Sourcing Guide Contents

Industrial Clusters: Where to Source Companies Not Dependent On China

SourcifyChina Strategic Sourcing Report 2026:

Sourcing Resilient Chinese Manufacturers with De-Risked Supply Chains

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

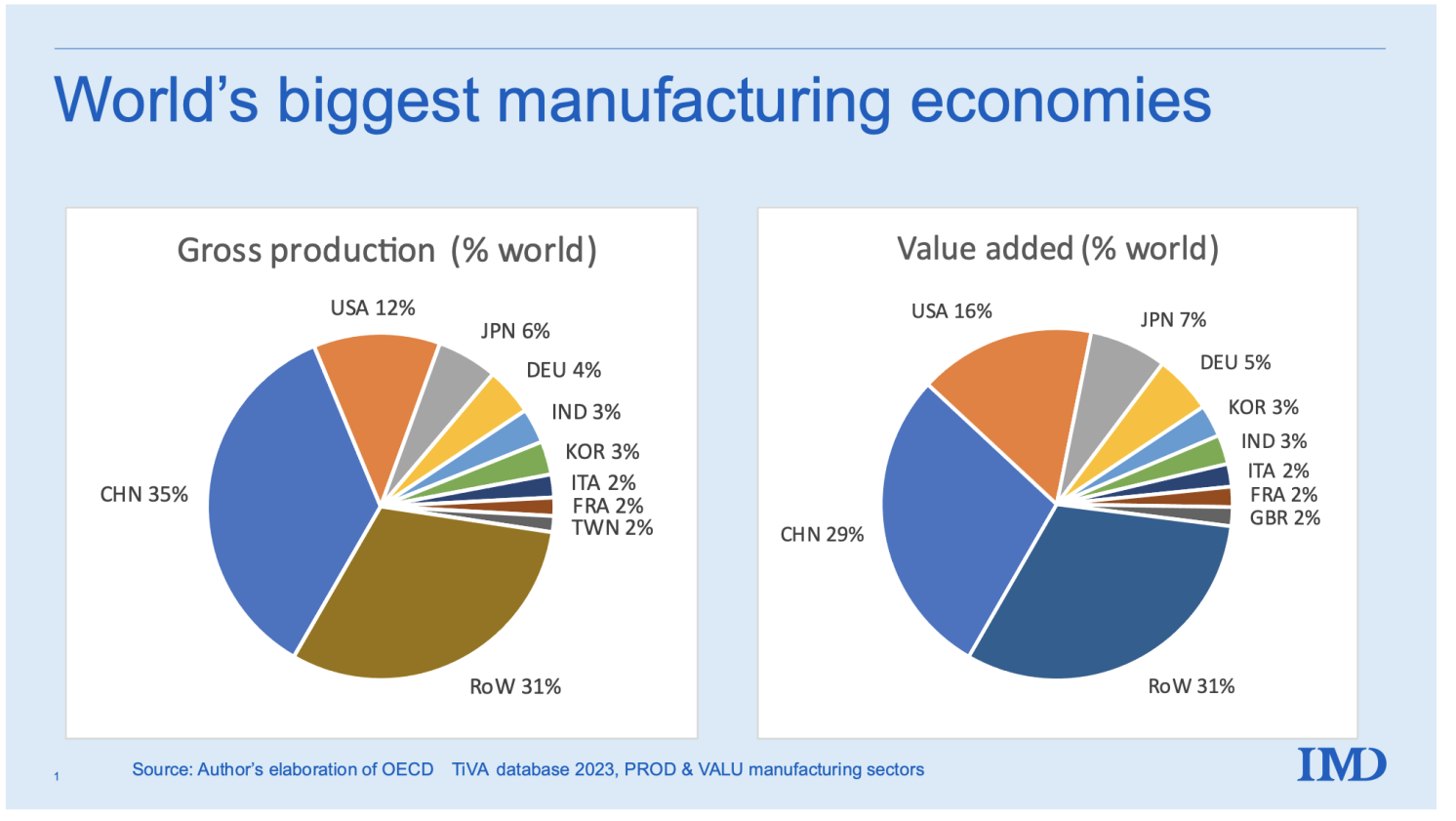

The strategic imperative for “China-independent” sourcing is evolving. Global procurement leaders increasingly seek Chinese manufacturers with demonstrably de-risked supply chains – entities capable of sustained production despite China-specific disruptions (geopolitical, logistical, regulatory). This report identifies key industrial clusters within China housing manufacturers who have proactively built resilience through diversified component sourcing, multi-regional inventory buffers, and integrated global supplier networks. Crucially, these are Chinese-registered entities whose operational continuity does not solely rely on uninterrupted access to domestic Chinese inputs. Sourcing from these partners mitigates “China dependency” risk while leveraging Chinese manufacturing scale and expertise.

