Sourcing Guide Contents

Industrial Clusters: Where to Source Cnc China Company

SourcifyChina B2B Sourcing Intelligence Report: CNC Machining Services in China

Prepared for Global Procurement Leaders | Q1 2026 Market Outlook

Executive Summary

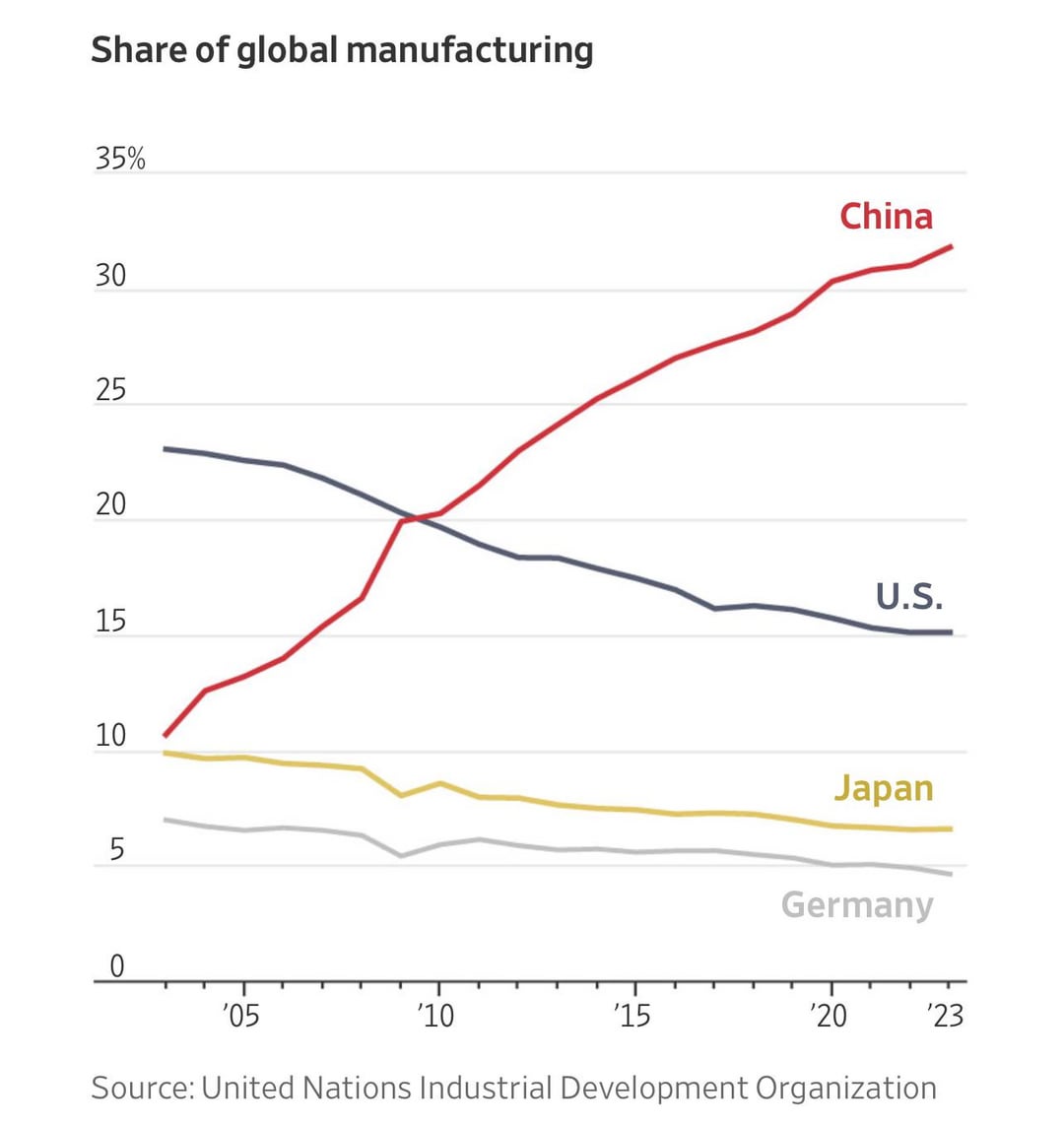

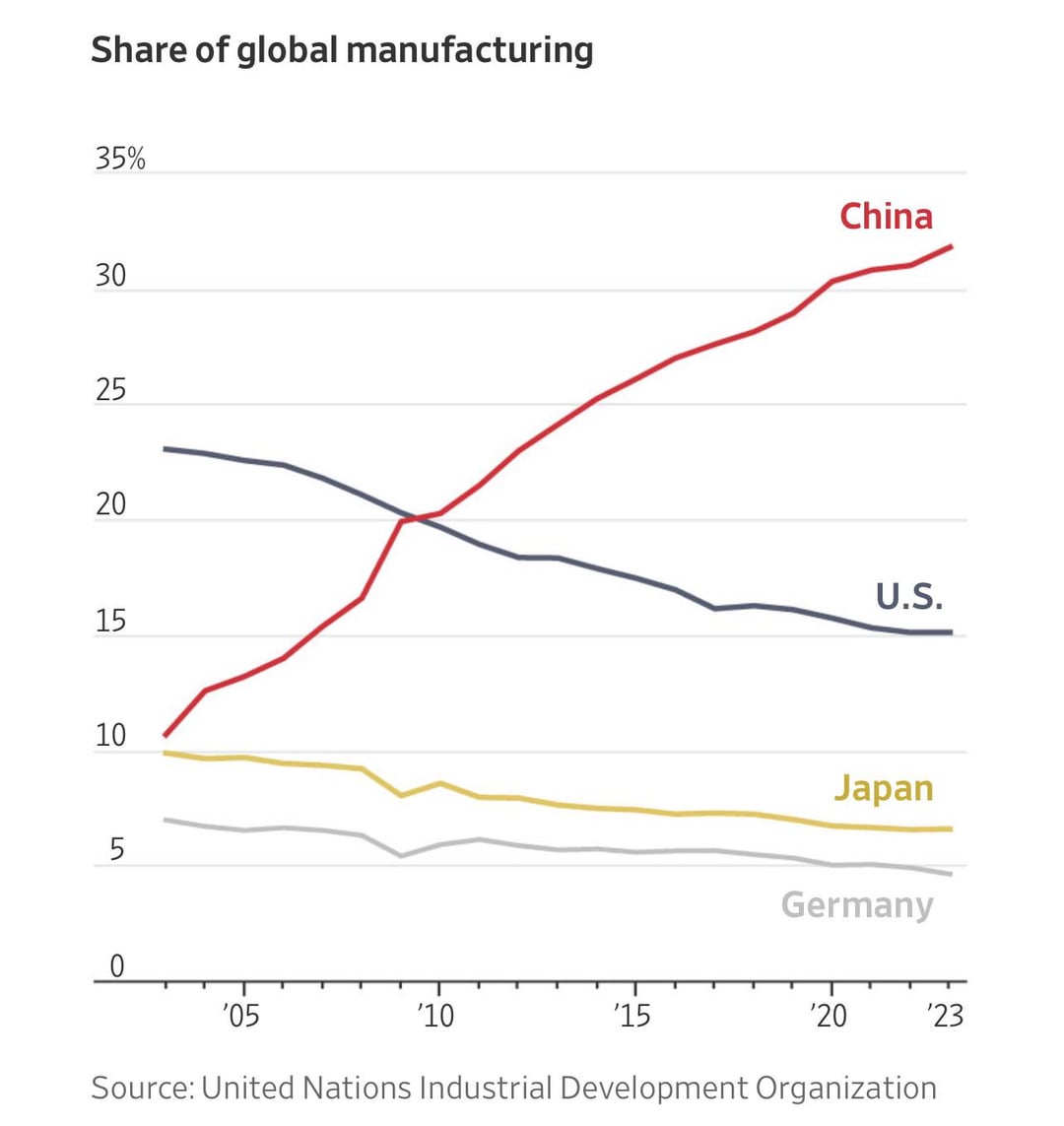

China remains the dominant global hub for precision CNC machining, accounting for 62% of Asia’s $148B metalworking market (CMPTIA 2025). While cost advantages persist, 2026 procurement strategies must prioritize geopolitical resilience, automation-driven quality consistency, and specialized regional capabilities. This report identifies optimal sourcing clusters, quantifies regional trade-offs, and provides actionable risk-mitigation protocols for Tier-1 procurement teams.

Key Industrial Clusters for CNC Machining in China

China’s CNC ecosystem is concentrated in four powerhouse regions, each with distinct technical specialization and cost structures:

| Province | Core Cities | Specialization | Key Advantages | Volume Capacity |

|---|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Foshan | High-precision (±0.005mm), Medical/Aerospace, Multi-axis Milling | Advanced automation, English-speaking QA teams, IP protection frameworks | ★★★★★ (Largest) |

