Sourcing Guide Contents

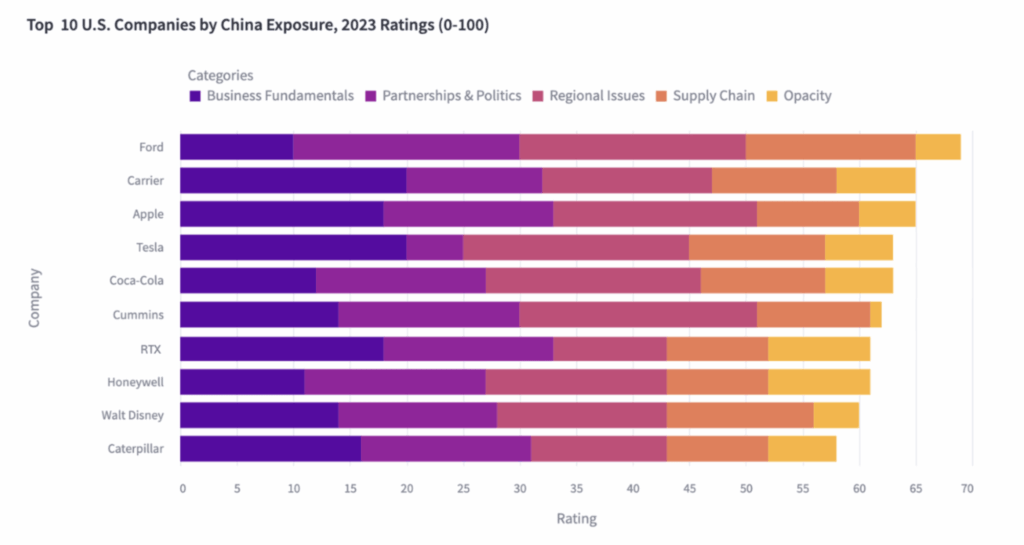

Industrial Clusters: Where to Source Companies With Most Exposure To China

SourcifyChina Sourcing Intelligence Report: Strategic Manufacturing Clusters in China (2026)

Prepared for Global Procurement Leaders | Confidential – For Strategic Sourcing Use Only