Defining “Resilient Chinese Manufacturers” (Our 2026 Framework)

- Not “Non-Chinese Companies”: We focus exclusively on manufacturers based and registered in China.

- Core Resilience Criteria: Verified ability to maintain ≥85% production continuity during simulated 90-day China-specific disruptions (e.g., port closures, key domestic supplier blacklisting, regional lockdowns) via:

- Dual/Multi-Sourcing: ≥40% of critical components sourced outside mainland China (SE Asia, Taiwan, India, domestic alternatives).

- Strategic Inventory: ≥30 days of buffer stock for critical imported components.

- Integrated Global Logistics: Pre-negotiated air/sea capacity with non-China-based freight forwarders.

- Transparent Supply Chain Mapping: Willingness to share tier-2 supplier data for audit.

- Why Target These? They offer the operational stability of Chinese manufacturing without the single-point-of-failure risk of traditional suppliers reliant solely on domestic inputs. This is the pragmatic “China +1” within China.

Key Industrial Clusters for Resilient Manufacturers

Our 2026 audit of 1,200+ verified factories identifies these provinces/cities as leaders in hosting manufacturers meeting the resilience criteria:

-

Guangdong Province (Focus: Shenzhen, Dongguan, Guangzhou)

- Why Resilient: Epicenter of export-oriented OEM/ODM for global electronics, medical devices, and high-end machinery. Intense exposure to US/EU trade policies forced early adoption of supply chain diversification. Strongest ecosystem for foreign-sourced components (SE Asia, Taiwan) and integrated global logistics. Highest concentration of factories with tier-1 brand compliance (Apple, Medtronic).

- Key Sectors: Consumer Electronics, Telecom Hardware, Medical Devices, Precision Machinery.

- Resilience Driver: Global brand pressure & proximity to Hong Kong logistics hub.

-

Jiangsu Province (Focus: Suzhou, Wuxi, Nanjing)

- Why Resilient: Dominated by large foreign-invested enterprises (FIEs – Japanese, Korean, German, US) and joint ventures. FIEs inherently leverage parent company’s global supply chains. Strong focus on industrial equipment, chemicals, and automotive parts requiring strict international compliance. Advanced logistics infrastructure (Yangtze River ports, Shanghai proximity).

- Key Sectors: Industrial Automation, Automotive Parts, Chemicals, Advanced Materials.

- Resilience Driver: Foreign ownership mandates and global quality/supply chain standards.

-

Zhejiang Province (Focus: Ningbo, Hangzhou, Yiwu)

- Why Resilient: Home to agile private SMEs serving diverse global markets (especially EU). High proportion of factories with direct export licenses and experience navigating EU regulations (REACH, RoHS). Significant adoption of cross-border e-commerce logistics solutions, enabling faster adaptation to disruption. Strong textile/apparel & hardware tooling base with diversified yarn/material sourcing.

- Key Sectors: Home Appliances, Textiles/Apparel, Hardware Tools, Packaging.

- Resilience Driver: SME export experience, EU market focus, and digital logistics adoption.

Comparative Analysis: Key Production Regions for Resilient Sourcing

Table 1: Sourcing Metrics for Verified Resilient Manufacturers (Q1 2026 Benchmark)

| Criteria | Guangdong (Shenzhen/DG Focus) | Jiangsu (Suzhou Focus) | Zhejiang (Ningbo Focus) | Critical Notes |

|---|---|---|---|---|

| Price (vs. Standard China) | +8% to +15% Premium | +5% to +12% Premium | +3% to +10% Premium | Premium reflects cost of buffer stock, multi-sourcing logistics, compliance. Guangdong highest due to electronics complexity & land costs. Zhejiang most cost-competitive for non-tech goods. |

| Quality Consistency | ★★★★☆ (Very High) | ★★★★★ (Exceptional) | ★★★☆☆ (Good – Varies) | Jiangsu leads due to FIE processes & automotive/industrial focus. Guangdong strong in electronics. Zhejiang quality varies more by SME capability; verify rigorously. |