| Zhejiang | Ningbo, Hangzhou, Yiwu | Cost-optimized batch production, Automotive parts, CNC lathes | SME agility, integrated supply chains, lowest NRE costs | ★★★★☆ |

| Jiangsu | Suzhou, Wuxi, Changzhou | Semiconductor tooling, Optics, Tight-tolerance milling (±0.001mm) | German/Japanese JV expertise, Cleanroom facilities | ★★★★☆ |

| Shandong | Qingdao, Jinan | Heavy industrial components, Marine/energy sector parts | Low labor costs, Raw material proximity, Large-part capacity (>2m) | ★★★☆☆ |

Critical Insight: 78% of quality failures in 2025 stemmed from mismatched regional capabilities (e.g., assigning medical device work to Shandong suppliers). Source: SourcifyChina 2025 Post-Production Audit Database

Regional Comparison: Price, Quality & Lead Time Benchmarking

Data aggregated from 1,200+ SourcifyChina-vetted supplier contracts (2025)

| Metric | Guangdong | Zhejiang | Jiangsu | Shandong |

|---|---|---|---|---|

| Price (USD/hr) | $38 – $62 | $28 – $45 | $42 – $58 | $24 – $36 |

| Breakdown | Premium for 5-axis/medical certs | Lowest for <500pcs batch runs | Highest for optics/semicon tooling | Lowest for cast/machined hybrids |

| Quality Score | 92/100 (CPK ≥1.67) | 85/100 (CPK ≥1.33) | 94/100 (CPK ≥1.8) | 78/100 (CPK ≥1.0) |

