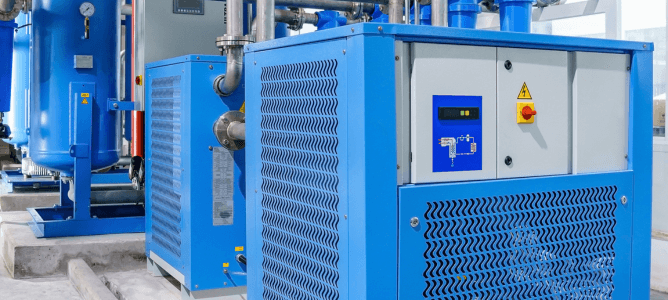

The global compressor filter dryer market is experiencing robust growth, driven by increasing demand for energy-efficient compressed air systems across industrial and manufacturing sectors. According to a report by Mordor Intelligence, the global compressed air treatment equipment market—encompassing filters, dryers, and related components—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. Similarly, Grand View Research estimates that the market size was valued at USD 3.4 billion in 2022 and is expected to expand at a CAGR of 6.1% through 2030, fueled by stringent air quality standards and rising adoption in automotive, pharmaceuticals, and food & beverage industries. As operational efficiency and contamination control become critical, the role of high-performance compressor filter dryers has intensified, elevating the prominence of leading manufacturers committed to reliability, innovation, and compliance. Based on market presence, technological advancement, and product range, we’ve identified the top 10 compressor filter dryer manufacturers shaping the industry’s future.

Top 10 Compressor Filter Dryer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 KELTEC Technolab

Domain Est. 1998

Website: keltecinc.com

Key Highlights: KELTEC Technolab offers OEM quality air compressor replacement parts, as well as air treatment accessories; dryers, compressor oil, coalescors….

#2 BEKO TECHNOLOGIES – Compressed air technology

Domain Est. 2011

Website: beko-technologies.us

Key Highlights: BEKO TECHNOLOGIES develops, manufactures and sells components and systems worldwide for an optimised compressed air quality….

#3 Refrigeration and A/C filter drier

Domain Est. 1995

Website: danfoss.com

Key Highlights: Filter driers in hermetic design are ideal for commercial refrigeration applications requiring high drying capacity to prevent acid formation in the system….

#4 Separator Filter Dryer

Domain Est. 1996

Website: skf.com

Key Highlights: This innovative 3 in 1 duplex design SFD (Separator Filter Dryer) protects compressed air systems by removing damaging oil, water vapor and contaminants….

#5 Dryer Filters Standard & Custom sizes

Domain Est. 1997

Website: snydermfg.com

Key Highlights: In stockDryer Filters Standard & Custom sizes. $77.00. replace every 24 – 36 months. Size: 23 ” x 21 3/4″….

#6 Refrigerated and Desiccant Dryers for Sale

Domain Est. 1997

Website: quincycompressor.com

Key Highlights: Quincy compressors are complemented by a wide selection of dryers and accessories. Our products form a solution for your compressed air needs. View now!…

#7 Compressed Air and Gas Filtration and Drying Equipment …

Domain Est. 2000

Website: walkerfiltration.com

Key Highlights: Serving a global market, Walker Filtration manufactures an extensive range of compressed air and gas filtration, drying and vacuum equipment….

#8 Air Compressor Filters

Domain Est. 2001

Website: ingersollrand.com

Key Highlights: Ingersoll Rand Compressor Filters guarantee superior air quality by effectively removing damaging oil & water aerosols from your system….

#9 Dry All

Domain Est. 2001

Website: dryall.net

Key Highlights: Filter Driers. Dry All Filter Driers are uniquely designed to protect the refrigerant system from solid contaminants, adsorb moisture and acid….

#10 Deltech: Air Treatment Products

Domain Est. 2022

Website: deltechair.com

Key Highlights: Discover Deltech’s revolutionary compressed air solutions for superior performance, energy efficiency, and impeccable air quality….

Expert Sourcing Insights for Compressor Filter Dryer

2026 Market Trends for Compressor Filter Dryer

The global Compressor Filter Dryer (CFD) market is poised for significant evolution by 2026, driven by industrial automation, energy efficiency mandates, and the growing demand for clean compressed air across manufacturing, pharmaceuticals, food and beverage, and automotive sectors. This analysis explores key trends expected to shape the CFD landscape in 2026, offering insights into technological advancements, regional dynamics, and strategic opportunities.

