The global CNC screws market has experienced steady growth, driven by rising demand from precision manufacturing, automotive, aerospace, and electronics industries. According to a report by Mordor Intelligence, the global fasteners market—of which CNC screws are a critical component—was valued at USD 118.5 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029. This expansion is fueled by increasing automation, tighter tolerances in production, and the need for high-precision components compatible with CNC machining processes. Additionally, Grand View Research highlights that advancements in materials and thread-forming technologies are further enhancing performance and reliability, spurring adoption across high-value sectors. As demand for consistent quality, scalability, and compliance with international standards intensifies, manufacturers specializing in CNC screws are at the forefront of innovation. Here, we spotlight the top 10 CNC screws manufacturers leading this growth through technological expertise, global reach, and robust quality certifications.

Top 10 Cnc Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

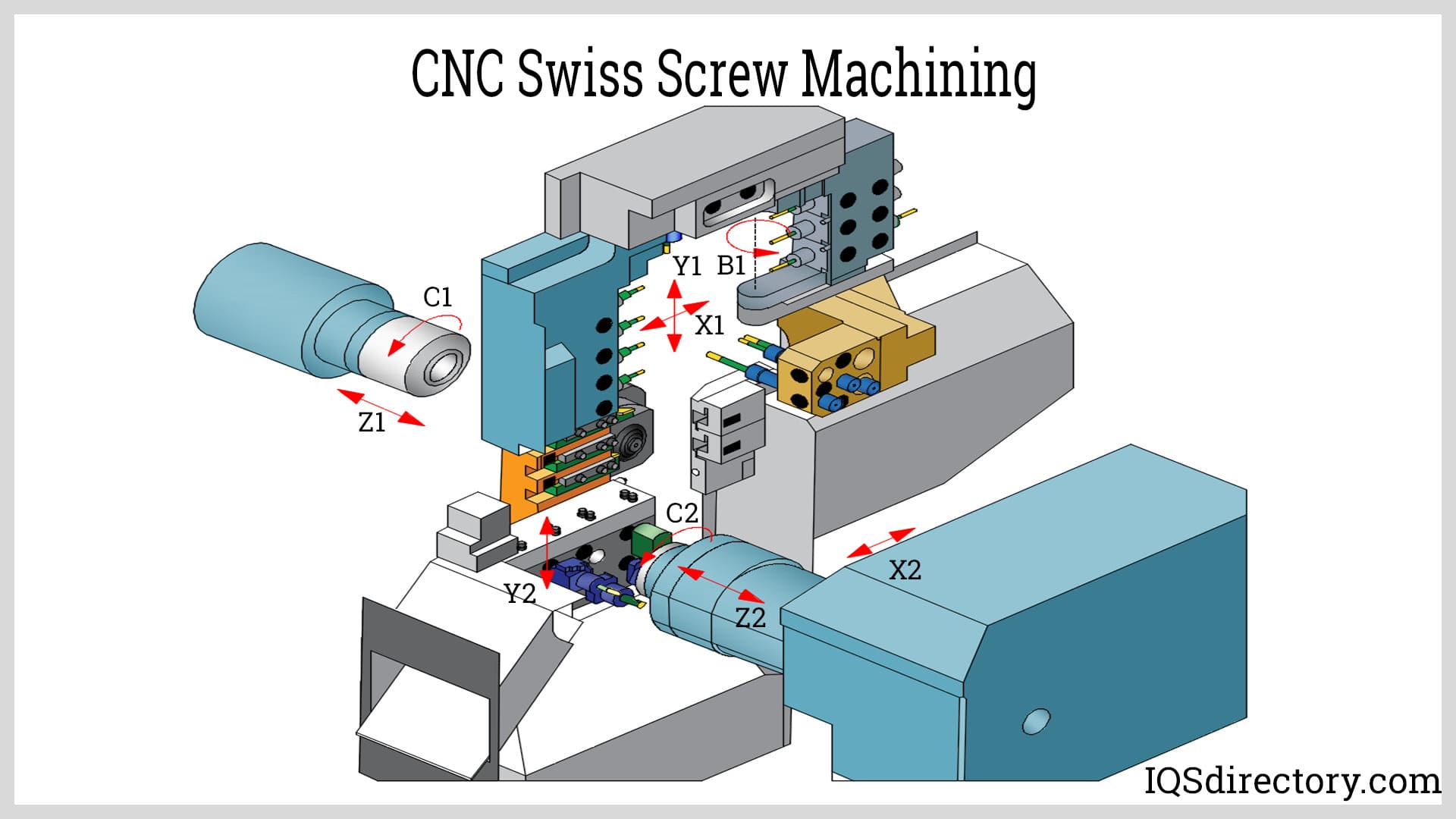

#1 CNC Swiss Screw Machining Products

Domain Est. 1997

Website: torin.com

Key Highlights: TORIN Products, Inc. is a contract manufacturer of high precision screw machine components and turned parts made from stainless steels, exotic metals, titanium ……

#2 Hogge Precision Parts Co., Inc.

