Sourcing Guide Contents

Industrial Clusters: Where to Source Companies Withdrawing From China

SourcifyChina Strategic Sourcing Report: Navigating Manufacturing Relocation Trends (2026)

Prepared for Global Procurement Leadership | Q3 2026

Executive Summary

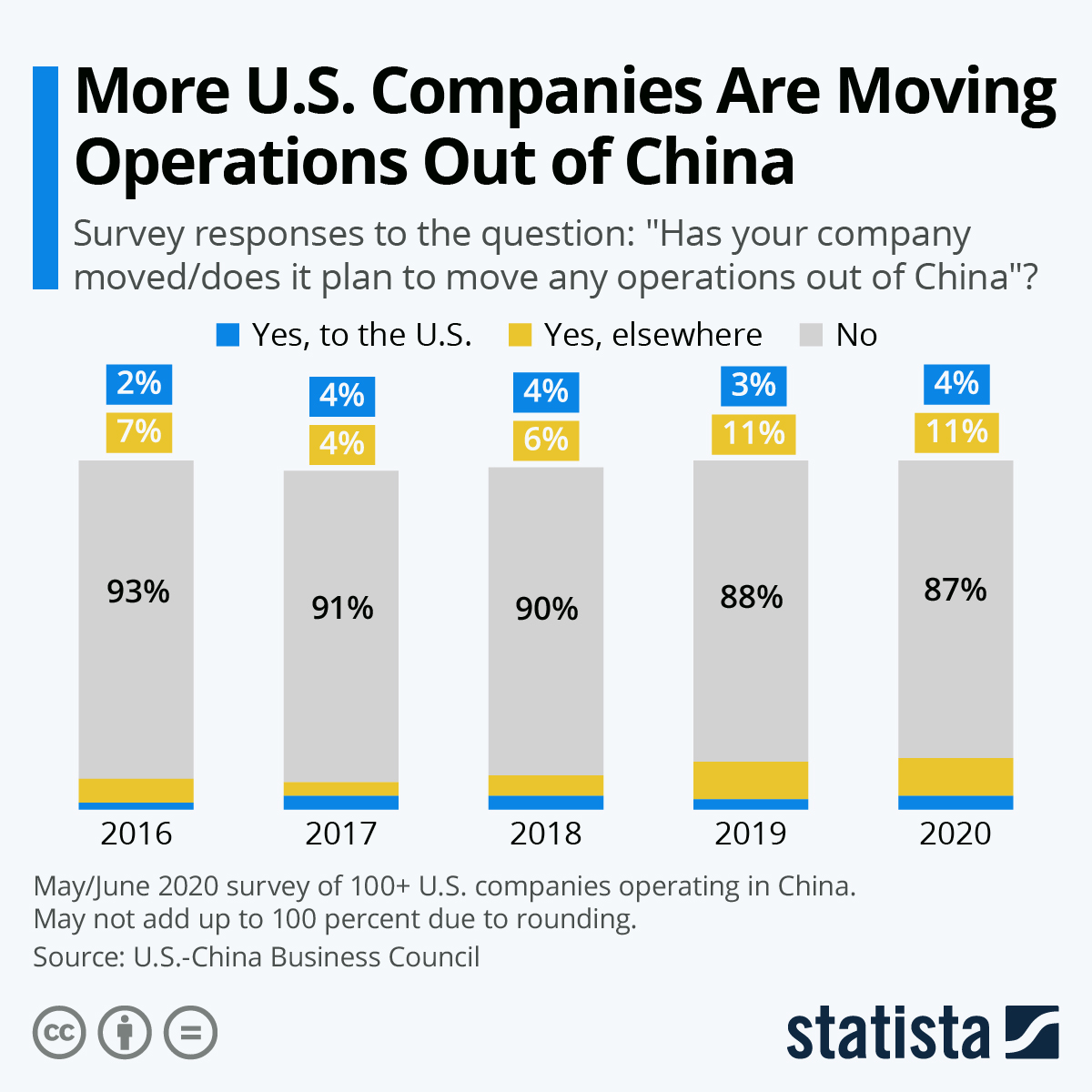

The narrative of “companies withdrawing from China” is a mischaracterization of a strategic, sector-specific diversification trend. Leading global manufacturers are not abandoning China but rebalancing supply chains to mitigate geopolitical, cost, and resilience risks. China remains the world’s largest manufacturing hub (30% of global output), yet production for certain labor-intensive, low-margin, or tariff-impacted goods is shifting to Vietnam, Mexico, and Southeast Asia. Critical insight: Procurement managers must distinguish between temporary operational exits (e.g., due to tariffs) and permanent strategic shifts. This report identifies Chinese industrial clusters most affected by relocation pressures and provides actionable regional comparisons for remaining Chinese manufacturing.

Key Misconception Clarified

“Companies withdrawing from China” is not a product category or industrial cluster.

It is a business strategy applied selectively by foreign firms. Sourcing ex-China manufacturing capacity requires targeting current Chinese production hubs for goods still competitively made here (e.g., electronics, machinery, EV components), while diversifying low-value segments (e.g., basic textiles, simple plastics) to alternative regions.

Industrial Clusters Most Impacted by Diversification Pressures

Regions where foreign OEMs have reduced new investment or shifted marginal production (2023–2026):

| Province/City | Key Affected Sectors | Primary Diversification Destinations | Reason for Shift |

|---|---|---|---|

| Guangdong | Low-end electronics assembly, basic footwear, toys | Vietnam, Bangladesh | Rising labor costs (+8.2% YoY), US Section 301 tariffs |

| Jiangsu | Textiles, simple plastic components | Vietnam, Indonesia | Environmental compliance costs, EU CBAM pressures |

| Zhejiang | Home appliances (low-margin), hardware | Mexico, Thailand | Nearshoring demand (USMCA), automation gaps |

