The global CNC laser cutting machine market is experiencing robust expansion, driven by rising demand for precision manufacturing across industries such as automotive, aerospace, and electronics. According to Grand View Research, the market size was valued at USD 4.87 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. This growth is fueled by increasing automation, advancements in laser technology, and the need for high-speed, accurate cutting solutions. As manufacturers seek enhanced efficiency and repeatability, CNC laser tables have become critical components in modern fabrication workflows. Against this backdrop, several leading manufacturers have emerged, combining innovation, durability, and intelligent design to meet evolving industry demands. The following list highlights the top nine CNC laser table manufacturers poised to shape the future of precision manufacturing.

Top 9 Cnc Laser Table Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mazak Leading Laser Machine Manufacturer

Domain Est. 1998

Website: mazak.com

Key Highlights: Mazak provides products and solutions that can support a wide range of parts machining processes, such as high-speed and high-accuracy machines….

#2 Large Format Laser Cutting Systems and Laser Engravers

Domain Est. 1998

Website: kernlasers.com

Key Highlights: USA manufacturer of large format laser cutting systems and laser engraver equipment. Specializing in metal and acrylic cutting machines….

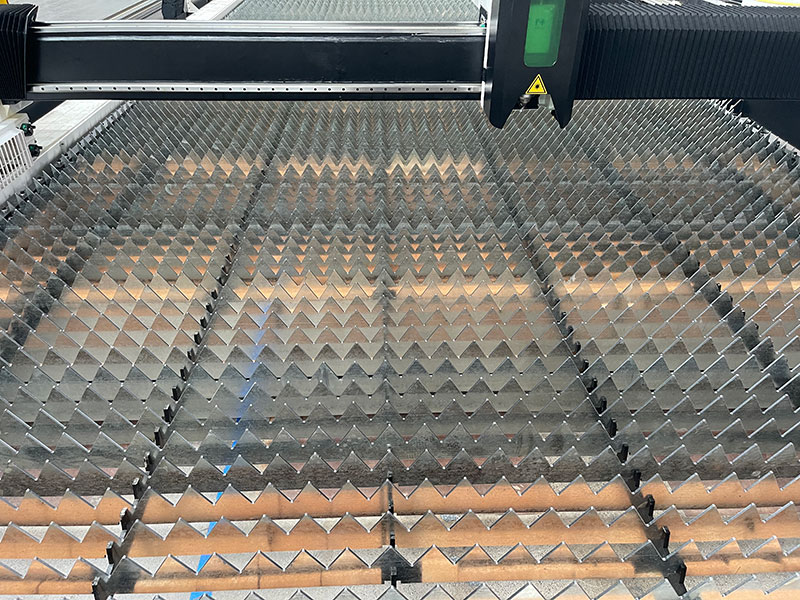

#3 CNC Laser

Domain Est. 2002

Website: shopsabre.com

Key Highlights: The ShopSabre FiberSabre is an American-made CNC laser system that combines cutting-edge technology and premium components….

#4 ISx000

Domain Est. 2007

Website: gravotech.us

Key Highlights: ISx000 is a modular, industrial-grade CNC cutting and engraving machine that combines versatile applications with high-performance productivity….