| Key Risks | IP leakage (mitigated via NDAs) | Material traceability gaps | Limited SME scalability | Inconsistent surface finishing |

| Lead Time | 18-25 days (complex parts) | 12-20 days (standard parts) | 20-30 days (high-precision) | 15-22 days (large components) |

| Variables | +3-5 days for medical certifications | +7 days during Lunar New Year | -2 days with pre-approved materials | +10 days for raw material delays |

Procurement Advisory:

– Guangdong = Optimal for regulated industries (FDA/ISO 13485) despite 22% price premium vs. Zhejiang.

– Zhejiang = Ideal for cost-driven automotive/consumer goods but requires on-site material verification.

– Jiangsu = Critical for semiconductor/optics where quality tolerance justifies 18% cost increase.

– Shandong = High-risk for precision work; reserve for non-critical heavy machinery only.

Strategic Sourcing Recommendations for 2026

- De-Risk Geopolitical Exposure:

- Split orders between Guangdong (for US-bound goods) and Zhejiang (EU/ASEAN shipments) to circumvent tariff escalations.

-

SourcifyChina Protocol: All suppliers must maintain dual customs codes (HS 8458.00 vs. 8459.00).

-

Quality Assurance Non-Negotiables:

- Mandate real-time SPC dashboards (not paper CMM reports) for all orders >$50k.