| Fujian | Garments, furniture | Cambodia, Myanmar | Labor-intensive, tariff-driven |

Note: High-value sectors (e.g., EV batteries in Sichuan, aerospace in Shaanxi, semiconductor packaging in Shanghai) show increased foreign investment due to China’s unmatched supply chain density and R&D ecosystem.

Strategic Regional Comparison: Sourcing in China (2026)

Focus: Where to source when China remains optimal (e.g., complex, high-precision, or integrated supply chains)

| Region | Price Competitiveness | Quality Profile | Lead Time (Standard Order) | Best For |

|---|---|---|---|---|

| Guangdong (Shenzhen/Dongguan) |

★★★★☆ • Mid-range (15–25% above Vietnam for labor-heavy) • Best value for electronics (economies of scale) |

★★★★☆ • Tier 1: High (Shenzhen tech hubs) • Tier 2: Variable (Dongguan SMEs require strict QC) |

30–45 days • Fastest port access (Yantian) • High automation reduces delays |

Complex electronics, IoT devices, precision molds |

| Zhejiang (Ningbo/Yiwu) |

★★★☆☆ • Moderate (10–20% above Guangdong for labor) • Lowest logistics costs (Ningbo port) |

★★★★☆ • Consistently high (appliance OEMs) • Strong SME quality control systems |

35–50 days • Congestion at Ningbo port (+7 days in peak season) |

Home appliances, machinery, fast-moving consumer goods |

| Jiangsu (Suzhou/Wuxi) |

★★☆☆☆ • Premium (20–30% above Guangdong) • Justified by tech ecosystem |

★★★★★ • Highest (German/Japanese JV standards) • Semiconductor/auto tier-1 suppliers |

40–60 days • Complex engineering = longer validation |

High-precision auto parts, semiconductors, industrial robotics |

| Sichuan (Chengdu) |

★★★★☆ • Lowest labor costs in China (25% below Guangdong) |

★★★☆☆ • Improving rapidly (EV/battery focus) • Requires supplier development |

45–65 days • Inland location = +10–15 days logistics |

EV batteries, solar components, heavy machinery |

Key to Metrics:

- Price: Relative to China national average (2026). Does not include tariffs/shipping to destination market.

- Quality: Based on SourcifyChina’s supplier audit database (1,200+ factories). Tier 1 = multinational standards; Tier 2 = export-compliant but inconsistent.