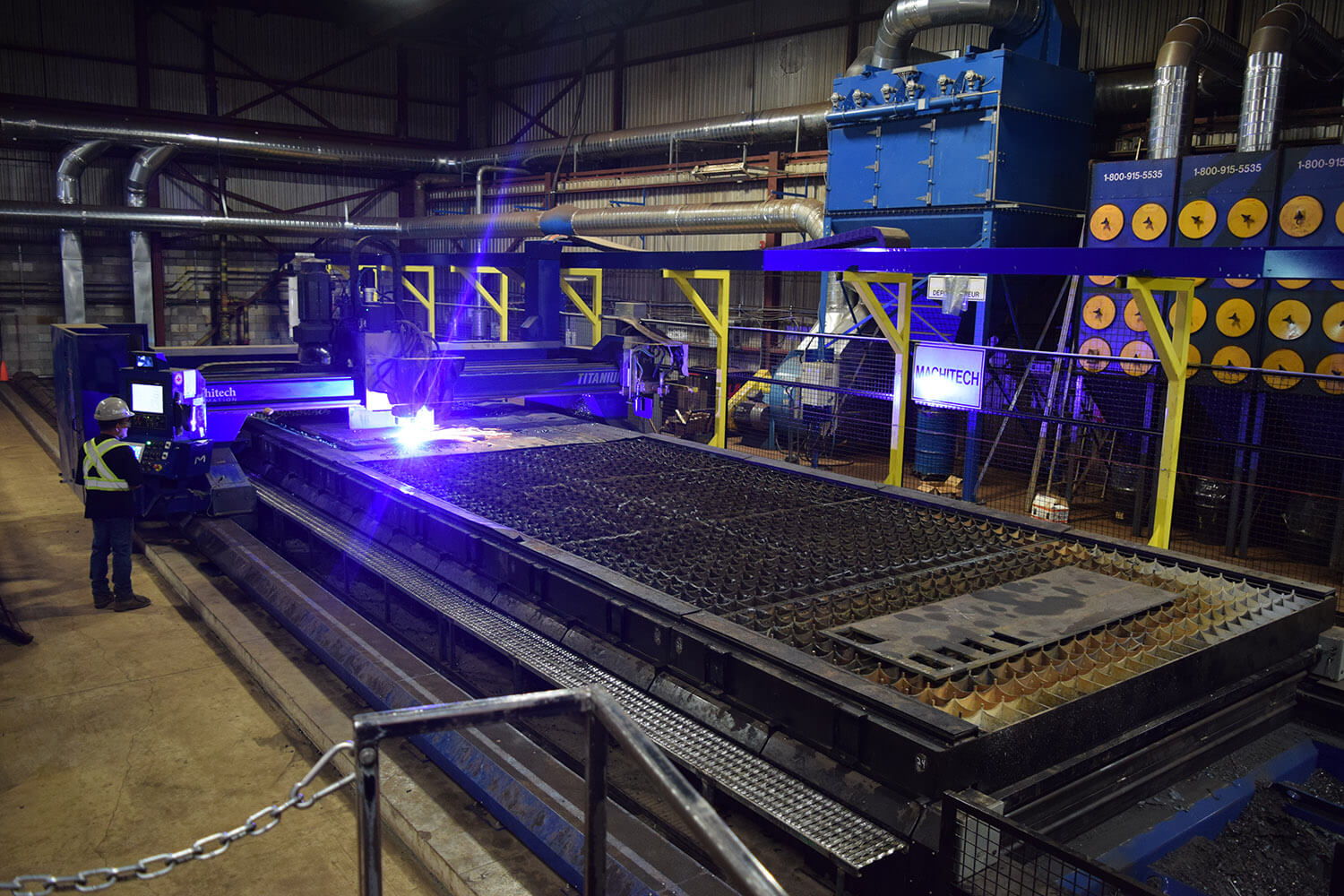

#5 Machitech

Domain Est. 2014

Website: machitech.com

Key Highlights: Leading Manufacturer of custom CNC Plasma Tables. For over 15 years, we have offered fully customizable CNC Plasma Cutting Systems of the highest quality….

#6 Wattsan

Domain Est. 2016

Website: wattsan.com

Key Highlights: Wattsan is a manufacturer of laser and cnc milling machines of European quality at affordable prices with worldwide delivery….

#7 Langmuir Systems

Domain Est. 2017

Website: langmuirsystems.com

Key Highlights: Powerful, affordable, and well-supported CNC Machines for hobbyists, small business owners, educational institutions, and industrial facilities….

#8 CNC Fiber LASER Metal Cutting Machines

Domain Est. 1999

Website: piranhafab.com

Key Highlights: CNC Fiber LASER Metal Cutting Machines. starting at $132,900. Piranha Whitney CNC Fiber Lasers deliver unmatched cut quality and reliability — backed by U.S. ……

#9 CNC Sheet metal laser cutting machines

Domain Est. 2000

Website: blmgroup.com

Key Highlights: Sheet metal laser cutting machines by BLM GROUP up to 20 kW. All systems are fully automatic and configurable….

Expert Sourcing Insights for Cnc Laser Table

H2: Projected 2026 Market Trends for CNC Laser Cutting Tables

The global market for CNC laser cutting tables is poised for significant transformation by 2026, driven by technological innovation, rising industrial automation, and expanding applications across key sectors. Below is an analysis of the anticipated trends shaping the CNC laser table market in 2026.

-

Increased Adoption of Fiber Laser Technology

By 2026, fiber lasers are expected to dominate the CNC laser cutting table market due to their superior efficiency, faster cutting speeds, and lower maintenance requirements compared to traditional CO2 lasers. Advancements in high-power fiber lasers (10kW and above) will enable faster processing of thick metals, making them ideal for heavy industries such as automotive and aerospace. -

Integration with Industry 4.0 and Smart Manufacturing

CNC laser tables will increasingly feature IoT connectivity, real-time monitoring, predictive maintenance, and AI-driven optimization. By 2026, smart manufacturing integration will allow seamless data exchange between CNC systems, CAD/CAM software, and enterprise resource planning (ERP) platforms, enhancing productivity and reducing downtime. -