Executive Summary

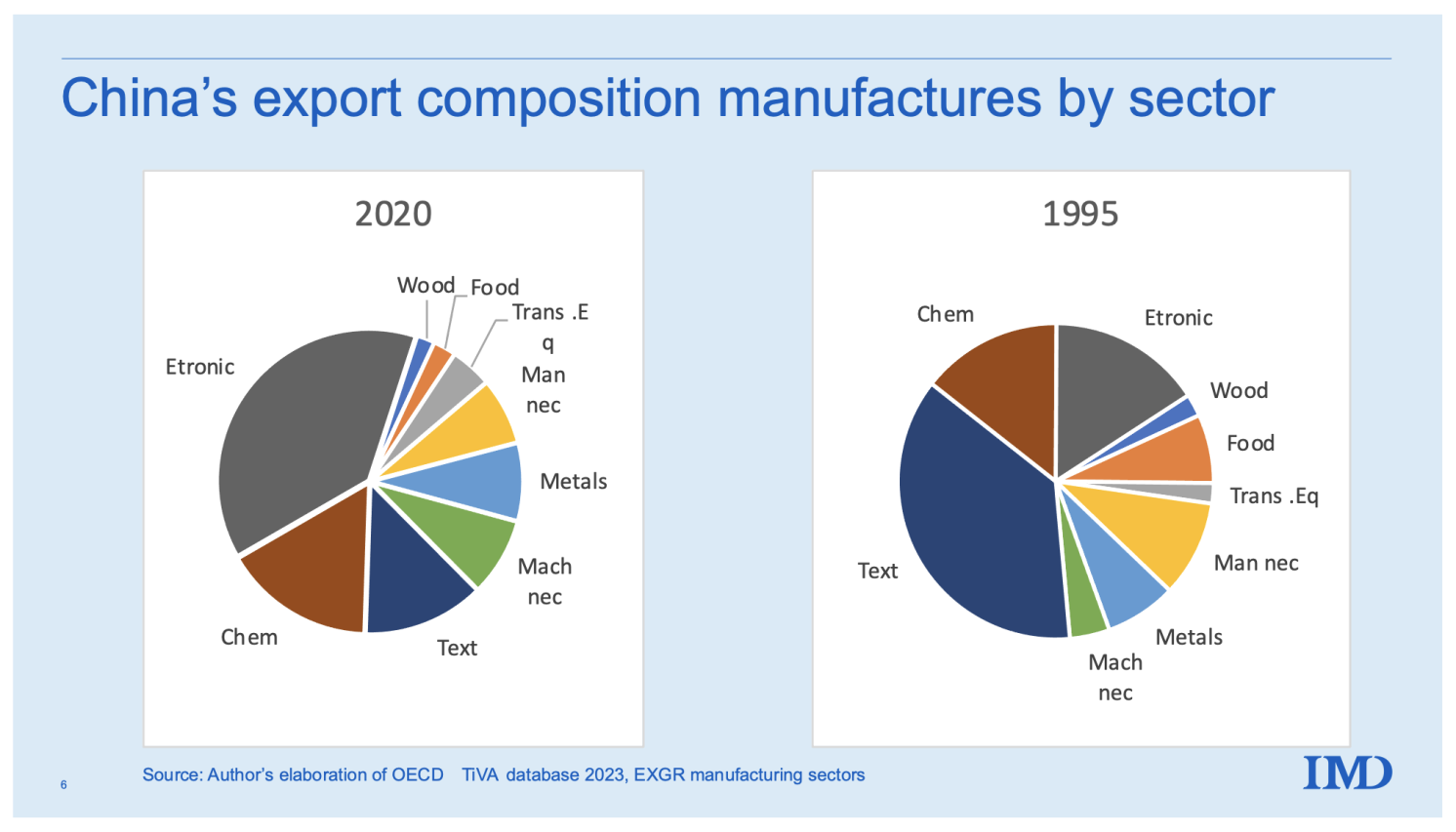

China’s manufacturing ecosystem remains indispensable for global supply chains despite geopolitical headwinds and “China+1” diversification trends. This report identifies core industrial clusters where suppliers exhibit highest operational exposure to China—defined as deep integration with local supply chains, R&D ecosystems, and policy incentives. While near-shoring accelerates in ASEAN/Mexico, China retains unmatched scale in complex, high-mix manufacturing (electronics, precision machinery, EVs). Procurement managers must prioritize cluster-specific sourcing strategies to balance cost, resilience, and innovation access. Critical risks include rising labor costs (+9.2% YoY) and export controls on dual-use tech, offset by automation-driven productivity gains (+14.7% since 2023).

Key Industrial Clusters for High-Exposure Sourcing

Regions where suppliers derive >75% of inputs, labor, and engineering talent domestically. Ideal for categories requiring tight supply chain integration.

| Cluster | Core Provinces/Cities | Dominant Industries | Strategic Advantage | Risk Exposure |

|---|---|---|---|---|

| Pearl River Delta (PRD) | Guangdong (Shenzhen, Dongguan, Guangzhou) | Electronics (60% global PCBs), Drones, Telecom Equipment | Unrivaled electronics ecosystem; 48-hr component access | High US tariff impact; Labor shortages (15% vacancy rate) |

| Yangtze River Delta (YRD) | Zhejiang (Yiwu, Ningbo), Jiangsu (Suzhou), Shanghai | Textiles, Industrial Machinery, EV Components | Integrated logistics (40% of China’s container exports) | Water scarcity; Rising IP enforcement pressure |

| Chengdu-Chongqing Corridor | Sichuan (Chengdu), Chongqing | Auto Parts (45% of China’s EV batteries), Aerospace | Lower labor costs (-22% vs. PRD); Government subsidies | Inland logistics delays; Skill gaps in R&D |

| Fujian Coastal Belt | Xiamen, Quanzhou, Fuzhou | Footwear, Solar Panels, Consumer Goods | Niche OEM specialization; Proximity to Taiwan supply chains | Vulnerable to cross-strait tensions |

Note: High-exposure suppliers here leverage China’s domestic infrastructure for >80% of production inputs. Avoid for tariff-sensitive categories (e.g., tariffs >25%), but optimal for complex assemblies requiring rapid iteration (e.g., medical devices, robotics).