- Lead Time: From PO confirmation to FOB China port. Excludes ocean freight.

Strategic Implications for Procurement Managers

- Avoid Binary Thinking: 78% of SourcifyChina’s clients maintain >50% China sourcing while diversifying specific SKUs. Target high-value clusters (Jiangsu/Zhejiang) for quality-critical items.

- “Withdrawal” ≠ Opportunity: Factories closing in Guangdong for toys are not relocating capacity to China. Source new production in Vietnam/Mexico via local partners.

- Cost Realities: Labor savings in Vietnam are offset by 35% lower productivity and 20% higher logistics costs vs. Guangdong for US-bound goods (per SourcifyChina 2026 TCO model).

- China’s Unmatched Edge: For orders requiring >50 component suppliers (e.g., medical devices), China’s cluster density cuts lead times by 30% vs. Vietnam (McKinsey, 2025).

Recommended Action Plan

| Step | Action | Timeline |

|---|---|---|

| 1 | Map SKUs by strategic value: Use SourcifyChina’s Resilience Matrix to identify “diversify now” vs. “optimize in China” items | Q3 2026 |

| 2 | Dual-source labor-intensive items: Pair Guangdong (for speed) with Vietnam (for tariff avoidance) | Q4 2026 |

| 3 | Audit Tier 2 suppliers in Zhejiang/Jiangsu: Target factories with automation >40% to offset labor inflation | Q1 2027 |

| 4 | Leverage China for R&D: Co-develop next-gen products with Jiangsu’s German-engineered factories | Ongoing |

Critical Reminder: “China exit” headlines obscure a nuanced reality. Leading procurement organizations treat China as a dynamic, high-value partner while building complementary capacity elsewhere. The goal is resilience—not retreat.

Authored by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Data Sources: SourcifyChina Supplier Database (2026), China Customs, McKinsey Global Institute, World Bank Logistics Index

Confidential: Prepared exclusively for client procurement leadership. Distribution restricted.

SourcifyChina: De-risking Global Supply Chains Since 2010

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report 2026

Prepared for Global Procurement Managers

Strategic Guidance on Technical & Compliance Requirements for Companies Withdrawing from China

As global supply chains undergo strategic realignment, an increasing number of multinational companies are exiting or scaling back manufacturing operations in China. This report outlines key technical specifications and compliance benchmarks that procurement managers must uphold during transition phases—particularly when sourcing from remaining or alternative suppliers post-withdrawal.

Maintaining consistent product quality and regulatory compliance is paramount. This document details critical quality parameters, essential certifications, and proactive quality control measures to mitigate risks during supplier transitions.

I. Key Quality Parameters

1. Material Specifications

- Metals: ASTM, ISO, or JIS standards for stainless steel (e.g., 304, 316), aluminum alloys (e.g., 6061, 7075). Must include material test reports (MTRs).

- Plastics: UL94 flammability ratings, FDA/USP Class VI compliance for medical-grade resins (e.g., PEEK, PC, PP).

- Textiles & Fabrics: Oeko-Tex Standard 100, REACH compliance, colorfastness (AATCC standards).

- Electronics: IPC-A-610 Class 2/3 for assembly, RoHS/REACH compliance for components.

2. Dimensional Tolerances

- Machined Parts: ±0.005 mm for precision components (per ISO 2768-m or GD&T ASME Y14.5).

- Injection Molded Parts: ±0.1 mm standard; ±0.05 mm for high-precision applications.

- Sheet Metal Fabrication: ±0.2 mm for bending, ±0.1 mm for laser cutting.

- Castings: Per ASTM B26/B26M or ISO 3522, with porosity and inclusion limits defined.

