standards of the destination country (e.g., CE in Europe, UL in the U.S., CCC in China). -

Machinery Safety Regulations:

Comply with local occupational safety laws (e.g., OSHA in the U.S., PUWER in the UK, Machinery Directive 2006/42/EC in EU). Include safety guards, emergency stops, and risk assessments. -

EMC & Noise Emissions:

Confirm Electromagnetic Compatibility (EMC) and noise level compliance (e.g., EU EMC Directive, ISO 4871 for noise testing).

Site Preparation & Installation

-

Foundation Requirements:

Provide a level, reinforced concrete base according to manufacturer specifications. Account for vibration isolation if needed. -

Utilities & Infrastructure:

Confirm availability of required power supply (voltage, phase, amperage), compressed air, water, and drainage systems. -

Access & Clearance:

Ensure adequate space for machine operation, maintenance, and material handling. Verify door height, ceiling clearance, and forklift access.

Customs Clearance & Local Regulations

-

Engage a Licensed Customs Broker:

Submit required documents and pay duties/taxes promptly. Provide technical manuals if requested. -

Local Permits:

Obtain necessary permits for industrial equipment operation, environmental compliance (e.g., dust/noise emissions), and building/zoning approvals. -

Inspections:

Schedule post-import inspections if mandated by local authorities (e.g., SONCAP for Nigeria, SASO for Saudi Arabia).

After-Sales & Maintenance Compliance

-

Warranty & Service:

Confirm warranty terms, spare parts availability, and technician access. Maintain logs for compliance audits. -

Training & Documentation:

Provide operator training on safe use and maintenance. Keep user manuals, CE or other conformity certificates, and maintenance records on-site. -

Environmental Compliance:

Manage waste materials (concrete slurry, oil) in accordance with local environmental laws. Implement dust suppression and recycling systems if required.

Conclusion

Proper logistics planning and adherence to compliance standards are critical when transporting and installing a concrete block machine. Partner with experienced freight forwarders, customs brokers, and local authorities to ensure a seamless and legally compliant setup. Always consult the manufacturer’s guidelines and local regulatory bodies for up-to-date requirements.

In conclusion, sourcing a concrete block machine requires careful consideration of several key factors to ensure optimal performance, cost-efficiency, and long-term reliability. It is essential to assess your production needs, desired block types, and capacity requirements before selecting the appropriate machine type—whether manual, semi-automatic, or fully automatic. Evaluating the supplier’s reputation, warranty, after-sales support, and availability of spare parts is crucial for minimizing downtime and maintaining consistent output. Additionally, energy efficiency, ease of operation, and compliance with safety and environmental standards should not be overlooked. By conducting thorough research and due diligence, businesses can make an informed investment that enhances productivity, reduces operational costs, and supports sustainable growth in the construction materials industry.