Technological Innovation and Smart Integration

A defining trend in the 2026 CFD market is the integration of smart technologies. Manufacturers are increasingly embedding Internet of Things (IoT) sensors and cloud-connected monitoring systems into filter dryers. These smart CFDs enable real-time performance tracking, predictive maintenance alerts, and remote diagnostics. This shift not only reduces operational downtime but also enhances energy efficiency by optimizing filtration cycles based on actual air quality and usage patterns. Additionally, AI-driven analytics are being used to forecast maintenance needs and improve system longevity, especially in mission-critical applications.

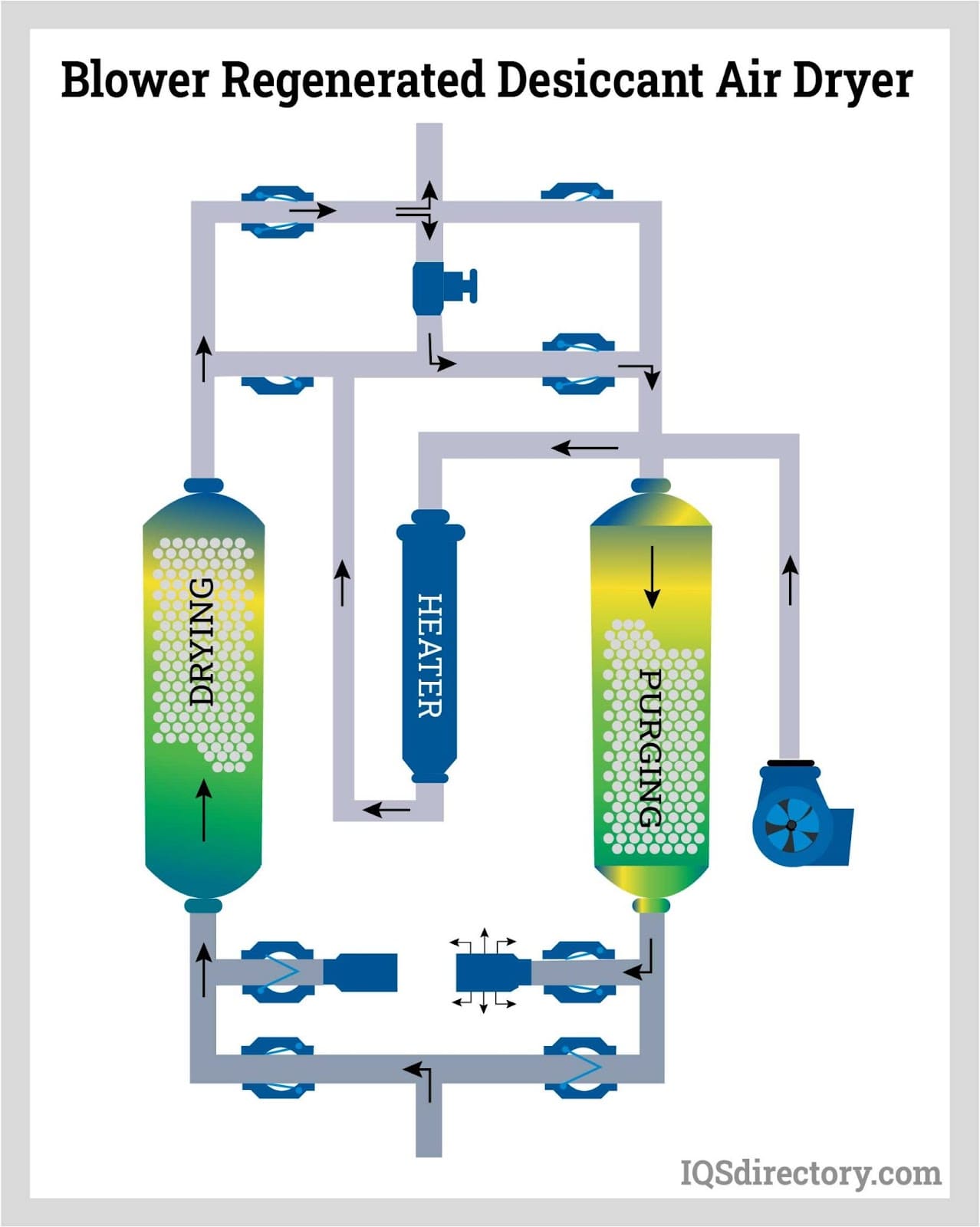

Rising Demand for Energy-Efficient and Sustainable Solutions

With global emphasis on sustainability and carbon reduction, energy efficiency has become a primary purchasing criterion. By 2026, compressors and associated filtration systems are expected to comply with stricter environmental regulations such as the EU Ecodesign Directive and ISO 50001 standards. As a result, CFD manufacturers are focusing on low-pressure drop designs, regenerative desiccant dryers with heat recovery, and zero purge air technologies. These advancements reduce energy consumption by up to 30%, appealing to industries aiming to lower their carbon footprint and operational costs.