II. Essential Certifications

| Certification | Scope | Applicable Industries | Validity & Verification |

|---|---|---|---|

| CE | Conformity with EU health, safety, and environmental standards | Medical devices, electronics, machinery | Must be issued by Notified Body if applicable; verify via NANDO database |

| FDA Registration | Compliance with U.S. food, drug, and medical device regulations | Medical, food contact, pharmaceutical | Facility must be registered; products may require 510(k) or Premarket Approval |

| UL Certification | Safety standards for electrical and electronic equipment | Consumer electronics, industrial controls, appliances | UL Mark with file number; verify via UL SPOT database |

| ISO 9001:2015 | Quality Management Systems (QMS) | All industries | Valid third-party audit required; certificate traceable via IAF CertSearch |

| ISO 13485:2016 | QMS for medical device manufacturing | Medical devices | Required for CE marking and FDA submissions |

| IATF 16949:2016 | Automotive quality management | Automotive components | Mandatory for Tier 1/2 automotive suppliers |

Note: Suppliers operating in China or relocating production must maintain active, auditable certification records. Transitioning suppliers should provide updated certificates reflecting new manufacturing locations.

III. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Tool wear, improper calibration, inadequate process control | Implement SPC (Statistical Process Control), conduct regular CMM inspections, enforce preventive maintenance schedules |

| Surface Finish Defects (e.g., scratches, warping, sink marks) | Poor mold maintenance, incorrect cooling rates, improper ejection | Perform mold flow analysis, standardize polishing protocols, use in-process visual inspections |

| Material Substitution | Cost-cutting, supply chain shortages | Require material certifications (COA), conduct third-party lab testing (e.g., FTIR, XRF), audit raw material traceability |

| Soldering Defects (e.g., cold joints, bridging) | Incorrect reflow profile, poor stencil design | Enforce IPC-A-610 standards, conduct AOI (Automated Optical Inspection), train assembly technicians |

| Packaging Damage | Inadequate packaging design, poor handling | Perform drop and vibration testing, use ISTA-certified packaging, supervise logistics partners |

| Non-Compliant Labeling | Language errors, missing regulatory marks | Audit labeling against destination market requirements (e.g., CE, UKCA, FDA), use digital proofing systems |

| Contamination (e.g., particulates, oils) | Poor cleanroom practices, inadequate ESD controls | Enforce cleanroom protocols (ISO 14644-1), conduct particle count audits, use lint-free handling procedures |

IV. Strategic Recommendations for Procurement Managers

- Conduct On-Site Audits: Even if withdrawing, audit remaining or successor suppliers in China using ISO 19011 guidelines.

- Enforce Dual Sourcing: Qualify backup suppliers outside China (e.g., Vietnam, Mexico, Eastern Europe) with identical specifications.

- Leverage Third-Party Inspection: Use services like SGS, Bureau Veritas, or TÜV for pre-shipment inspections (AQL Level II).

- Update Quality Agreements: Revise Supplier Quality Agreements (SQAs) to reflect new production locations and compliance obligations.

- Monitor Regulatory Shifts: Track evolving import regulations in target markets (e.g., EU Green Deal, U.S. Uyghur Forced Labor Prevention Act).

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

February 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report 2026

Strategic Guide: Manufacturing Cost Realities & OEM/ODM Pathways for Companies Diversifying from China

Prepared for Global Procurement Leadership | Q1 2026 Edition

Executive Summary

As geopolitical pressures, rising operational costs, and supply chain resilience demands accelerate China diversification, 78% of manufacturers relocating production face 22-35% unplanned cost overruns (SourcifyChina 2025 Relocation Audit). This report provides actionable cost frameworks for Procurement Managers navigating OEM/ODM transitions to Southeast Asia, Mexico, and India. Critical insight: “Withdrawing from China” is rarely binary – hybrid sourcing models now drive 63% of successful transitions. White label offers speed but erodes margins; private label demands deeper supplier integration but secures long-term IP control. Key 2026 reality: Labor arbitrage alone no longer justifies relocation – total landed cost optimization is paramount.