Domain Est. 1998

Website: hoggeprecision.com

Key Highlights: An ISO 9001:2015 QMS registered contract manufacturer specializing in precision CNC turning, milling, and Swiss screw machining….

#3 OEM Speciality Nuts & Bolts Made in USA

Domain Est. 1995

Website: wyandotte.com

Key Highlights: Choose American-made nuts and bolts for unmatched strength and precision. Specialty fasteners and CNC parts built in the USA. Get a quote today!…

#4 Custom Fasteners Manufacturer

Domain Est. 1999

Website: nationalbolt.com

Key Highlights: National Bolt and Nut Corporation is a ISO Certified Nationwide custom fasteners manufacturer of nuts, washers, bolts and fasteners. Contact us today!…

#5 Screw Machine Products Manufacturers Suppliers

Website: screwmachinecompanies.com

Key Highlights: CNC screw machines are indispensable for manufacturing high-precision, repeatable parts in fields like medical device manufacturing, automotive assemblies ……

#6 PENCOM

Domain Est. 1996

Website: pencomsf.com

Key Highlights: PENCOM delivers tailored solutions designed to streamline operations and ensure exceptional quality. From advanced CNC machining to multi-axis production and ……

#7 Precision CNC Machining & Screw Machined Products

Domain Est. 1997

Website: nationaltechnologies.com

Key Highlights: With over 50 years experience and extensive capabilities in CNC and screw machining, National Technologies provides hundreds of processing solutions….

#8 Cox Manufacturing Company

Domain Est. 2003

Website: coxmanufacturing.com

Key Highlights: We excel in manufacturing high precision, high production custom CNC screw machined parts and products to meet ISO 9001:2015 certification standards….

#9 LV Swiss

Domain Est. 2009

Website: lvswiss.com

Key Highlights: LV Swiss offers Precision CNC Swiss Screw Machining, Milling, & Turning of Your Specialty Parts. Located just outside Zion National Park in Utah….

#10 Nomura DS

Domain Est. 2023

Website: nomura-ds.com

Key Highlights: Nomura DS has a range of CNC machines that excel under pressure. Easily produce more parts with reduced setup, increased tooling capacity, and longer tool life….

Expert Sourcing Insights for Cnc Screws

2026 Market Trends for CNC Screws

The CNC screws market is poised for significant evolution by 2026, driven by technological innovation, shifting manufacturing demands, and global economic currents. As precision engineering becomes increasingly critical across industries, the demand for high-performance, reliable fasteners continues to rise. Here are the key trends shaping the CNC screws landscape in 2026:

Rising Demand from High-Tech Manufacturing Sectors

Industries such as aerospace, medical devices, electric vehicles (EVs), and advanced robotics are placing greater emphasis on precision, durability, and miniaturization. CNC screws, known for tight tolerances and consistent quality, are essential in these applications. The expansion of EV production and the growing complexity of medical implants are particularly boosting demand for specialized screws made from advanced materials like titanium, stainless steel, and high-strength alloys.

Advancements in CNC Machining and Automation

The integration of AI-driven quality control, IoT-enabled monitoring, and lights-out manufacturing is enhancing CNC screw production efficiency. By 2026, smart factories are expected to dominate leading suppliers’ operations, reducing waste, improving traceability, and enabling real-time adjustments to meet exact specifications. This trend supports tighter tolerances and faster turnaround times, meeting the just-in-time (JIT) delivery expectations of OEMs.

Material Innovation and Sustainability Focus

There is a growing shift toward eco-friendly materials and sustainable manufacturing practices. Suppliers are investing in recyclable metals, reduced-energy machining processes, and corrosion-resistant coatings that extend product life. Additionally, regulatory pressures in Europe and North America are pushing companies to adopt RoHS and REACH-compliant finishes, influencing screw design and material selection.

Supply Chain Localization and Resilience

Geopolitical uncertainties and pandemic-driven disruptions have prompted manufacturers to reevaluate global supply chains. In 2026, regionalization of CNC screw production is accelerating, with increased investment in local manufacturing hubs in North America, Europe, and Southeast Asia. This trend enhances supply chain security and reduces lead times, particularly for critical industries like defense and healthcare.

