The global CNC router market is experiencing robust growth, driven by increasing demand for precision machining in industries such as woodworking, aerospace, automotive, and signage. According to Grand View Research, the global CNC machine market size was valued at USD 74.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. This growth is fueled by the rising adoption of automation, advancements in computer-aided manufacturing (CAM) software, and the need for high-efficiency production systems. Within this expanding landscape, the 4×8-foot CNC router table segment has emerged as a cornerstone for medium to large-scale fabrication, offering optimal work envelope dimensions for sheet-based materials. As demand intensifies, manufacturers are focusing on enhancing accuracy, durability, and ease of integration. Based on production capacity, technological innovation, customer reviews, and global footprint, the following is a data-driven analysis of the top 10 manufacturers leading the 4×8 CNC router table market.

Top 10 Cnc Router Table 4X8 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CNC Routers

Domain Est. 2002

Website: shopsabre.com

Key Highlights: ShopSabre’s American-made CNC Routers feature cutting-edge technology and premium components, the kind typically only seen on much higher-priced machines….

#2 Stepcraft Inc.

Domain Est. 2014

Website: stepcraft.us

Key Highlights: Stepcraft is a global leader in the design and manufacturing of high-precision desktop, hobby and production CNC router systems and accessories. Stepcraft ……

#3 Langmuir Systems

Domain Est. 2017

Website: langmuirsystems.com

Key Highlights: Engineered to increase your manufacturing output, the CrossFire XR is a high performance industrial CNC Plasma table with 4×8′ cutting envelope, heavy-duty ……

#4 AXYZ CNC Routers

Domain Est. 1995

Website: axyz.com

Key Highlights: AXYZ delivers customizable CNC router systems for signage, woodworking, plating, plastics, metal fabrication and cladding. We help you automate better with ……

#5 4×8 cnc routers for sign making, wood, plastic, aluminum.

Domain Est. 2011

Website: veloxcnc.com

Key Highlights: VELOX CNC router cutting through .0625″ thick carbon fiber/fiber glass material. Using a custom size machine 74×14. This is similar to our 4×4 and 2×2 machines….

#6 Artisan 408

Domain Est. 2011

Website: industrialcnc.com

Key Highlights: This CNC Router has the capacity to process a full 4′ x 8′ sheet of material with an unmatched, industry leading 12” of standard gantry clearance….

#7 CNC Router Machine

Domain Est. 2015

Website: varisigns.com

Key Highlights: The best affordable CNC router machine, CNC router table for sale with different working table sizes for your needs, 4×4, 4×6, 4×8, 5×10 and more!…

#8 Avid CNC

Domain Est. 2016

Website: avidcnc.com

Key Highlights: Our AVID CNC makes quick work of wood and especially aluminum to help us build projects faster, 100% in-house….

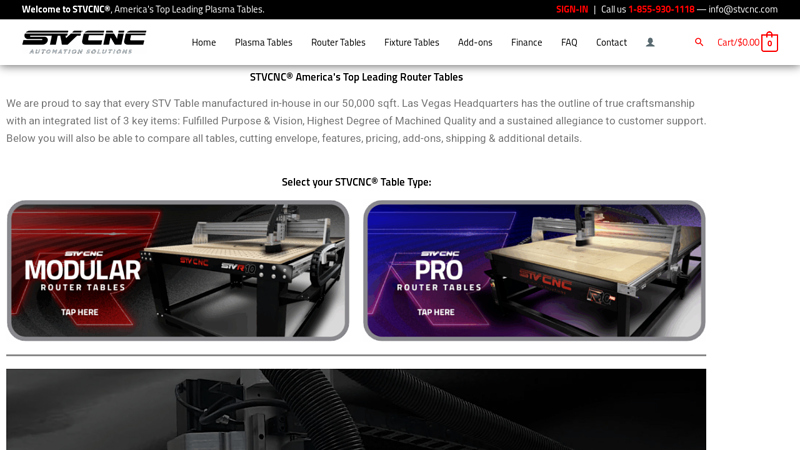

#9 STVCNC® America’s Top Leading Router Tables

Domain Est. 2018

Website: stvcnc.com

Key Highlights: Here at STV CNC, we provide some of the best CNC plasma cutting table machine. Click here to view all of our plasma cutter tables kit, ……

#10 CNC Router Table 4×8 with Single Italy HSD Spindle

Domain Est. 2019

Website: eagletec-cnc.com

Key Highlights: Rating 4.7 (45) CNC router table 4×8 is a general-purpose machine and good choice for newbie. Equipped with single Italy spindle, more durable than other machine….