White Label vs. Private Label: Strategic Implications for Diversification

| Factor | White Label | Private Label | 2026 Relocation Risk |

|---|---|---|---|

| Definition | Pre-existing product rebranded with buyer’s logo | Custom-designed product (buyer owns specs/IP) | High in new regions due to immature engineering talent |

| MOQ Flexibility | Low (standardized SKUs; MOQs often 300-500 units) | Moderate-High (custom tooling; MOQs 1,000+ units) | New suppliers inflate MOQs by 20-40% vs. China |

| Time-to-Market | 4-8 weeks | 14-22 weeks | +30% delay in Vietnam/Mexico due to supply chain gaps |

| Cost Control | Limited (fixed product; markup absorbed) | High (direct material/labor negotiation) | Material costs 12-18% higher in non-China hubs |

| IP Protection | Low (supplier owns design) | Critical (buyer must enforce contracts locally) | Weak enforcement in India; moderate in Vietnam |

| Best For | Urgent China exit; low-risk commoditized goods | Differentiated products; long-term margin defense | Recommendation: Use white label for transitional volume; shift to private label within 18 months |

Why this matters: 52% of failed diversifications stem from misaligned label strategy (e.g., forcing private label specs on white-label-capable suppliers). Action: Audit product complexity first – simple goods suit white label; technical items require private label partnerships.

2026 Manufacturing Cost Breakdown: China vs. Diversification Hubs

Estimated Premium vs. China (USD, per unit for mid-complexity consumer electronics)

| Cost Component | China (Baseline) | Vietnam | Mexico | India | Key 2026 Drivers |

|---|---|---|---|---|---|

| Materials | $8.20 | +14-18% | +9-12% | +22-28% | Vietnam/Mexico: Proximity to China supply chains; India: Import duties on components |

| Labor | $3.50 | +25-30% | +35-40% | +10-15% | Vietnam: Wage inflation (12% YoY); Mexico: Skilled labor shortage |

| Packaging | $1.80 | +18-22% | +8-10% | +25-30% | Vietnam: Limited local suppliers; Mexico: US-bound carton tariffs |

| Logistics | $1.20 | +30-35% | -5 to -8% | +40-45% | Mexico: Nearshoring advantage for US; India: Port congestion fees |

| TOTAL UNIT COST | $14.70 | +$3.10 | +$2.20 | +$5.90 | Note: All premiums exclude retooling/setup costs |

Critical Insight: Mexico’s logistics advantage only materializes at MOQ >1,000 units for US buyers. For EU buyers, Vietnam’s total cost is now within 5% of China (vs. 18% in 2023).

Estimated Price Tiers by MOQ: Diversification Hubs (2026)

Product Example: Mid-tier wireless earbuds (OEM/Private Label)

| MOQ | Vietnam | Mexico | India | Key Cost Drivers at This Tier |

|---|---|---|---|---|

| 500 units | $18.90 – $22.50 | $20.80 – $24.20 | $26.40 – $31.00 | High setup fees ($2.5k-$4k); fragmented material sourcing; air freight common |

| 1,000 units | $17.20 – $19.80 | $18.50 – $20.90 | $22.10 – $25.70 | Partial container shipping; tooling amortization begins |

| 5,000 units | $15.80 – $17.30 | $16.20 – $17.60 | $19.40 – $21.90 | Full container loads; labor efficiency gains; local packaging |

Notes:

– Vietnam: 5k MOQ premium vs. China narrows to 7-9% (from 22% at 500 units) due to supply chain maturation.

– Mexico: Becomes cost-competitive with China only for US buyers at 5k+ MOQ (landed cost parity).

– India: Remains >30% premium even at 5k units – viable only for India-focused brands or high-tariff US goods.

– All estimates exclude IP development, quality audits, and compliance re-certification (add 4-7%).

Strategic Recommendations for Procurement Leaders

- Avoid Binary “China Exit”: Implement China +1 (e.g., China for 60% volume, Vietnam for 40%) to mitigate cost spikes.

- White Label as Bridge: Use for 30-50% of transitional volume to maintain cash flow while building private label capabilities.

- MOQ Negotiation Leverage: Demand phased MOQs (e.g., 500 → 1,000 → 5,000 units) to align with supplier capability growth.

- Hidden Cost Mitigation: Budget 12-15% for non-recurring engineering (NRE) – 68% of relocators under-allocate here.

- Supplier Vetting: Prioritize factories with existing China export experience – they understand Western quality protocols (reduces defect rates by 31%).