Customization and Industry-Specific Solutions

Off-the-shelf screws are no longer sufficient for many high-performance applications. By 2026, demand for customized thread designs, non-standard head types, and application-specific coatings is surging. CNC machining allows for cost-effective small-batch production, enabling manufacturers to offer tailored solutions without sacrificing precision or scalability.

Digitalization and E-Commerce Integration

Digital platforms are transforming how CNC screws are specified, ordered, and tracked. Leading suppliers now offer online configurators, CAD model downloads, and inventory management tools, improving customer experience and streamlining procurement. Predictive analytics are also being used to forecast demand and optimize inventory, reducing downtime for end users.

In summary, the 2026 CNC screws market will be defined by precision, customization, sustainability, and digital integration. Companies that embrace innovation, invest in automation, and adapt to regional and regulatory shifts will be best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing CNC Screws: Quality and Intellectual Property Risks

Sourcing CNC screws—especially for high-precision or mission-critical applications—comes with hidden challenges that can compromise product integrity, performance, and legal compliance. Overlooking these pitfalls can lead to costly rework, supply chain disruptions, or even legal disputes. Below are key risks related to quality and intellectual property (IP) that procurement teams and engineers must be aware of.

Inconsistent Material and Dimensional Quality

One of the most frequent issues when sourcing CNC screws is variability in material composition and dimensional accuracy. Low-cost suppliers—particularly those in less regulated markets—may use substandard alloys or fail to adhere to specified tolerances. Screws that deviate even slightly from required dimensions can lead to assembly failures, reduced fatigue resistance, or thread stripping. Always verify that suppliers provide material certifications (e.g., mill test reports) and conduct incoming inspections using calibrated measurement tools.

Lack of Traceability and Certification

Many suppliers, especially non-reputable ones, fail to provide full traceability for raw materials and manufacturing processes. Without proper documentation such as ISO 9001 certification, RoHS compliance, or AS9100 for aerospace applications, it becomes difficult to ensure that screws meet industry standards. This lack of traceability increases risk during audits, recalls, or failure investigations.

Counterfeit or Non-Compliant Fasteners

The fastener market is plagued by counterfeit products that mimic branded or standardized screws but do not meet required performance specifications. These counterfeit CNC screws may look identical but fail under stress or in corrosive environments. Sourcing from unauthorized distributors or gray-market channels significantly increases this risk. Always source through authorized channels and validate part markings and packaging.

Misrepresentation of IP and Patent Infringement

CNC screws often incorporate proprietary designs, thread profiles, or locking mechanisms protected by patents (e.g., Torx, Triangular Head, or specific thread forms like UNJ). Sourcing generic versions that replicate patented features—even unintentionally—can expose your company to intellectual property infringement claims. Always conduct due diligence on the design origin and ensure suppliers warrant that their products do not violate existing IP rights.

Unauthorized Reverse Engineering

Some suppliers engage in reverse engineering of branded or proprietary screws without licensing. While the physical screw might perform adequately, using such components can lead to legal liability if the original IP owner takes action. This is especially critical in regulated industries like medical devices, aerospace, or automotive, where compliance extends beyond functionality to legal provenance.

Inadequate Testing and Validation Data

Suppliers may claim compliance with standards like ASTM, ISO, or DIN without providing actual test data. For critical applications, relying solely on supplier declarations is risky. Insist on receiving independent test reports for tensile strength, torque performance, salt spray resistance, and other relevant metrics. Without proper validation, screws may fail prematurely in the field.

Poor Surface Finish and Coating Quality

CNC screws often require precise surface treatments—such as passivation, plating, or coatings like PTFE or Dacromet—for corrosion resistance or torque control. Inadequate or inconsistent coating application can lead to hydrogen embrittlement, galling, or reduced service life. Verify coating thickness and adherence to specification through third-party testing when necessary.

Conclusion: Mitigation Strategies

To avoid these pitfalls, establish a robust sourcing strategy that includes supplier audits, rigorous qualification processes, and contractual IP indemnification clauses. Prioritize suppliers with a proven track record, full documentation, and transparency in manufacturing practices. Investing time upfront to vet CNC screw suppliers significantly reduces long-term risks to quality, compliance, and legal exposure.

Logistics & Compliance Guide for CNC Screws

Overview

CNC screws—precision-engineered fasteners produced using computer numerical control (CNC) machining—are essential components in industries ranging from automotive and aerospace to electronics and medical devices. Proper logistics and compliance management ensures these components meet technical specifications, arrive on time, and adhere to regulatory standards across global supply chains.

Material & Manufacturing Compliance

CNC screws must be manufactured in accordance with international standards such as ISO, ASTM, ASME, and DIN. Key compliance points include:

– Material Certification: Provide mill test certificates (e.g., EN 10204 3.1) verifying chemical composition and mechanical properties (e.g., tensile strength, hardness).