Growth in Automation and Robotic Integration

Automated material handling systems, robotic loading/unloading, and pallet changers will become standard in high-end CNC laser tables. This trend is driven by the need for 24/7 operation, labor cost reduction, and improved precision—especially in high-volume production environments. -

Expansion in Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, will see robust demand for CNC laser tables due to rapid industrialization, government support for manufacturing (e.g., “Make in India,” “Made in China 2025”), and growing SME adoption of advanced fabrication tools. -

Sustainability and Energy Efficiency

Environmental regulations and rising energy costs will push manufacturers to develop energy-efficient CNC laser systems. Expect increased focus on recyclable components, reduced power consumption, and closed-loop cooling systems to meet green manufacturing standards. -

Customization and Modular Design

OEMs will offer more modular and scalable CNC laser table solutions to meet diverse customer needs. Customizable work envelopes, interchangeable cutting heads, and software adaptability will allow businesses to tailor systems for specific materials and production volumes. -

Rising Demand in Renewable Energy and Electric Vehicles (EVs)

The EV and renewable energy sectors will drive demand for precision metal fabrication. CNC laser tables will be essential in producing battery components, motor parts, and structural elements for solar and wind installations. -

Competitive Pricing and Market Consolidation

Increased competition, especially from Chinese manufacturers, will lead to price reductions and broader market access. At the same time, consolidation among key players may result in strategic partnerships and acquisitions to enhance technology portfolios.

In conclusion, the 2026 CNC laser table market will be characterized by smarter, faster, and more sustainable systems, with strong growth fueled by digitalization, automation, and expanding industrial applications. Companies that invest in innovation and adapt to regional market dynamics will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing CNC Laser Tables (Quality & Intellectual Property)

Sourcing a CNC laser table, especially from international or lesser-known suppliers, can present significant challenges related to quality assurance and intellectual property (IP) risks. Avoiding these pitfalls is crucial to ensure reliable performance, long-term value, and legal compliance.

Poor Build Quality and Component Selection

Many low-cost CNC laser tables suffer from substandard construction, including inadequate frame rigidity, poor linear guide systems, and underpowered or unreliable laser sources. This leads to reduced accuracy, frequent downtime, and higher total cost of ownership due to maintenance and part replacements.

Misrepresentation of Laser Power and Specifications

Suppliers may exaggerate laser power (e.g., advertising a “1000W” laser when the actual optical output is significantly lower) or quote peak power instead of continuous output. This misleading information results in underperforming machines that cannot handle intended materials or production speeds.

Lack of Quality Control and Testing

Some manufacturers skip rigorous factory acceptance testing (FAT), delivering machines without proper calibration or performance validation. Buyers may receive units with alignment issues, software bugs, or safety hazards that only become apparent after installation.

Inadequate or Non-Compliant Safety Features

Lower-tier machines often lack essential safety certifications (e.g., CE, FDA, or IEC standards) and critical safety components such as interlocks, emergency stops, and proper fume extraction integration. This poses operational risks and can lead to regulatory non-compliance.

Software Limitations and Proprietary Lock-In

Many sourced machines use closed-source or poorly documented control software with limited functionality, difficult user interfaces, or lack compatibility with common design tools (e.g., CAD/CAM). This reduces flexibility and can create dependency on the supplier for updates or troubleshooting.

Intellectual Property Infringement Risks

Purchasing a machine that incorporates cloned or reverse-engineered components (e.g., copied control systems, pirated software, or patented mechanical designs) exposes the buyer to legal liability. Companies may unknowingly become complicit in IP violations, risking fines or import bans.

Weak After-Sales Support and Spare Parts Availability

Suppliers in certain regions may offer limited technical support, delayed response times, or difficulty sourcing genuine spare parts. This leads to extended machine downtime and operational disruptions, undermining productivity.

Ambiguous Warranty Terms and Limited Accountability

Warranty coverage may be vague, geographically restricted, or exclude critical components. Some suppliers disclaim responsibility after the initial period, leaving buyers with high repair costs and little recourse for defects.

Hidden Costs and Lack of Transparency

Initial quotes may omit shipping, import duties, installation, training, or required ancillary equipment (e.g., chillers, air compressors). These hidden expenses can significantly increase the total investment and affect ROI calculations.

Failure to Verify Supplier Authenticity

Buyers may engage with trading companies posing as manufacturers or fall victim to counterfeit brands. This increases the risk of receiving inferior products and complicates accountability when issues arise.

To mitigate these risks, conduct thorough due diligence: request references, perform factory audits, verify certifications, test sample parts, and consult legal experts regarding IP and compliance—especially when sourcing from high-risk regions.

Logistics & Compliance Guide for CNC Laser Table

Overview

This guide outlines key logistics considerations and compliance requirements for the transportation, import/export, installation, and operation of a CNC Laser Table. Adhering to these guidelines ensures legal, safe, and efficient handling throughout the equipment lifecycle.

