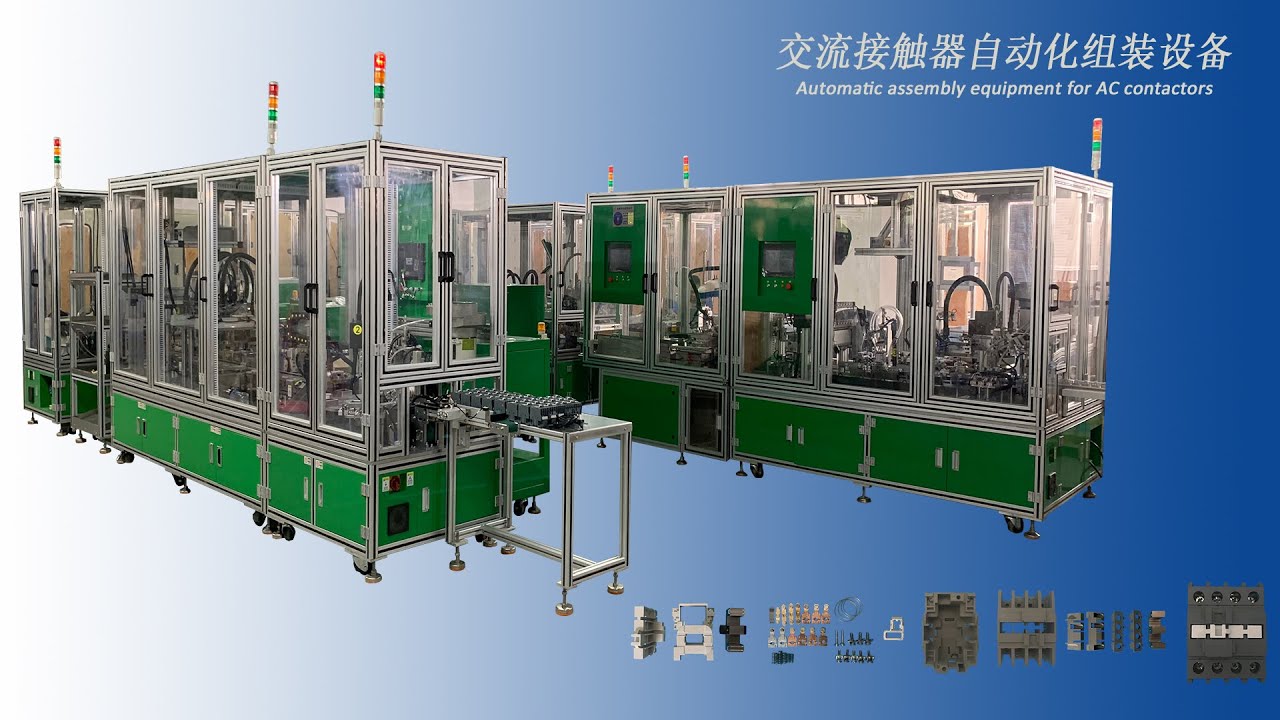

The global compressor contactor market is experiencing robust growth, driven by rising demand for HVAC systems, refrigeration units, and industrial automation. According to a report by Mordor Intelligence, the global HVAC market is projected to grow at a CAGR of over 6% from 2023 to 2028, directly boosting the need for reliable compressor contactors that ensure efficient operation of compressors across residential, commercial, and industrial applications. Additionally, Grand View Research estimates that the global motor contactor market, a key segment encompassing compressor contactors, was valued at USD 5.9 billion in 2022 and is expected to expand at a CAGR of 6.3% through 2030, fueled by advancements in energy-efficient technologies and the integration of smart building systems. As demand intensifies, manufacturers are focusing on durability, miniaturization, and compatibility with variable frequency drives. In this competitive landscape, a select group of companies are leading innovation and market share—here are the top 10 compressor contactor manufacturers shaping the industry’s future.

Top 10 Compressor Contactor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sprecher + Schuh

Domain Est. 1999

Website: sprecherschuh.com

Key Highlights: Sprecher + Schuh offers a wide range of low-voltage industrial control products, including contactors, a variety of relays, starters, push buttons, switches, ……

#2 AC Contactor Manufacturers

Domain Est. 2005

Website: cncele.com

Key Highlights: Diverse product line: Their CJX2 series contactors cover voltages from 24V to 380V, making them suitable for everything from residential HVAC ……

#3 Contactors and contactor relays

Domain Est. 1990

Website: new.abb.com

Key Highlights: ABB offers a comprehensive selection of contactors for simple and extreme application as well as products with specific purposes….