Growth in Emerging Economies

Asia-Pacific, particularly China, India, and Southeast Asian nations, is projected to lead market expansion in 2026. Rapid industrialization, infrastructure development, and increased investments in manufacturing are fueling demand for reliable compressed air systems. Local production of CFDs is also rising, supported by government initiatives to boost domestic manufacturing. Latin America and Africa are emerging as secondary growth regions, with increasing adoption in mining, oil & gas, and food processing industries.

Expansion in End-Use Applications

Beyond traditional industrial sectors, new applications are driving CFD demand. The healthcare and pharmaceutical industries require ultra-pure compressed air for cleanrooms and medical devices, mandating high-efficiency filtration and drying. Similarly, the electric vehicle (EV) manufacturing boom is increasing the need for precision tools and automated assembly lines that depend on clean, dry air. These niche applications are pushing the development of compact, high-performance CFD units with advanced contamination control.

Consolidation and Strategic Partnerships

The competitive landscape is expected to see increased consolidation by 2026, with major players acquiring niche technology firms to expand their smart and sustainable product portfolios. Strategic partnerships between CFD manufacturers and compressor OEMs are becoming common, enabling integrated system solutions that improve compatibility and performance. Companies are also investing in digital platforms to offer value-added services such as remote monitoring subscriptions and energy audits.

Regulatory and Standardization Pressures

Regulatory bodies worldwide are tightening air quality standards, including limits on oil content, particulate matter, and moisture levels in compressed air systems. ISO 8573 standards are being more rigorously enforced, especially in food-grade and medical air applications. This regulatory push is compelling end-users to upgrade legacy systems, creating a robust replacement market for advanced CFDs by 2026.

Conclusion

By 2026, the Compressor Filter Dryer market will be characterized by innovation, sustainability, and digital transformation. Companies that invest in smart, energy-efficient technologies and expand their presence in high-growth regions will be best positioned to capture market share. As industries continue to prioritize air quality and operational efficiency, the CFD market will play an increasingly vital role in the global industrial ecosystem.

Common Pitfalls When Sourcing Compressor Filter Dryers (Quality, IP)

Sourcing Compressor Filter Dryers (CFDs) is critical for ensuring clean, dry compressed air in industrial systems. However, overlooking key quality and Ingress Protection (IP) factors can lead to system failures, increased maintenance, and costly downtime. Below are common pitfalls to avoid:

1. Prioritizing Low Cost Over Build Quality

One of the most frequent mistakes is selecting CFDs based solely on price. Low-cost units often use inferior materials such as thin-gauge steel housings, substandard filtration media, or weak seals. These compromises lead to:

- Premature filter element collapse or clogging

- Reduced moisture removal efficiency

- Risk of internal corrosion and contamination

- Shorter service life, increasing total cost of ownership

Tip: Evaluate materials, construction standards (e.g., ISO 8573 compliance), and manufacturer reputation—not just upfront cost.

2. Ignoring Ingress Protection (IP) Ratings for Installation Environment

The IP rating indicates protection against solid particles and liquids. Selecting a CFD with an inadequate IP rating for the operating environment causes:

- Moisture or dust ingress into electrical components (for refrigerated or desiccant dryers with controls)

- Corrosion of internal parts

- Malfunction of sensors or control panels

- Safety hazards in wet or outdoor installations

Example: Using an IP54-rated unit outdoors in heavy rain may still allow water ingress; IP65 or higher is often required for harsh environments.

3. Overlooking Filter Efficiency and Pressure Drop

Some suppliers exaggerate filtration performance. Using underspecified filters results in:

- Inadequate particulate, oil, and aerosol removal

- High pressure drop across the unit, reducing system efficiency

- Increased energy consumption and compressor loading

Best Practice: Verify performance claims with third-party test data and ensure filters meet ISO 8573-1 Class 2 or better for critical applications.

4. Mismatched Flow Capacity and System Requirements

Sizing a CFD too small for the compressor output leads to:

- Incomplete drying and filtration

- Excessive pressure drop

- Bypassing of contaminants

- Dryer overload and premature failure

Always match or slightly oversize the CFD to the compressor’s free air delivery (FAD), accounting for peak demand and temperature conditions.