– RoHS & REACH Compliance: For screws used in electronics or consumer products, ensure restricted substances (e.g., lead, cadmium) are within allowable limits.

– Traceability: Each batch should be traceable to raw material source, heat number, and production date.

Packaging & Labeling Requirements

Proper packaging prevents damage during transit and ensures regulatory compliance:

– Anti-Corrosion Protection: Use VCI (Vapor Corrosion Inhibitor) papers or coated packaging for carbon steel or alloy screws to prevent rust.

– Tamper-Evident Sealing: Critical for aerospace or medical applications.

– Labeling Standards: Include part number, material grade, finish (e.g., zinc-plated, passivated), quantity, batch/lot number, and country of origin. Labels must be durable and legible.

– HS Code Classification: Accurately classify under Harmonized System codes (e.g., 7318.15 for threaded steel screws) for customs clearance.

Export & Import Regulations

International shipments require adherence to trade laws and documentation:

– Export Controls: Screws with high precision or special alloys may fall under dual-use regulations (e.g., EU Dual-Use Regulation, U.S. EAR). Verify if export licenses are needed.

– Customs Documentation: Provide commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. For preferential tariffs (e.g., USMCA, RCEP), include a valid Certificate of Origin.

– Sanctions Screening: Ensure end-users are not on restricted party lists (e.g., OFAC, EU sanctions).

Transportation & Handling

- Mode of Transport: Choose based on urgency and volume—air freight for time-sensitive orders, sea freight for large batches.

- Environmental Controls: Avoid exposure to moisture or extreme temperatures, especially for corrosion-sensitive finishes.

- Handling Procedures: Use ESD-safe packaging for electronic applications; secure loads to prevent movement during transit.

Industry-Specific Compliance

Different sectors have unique requirements:

– Aerospace (AS9100): Screws must meet AS9100 quality management standards, with full traceability and first-article inspection reports (FAIR).

– Medical Devices (ISO 13485): Require biocompatible materials (e.g., ASTM F138 stainless steel), cleanroom manufacturing, and sterilization validation.

– Automotive (IATF 16949): Demand PPAP (Production Part Approval Process) documentation and adherence to APQP protocols.

Quality Assurance & Testing

- Dimensional Inspection: Use coordinate measuring machines (CMM) or optical comparators to verify thread pitch, diameter, and length per GD&T specifications.

- Mechanical Testing: Conduct tensile, torque, and head hardness tests as per ISO 898-1 or ASTM A370.

- Surface Finish & Coating Verification: Perform salt spray testing (e.g., ISO 9227) for plated screws to ensure corrosion resistance.

Storage & Inventory Management

- Controlled Environment: Store in dry, temperature-stable warehouses to prevent oxidation or moisture damage.

- First-Expiry, First-Out (FEFO): Especially important for coated or chemically treated screws with shelf-life limits.

- Inventory Audits: Regular cycle counts ensure accuracy and regulatory readiness for audits.

Regulatory Updates & Audit Preparedness

- Monitor Changes: Stay informed on updates to trade policies, environmental regulations (e.g., SCIP database for SVHCs), and industry standards.

- Internal Audits: Conduct regular reviews of compliance documentation, supplier qualifications, and shipping records.

- Third-Party Certifications: Maintain up-to-date ISO 9001, ISO 14001, or industry-specific certifications to facilitate compliance.

Conclusion

Effective logistics and compliance for CNC screws require a proactive approach integrating quality control, regulatory knowledge, and supply chain coordination. By adhering to international standards, maintaining full traceability, and preparing accurate documentation, manufacturers and distributors can ensure reliable delivery and regulatory acceptance across global markets.

Conclusion for Sourcing CNC Screws

Sourcing CNC screws requires a strategic approach that balances quality, precision, cost, and reliability. Given the critical role these fasteners play in CNC machining and assembly processes, selecting the right supplier is essential to ensure dimensional accuracy, material integrity, and compliance with industry standards. Factors such as material type (e.g., stainless steel, aluminum, or alloy steel), thread specifications, coating requirements, and volume needs must be carefully evaluated.

Working with reputable suppliers who offer consistent quality control, certifications (such as ISO or AS9100), and technical support can significantly reduce the risk of component failure and production delays. Additionally, considering lead times, scalability, and logistical support helps maintain efficient operations, particularly for high-volume or time-sensitive projects.

In conclusion, successful sourcing of CNC screws involves thorough supplier vetting, clear communication of technical requirements, and a focus on long-term partnerships that support both performance and cost-efficiency in precision manufacturing environments.