Expert Sourcing Insights for Cnc Router Table 4X8

2026 Market Trends for 4×8 CNC Router Tables

The 4×8 CNC router table market is poised for significant evolution by 2026, driven by technological innovation, shifting industrial demands, and broader economic factors. Key trends shaping this landscape include increased automation, enhanced software integration, sustainability considerations, and expanding applications across diverse sectors.

1. Dominance of Automation and Industry 4.0 Integration

By 2026, 4×8 CNC routers will increasingly feature advanced automation capabilities. Expect widespread adoption of robotic material loading/unloading systems, automatic tool changers (ATCs), and integrated vacuum hold-down systems. These enhancements aim to minimize human intervention, boost productivity, and support lights-out manufacturing—particularly in high-volume operations like cabinetry and signage. Seamless connectivity with factory IoT networks will allow real-time monitoring, predictive maintenance, and centralized control, aligning with Industry 4.0 standards.

2. Advancements in Software and AI-Driven Optimization

Software integration will be a major differentiator. CAD/CAM platforms will become more intuitive, with AI-powered nesting algorithms maximizing material yield and reducing waste. Cloud-based solutions will gain traction, enabling remote machine monitoring, job scheduling, and collaborative design workflows. Generative design tools may allow users to create complex, optimized geometries tailored to CNC fabrication, expanding creative and engineering possibilities.

3. Expansion into New Industries and Applications

While woodworking remains dominant, 4×8 CNC routers will see growing use in emerging sectors. The composites and aerospace industries will adopt high-precision routers for trimming and milling lightweight materials. Modular construction and prefabricated housing will drive demand for large-format machines capable of processing structural panels. Additionally, the rise of personalized manufacturing and on-demand production will fuel adoption by small-to-midsize enterprises (SMEs) and makerspaces.

4. Sustainability and Energy Efficiency Focus

Environmental concerns will influence machine design and operation. Manufacturers will prioritize energy-efficient spindles, dust collection systems with improved filtration (including HEPA standards), and recyclable material compatibility. Demand for routers capable of working with sustainable substrates—such as mass timber, recycled plastics, and bio-composites—will grow, reflecting broader green manufacturing trends.

5. Price Differentiation and Market Segmentation

The market will further segment into entry-level, mid-range, and industrial-grade systems. While budget-friendly Chinese imports will continue to capture the hobbyist and small workshop segment, North American and European manufacturers will focus on high-reliability, service-supported machines for industrial users. Hybrid models combining affordability with industrial features—such as reinforced gantries and upgraded spindles—will bridge the gap, appealing to growing fabrication businesses.

6. Supply Chain Resilience and Localization

Ongoing global supply chain volatility will push manufacturers toward regional production and inventory strategies. By 2026, expect more localized assembly of CNC components and increased use of domestic sourcing to reduce lead times and mitigate disruptions. This shift may accelerate nearshoring in North America and Europe, especially for mission-critical industrial applications.

In conclusion, the 4×8 CNC router market in 2026 will be defined by smarter, more connected, and adaptable machines serving a broadening user base. Success will depend on balancing cutting-edge technology with operational efficiency, sustainability, and accessible support ecosystems.

Common Pitfalls When Sourcing a CNC Router Table 4×8 (Quality, IP)

Sourcing a 4×8 CNC router table can be a significant investment for fabrication shops, woodworking businesses, or prototyping labs. While the large work envelope offers versatility, several pitfalls related to quality and intellectual property (IP) can compromise long-term value and operational safety. Below are key issues to avoid.