5. Neglecting Serviceability and Maintenance Access

Poorly designed CFDs make maintenance difficult, leading to:

- Extended downtime during filter changes

- Risk of contamination during servicing

- Increased labor costs

Look for units with easy access to filter elements, coalescing stages, and drain valves. Swing-out or cartridge-style designs often simplify maintenance.

6. Assuming All “Industrial” Units Are Suitable for Harsh Conditions

Not all industrial-grade CFDs are built for extreme conditions. Using a standard unit in high-temperature, high-vibration, or corrosive environments accelerates wear. Always confirm:

- Ambient temperature limits

- Vibration resistance

- Corrosion protection (e.g., powder coating, stainless steel options)

7. Failing to Verify Compliance and Certifications

Lack of proper certifications (e.g., CE, ISO, ATEX for hazardous areas) can result in:

- Non-compliance with safety or industry regulations

- Voided warranties

- Liability in case of failure

Ensure documentation is provided, and verify claims with the manufacturer.

By addressing these quality and IP-related pitfalls during procurement, you ensure reliable performance, lower lifecycle costs, and protection of downstream equipment and processes.

H2: Logistics & Compliance Guide for Compressor Filter Dryer

This guide outlines the essential logistics considerations and compliance requirements for the safe, efficient, and legally compliant handling, transportation, installation, operation, and maintenance of Compressor Filter Dryers (CFDs). Adherence ensures operational reliability, personnel safety, and regulatory conformity.

H2.1: Logistics Planning & Handling

- Pre-Shipment Verification:

- Confirm filter dryer model, specifications, and accessories match the purchase order and application requirements.

- Ensure all components (housing, filter elements, desiccant, valves, gauges, drains) are included and undamaged.

- Verify packaging is robust (wooden crate or heavy-duty cardboard) with adequate internal bracing to prevent movement during transit. Moisture-sensitive items (desiccant) must be vacuum-sealed or in sealed moisture-barrier bags.

- Transportation:

- Handle units with care using appropriate lifting equipment (forklifts, cranes with slings rated for the unit’s weight). Never lift by internal components, valves, or gauges.

- Secure the unit firmly on the transport vehicle to prevent shifting, rolling, or impact. Use straps and blocking.

- Protect from extreme temperatures (especially freezing for wet/damaged units, high heat for desiccant), excessive moisture, and direct sunlight during transit and storage.

- Ensure transport complies with relevant road/rail/air freight regulations regarding dimensions, weight, and hazardous materials (if applicable – e.g., oil-laden filters).

- Receiving & Storage:

- Inspect packaging for damage upon arrival. Document and report any damage immediately before opening.

- Store upright in a clean, dry, temperature-controlled (ideally 10-40°C / 50-104°F), well-ventilated indoor area, away from contaminants, vibration, and direct sunlight.

- Keep original packaging (especially for desiccant/filter elements) until ready for installation to protect from moisture and dirt.

- Store spare filter elements and desiccant in their original vacuum-sealed or moisture-proof packaging until needed.

H2.2: Installation Logistics

- Site Preparation:

- Ensure adequate space for the unit, maintenance access (front and sides for filter/dryer servicing), and future expansion. Follow manufacturer’s minimum clearance recommendations.

- Verify the foundation/platform is level, stable, and capable of supporting the unit’s weight, especially when filled with desiccant.

- Plan piping layout considering inlet/outlet connections, drain line routing (to safe disposal point), and isolation valves. Minimize bends and ensure proper support.

- Confirm electrical supply (if applicable for controls, heaters, solenoid valves) meets specifications (voltage, phase, frequency, grounding).

- Handling During Installation:

- Use lifting points or lifting eyes if provided. Protect painted surfaces and components.

- Avoid dropping, rolling, or impacting the unit. Use skates or rollers carefully.

- Keep inlet/outlet ports clean and capped until piping is connected.

H2.3: Regulatory & Safety Compliance

- Pressure Equipment Safety:

- ASME Certification (USA/Canada): Ensure the filter dryer vessel has a valid ASME “U” or “UM” stamp (or equivalent PED certification in Europe – see below) appropriate for its design pressure and temperature. Verify the Manufacturer’s Data Report (MDR) is available.

- Pressure Equipment Directive (PED) (EU/UK): Units must comply with PED 2014/68/EU (or UK equivalent). Look for the CE/UKCA mark and a Declaration of Conformity (DoC). The required conformity assessment module (e.g., Module H, Module B+D) depends on the pressure/volume category.

- Local Jurisdictional Requirements: Comply with national and local pressure vessel codes and registration/inspection mandates (e.g., registration with state boiler inspector in some US states).