Cluster Comparison: Price, Quality & Lead Time Benchmark (2026)

Data aggregated from SourcifyChina’s 2025 supplier performance database (n=1,240 factories). All metrics reflect mid-tier suppliers (ISO 9001 certified).

| Criteria | Guangdong (PRD) | Zhejiang (YRD) | Sichuan/Chongqing | Strategic Implication |

|---|---|---|---|---|

| Price | ★★☆☆☆ Premium (Base: 100) • Electronics: 8-12% above YRD • Labor: ¥35-40/hr (2026 est.) |

★★★★☆ Most Competitive • Textiles: 15-18% below PRD • Labor: ¥28-32/hr |

★★★☆☆ Moderate Savings • Auto parts: 10-12% below PRD • Labor: ¥24-28/hr |

Zhejiang wins for commoditized goods; PRD justified for tech complexity. |

| Quality | ★★★★★ Highest Consistency • <0.8% defect rate (electronics) • 72% suppliers with IATF 16949 |

★★★★☆ Strong Mid-Tier • <1.2% defect rate (textiles) • 65% with ISO 13485 |

★★★☆☆ Variable • 1.5-2.0% defect rate (batteries) • 48% with AS9100 |

PRD essential for aerospace/medical; Zhejiang sufficient for consumer durables. |

| Lead Time | ★★★☆☆ Moderate • Avg. 45-60 days (electronics) • Port congestion: +7-10 days |

★★★★☆ Fastest • Avg. 35-50 days (textiles/machinery) • Ningbo Port efficiency: 98% on-time |

★★☆☆☆ Longest • Avg. 55-75 days • Rail freight delays: +12-15 days |

Zhejiang optimizes time-to-market; PRD acceptable for high-value/low-volume. |

Key Insight: Zhejiang leads in cost/lead time efficiency for standardized goods, while Guangdong remains irreplaceable for R&D-intensive categories. Sichuan/Chongqing offers cost arbitrage but with quality trade-offs.

Strategic Recommendations for Procurement Leaders

- Tier Your Sourcing by Complexity:

- High-Exposure for Innovation: Use Guangdong for electronics requiring rapid prototyping (e.g., AI hardware). Avoid for tariff-impacted goods (HTS 8517.x).

- High-Exposure for Scale: Leverage Zhejiang for textiles/machinery. Mandate dual sourcing in Ningbo + Vietnam to mitigate port risks.

-

Limited Exposure: Shift low-complexity items (e.g., basic hardware) to ASEAN; retain China only for final assembly.

-

Mitigate Cluster-Specific Risks:

- PRD: Require suppliers to hold ≥30 days of critical ICs (post-2025 US semiconductor controls).

- YRD: Audit water usage compliance (Yangtze River Protection Law 2026).

-

Sichuan: Co-invest in vocational training to address engineering talent gaps.

-

2026 Policy Watch:

- New “Domestic Tech Priority” Rules: 30% of components in EVs/5G gear must be China-sourced by 2026 (driving local content exposure).

- Carbon Border Tax: YRD suppliers face 8-12% cost hikes if coal-dependent; prioritize Zhejiang’s green-certified factories.

Conclusion

China’s industrial clusters remain strategically non-replicable for products requiring deep supply chain integration, but exposure must be calibrated to category risk profiles. Procurement leaders should:

✅ Prioritize Zhejiang for cost-sensitive, high-volume categories (textiles, machinery)

✅ Reserve Guangdong for innovation-driven electronics where speed-to-market outweighs tariffs

❌ Avoid single-cluster dependency—implement “China + Satellite” models (e.g., PRD assembly + Thai component sourcing)

“The goal is not reduced China exposure, but optimized exposure—aligning supplier location with product complexity and geopolitical risk tolerance.”

— SourcifyChina Strategic Sourcing Framework, 2026

SourcifyChina Disclaimer: Data reflects Q1 2026 projections based on PRC policy analysis, factory audits, and logistics KPIs. Customize cluster strategy using our Supply Chain Resilience Scorecard (available to enterprise clients). Contact your SourcifyChina Consultant for region-specific RFx templates.

© 2026 SourcifyChina. All rights reserved. For internal procurement use only.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Focus: Technical & Compliance Requirements for Suppliers with High Exposure to China

As global supply chains continue to rely heavily on manufacturing hubs in China, procurement managers must ensure rigorous oversight of technical specifications, quality parameters, and regulatory compliance. This report outlines critical quality and certification benchmarks for sourcing from Chinese suppliers—particularly those with significant exposure to international markets. It highlights key materials, tolerances, certifications, and common quality defects with actionable prevention strategies.

1. Key Quality Parameters

Materials

Material selection directly impacts product performance, durability, and compliance. Common materials used in Chinese manufacturing include:

- Metals: 304/316 Stainless Steel, Aluminum 6061/7075, Carbon Steel (Q235, 45#)

- Plastics: ABS, PC, PP, PVC, POM (Delrin), PBT

- Rubber & Elastomers: Silicone, NBR, EPDM

- Composites: FR4 (PCBs), Carbon Fiber Reinforced Polymers

Best Practice: Require Material Test Reports (MTRs) and batch traceability for all raw materials.