Underestimating Build Quality and Material Specifications

Many suppliers offer 4×8 CNC router tables at attractive prices, but cut corners on structural integrity. Common red flags include thin-walled steel frames, inadequate gantry rigidity, or substandard linear rails. Poor build quality leads to vibration, reduced accuracy, and premature wear. Always verify frame material thickness, type of linear motion systems (e.g., linear guides vs. round rails), and spindle mounting stability.

Overlooking Spindle and Drive System Compatibility

A high-quality frame is only part of the equation. Low-cost routers may use underpowered spindles or stepper motors instead of servo systems, limiting cutting performance on dense materials. Ensure spindle power (typically 3–10 HP for industrial use), cooling method (air vs. water-cooled), and motor type match your production needs. Incompatible components reduce precision and increase downtime.

Ignoring IP and Software Licensing Risks

Some budget CNC machines come with embedded control systems using pirated or unlicensed software (e.g., fake licenses for Mach4, ArtSoft, or proprietary motion controllers). This poses legal risks and may prevent future upgrades or support. Verify that the control system (e.g., DSP, Syil, or Siemens) is licensed and supported. Open-source alternatives like LinuxCNC avoid IP issues but require technical expertise.

Falling for Misleading Accuracy Claims

Manufacturers may advertise “high precision” without disclosing test conditions. Look for documented repeatability and positioning accuracy (e.g., ±0.005″ or better). Machines without proper calibration certificates or backlash compensation may not maintain tolerances over time, especially on larger 4×8 platforms where deflection is more pronounced.

Skipping After-Sales Support and Technical Documentation

Many overseas suppliers offer low prices but lack reliable technical support, spare parts availability, or detailed assembly/maintenance manuals. Ensure access to English-speaking support, firmware updates, and documented maintenance procedures. Poor documentation can lead to extended downtime and increased risk of improper repairs.

Neglecting Safety and CE/UL Compliance

Non-compliant machines may lack emergency stops, proper grounding, or guarding—posing safety hazards. Verify if the machine meets regional safety standards (e.g., CE in Europe, UL in North America). Non-compliant systems may also be blocked at customs or uninsurable, adding hidden costs.

Assuming All 4×8 Tables Are Interchangeable

Not all 4×8 CNC routers are designed for the same applications. Some are optimized for soft materials like foam or MDF, while others handle aluminum or hardwoods. Confirm the machine’s dynamic load capacity, Z-axis travel, and dust collection integration. Using a light-duty router for heavy industrial work leads to rapid degradation.

By addressing these pitfalls early, buyers can avoid costly mistakes and ensure a CNC router that delivers long-term performance, precision, and IP compliance.

Logistics & Compliance Guide for CNC Router Table 4×8

Product Overview

The 4×8 CNC Router Table is a large-format computer numerical control (CNC) machine designed for precision cutting, carving, and milling of materials such as wood, plastics, aluminum, and composites. Due to its size, weight, and technical specifications, special attention must be paid to logistics, import/export compliance, safety standards, and regulatory requirements.

Shipping and Transportation

- Dimensions & Weight: Typical 4×8 CNC router tables measure approximately 10′ x 12′ x 6′ (LxWxH) and weigh between 2,500–5,000 lbs depending on configuration. Confirm exact specs with manufacturer.

- Packaging: Units are typically crated on wooden pallets with protective foam and corner braces. Ensure all moving parts (spindle, gantry) are secured or removed for transit.

- Freight Type: Requires full truckload (FTL) or flatbed freight due to size. Less-than-truckload (LTL) may be used if disassembled, but increases reassembly risk.

- Delivery Access: Verify site access—door clearances, floor load capacity (especially for second-floor installations), and availability of forklifts or crane for unloading.

- Insurance: Ship with all-risk freight insurance covering damage, loss, or delay. Retain photos and condition reports before and after transit.

Import/Export Compliance

- HS Code: Typically classified under 8461.50.00 (Machines for working metal by removal of material, numerically controlled). Confirm with customs broker.

- Country-Specific Regulations:

- USA: Complies with FCC Part 15 for electromagnetic interference; may require NRTL certification (e.g., UL, ETL) under OSHA.