- Workplace Safety (OSHA/GHS – Global):

- Hazard Communication (HazCom/GHS): Ensure Safety Data Sheets (SDS) are available for any chemicals involved (e.g., lubricants for valves, cleaning agents, potentially the desiccant itself – check SDS). Label containers appropriately.

- Personal Protective Equipment (PPE): Mandate PPE during handling, installation, and maintenance: Safety glasses, gloves (chemical/abrasion resistant), hearing protection (if high noise), and steel-toed boots. Respiratory protection may be needed when handling spent desiccant (dust) or during confined space entry.

- Lockout/Tagout (LOTO): Strictly follow LOTO procedures before any maintenance, servicing, or entry. Isolate energy sources (compressed air, electrical power).

- Confined Space Entry: Treat the dryer vessel as a confined space if entry is required (e.g., for desiccant change in large units). Follow permit-required confined space entry procedures.

- Environmental Regulations:

- Spent Filter/Desiccant Disposal: Classify waste according to local, state/provincial, and national regulations (e.g., RCRA in the USA, WEEE/ELV directives in EU).

- Oil-Laden Filters/Desiccant: Often classified as hazardous waste due to absorbed compressor oil (typically petroleum-based). Do not dispose of in regular trash. Use licensed hazardous waste disposal contractors.

- Clean Desiccant (e.g., Silica Gel, Molecular Sieve): May be non-hazardous but check local rules. Some can be regenerated professionally; others require landfill disposal (check landfill acceptance).

- Metal Housing: Recycle as scrap metal.

- Drain Disposal: Condensate from automatic drains may contain oil and other contaminants (from the compressed air stream). Do not discharge directly into sewers or storm drains without proper oil/water separation and compliance with local wastewater discharge permits. Use oil/water separators.

- Spent Filter/Desiccant Disposal: Classify waste according to local, state/provincial, and national regulations (e.g., RCRA in the USA, WEEE/ELV directives in EU).

- Electrical Safety (If Applicable):

- Installation and wiring must comply with national electrical codes (e.g., NEC in USA, CEC in Canada, IEC/BS 7671 in UK/EU).

- Ensure proper grounding of the unit and electrical components.

- Operational Compliance:

- Pressure Relief Devices (PRDs): Verify the unit has correctly sized and rated safety/relief valves installed and directed to a safe location. PRDs must be tested and certified according to jurisdictional requirements (e.g., ASME Section I or VIII, PED).

- Piping & Valves: Use materials and components rated for compressed air service and the system’s maximum pressure/temperature. Follow good piping practices.

- Documentation: Maintain records of: Purchase specs, MDR/DoC, Installation records, Inspection & testing records (including PRD tests), Maintenance logs (filter changes, desiccant changes, drain servicing), Waste disposal manifests.

H2.4: Maintenance & Operational Logistics

- Scheduled Maintenance:

- Establish and follow a preventive maintenance schedule based on manufacturer recommendations and operating conditions (air quality, duty cycle, temperature).

- Log all maintenance activities (date, task performed, parts used, technician).

- Spare Parts Management:

- Stock critical spares: Filter elements (coalescing, particulate), drain valves/traps, desiccant (if applicable), fuses, O-rings.

- Store spares according to manufacturer instructions (e.g., desiccant in sealed moisture-proof containers).

- Waste Management Logistics:

- Establish clear procedures for collection, segregation, labeling, and storage of spent filters and desiccant.

- Contract with licensed hazardous/non-hazardous waste disposal companies. Retain disposal manifests for regulatory compliance (typically 3-5 years).

- Ensure drain condensate is properly treated before disposal.

Disclaimer: This guide provides general best practices. Always consult and strictly adhere to the specific manufacturer’s installation, operation, and maintenance manual (IOM) for your Compressor Filter Dryer model, as well as all applicable local, state/provincial, national, and international regulations. Regulations and requirements vary significantly by location and application.

Conclusion for Sourcing Compressor Filter Dryer:

Sourcing a reliable compressor filter dryer is critical to ensuring the efficiency, longevity, and performance of compressed air systems. After evaluating technical specifications, quality standards, supplier credibility, and total cost of ownership, it is evident that selecting a high-quality filter dryer from a reputable supplier directly impacts operational reliability and maintenance costs. Key factors such as filtration efficiency, dew point control, energy consumption, compatibility with existing systems, and after-sales support must be carefully considered. Investing in a well-engineered filter dryer not only protects downstream equipment from moisture and contaminants but also enhances overall system productivity and air quality. Therefore, a strategic sourcing approach that balances performance, durability, and cost-effectiveness will lead to long-term operational success and reduced downtime.