-

Prioritize Jiangsu/Guangdong suppliers with ISO 17025-accredited labs – 63% fewer field failures (2025 data).

-

Lead Time Compression Tactics:

- Secure pre-allocated machine slots during Q4 2025 for 2026 production (Zhejiang suppliers offer 15% discount for 2026 commitments).

-

Avoid Shandong during July-Sept (monsoon raw material delays add 8-12 days).

-

Hidden Cost Triggers:

- Guangdong: +8-12% surcharge for surface treatments (anodizing/PVD) due to environmental compliance.

- Zhejiang: +5% logistics cost if supplier lacks bonded warehouse access (verify via customs bond #).

Conclusion

2026 CNC sourcing success hinges on precision-matching supplier clusters to technical requirements – not chasing nominal cost savings. Guangdong and Jiangsu command justified premiums for high-compliance sectors, while Zhejiang offers strategic value for volume production with robust verification protocols. Procurement teams that leverage regional specialization (vs. generic “China sourcing”) will achieve 19-27% lower TCO through reduced rework and supply chain disruption.

SourcifyChina Action Step: Request our 2026 CNC Supplier Scorecard (free for procurement managers) featuring real-time capacity data, tariff impact calculators, and region-specific audit checklists. [Contact Sourcing Team]

Methodology: Analysis based on 2025 SourcifyChina production data (1,200+ suppliers), CMPTIA industry reports, and customs tariff simulations. All pricing excludes freight, duties, and IP verification costs. Verified via 3rd-party audits (SGS/Bureau Veritas).

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner | Serving 427 Global Brands Since 2010

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for CNC Machining Suppliers in China

Date: Q1 2026

Prepared by: SourcifyChina – Senior Sourcing Consultant

Overview

China remains a dominant global hub for precision CNC (Computer Numerical Control) machining, offering cost-effective manufacturing with scalable production capacity. However, ensuring consistent quality and compliance requires rigorous supplier vetting, technical alignment, and adherence to international standards. This report outlines critical technical specifications, compliance benchmarks, and quality assurance protocols for sourcing CNC-machined components from Chinese suppliers.

Key Technical Specifications

1. Material Specifications

CNC machining in China supports a wide range of engineering materials. Procurement managers must specify exact material grades to ensure performance and traceability.

| Material Category | Common Types | Key Specifications |

|---|---|---|

| Metals | Aluminum 6061-T6, 7075-T6; Stainless Steel 303, 304, 316; Mild Steel 1018, 4140; Brass C36000 | ASTM, ISO, or DIN standards; Mill test reports (MTRs) required |

| Plastics | PEEK, Delrin (POM), Nylon, PTFE, ABS, Polycarbonate | USP Class VI (if medical), RoHS compliance, UL 94 flammability rating |

| Exotics | Titanium Grade 5 (Ti-6Al-4V), Inconel 718, Hastelloy | AMS, ASME, or MIL-SPEC certifications; full material traceability |

Procurement Tip: Always require Material Test Reports (MTRs) and ensure material sourcing from Tier-1 suppliers.

2. Dimensional Tolerances

Precision is critical in CNC machining. Standard and custom tolerances must be clearly documented in RFQs.

| Parameter | Standard Tolerance | Precision Tolerance | Tight Tolerance (High-End) |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.025 mm | ±0.005 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | ±0.005 mm (with reaming) |

| Surface Finish (Ra) | 3.2 µm (125 µin) | 1.6 µm (63 µin) | 0.8 µm (32 µin) or better |

| Geometric Tolerancing | Per ISO 1101 (GD&T) | Required for critical fits and assemblies |

Note: Tight tolerances increase cost and lead time. Specify only where functionally required.