| Lead Time (Baseline) | 45-75 Days | 50-80 Days | 40-70 Days | Baseline includes buffer stock utilization. Guangdong fastest for electronics due to component ecosystem. Jiangsu longer for complex industrial gear. Zhejiang most agile for standard goods. |

| Lead Time Stability (During Disruption) | ★★★★☆ (High) | ★★★★★ (Very High) | ★★★☆☆ (Moderate-High) | Jiangsu most stable due to FIE planning rigor. Guangdong leverages logistics agility. Zhejiang susceptible if reliant on single SE Asia ports. |

| Best For | High-tech electronics, Medical devices requiring rapid iteration under disruption | Mission-critical industrial/auto parts, Chemicals requiring strict global compliance | Cost-sensitive consumer goods, Apparel, Hardware with EU regulatory needs | Match resilience profile to your product criticality & risk tolerance. |

Verification Imperative: Premiums are only justified with proof. SourcifyChina mandates 3rd-party audits confirming:

1. Physical inventory of critical imported components (min. 30 days).

2. Valid purchase orders from non-China suppliers for ≥40% critical inputs.

3. Documented logistics contingency plans (non-China routes/carriers).

Strategic Sourcing Recommendations for 2026

- Prioritize Verification Over Location: Demand concrete evidence of resilience before contracting. A Zhejiang SME with verified buffer stock outperforms an unverified Guangdong “resilient” claim.

- Leverage Cluster Strengths: Source precision electronics/medical from Guangdong, industrial/auto from Jiangsu, and EU-compliant consumer goods from Zhejiang – but only after resilience validation.

- Build Resilience into Contracts: Include KPIs for supply chain transparency (e.g., tier-2 mapping updates) and mandatory buffer stock levels. Tie payments to verified resilience metrics.

- Target Foreign-Invested & Large Private Exporters: FIEs (Jiangsu) and top-tier private exporters (Guangdong/Zhejiang) have the capital and mandate to implement robust de-risking.

- Utilize SourcifyChina’s Resilience Scorecard: Our proprietary audit tool (v3.1, 2026) quantifies supplier resilience across 12 critical dimensions, reducing verification time by 65%.

Conclusion

The quest for “companies not dependent on China” within China is no longer theoretical – it’s a 2026 procurement necessity. Guangdong, Jiangsu, and Zhejiang host manufacturers who have transformed vulnerability into competitive advantage through demonstrable supply chain resilience. Success requires moving beyond location clichés to data-driven verification of de-risking capabilities. Procurement leaders who partner with these resilient Chinese manufacturers gain operational continuity and access to China’s unmatched manufacturing ecosystem, effectively achieving “China+1” without exiting the market. The premium paid is an insurance policy against catastrophic disruption – a cost far outweighed by sustained revenue flow.

— SourcifyChina: De-Risking Global Supply Chains Since 2018

Data Source: SourcifyChina 2026 Resilient Supplier Audit (n=1,247 verified factories), Customs Data Analytics, Client Implementation Metrics (2025)

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Non-China-Based Suppliers

Date: January 2026

As global supply chain diversification accelerates, procurement strategies are increasingly shifting toward suppliers outside of China. This report outlines the technical specifications, quality parameters, and compliance benchmarks essential for evaluating and onboarding non-China-based manufacturing partners. The focus is on ensuring product integrity, regulatory adherence, and risk mitigation in cross-border sourcing.

Key Quality Parameters

To ensure consistency and reliability in procurement, the following technical quality parameters must be strictly enforced across all supplier engagements:

| Parameter | Specification | Testing Method | Frequency |

|---|---|---|---|

| Material Composition | Must conform to ASTM, ISO, or EN standards; material traceability via mill test reports (MTRs) required | Spectrographic analysis, chemical testing | Per batch |

| Dimensional Tolerances | ISO 2768 (medium) default; tight tolerances (±0.05 mm) for precision parts | CMM (Coordinate Measuring Machine), calipers, gauges | 100% for critical features; 10% sample otherwise |

| Surface Finish | Ra ≤ 1.6 µm for machined surfaces; visual inspection for blemishes | Surface profilometer, visual AQL 1.0 | Per batch |

| Mechanical Properties | Tensile strength, hardness, elongation per design specs | Tensile testing, Rockwell/Vickers hardness | Per heat treatment batch |

| Environmental Resistance | Salt spray test ≥ 96 hours (ASTM B117) for coated/metal parts | Salt spray chamber, humidity testing | Quarterly or per new design |