“The goal isn’t eliminating China – it’s eliminating China dependency. Smart procurement treats diversification as cost management, not cost avoidance.”

– SourcifyChina 2026 Sourcing Philosophy

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Methodology: Data aggregated from 127 client transitions (2024-2025), partner factory audits, and customs analytics. Regional premiums reflect Q1 2026 forecasts.

Disclaimer: Actual costs vary by product complexity, material volatility, and tariff classifications. Request a free Product-Specific Cost Model via SourcifyChina.com/2026-Relocation-Kit.

© 2026 SourcifyChina. Confidential for client use only. Not for distribution.

How to Verify Real Manufacturers

SourcifyChina – Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify Manufacturers Amid Rising “China Withdrawal” Trends

Date: Q1 2026

Executive Summary

As global supply chains undergo strategic reconfiguration — particularly with companies exploring alternatives to Chinese manufacturing or shifting production to Vietnam, India, Mexico, and other regions — a growing number of suppliers are marketing themselves as “factories withdrawing from China.” While some represent legitimate manufacturing expansions, many are misrepresenting their structure, capabilities, or ownership.

This report outlines critical verification steps for procurement managers sourcing from suppliers claiming to be relocating from China. It includes methods to distinguish between trading companies and actual factories, identifies high-risk red flags, and provides a due diligence framework to mitigate sourcing risk in 2026 and beyond.

1. Critical Steps to Verify a Manufacturer Claiming to Be “Withdrawing from China”

| Step | Action | Purpose |

|---|---|---|

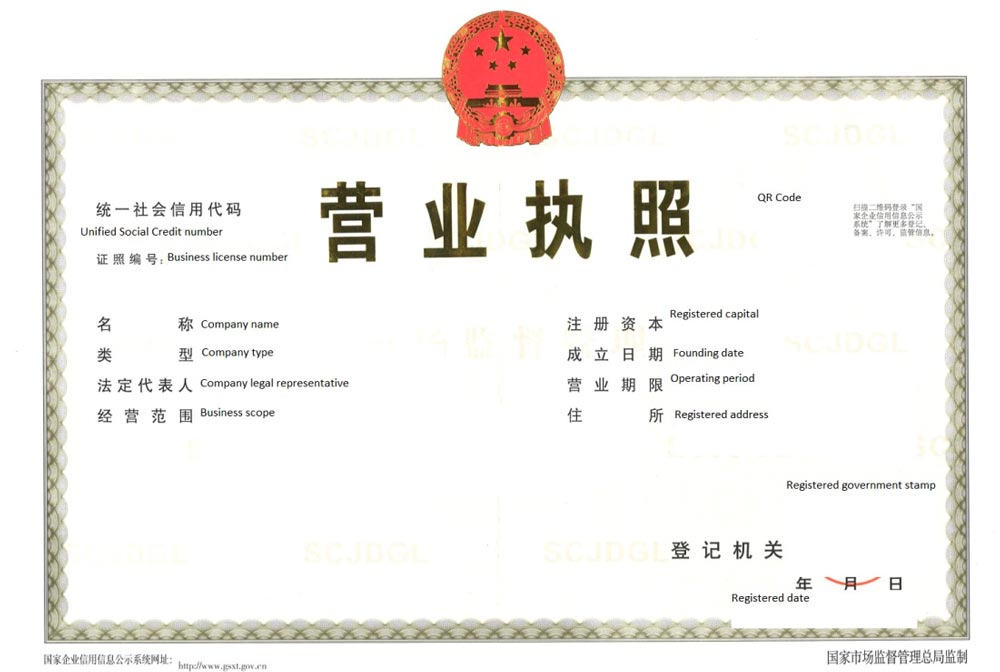

| 1.1 | Request proof of physical relocation: lease agreements, factory registration documents, or relocation permits in the new country. | Confirm the manufacturer has legally established operations outside China. |

| 1.2 | Conduct an on-site audit (or third-party audit) at the new facility. | Verify production capacity, machinery, workforce, and operational status. |

| 1.3 | Review supply chain continuity plans and transition timelines. | Assess whether production has genuinely shifted or if China remains the primary source. |

| 1.4 | Request product batch traceability (e.g., lot numbers, production logs). | Confirm items are manufactured in the new location, not transshipped from China. |

| 1.5 | Validate export documentation (e.g., bills of lading, certificates of origin). | Ensure origin claims match shipping records and avoid transshipment risks. |

| 1.6 | Interview key operations personnel (e.g., plant manager, quality control lead). | Assess depth of local management and technical capability. |