- EU: Must carry CE Marking per Machinery Directive (2006/42/EC), EMC Directive (2014/30/EU), and RoHS compliance.

- UK: Requires UKCA marking post-Brexit for machines placed on the market in Great Britain.

- Canada: Must meet CSA C22.2 No. 61010-1 safety standard; may require ICES-003 EMC compliance.

- Documentation: Prepare commercial invoice, packing list, bill of lading, certificate of origin, and manufacturer’s declaration of conformity (DoC).

- Duties & Taxes: Research applicable tariffs, VAT, or GST based on destination country and trade agreements (e.g., USMCA, RCEP).

Safety and Regulatory Standards

- Electrical Compliance: Voltage (110V, 220V, or 480V), phase (single or three-phase), and frequency (50/60 Hz) must match local utility standards. Include step-down transformers if needed.

- Machine Safety: Must include:

- Emergency stop buttons (E-stop)

- Protective guarding for moving parts

- Proper grounding and overload protection

- Dust extraction interface (compliance with OSHA/NIOSH or EU EN 60204-1)

- Laser/Spindle Certification: If equipped with a laser or high-power spindle, additional safety certifications may apply (e.g., FDA compliance in U.S. for Class I lasers).

Installation and Site Requirements

- Foundation: Requires a level, vibration-resistant concrete floor. Isolation mounts recommended for high-precision applications.

- Power Supply: Dedicated circuit with proper amperage (typically 30–100A depending on spindle size). Include surge protection.

- Ventilation & Dust Control: Integration with industrial dust collection system (≥500 CFM recommended). Complies with OSHA PELs or EU Directive 2004/37/EC for airborne particulates.

- Software Licensing: Verify CNC control software (e.g., Mach4, UCCNC) is legally licensed and compatible with local languages and regulations.

Maintenance and Operational Compliance

- Training: Operators must be trained per manufacturer guidelines and local occupational safety laws (e.g., OSHA 29 CFR 1910.212 in U.S.).

- Routine Inspections: Maintain logs for mechanical integrity, electrical safety, and emergency systems.

- Waste Disposal: Metal/plastic dust and coolant waste must be handled according to local environmental regulations (e.g., EPA, REACH).

Warranty and Support

- Confirm warranty terms (typically 12 months), coverage scope, and availability of local technical support or authorized service centers.

- Retain all compliance documentation (DoC, test reports, manuals) for audit or insurance purposes.

Conclusion

Proper logistics planning and compliance with international and local regulations are essential for the successful import, installation, and operation of a 4×8 CNC Router Table. Engage certified freight forwarders, customs brokers, and safety consultants early in the process to mitigate risks and ensure regulatory adherence.

Conclusion: Sourcing a 4×8 CNC Router Table

After thorough research and evaluation, sourcing a 4×8 CNC router table requires careful consideration of several key factors including build quality, spindle power, control systems, software compatibility, after-sales support, and budget. A 4×8 (4 feet by 8 feet) work envelope is ideal for large-scale fabrication in woodworking, signage, cabinetry, and prototyping, making machine rigidity and accuracy paramount.

Among the options available, it is evident that while budget-friendly models from overseas manufacturers offer cost advantages, they often come with trade-offs in customer support, delivery times, and ease of assembly. On the other hand, domestically produced or well-established brand CNC machines typically provide better technical support, faster service, and higher precision out of the box—critical for minimizing downtime and ensuring long-term reliability.

Ultimately, the decision should balance initial investment with total cost of ownership. Investing in a reputable brand with robust construction, reliable components (such as linear rails, quality drivers, and a high-torque spindle), and strong customer support will yield better performance, longevity, and return on investment. Additionally, ensuring compatibility with existing design software (e.g., VCarve, Fusion 360) and evaluating available training or installation services can significantly enhance operational efficiency.

In conclusion, while multiple sourcing options exist for a 4×8 CNC router, prioritizing quality, support, and scalability will lead to a more productive and sustainable manufacturing capability. Conducting due diligence through reviews, supplier references, and if possible, live demonstrations, is highly recommended before finalizing the purchase.