#4 Contactors: Electrical

Domain Est. 1992

Website: te.com

Key Highlights: We have extensive capabilities in designing and manufacturing contactors for a wide variety of applications, including HVAC, power supply, locomotives ……

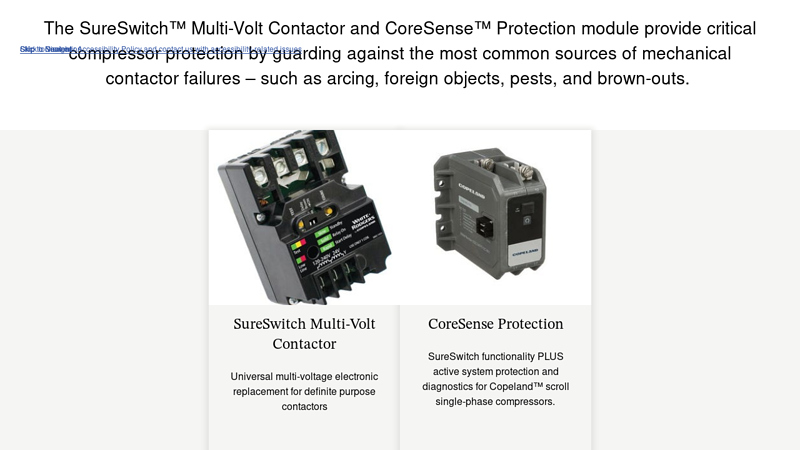

#5 Contactor Upgrade

Domain Est. 1995

Website: copeland.com

Key Highlights: Contactors, which include SureSwitch relay and CoreSense Protection module, provide critical compressor protection against mechanical contactor failure….

#6 Contactor

Domain Est. 1995

Website: emerson.com

Key Highlights: Universal Electronic Upgrade for Mechanical Compressor Contactors.5x Contactor Life, Sealed to Keep Out Ants and Debris….

#7 Contactors and starters

Domain Est. 1996

Website: eaton.com

Key Highlights: Contactors and starters. With a broad portfolio that includes everything from phase, voltage and current monitoring relays to motor protection breakers, Eaton ……

#8 Gigavac

Domain Est. 2001

Website: sensata.com

Key Highlights: Use the links below to browse our line of Contactors & Fuses and High Voltage Relays. CONTACTORS AND FUSES. Reliable and energy-efficient solutions for a ……

#9 AC Contactor

Domain Est. 2024

Website: weltrus.com

Key Highlights: Product Features. Wide range of models from FX-6 to FX-630; Suitable for AC-1, AC-2, AC-3, and AC-4 applications; Multiple coil voltage options (24V to 380V) ……

#10 The Ultimate Guide to AC Contactor

Website: tosunlux.eu

Key Highlights: In this comprehensive guide, we will explore what AC contactors are, how they work, their applications, and essential maintenance practices….

Expert Sourcing Insights for Compressor Contactor

H2: 2026 Market Trends for Compressor Contactors

The global compressor contactor market is poised for significant transformation by 2026, driven by advancements in energy efficiency, industrial automation, and the growing demand for climate control solutions. As critical components in HVAC (Heating, Ventilation, and Air Conditioning) systems, refrigeration units, and industrial compressors, contactors play a pivotal role in managing electrical loads and ensuring reliable operation. The following analysis highlights key trends expected to shape the compressor contactor landscape in 2026:

1. Rising Demand in HVAC and Refrigeration Sectors

The continued expansion of residential, commercial, and industrial infrastructure—particularly in emerging economies—will drive demand for HVAC and refrigeration systems. With increasing urbanization and focus on indoor environmental quality, compressor contactors will see sustained growth as essential switching devices in these systems. The global push for cold chain logistics, especially in pharmaceuticals and food storage, further amplifies this demand.

2. Energy Efficiency and Regulatory Compliance

Stringent energy efficiency regulations, such as those set by the U.S. Department of Energy (DOE) and the European Union’s Ecodesign Directive, are pushing manufacturers to adopt high-efficiency compressor systems. Compressor contactors that support soft-start mechanisms, reduced arcing, and lower power consumption will be in higher demand. By 2026, contactors designed to work seamlessly with variable frequency drives (VFDs) and smart controls are expected to dominate the market.