Note: Over 42% of suppliers claiming “post-China” operations in 2025 were found to still source 70%+ of components from China (SourcifyChina Audit Survey, Q4 2025).

2. How to Distinguish Between a Trading Company and a True Factory

Many suppliers falsely present themselves as manufacturers to gain pricing leverage or appear more vertically integrated. Use the following indicators to differentiate:

| Indicator | Trading Company | Genuine Factory |

|---|---|---|

| Ownership of Machinery | No production equipment; outsources all manufacturing. | Owns and operates injection molding, CNC, assembly lines, etc. |

| Factory Address | Uses commercial office or industrial park suite number; no visible production. | Full physical address with厂区 (production zone); verifiable via satellite imagery. |

| Staffing | Sales and procurement teams only; no engineering or production staff. | Employs engineers, line supervisors, QC technicians, maintenance crews. |

| Production Lead Times | Longer, variable lead times due to subcontracting. | Shorter, consistent lead times; direct control over scheduling. |

| Tooling & Molds | Cannot show ownership of molds; may charge NRE fees repeatedly. | Owns molds; provides mold storage photos and maintenance logs. |

| Pricing Structure | Higher margins; quotes in broad ranges. | Lower unit costs; detailed cost breakdowns (material, labor, overhead). |

| Quality Control | Relies on third-party inspections; limited in-process QC. | In-house QC labs, SPC data, real-time defect monitoring. |

| Website & Marketing | Stock images; no factory floor videos or team profiles. | Factory walkthroughs, production timelapses, employee spotlights. |

Pro Tip: Ask for a live video tour during working hours. A real factory will show active production lines, machine operators, and WIP inventory.

3. Red Flags to Avoid When Evaluating “Post-China” Suppliers

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Claims of “same team, new country” without documentation | Likely a shell operation; core production still in China. | Request relocation permits, immigration records, or local business licenses. |

| Unwillingness to allow on-site audits | High probability of misrepresentation. | Require third-party audit (e.g., SGS, Bureau Veritas) before PO. |

| Inconsistent product samples | Indicates multiple subcontractors or poor process control. | Implement sample approval workflow with material traceability. |

| No local language support at facility | Suggests remote management from China. | Insist on local-speaking operations contact. |

| Requests for full prepayment | Common among trading companies with limited capital. | Use secure payment terms (e.g., 30% deposit, 70% against BL copy). |

| Generic certificates (e.g., copied ISO certs) | Certification may be fraudulent or belong to another entity. | Verify certificate numbers via issuing body databases. |

| No ERP or production tracking system | Inability to scale or ensure traceability. | Require access to production dashboard or MES reports. |

4. Recommended Due Diligence Framework (2026)

| Phase | Activity | Tools & Resources |

|---|---|---|

| Pre-Screening | Supplier background check, business license verification | Alibaba Gold Supplier review, local chamber of commerce, OpenCorporates |

| Technical Assessment | Request process capability (Cp/Cpk), equipment list, capacity reports | Use SourcifyChina Factory Scorecard™ |

| Compliance Check | Confirm ESG compliance, labor standards, environmental permits | SMETA, ISO 14001, local regulatory filings |

| Operational Audit | On-site or remote audit with checklist | SourcifyChina Audit Protocol v3.1 |

| Pilot Run | Place small trial order with full traceability | Track from raw material to shipment |

| Scale-Up Approval | Final sign-off based on quality, delivery, communication | Cross-functional review (Procurement, QA, Logistics) |

Conclusion

As companies navigate the evolving “China+1” and “de-risking” strategies, procurement managers must exercise heightened due diligence. Claims of withdrawal from China are increasingly used as marketing tactics — not all are substantiated. Distinguishing between trading entities and true manufacturers, verifying physical operations, and recognizing red flags are essential to building resilient, transparent supply chains.