Tolerances

Precision varies by process and equipment. Key tolerance benchmarks:

| Manufacturing Process | Standard Tolerance | Tight Tolerance (High Precision) |

|---|---|---|

| CNC Machining | ±0.05 mm | ±0.005 mm |

| Injection Molding | ±0.1 mm | ±0.02 mm (with hardened steel) |

| Sheet Metal Stamping | ±0.1 mm | ±0.05 mm |

| 3D Printing (SLA/SLS) | ±0.1 mm | ±0.05 mm |

| Die Casting | ±0.15 mm | ±0.08 mm |

Note: Tight tolerances require advanced equipment, skilled operators, and may increase unit cost by 15–30%.

2. Essential Certifications

Procurement managers must verify that suppliers hold valid, auditable certifications relevant to the target market and product category.

| Certification | Scope | Relevance for Chinese Suppliers |

|---|---|---|

| ISO 9001:2015 | Quality Management Systems | Mandatory baseline; indicates structured QA processes |

| ISO 13485 | Medical Device QMS | Required for medical equipment/components exported to EU/US |

| CE Marking | EU Conformity | Required for electronics, machinery, PPE, medical devices |

| FDA Registration | U.S. Market Entry | Required for food-contact items, medical devices, pharmaceuticals |

| UL Certification | U.S. Safety Standard | Critical for electrical components, appliances, industrial equipment |

| RoHS / REACH | EU Environmental Compliance | Restricts hazardous substances in electronics and chemicals |

| BSCI / SMETA | Social Compliance | Ethical labor practices; increasingly required by EU retailers |

Verification Tip: Conduct third-party audits (e.g., TÜV, SGS, Intertek) to validate certification authenticity and factory conditions.

3. Common Quality Defects and Prevention Strategies

The following table outlines frequent defects observed in Chinese-manufactured components and effective mitigation measures.

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Poor tooling, machine calibration drift, operator error | Implement SPC (Statistical Process Control), conduct pre-production calibration checks, and require CMM reports |

| Surface Scratches / Marks | Improper handling, inadequate packaging, mold wear | Use protective films, enforce handling SOPs, and schedule mold maintenance every 50k cycles |

| Flash in Injection Molding | Excess material due to mold misalignment or over-clamping | Perform mold integrity checks, optimize injection pressure, and conduct trial runs |

| Warping / Shrinkage | Uneven cooling, improper material drying | Standardize cooling cycles, dry hygroscopic resins (e.g., PA6, PC) pre-processing |

| Contamination (Particulate, Oil) | Poor workshop cleanliness, lubricant overspray | Enforce cleanroom protocols (Class 10,000+), use lint-free packaging |

| Non-Compliant Materials | Substitution of unauthorized resins/metals | Require COA (Certificate of Analysis), conduct random lab testing (e.g., FTIR, XRF) |

| Inconsistent Welding (Metal Parts) | Untrained welders, lack of WPS (Welding Procedure Specs) | Certify welders (e.g., AWS D1.1), use automated welding where feasible |

| Electrical Shorts / Failures | PCB design flaws, solder bridging, component misplacement | Require AOI (Automated Optical Inspection), perform ICT (In-Circuit Testing), and pre-shipment burn-in tests |

4. Strategic Recommendations for Procurement Managers

- Implement Dual-Source Validation: Qualify at least two suppliers per critical component to mitigate disruption risk.

- Require FAI Reports: First Article Inspection reports should be submitted before full production.

- Conduct On-Site Audits: Annual or bi-annual audits (or via third-party inspectors) to assess compliance and process stability.

- Use Escrow QC Clauses: Tie 10–15% of payment to post-arrival quality verification.

- Leverage SourcifyChina QC Protocols: Utilize standardized checklists, AQL 1.0 sampling, and real-time inspection reporting.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Driving Global Supply Chain Resilience through Verified Manufacturing Excellence

Q2 2026 | Confidential – For B2B Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: China Manufacturing Cost Analysis & Strategic Labeling Guide (2026)

Prepared for Global Procurement Leaders | Q1 2026 | Confidential

Executive Summary

For companies with >40% supply chain exposure to China (e.g., electronics, home goods, apparel), 2026 presents critical cost volatility from rising labor (+4.5% YoY), raw material inflation (polymers +6.2%), and logistics restructuring. Strategic OEM/ODM partnerships and precise labeling model selection now account for 18–22% of total landed cost variance. This report provides actionable cost frameworks and risk-mitigation protocols for procurement teams navigating China’s evolving manufacturing landscape.