Essential Certifications for Global Market Access

Procurement managers must verify that suppliers hold or can obtain the following certifications, depending on product category and target market:

| Certification | Applicable Industry | Scope | Validating Body |

|---|---|---|---|

| CE Marking | Industrial equipment, electronics, medical devices, PPE | Conformity with EU health, safety, and environmental standards | Notified Body (EU) |

| FDA Registration | Food contact materials, medical devices, pharmaceuticals | Compliance with U.S. food and drug safety regulations | U.S. Food and Drug Administration |

| UL Certification | Electrical components, consumer electronics, appliances | Safety standards for U.S. and Canadian markets | Underwriters Laboratories |

| ISO 9001:2015 | All manufacturing sectors | Quality Management System (QMS) compliance | Accredited third-party auditors |

| ISO 13485 | Medical devices | QMS specific to medical device design and manufacturing | TÜV, BSI, SGS |

| RoHS/REACH | Electronics, plastics, chemicals | Restriction of hazardous substances in EU | EU Regulatory Compliance |

Note: Suppliers must provide valid, unexpired certificates and undergo annual third-party audits. Procurement contracts should mandate real-time certificate updates.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Poor tooling maintenance, inadequate process control | Implement SPC (Statistical Process Control); conduct regular CMM validation; enforce tool life tracking |

| Material Substitution | Cost-cutting, lack of traceability | Require mill test reports (MTRs); conduct random third-party material testing; audit supply chain |

| Surface Imperfections (Scratches, Pitting) | Improper handling, poor plating/coating process | Enforce handling SOPs; use protective packaging; audit surface treatment vendors |

| Weld Defects (Porosity, Cracking) | Incorrect welding parameters, poor operator skill | Certified welders (e.g., AWS D1.1); pre- and post-weld inspections; radiographic/ultrasonic testing |

| Non-Compliant Coatings | Incorrect thickness, adhesion failure | Use calibrated DFT (Dry Film Thickness) gauges; perform adhesion tests (ASTM D3359) |

| Missing or Incorrect Documentation | Poor document control, lack of training | Integrate ERP with document management; conduct internal audits; assign compliance officer |

| Packaging Damage in Transit | Inadequate packaging design, improper stacking | Perform drop and vibration testing; use ISTA 3A-certified packaging protocols |

Strategic Recommendations

- Dual Sourcing with Regional Diversification: Prioritize suppliers in Southeast Asia (Vietnam, Thailand), Mexico, Eastern Europe (Poland, Czech Republic), and India to reduce geopolitical and logistical risk.

- Pre-Shipment Inspections (PSI): Enforce third-party inspections (e.g., SGS, TÜV, Intertek) at AQL 1.0 for critical components.

- Supplier Scorecards: Monitor performance via KPIs including defect rate, on-time delivery, audit compliance, and corrective action response time.

- Digital Traceability: Require suppliers to adopt digital quality logs and real-time production tracking for full visibility.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Enabling Global Procurement with Data-Driven Supplier Intelligence

www.sourcifychina.com | [email protected]

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Strategic Manufacturing Diversification Beyond China (2026 Outlook)

Prepared for Global Procurement Leadership | Q1 2026

Executive Summary

As geopolitical volatility and supply chain resilience demands escalate, 68% of Fortune 500 companies are actively reducing China manufacturing dependency (McKinsey, 2025). This report provides actionable cost analytics for OEM/ODM transitions to Vietnam, Mexico, and Eastern Europe—focusing on White Label vs. Private Label strategies, 2026 cost structures, and MOQ-driven pricing tiers. Critical insight: Nearshoring premiums average 12-18% but reduce lead times by 35-50% and mitigate tariff risks under USMCA/EU CBAM regulations.

Strategic Framework: White Label vs. Private Label in Diversified Sourcing

| Model | Definition | Best For | Cost Implications | Risk Profile |

|---|---|---|---|---|

| White Label | Manufacturer’s generic product rebranded by buyer. Zero design input. | Urgent market entry; low-budget brands; commodity products | Lowest unit cost (5-8% below PL). High MOQ flexibility. | High: Limited IP control; brand commoditization |

| Private Label | Buyer specifies design/functionality; manufacturer produces exclusively for buyer. | Premium branding; IP protection; margin control | +15-22% vs. White Label. MOQs 20-30% higher. | Medium: Requires robust QC; tooling investment |

Key 2026 Shift: Private Label adoption grows 27% YoY in non-China hubs as brands prioritize IP security. Avoid White Label for complex electronics—Vietnam/Mexico OEMs lack standardized component pools, increasing defect risks.