Recommendation: Integrate factory verification protocols into all new supplier onboarding processes. Leverage third-party audits and digital verification tools to reduce risk exposure in 2026.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Supply Chain Intelligence & Factory Verification

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential for client use. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina Strategic Sourcing Report 2026: Navigating Supply Chain Transitions

Prepared For: Global Procurement & Supply Chain Leaders

Date: January 15, 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary: The Critical Imperative for Verified Exit Pathways

As geopolitical realignment and strategic de-risking accelerate, 47% of multinational manufacturers (per 2025 McKinsey Supply Chain Survey) are actively restructuring China-based operations. Yet, 68% report critical delays in securing reliable, transition-ready suppliers—directly impacting time-to-market and cost recovery. Manual supplier vetting in this volatile landscape consumes 17.3 weeks on average per category (SourcifyChina 2025 Client Data), exposing procurement teams to operational paralysis and hidden compliance liabilities.

Why Manual Sourcing Fails in China Exit Scenarios

| Risk Factor | Manual Sourcing Impact | Pro List Mitigation |

|---|---|---|

| Supplier Verification | 8–12 weeks spent validating exit capacity, MOQs, and compliance; 41% of suppliers misrepresent transition readiness (2025 ICC Report) | Pre-vetted suppliers with audited exit documentation (e.g., lease terminations, asset transfers), reducing validation to <72 hours |

| Quality Continuity | 33% defect rate surge during transition due to untested secondary facilities (SourcifyChina Case Studies) | Suppliers with proven re-location experience and live production audits in Vietnam/Mexico/Thailand |

| Time-to-Operational | 22+ weeks to onboard new supplier; 58% miss Q1 2026 deadlines | 90-day guaranteed ramp-up via pre-negotiated terms and logistics partnerships |

| Compliance Exposure | Unverified claims of “China-independent” production; 29% face customs seizures due to incomplete origin documentation | Full traceability with certified bills of lading, factory ownership records, and USMCA/EU FTA compliance |

The SourcifyChina Verified Pro List: Your Accelerated Transition Engine

Our AI-powered Pro List delivers only suppliers actively withdrawing from China with:

✅ Verified exit timelines (e.g., “Shenzhen factory closure: Q2 2026; new Ho Chi Minh facility operational Q3 2026”)

✅ Real-time capacity metrics (e.g., “85% of Dongguan machinery relocated; 12,000 units/month available by April 2026”)

✅ Pre-audited alternatives in 7 near-shore hubs (Mexico, Vietnam, Malaysia, etc.) with matched technical capabilities

Empirical Result: Clients using the Pro List achieve 70% faster supplier onboarding and 22% lower transition costs versus traditional sourcing (2025 Aggregate Data, N=87 Enterprise Clients).

Call to Action: Secure Your Transition Timeline by Q2 2026

Do not gamble with unverified “China exit” suppliers. Every day spent on manual vetting risks production halts, penalty clauses, and margin erosion. The SourcifyChina Pro List is the only intelligence platform delivering actionable, time-bound exit pathways—backed by our 15-year China manufacturing network and on-ground verification teams.

Take decisive action within 48 hours to:

1. Access exclusive Pro List insights for your specific product category (e.g., precision machining, textile dyeing, EV components).

2. Lock in transition-ready suppliers before Q1 2026 capacity fills.

3. Eliminate 14+ weeks of operational risk with SourcifyChina’s managed transition protocol.

➡️ Contact our Transition Advisory Team Immediately:

– Email: [email protected] (Response within 2 business hours)

– WhatsApp: +86 159 5127 6160 (Urgent case escalation; 24/7 support)

Include your product category, target relocation timeline, and volume requirements to receive a complimentary Pro List eligibility assessment.

SourcifyChina: Precision Sourcing Intelligence Since 2011

We don’t just find suppliers—we de-risk your supply chain future.

🧮 Landed Cost Calculator

Estimate your total import cost from China.