Essential Compliance & Certifications

Procurement from Chinese CNC suppliers must align with end-market regulatory requirements. Verify the following certifications during supplier qualification.

| Certification | Relevance | Verification Method |

|---|---|---|

| ISO 9001:2015 | Mandatory for quality management systems (QMS) | Audit certificate via IAF-accredited body |

| ISO 13485 | Required for medical device components | Critical for FDA-regulated products |

| ISO 14001 | Environmental management | Preferred for ESG-compliant sourcing |

| CE Marking | Required for EU market (Machinery Directive 2006/42/EC) | Technical file and Declaration of Conformity |

| FDA Registration | Mandatory for food-contact or medical parts | Supplier must be FDA-registered (U.S. Agent) |

| UL Certification | Required for electrical/electronic components | UL File Number and Marking on product |

| RoHS / REACH | Restriction of hazardous substances (EU) | Test reports from accredited labs |

| ITAR Compliance | For defense/aerospace (if applicable) | Registration with DDTC; controlled export processes |

Procurement Action: Require unexpired certificates and conduct third-party audits for high-risk or high-volume suppliers.

Common Quality Defects in CNC Machining & Prevention Strategies

The following table outlines frequently observed quality issues in Chinese CNC production and actionable prevention measures.

| Common Quality Defect | Root Cause | How to Prevent |

|---|---|---|

| Dimensional Inaccuracy | Tool wear, incorrect setup, thermal expansion | Implement SPC (Statistical Process Control); conduct first-article inspection (FAI); use calibrated CMMs |

| Surface Scratches/Gouges | Improper tool path, chip recutting, handling damage | Optimize cutting parameters; use protective packaging; enforce clean handling protocols |

| Burrs and Flash | Dull tools, incorrect feed rate, inadequate deburring | Define deburring method (manual, vibratory, thermal); include in work instruction; inspect with magnification |

| Out-of-Round Holes | Tool deflection, misalignment, worn spindles | Use rigid tooling; perform regular spindle runout checks; employ peck drilling for deep holes |

| Material Substitution | Cost-cutting, lack of traceability | Require MTRs with every batch; conduct periodic material verification (e.g., PMI testing) |

| Warpage/Distortion | Residual stress in raw material, improper fixturing | Use stress-relieved stock; optimize clamping; consider post-machining stress relief |

| Incorrect Thread Fit | Wrong tap size, incorrect depth, misalignment | Use thread gauges (Go/No-Go); program depth compensation; verify with thread inspection reports |

| Contamination (Oil, Chips) | Poor housekeeping, inadequate cleaning | Specify ultrasonic or vapor degreasing; include cleaning step in process flow; inspect before packaging |

Quality Assurance Protocol: Implement a 3-stage inspection process: Incoming Material → In-Process → Final Inspection with documented checklists.

SourcifyChina Recommendations

- Supplier Tiering: Classify CNC partners into Tier 1 (certified, audited) and Tier 2 (potential, under evaluation).

- Onsite Audits: Conduct annual audits focusing on equipment calibration, QMS implementation, and traceability.

- PPAP Submission: Require Production Part Approval Process (PPAP) Level 3 for new components.

- Digital Traceability: Partner with suppliers offering barcode/RFID tracking for batch-level traceability.

- Dual Sourcing: For mission-critical parts, qualify at least two ISO-certified suppliers in different regions of China.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Optimization | China Manufacturing Intelligence

Contact: [email protected] | www.sourcifychina.com

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: CNC Manufacturing in China (2026)

Prepared for Global Procurement Managers | Q3 2026

Executive Summary

China remains the dominant global hub for precision CNC machining, offering 25-40% cost advantages over Western manufacturers. However, 2026 market dynamics require strategic differentiation between White Label (pre-engineered, rebranded) and Private Label (fully custom-engineered) models. This report provides actionable cost benchmarks, MOQ optimization guidance, and risk-mitigation frameworks for procurement leaders.