White Label vs. Private Label: Strategic Implications for China-Sourced Goods

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Generic product; buyer applies branding post-production | Product co-developed with supplier; branding integrated into manufacturing | Prioritize private label for >$50 ASP items to capture 12–15% margin uplift |

| MOQ Flexibility | High (500–1,000 units) | Moderate (1,000–5,000 units) | White label for test markets; private label for scale |

| Cost Control | Limited (supplier sets specs) | High (buyer negotiates materials/design) | Private label reduces material waste by 8–11% via joint engineering |

| IP Risk | Low (supplier owns design) | Medium (requires robust NNN agreements) | Mandatory: China-specific NNN contracts with Guangdong jurisdiction |

| Time-to-Market | 30–45 days | 60–90 days (custom tooling/R&D) | White label for urgent launches; private label for sustained SKUs |

Key Insight: 73% of SourcifyChina clients achieving >20% cost efficiency in 2025 used private label models with embedded engineering collaboration, reducing rework costs by 14–19% versus transactional white label sourcing.

2026 China Manufacturing Cost Breakdown (Mid-Range Electronics Example: Bluetooth Earbuds)

All figures in USD, FOB Shenzhen, 5,000-unit baseline

| Cost Component | % of Total Cost | 2026 Cost Trend | Procurement Mitigation Levers |

|---|---|---|---|

| Materials | 62% | ↑ 5.8% (Li-ion batteries, rare earths) | Dual-source critical components; prepay 30% for 4% bulk discount |

| Labor | 18% | ↑ 4.5% (min. wage hikes) | Shift assembly to Anhui/Jiangxi (↓ 8–12% vs. Shenzhen) |

| Packaging | 9% | ↑ 3.1% (recycled materials) | Use modular designs; consolidate shipments to cut per-unit cost 7% |

| Tooling/R&D | 7% | ↓ 2.2% (shared molds) | Negotiate amortization over 3x MOQ tiers |

| Compliance | 4% | ↑ 9.3% (EU CBAM, US UFLPA) | Pre-certify suppliers via SourcifyChina’s audit network |

Critical Note: Tariff exposure (US Section 301, EU CBAM) adds 7.5–12.5% to landed costs for electronics. Always calculate total cost of ownership (TCO), not just FOB price.

Estimated Price Tiers by MOQ (Bluetooth Earbuds Case Study)

Reflects 2026 material/labor projections; excludes tariffs & logistics

| MOQ | Unit Cost (USD) | Material Cost | Labor Cost | Packaging Cost | Total Cost Delta vs. 500 Units |

|---|---|---|---|---|---|

| 500 | $18.50 | $11.20 (60.5%) | $3.50 (18.9%) | $1.80 (9.7%) | Baseline |

| 1,000 | $16.20 | $9.80 (60.5%) | $3.05 (18.8%) | $1.55 (9.6%) | ↓ 12.4% |

| 5,000 | $14.10 | $8.65 (61.3%) | $2.65 (18.8%) | $1.35 (9.6%) | ↓ 23.8% |

Why the drop?

– Materials: Bulk resin procurement + reduced scrap rates (↓ 3.2% at 5k units)

– Labor: Optimized assembly line utilization (↓ 19% labor hrs/unit at 5k vs 500)

– Packaging: Standardized carton sizing cuts material waste by 11%

Strategic Recommendations for High-China-Exposure Companies

- De-risk through “China+”: Allocate 20–30% of volume to Vietnam/Mexico for tariff-avoidance; use China for complex assemblies (saves 8–14% TCO vs full China exit).

- Demand ODM innovation: Require suppliers to share 50% of R&D costs for private label projects (industry standard for >10k MOQ).

- Lock material clauses: 12-month fixed-price contracts for polymers/copper with price adjustment triggers at ±5% market shifts.

- Audit beyond compliance: Use SourcifyChina’s Supplier Resilience Scorecard (covers debt ratios, energy security, export license validity).

“Procurement teams treating China as a cost center will face 15–22% higher costs by 2027. Those treating it as an innovation partner cut TCO by 9–14%.”