International Shipping & Logistics

Packaging & Handling

CNC laser tables must be securely crated with shock-absorbing materials to protect sensitive components (e.g., laser head, linear guides, control panel). Use moisture barriers and desiccants for ocean freight. Clearly label crates with handling instructions (e.g., “Fragile,” “This Side Up,” “Do Not Stack”).

Transportation Mode Selection

Choose transportation based on distance, urgency, and cost:

– Air Freight: Recommended for urgent deliveries; faster but more expensive.

– Sea Freight: Cost-effective for large/heavy tables; use FCL (Full Container Load) for better protection.

– Ground Transport: Suitable for regional delivery; ensure flatbed or enclosed trailers with liftgate service.

Customs Documentation

Prepare accurate documentation to avoid delays:

– Commercial Invoice

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin

– Technical Specifications Sheet

Ensure Harmonized System (HS) code classification (typically 8456.20 for laser cutting machines) is correct for duty calculation.

Import/Export Compliance

Export Controls

CNC laser tables may be subject to export regulations due to laser power and precision capabilities:

– ITAR (International Traffic in Arms Regulations): Generally not applicable unless military-grade.

– EAR (Export Administration Regulations): Most commercial CNC lasers fall under ECCN 2B999 or 3B992 (check based on laser wavelength, power, and control software).

– Obtain necessary export licenses for restricted destinations (e.g., sanctioned countries).

Import Duties & Taxes

Research destination country regulations:

– Confirm applicable import tariffs based on HS code.

– Include VAT, GST, or other local taxes in cost calculations.

– Use Incoterms (e.g., DAP, DDP, EXW) to clarify responsibility for duties and taxes.

Regulatory & Safety Compliance

Laser Safety Standards

Ensure the CNC laser table meets international safety standards:

– IEC 60825-1: Safety of laser products (classification, labeling, emission limits).

– ANSI Z136.1: U.S. standard for safe laser use.

– Equipment must have interlocks, emergency stops, beam enclosures, and proper warning labels.

Electrical & EMC Compliance

Verify compliance with regional electrical and electromagnetic standards:

– CE Marking (EU): Required; includes EMC Directive (2014/30/EU), Machinery Directive (2006/42/EC), and LVD (2014/35/EU).

– UL/CSA (North America): UL 61010-1 for electrical safety.

– KC Mark (South Korea), PSE (Japan): Local certification may be required.

Installation & Operational Compliance

Site Preparation

Ensure the installation site meets requirements:

– Stable, level concrete floor with adequate load-bearing capacity.

– Proper power supply (voltage, phase, grounding) per manufacturer specs.

– Adequate ventilation or fume extraction system for laser emissions.

– Fire suppression system nearby (especially for high-power lasers).

Training & Documentation

Provide operators with:

– Manufacturer’s operation and maintenance manuals.

– Laser safety training (including PPE usage).

– Local regulatory compliance documentation (e.g., risk assessments, safety policies).

Environmental & Disposal Considerations

Waste Management

Laser cutting produces fumes, particulates, and waste materials (e.g., metal slag, filters):

– Use certified fume extractors with HEPA and carbon filtration.

– Dispose of contaminated filters and waste per local environmental regulations (e.g., EPA, REACH).

End-of-Life Disposal

Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU or equivalent local laws:

– Recycle metals, electronics, and hazardous components responsibly.

– Partner with certified e-waste recyclers.

Recommended Actions

- Verify compliance with destination country regulations before shipping.

- Obtain necessary certifications (CE, UL, etc.) based on market.

- Engage a customs broker for complex international shipments.

- Conduct a site audit prior to installation.

- Maintain compliance records for audits and inspections.

Adhering to this guide ensures safe, legal, and efficient deployment of your CNC Laser Table across global operations.

Conclusion for Sourcing a CNC Laser Cutting Table

Sourcing a CNC laser cutting table is a strategic investment that can significantly enhance manufacturing capabilities, improve production precision, and increase operational efficiency. After evaluating various suppliers, machine specifications, cutting capacities, laser power options, software integration, and after-sales support, it is clear that selecting the right CNC laser table requires a balanced approach that considers both upfront costs and long-term value.

Key factors such as cutting accuracy, material compatibility, automation features, maintenance requirements, and technical support play a crucial role in ensuring optimal performance and return on investment. It is recommended to partner with reputable suppliers who offer reliable technology, comprehensive training, and responsive service support.

Ultimately, the chosen CNC laser table should align with current production needs while allowing scalability for future growth. By carefully assessing options and prioritizing quality, durability, and support, the organization can secure a solution that enhances competitiveness, reduces downtime, and supports long-term manufacturing excellence.