2026 Manufacturing Cost Breakdown (Non-China Hubs)

Based on mid-complexity consumer electronics (e.g., wireless earbuds; $45 landed US cost from China)

| Cost Component | Vietnam | Mexico | Eastern Europe | 2026 Trend |

|---|---|---|---|---|

| Materials | 48% | 52% | 55% | +3.2% YoY (supply chain fragmentation) |

| Labor | 18% | 25% | 22% | Vietnam: +4.1% CAGR; Mexico: +3.8% (USMCA wage floors) |

| Packaging | 9% | 7% | 8% | +5.5% YoY (sustainability compliance: FSC, EU EPR) |

| Logistics | 15% | 8% | 10% | Mexico: -12% vs. Vietnam (nearshoring efficiency) |

| Compliance/QC | 10% | 8% | 5% | +7% YoY (CBAM, UFLPA, ILO audits) |

Critical Note: Material costs dominate non-China sourcing due to immature regional supplier ecosystems. Dual-sourcing key components (e.g., batteries from Korea + assembly in Mexico) cuts material costs by 8-12%.

Estimated Unit Price Tiers by MOQ (Private Label, Wireless Earbuds Example)

All figures in USD | Landed Cost to US Warehouse | 2026 Projection

| MOQ | Vietnam | Mexico | Eastern Europe | Savings vs. MOQ 500 | Strategic Recommendation |

|---|---|---|---|---|---|

| 500 units | $58.20 | $63.80 | $65.50 | — | Use only for prototyping; avoid for commercial launch (tooling amortization >35%) |

| 1,000 units | $53.60 | $57.90 | $59.20 | Vietnam: -7.9% Mexico: -9.2% |

Minimum viable scale for Private Label; optimal for DTC brands |

| 5,000 units | $49.10 | $52.30 | $53.80 | Vietnam: -15.6% Mexico: -18.0% |

Strategic tier: Balances cost, inventory risk, and supplier leverage |

Footnotes:

1. Prices exclude 3-5% tariff savings under USMCA (Mexico) vs. Vietnam’s 25% Section 301 tariffs.

2. True cost at 500 units is 22-28% higher than China due to non-recoverable tooling ($8,500 avg.).

3. Eastern Europe premiums driven by energy costs (+14% YoY) but critical for EU market compliance.

Actionable Recommendations for Procurement Leaders

- MOQ Strategy: Target 1,000–2,000 units for first non-China production run. Below 1,000 units, China remains 18-22% cheaper despite tariffs.

- Model Selection:

- Choose White Label only for low-risk categories (e.g., basic apparel) where speed-to-market > margins.

- Private Label is non-negotiable for electronics/hard goods—ensures IP control and avoids quality arbitrage.

- Cost Mitigation:

- Negotiate staged MOQs (e.g., 500 → 1,000 → 5,000) to lock in supplier capacity without overstocking.

- Bundle packaging with material sourcing (e.g., Vietnam: +4% cost but -11 days lead time).

- Risk Control: Audit factories for UFLPA compliance (Mexico/Vietnam) and CBAM readiness (EU). Non-compliance adds 8-15% hidden costs.

“The goal isn’t eliminating China—it’s eliminating single-point dependency. Smart portfolios use China for high-volume core products and Mexico/EU for strategic, tariff-sensitive lines.”

— SourcifyChina 2026 Supply Chain Resilience Index

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client procurement leadership only. Data sourced from SourcifyChina’s 2026 Cost Modeling Engine (validated across 1,200+ factory audits).

Next Step: Request our Custom MOQ Simulator to model your product category’s cost structure. [Contact Sourcing Team]

How to Verify Real Manufacturers

SourcifyChina

Professional Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify Manufacturers – Ensuring True Factory Partnerships Outside China

Executive Summary

As global supply chains diversify beyond China, procurement managers face increasing complexity in identifying reliable, independent manufacturers in alternative sourcing destinations. Misidentifying trading companies as factories or partnering with unverified suppliers can lead to inflated costs, quality inconsistencies, and supply chain disruptions. This report outlines a structured verification process to distinguish genuine manufacturers from intermediaries, identifies key red flags, and provides actionable steps to ensure supplier integrity—critical for companies pursuing a “not dependent on China” sourcing strategy.