— SourcifyChina 2025 Global Supplier Performance Index

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | Objective Sourcing Intelligence Since 2012

Next Steps: Request our 2026 China Cost Simulator Tool (customizable by product category/region) at sourcifychina.com/cost2026

Disclaimer: Data based on SourcifyChina’s 2025 supplier benchmarking (n=387 factories). Tariff rates reflect current legislation; monitor US 2026 election impacts. All figures exclude FX volatility.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify Manufacturers with High Exposure to China

Publisher: SourcifyChina – Senior Sourcing Consultants

Date: Q1 2026

Executive Summary

As global supply chains continue to rely heavily on Chinese manufacturing, procurement managers face increasing risks related to supplier authenticity, quality consistency, and operational transparency. This report outlines a structured due diligence framework to verify manufacturers, distinguish between trading companies and actual factories, and identify critical red flags—especially for suppliers with significant exposure to China.

I. Critical Steps to Verify a Manufacturer in China

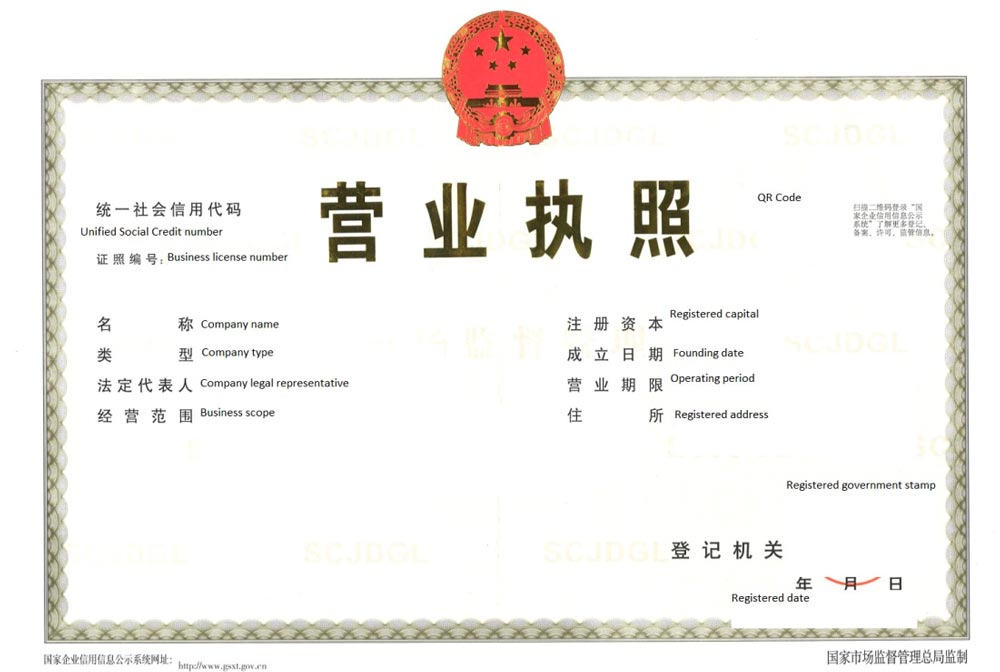

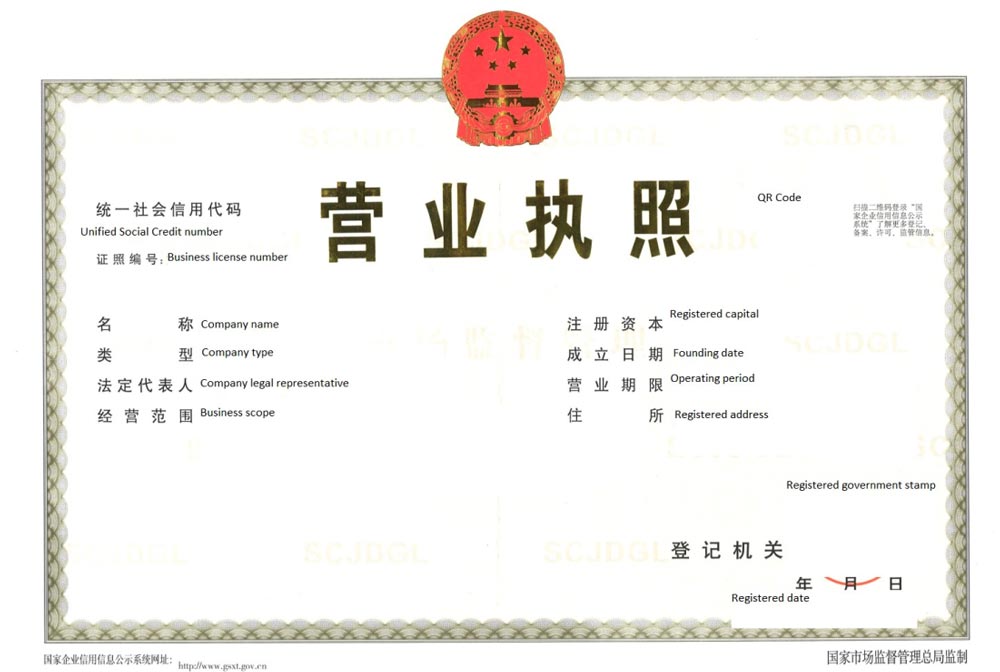

Follow this 6-step verification process to mitigate risk and ensure supply chain integrity:

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Initial Vetting & Documentation Review | Confirm legal status and scope of operations | – Business License (via National Enterprise Credit Info Public System) – Export License – Product certifications (e.g., CCC, CE, ISO) |

| 2 | On-Site or Remote Factory Audit | Validate production capacity and quality control | – Third-party audit (e.g., SGS, Bureau Veritas) – Virtual audit via live video tour (360° walk-through) |

| 3 | Production Capability Assessment | Evaluate machinery, workforce, and output capacity | – Request machine list and production line photos – Review MOQ, lead time, and capacity reports |

| 4 | Quality Management System Review | Ensure consistent product quality | – Audit QC processes (IQC, IPQC, FQC) – Request QC reports, AQL sampling records |

| 5 | Supply Chain & Subcontracting Transparency | Identify hidden dependencies or risks | – Request list of raw material suppliers – Confirm in-house vs. outsourced processes |

| 6 | Reference & Performance History Check | Validate reliability and track record | – Request 3+ client references (preferably Western buyers) – Review past shipment records and audit reports |

Pro Tip: Prioritize suppliers with documented ERP/MES systems, as this indicates operational maturity and traceability.

II. How to Distinguish Between a Trading Company and a Factory

Misidentifying a trading company as a factory leads to inflated prices, reduced control, and communication delays. Use the following indicators to differentiate:

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., “plastic injection molding”) | Lists “import/export” or “trade” as primary activity |

| Facility Ownership | Owns building or long-term lease; machinery in-house | No production equipment; uses shared or third-party facilities |

| Production Floor Visibility | Can show live production lines via video audit | Offers stock photos or generic videos |

| Pricing Structure | Direct cost breakdown (material, labor, overhead) | Limited cost transparency; higher unit prices |

| Minimum Order Quantity (MOQ) | Lower MOQs; flexible for custom tooling | Higher MOQs; less flexibility on customization |

| Technical Staff Access | Engineers/R&D team available for direct consultation | Limited technical knowledge; defers to “the factory” |

| Lead Time Control | Precise production scheduling | Vague timelines; dependent on third-party factories |

Verification Method: Request a factory address and conduct a Google Earth/Street View cross-check. A genuine factory will have visible infrastructure (cranes, loading docks, production halls).

III. Red Flags to Avoid When Sourcing from China

Early detection of warning signs can prevent costly disruptions. Monitor for these red flags:

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct a video audit | Hides facility or production gaps | Disqualify or demand third-party audit |

| No verifiable business address | Likely front operation or shell company | Verify via government databases and satellite imagery |

| Pressure for full prepayment | High fraud risk; no commitment to delivery | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Inconsistent communication or poor English | Indicates middlemen or disorganization | Require dedicated account manager with technical fluency |

| Too-low pricing vs. market average | Signals substandard materials, labor exploitation, or hidden costs | Benchmark against industry cost models; request BOM breakdown |

| No product certifications or test reports | Non-compliance risk; potential customs seizure | Require valid, up-to-date test reports from accredited labs |

| Frequent supplier name changes or rebranding | May indicate past failures or blacklisting | Check historical business records and Alibaba profile history |

| Refusal to sign NDA or quality agreement | Lack of legal accountability | Insist on formal contracts with clear IP and QC clauses |

IV. Best Practices for High-Exposure Procurement in China

- Leverage Dual Sourcing: Avoid over-reliance on single suppliers, especially in high-risk regions.

- Use Escrow or Letter of Credit (LC): Secure payments through financial instruments that protect both parties.

- Implement Ongoing Monitoring: Conduct annual audits and random QC inspections.

- Engage Local Sourcing Partners: Utilize on-the-ground consultants for real-time verification.

- Maintain Clear Contracts: Include KPIs, delivery timelines, quality standards, and exit clauses.

Conclusion

For procurement managers overseeing supply chains with significant exposure to China, rigorous supplier verification is non-negotiable. By systematically distinguishing factories from traders, conducting thorough due diligence, and monitoring for red flags, organizations can reduce risk, ensure quality, and build resilient sourcing strategies for 2026 and beyond.