3. Integration with Smart and IoT-Enabled Systems

The rise of smart buildings and Industry 4.0 is accelerating the integration of IoT-enabled components in compressor systems. Smart contactors with built-in diagnostics, remote monitoring, and predictive maintenance capabilities will gain traction. These intelligent contactors can communicate with building management systems (BMS) to optimize performance, reduce downtime, and extend equipment life—key selling points for industrial and commercial users.

4. Shift Toward Compact and Modular Designs

Manufacturers are increasingly focusing on space-saving, modular contactor designs to meet the needs of compact HVAC units and retrofit applications. Miniaturized contactors with enhanced thermal performance and higher current ratings are expected to become standard by 2026, especially in residential and light commercial sectors.

5. Growth in Renewable Energy and Heat Pump Applications

As renewable energy adoption accelerates, particularly in solar and geothermal systems, there is a growing need for reliable compressor control in heat pump technologies. Compressor contactors that can handle fluctuating power inputs and support bidirectional energy flows will be critical. The global push for decarbonization and electrification of heating systems will further boost demand in this segment.

6. Supply Chain Resilience and Regional Manufacturing

Post-pandemic, companies are re-evaluating supply chain dependencies. By 2026, localized production of compressor contactors—especially in North America, Europe, and Southeast Asia—is expected to rise to mitigate risks and reduce lead times. This shift will encourage regional innovation and customization to meet specific market needs.

7. Sustainability and Material Innovation

Environmental concerns are driving the development of contactors using eco-friendly materials and processes. Reduced use of hazardous substances, recyclable components, and longer service life will become differentiators. Additionally, contactors with low electromagnetic interference (EMI) and high durability in harsh environments will be preferred in industrial applications.

Conclusion

By 2026, the compressor contactor market will be characterized by technological innovation, regulatory influence, and integration with digital ecosystems. Companies that invest in smart, energy-efficient, and sustainable contactor solutions will be best positioned to capture market share. As the boundaries between electrical components and intelligent systems blur, compressor contactors will evolve from simple switching devices to integral parts of connected, efficient, and resilient energy systems.

Common Pitfalls When Sourcing Compressor Contactors (Quality, IP)

Sourcing compressor contactors involves more than just matching voltage and current ratings. Overlooking key quality and Ingress Protection (IP) factors can lead to premature failure, safety hazards, and costly downtime. Here are common pitfalls to avoid:

Neglecting Environmental IP Rating Requirements

Choosing a contactor with insufficient IP (Ingress Protection) rating for the operating environment is a frequent error. For outdoor or washdown applications, using an IP20-rated contactor (basic touch protection only) exposes internal components to dust, moisture, and contaminants. Always match the IP rating to the environment—e.g., IP65 or higher for outdoor or high-humidity areas—to prevent corrosion, short circuits, and mechanical failure.

Prioritizing Low Cost Over Build Quality

Opting for the cheapest available contactor often results in substandard materials, such as inferior coil windings, weak contacts, or poor arc suppression. These compromise reliability and lifespan, especially under frequent cycling or high inrush currents typical in compressor applications. Low-quality contactors are more prone to welding, pitting, or coil burnout, increasing maintenance and replacement costs.

Assuming All Contactors Are Suitable for Motor Loads

Compressor motors generate high inrush currents during startup. Using a contactor rated only for resistive loads (e.g., lighting or heaters) leads to rapid contact erosion or failure. Always select contactors specifically rated for AC-3 duty (motor switching), which ensures they can handle starting currents and interrupt inductive loads safely.

Overlooking Coil Voltage Tolerance and Stability

Contactors with narrow voltage tolerance ranges may chatter or fail to pull in if supply voltage fluctuates—common in industrial settings. This causes arcing, overheating, and eventual contact damage. Select contactors with wide operating voltage ranges (e.g., 75–110% of nominal) and ensure compatibility with control circuit voltage to maintain reliable operation.

Ignoring Certification and Compliance Standards

Using non-certified contactors (e.g., lacking UL, CE, or IEC marks) poses safety and compliance risks. Certified components undergo rigorous testing for dielectric strength, temperature rise, and endurance. In regulated industries, non-compliant parts can void warranties, fail inspections, or lead to liability in case of failure.

Failing to Verify Auxiliary Contact Reliability

Many compressor control systems rely on auxiliary contacts for interlocking or signaling. Low-quality contactors may have unreliable or poorly rated auxiliary contacts, leading to control circuit malfunctions. Ensure auxiliary contacts are rated for the control load (e.g., AC-15) and built to withstand the required electrical and mechanical endurance.