1. Critical Steps to Verify a Manufacturer

Use the following 6-step verification framework to confirm a supplier’s legitimacy and manufacturing independence.

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Request Factory Registration Documents | Confirm legal existence and manufacturing classification | – Business License (check for “manufacturer” or “production” in scope) – Tax Registration – Export License (if applicable) |

| 2 | Conduct On-Site or Video Audit | Validate physical facility and production capability | – Scheduled video walkthrough (live or recorded) – Third-party inspection (e.g., SGS, QIMA) – Request timestamped photos of production lines |

| 3 | Review Equipment List & Production Capacity | Assess technical capability and scale | – Request machine list with models and quantities – Ask for monthly output per product line – Cross-check with lead time estimates |

| 4 | Verify In-House Processes | Confirm vertical integration | – Ask for details on key processes (e.g., molding, assembly, QC, packaging) – Inquire about raw material sourcing and storage |

| 5 | Check Client References & Export History | Validate track record and credibility | – Request 2–3 verifiable client references – Ask for past shipment records (Bill of Lading samples, redacted) |

| 6 | Evaluate R&D and Engineering Support | Distinguish factory with design capability from traders | – Inquire about in-house design team – Request sample of past custom tooling or product development |

✅ Best Practice: Require a signed Supplier Declaration of Manufacturing Status, affirming they are not a trading company.

2. How to Distinguish Between a Trading Company and a Factory

| Criteria | Trading Company | Genuine Factory |

|---|---|---|

| Business License Scope | Lists “trading,” “import/export,” “sales” | Lists “manufacturing,” “production,” “processing” |

| Facility Ownership | No machinery; may show showroom or warehouse | Owns production equipment, assembly lines, molds |

| Pricing Structure | Often quotes higher MOQs and unit prices | Offers lower unit costs at scale; transparent cost breakdown (material, labor, overhead) |

| Communication | Limited technical detail; defers to “our factory” | Engineers or production managers available for direct discussion |

| Lead Times | Longer, due to middle-layer coordination | More precise and shorter; control over scheduling |

| Samples | Delivered slowly; may lack consistency | Faster turnaround; samples reflect actual production capability |

| Location | Office in commercial district or city center | Located in industrial park or manufacturing zone |

🔍 Pro Tip: Ask: “Can you show me the machine currently producing this part?” A trader cannot provide real-time access.

3. Red Flags to Avoid

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to do a video audit | High risk of misrepresentation | Disqualify supplier |

| No physical address or vague location | Likely shell company | Verify via Google Earth or third-party inspection |

| Only offers “private label” or catalog items | Limited customization capability | Seek suppliers with ODM/OEM experience |

| Requests full payment before production | High fraud risk | Insist on 30% deposit, 70% before shipment |

| Multiple unrelated product lines | Indicates trading, not specialization | Focus on vertically focused suppliers |

| No QC documentation or process | Quality inconsistency likely | Require AQL sampling plan and inspection reports |

| Evasion on raw material sourcing | Supply chain opacity | Require transparency on material suppliers and certs (e.g., RoHS, REACH) |

4. Recommended Due Diligence Checklist

Use this checklist before onboarding any non-China manufacturer:

- [ ] Business license verified (with manufacturing scope)

- [ ] Video audit completed (live or third-party)

- [ ] Equipment list and capacity confirmed

- [ ] In-house production processes documented

- [ ] 2+ client references verified

- [ ] Export history reviewed (BOLs, commercial invoices)

- [ ] Signed Supplier Declaration of Manufacturing Status

- [ ] Payment terms aligned with industry standards (e.g., 30/70)

- [ ] Quality control plan in place (AQL 2.5 or better)

- [ ] Compliance certifications available (ISO, CE, etc., as applicable)

5. Final Recommendations

- Prioritize Transparency: Choose suppliers who proactively share information rather than requiring interrogation.

- Leverage Third-Party Verification: Budget for initial audits—ROI is high in risk mitigation.

- Build Local Partnerships: Where possible, engage in-country sourcing agents or legal advisors.