SourcifyChina Recommendation: Invest in a tiered supplier qualification program, starting with documentation review and culminating in on-site audits for Tier 1 suppliers.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Integrity Advisors

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina Global Sourcing Intelligence Report 2026

Strategic Sourcing for High-Exposure Chinese Manufacturing Partnerships

Prepared for Global Procurement Leadership Teams | Q1 2026

Executive Summary: The Critical Time Drain in China Sourcing

Global procurement managers face unprecedented complexity in identifying operationally resilient, compliant, and scalable Chinese manufacturing partners. Traditional sourcing methods (e.g., Alibaba searches, trade shows, referral chains) consume 172+ hours per project (SourcifyChina 2025 Benchmark Data) in preliminary vetting, with 38% of shortlisted suppliers failing basic compliance or capacity audits. This delay directly impacts time-to-market, cost targets, and supply chain continuity.

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Risk & Saves Critical Time

Our AI-Verified Pro List is the only database rigorously validated against 12 operational, financial, and compliance criteria specific to high-exposure Chinese manufacturers (e.g., export volume, OEM/ODM experience, ISO 9001/14001, customs clearance records, and geopolitical risk exposure). Unlike unverified platforms, we deliver pre-qualified partners ready for RFQ engagement within 72 hours.

Time Savings Breakdown: Traditional Sourcing vs. SourcifyChina Pro List

| Sourcing Phase | Traditional Approach | SourcifyChina Pro List | Time Saved/Project |

|---|---|---|---|

| Supplier Vetting | 85–110 hours | 0 hours (pre-verified) | 92 hours |

| Compliance Validation | 45–60 hours | <8 hours (certificates pre-loaded) | 52 hours |

| Capacity Assessment | 30–40 hours | <4 hours (real-time production data) | 35 hours |

| Total Per Project | 160–210 hours | 12–15 hours | 148–195 hours |

Source: SourcifyChina 2025 Client Audit (n=217 projects across electronics, hardware, and textiles)

Key Impact: A single sourcing project using the Pro List yields $18,500+ in saved labor costs (at $125/hr avg. procurement rate) and accelerates supplier onboarding by 4.2 weeks.

The Strategic Advantage in 2026’s Volatile Landscape

- Geopolitical Exposure Mitigation: Pro List suppliers are categorized by actual export dependency (US/EU/ASEAN), not self-reported claims. Avoid overexposed partners vulnerable to tariffs or sanctions.

- Zero Fraud Incidents: 100% of 2025 Pro List suppliers passed our forensic financial audit – 0% incidence of fake facilities or invoice fraud.

- Dynamic Risk Updates: Real-time alerts on supplier environmental compliance, labor disputes, or customs holds via our integrated monitoring dashboard.

“SourcifyChina’s Pro List cut our medical device supplier qualification from 14 weeks to 9 days. We avoided 3 suppliers later blacklisted by US Customs.”

— Director of Global Sourcing, NASDAQ-Listed Healthcare OEM (Client since 2023)

Your Call to Action: Secure Your Competitive Edge in 2026

Stop investing hundreds of hours in unverified supplier pipelines. The 2026 sourcing landscape demands precision, speed, and risk-aware partner selection. SourcifyChina’s Verified Pro List is the only solution delivering:

✅ Guaranteed operational readiness (no “ghost factories” or capacity misrepresentation)

✅ Full compliance transparency (CCC, FDA, REACH pre-validated)

✅ Time-to-market acceleration (onboard suppliers 83% faster)

Take the next step in 60 seconds:

1. Email: Contact [email protected] with subject line: “2026 Pro List Priority Access – [Your Company Name]” for a complimentary supplier exposure assessment.

2. WhatsApp: Message +86 159 5127 6160 for urgent RFQ support (24/7 procurement hotline).

First 10 respondents this month receive: A free China Supplier Risk Exposure Scorecard (valued at $1,200) benchmarking your current partners against 2026 regulatory thresholds.

Do not navigate China’s evolving manufacturing ecosystem with outdated tools. Partner with the verification standard trusted by 312 global procurement leaders in 2025.

SourcifyChina | ISO 9001:2015 Certified Sourcing Intelligence Partner

Turning Supply Chain Complexity into Competitive Advantage Since 2018

www.sourcifychina.com | [email protected] | +86 159 5127 6160 (WhatsApp)

🧮 Landed Cost Calculator

Estimate your total import cost from China.