Disregarding Thermal and Ambient Conditions

Contactors derate significantly at elevated ambient temperatures. Installing a contactor in a hot enclosure without considering temperature derating leads to overheating and reduced current-carrying capacity. Always check manufacturer derating curves and ensure adequate ventilation or use contactors rated for higher temperature environments.

Avoiding these pitfalls ensures reliable compressor operation, enhances system safety, and reduces lifecycle costs. Prioritize certified, appropriately rated components designed for motor load applications and harsh environments.

Logistics & Compliance Guide for Compressor Contactors

Overview

Compressor contactors are essential electrical components used to control the operation of compressors in HVAC, refrigeration, and industrial systems. Proper logistics handling and regulatory compliance are critical to ensure safety, reliability, and adherence to international standards throughout the supply chain.

Packaging and Handling Requirements

Use anti-static, moisture-resistant packaging to protect contactors from electrostatic discharge (ESD) and environmental damage. Handle components with ESD-safe tools and wear appropriate personal protective equipment (PPE). Avoid mechanical shock or vibration during transit—secure units in palletized, labeled containers with adequate cushioning.

Transportation Guidelines

Ship via temperature-controlled and humidity-monitored transport where possible. Maintain ambient conditions between 5°C and 40°C (41°F to 104°F) and relative humidity below 85%. Clearly label packages with “Fragile,” “Electrostatic Sensitive,” and orientation indicators. Comply with IATA, IMDG, or ADR regulations if shipping internationally or by air, sea, or road.

Storage Conditions

Store compressors contactors in a clean, dry environment with temperatures between 10°C and 35°C (50°F to 95°F) and humidity under 75%. Keep units in original packaging until ready for use. Elevate storage pallets from the floor to prevent moisture absorption and ensure adequate ventilation. Implement first-in, first-out (FIFO) inventory practices.

Regulatory Compliance Standards

Ensure contactors meet relevant international and regional standards, including:

– IEC 60947-4-1: Low-voltage electromechanical contactors and motor-starters

– UL 508: Standard for Industrial Control Equipment (North America)

– CE Marking: Compliance with EU directives (e.g., Low Voltage Directive, RoHS, REACH)

– RoHS (Restriction of Hazardous Substances): Restricts use of lead, cadmium, mercury, etc.

– REACH: Registration, Evaluation, Authorization of Chemicals (EU)

– EAC Certification: Required for sale in Eurasian Economic Union countries

Documentation and Traceability

Maintain complete technical documentation, including:

– Certificate of Conformity (CoC)

– Material Declarations (RoHS, REACH)

– Test Reports (dielectric strength, endurance, etc.)

– Unique serial or batch numbers for full traceability

Ensure all documentation accompanies shipments or is available upon request.

Import and Export Compliance

Verify export control classifications (e.g., ECCN under U.S. EAR or dual-use items under EU regulations). Complete accurate commercial invoices, packing lists, and customs declarations. Confirm destination country-specific requirements such as KC certification (South Korea), CCC (China), or BIS (India) if applicable.

Environmental and Safety Considerations

Dispose of defective or end-of-life contactors according to WEEE (Waste Electrical and Electronic Equipment) directives. Train logistics personnel on safe handling, emergency procedures, and hazardous material protocols. Report non-compliant shipments immediately to compliance officers.

Audit and Quality Assurance

Conduct regular audits of logistics partners and storage facilities. Verify compliance with contractual and regulatory requirements. Implement corrective actions for deviations and maintain audit trails for regulatory inspections.

Contact and Support

For compliance inquiries or logistics support, contact:

Compliance Department

Email: [email protected]

Phone: +1-800-XXX-XXXX

Include product model, batch number, and shipment details when reporting issues.

Conclusion for Sourcing Compressor Contactor:

After a thorough evaluation of technical requirements, supplier capabilities, cost considerations, and reliability, the sourcing of compressor contactors should prioritize components that meet industry standards (such as IEC or NEMA), offer durable performance under frequent cycling and high inrush currents, and are compatible with the specific compressor models in use. Partnering with reputable suppliers who provide certifications, warranty support, and consistent product quality ensures long-term operational efficiency and reduced maintenance costs. Additionally, considering energy-efficient and environmentally compliant contactors contributes to sustainable operations. Ultimately, a strategic sourcing approach balancing cost, quality, and supplier reliability will optimize system performance and minimize downtime in compressor applications.