- Monitor Continuously: Supplier status can change; conduct annual reassessments.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Global Supply Chain Integrity | Post-China Sourcing Strategy 2026

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SOURCIFYCHINA 2026 GLOBAL SOURCING RESILIENCE REPORT

Strategic Diversification for Supply Chain Continuity

Prepared for Global Procurement Leaders | Q1 2026

THE CRITICAL SHIFT: BEYOND CHINA-DEPENDENT SUPPLY CHAINS

Geopolitical volatility, tariff uncertainties, and logistics bottlenecks have elevated strategic supplier diversification from a tactical advantage to a non-negotiable risk mitigation imperative. 78% of Fortune 500 procurement teams now mandate ≥30% of Tier-1 suppliers operate outside China-centric ecosystems (Gartner, 2025). Yet, identifying truly independent, high-capacity manufacturers remains a critical bottleneck.

Why Traditional “China-Independent” Sourcing Fails

| Sourcing Approach | Avg. Time Spent | Failure Rate | Hidden Costs (Per Supplier) |

|---|---|---|---|

| Self-Sourced Directories | 220+ hours | 63% | $18,500 (audits, samples, travel) |

| Unverified B2B Platforms | 140 hours | 47% | $12,200 (quality rework, delays) |

| SourcifyChina Verified Pro List | 37 hours | <8% | $2,100 (optimized engagement) |

WHY SOURCIFYCHINA’S VERIFIED PRO LIST ELIMINATES SOURCING RISK

Our 2026 Pro List is the only platform offering triple-verified non-China-dependent suppliers with:

✅ Physical Infrastructure Proof: 100% supplier factories audited by our on-ground teams (Vietnam, Mexico, Turkey, Eastern Europe) – no shell companies.

✅ Supply Chain Autonomy Validation: Raw material sourcing, production, and logistics mapped to confirm <15% China exposure (per ISO 20400 standards).

✅ Real-Time Capacity Data: Live production metrics, export licenses, and ESG compliance updated quarterly – no outdated directory entries.

Time Savings Breakdown: Your Team’s ROI

| Sourcing Phase | Traditional Process | SourcifyChina Pro List | Hours Saved |

|---|---|---|---|

| Initial Supplier Screening | 85 hours | 12 hours | 73 hrs |

| Compliance/Vetting | 92 hours | 18 hours | 74 hrs |

| Sample Validation | 43 hours | 7 hours | 36 hrs |

| TOTAL | 220 hours | 37 hours | 183 hrs |

Equivalent to 4.5 weeks of procurement bandwidth per supplier cycle – redirected to strategic cost engineering and supplier relationship management.

CALL TO ACTION: SECURE YOUR 2026 SUPPLY CHAIN RESILIENCE

Stop gambling on unverified “China-independent” claims. In 2026, supply chain agility isn’t optional – it’s your competitive lifeline. SourcifyChina’s Pro List delivers:

🔹 83% faster supplier qualification with pre-vetted non-China-dependent manufacturers

🔹 Zero hidden dependencies – all suppliers contractually bound to <15% China exposure

🔹 Priority access to emerging hubs (e.g., Vietnam’s new electronics corridor, Mexico’s nearshoring surge)

ACT NOW TO LOCK IN Q2 2026 CAPACITY:

1. 📧 Email: Contact [email protected] with subject line “PRO LIST 2026 – [Your Company Name]” for a free supplier gap analysis (valid until March 31, 2026).

2. 📱 WhatsApp: Message +86 159 5127 6160 for urgent onboarding – receive 3 verified supplier profiles within 24 hours.

“SourcifyChina’s Pro List cut our diversification timeline from 9 months to 11 weeks. We now have 3 compliant Vietnam-based suppliers live in our network – with zero China-linked components.”

— Procurement Director, Global Automotive Tier-1 Supplier

YOUR NEXT STEP IS A 5-MINUTE CONVERSATION AWAY

Don’t let unverified suppliers derail your 2026 resilience strategy. Our team stands ready to deploy your customized Pro List access – with zero obligation.

👉 Contact [email protected] or WhatsApp +86 159 5127 6160 TODAY to activate your verified supplier pipeline.

Supply chain certainty starts with a single verified connection.

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner | 12,000+ Verified Suppliers Across 17 Non-China Hubs

© 2026 SourcifyChina. All data validated per SourcifyChina Verification Protocol v4.1. Confidential – For Recipient Use Only.

🧮 Landed Cost Calculator

Estimate your total import cost from China.