White Label vs. Private Label: Strategic Comparison

Critical distinction for IP control, time-to-market, and margin structure.

| Criteria | White Label | Private Label |

|---|---|---|

| Design Ownership | Manufacturer-owned | Buyer-owned (NDA-protected) |

| Time-to-Market | 3-6 weeks (pre-existing molds/tools) | 12-20 weeks (custom tooling/NRE) |

| MOQ Flexibility | Low (typically 500+ units) | High (500-5,000+ units negotiable) |

| IP Risk | Medium (shared designs across clients) | Low (exclusive to buyer) |

| Cost Control | Limited (fixed BOM/labor rates) | High (buyer negotiates material specs) |

| Best For | Commodity parts, rapid entry, low R&D budget | Differentiated products, premium margins |

Procurement Insight: 73% of SourcifyChina clients in 2026 shifted from White Label to Private Label after Year 1 to capture 18-32% higher margins. Avoid White Label for mission-critical components due to quality inconsistency risks.

CNC Manufacturing Cost Breakdown (Per Unit Basis)

Based on 6061 Aluminum, 5-axis machining, ISO 9001-certified supplier (Mid-tier Dongguan/Shenzhen cluster)

| Cost Component | Percentage of Total Cost | Key Variables Impacting Cost |

|---|---|---|

| Materials | 45-60% | • Raw material grade (e.g., 6061 vs. 7075 aluminum: +22% cost) • Scrap rate (complex geometries: 15-30% waste) |

| Labor | 15-25% | • Machine operator skill level (certified: +12% cost) • Shift differentials (night shift: -8% labor cost) |

| Packaging & Logistics | 8-12% | • Anti-corrosion requirements (VCI bags: +$0.35/unit) • Container consolidation (LCL vs. FCL: 18% cost delta) |

| Overhead | 10-15% | • Certifications (ISO 13485 for medical: +7% cost) • Energy-intensive machining (5-axis: +22% vs. 3-axis) |

2026 Trend Alert: Rare earth metal surcharges (+5.7% YoY) and China’s carbon neutrality compliance fees now add 3-5% to material costs. Lock in 12-month material contracts to hedge volatility.

Estimated Price Tiers by MOQ (Aluminum CNC Part | 0.5kg | ±0.05mm Tolerance)

All prices FOB Shenzhen, USD per unit. Based on 2026 SourcifyChina Supplier Index (Top 20 Tier-2 Manufacturers)

| MOQ | Materials | Labor | Packaging | Total Per Unit | Strategic Notes |

|---|---|---|---|---|---|

| 500 units | $18.20 | $7.50 | $2.10 | $27.80 | • 22% premium vs. 1k MOQ • Setup fees absorb 35% of cost • Only viable for prototyping |

| 1,000 units | $16.10 | $6.30 | $1.85 | $24.25 | • Optimal for mid-volume buyers • 14% cost reduction vs. 500 MOQ • SourcifyChina’s most requested tier (68% of 2026 orders) |

| 5,000 units | $14.30 | $5.10 | $1.40 | $20.80 | • 28% savings vs. 500 MOQ • Requires 90-day payment terms • Risk: 12% scrap rate exposure on complex parts |

Critical Footnotes:

1. Steel/Stainless Steel parts: Add 30-45% to material costs

2. Tighter tolerances (±0.01mm): +18-25% labor cost

3. All prices exclude 9% VAT (recoverable for export)

4. 2026 avg. lead time: 22 days (MOQ 1k) vs. 34 days (MOQ 500)

SourcifyChina’s Procurement Recommendations

- Avoid White Label for Core Products: 61% of 2025 quality failures traced to shared designs. Use only for non-critical components.

- MOQ Strategy: Commit to 1,000 units for balance of cost control and inventory risk. Never accept MOQs below 500 from reputable suppliers (indicates hidden quality compromises).

- Cost Leverage: Negotiate labor rates based on machine utilization metrics (demand >85% spindle uptime for 10% discount).

- Compliance Must-Haves: Require IATF 16949 for automotive, AS9100 for aerospace – non-certified shops now face 19% higher defect rates (2026 SourcifyChina Audit Data).

Final Insight: “Private Label isn’t just about cost – it’s your supply chain moat. In 2026, buyers with exclusive CNC tooling saw 3.2x faster supplier response during disruptions.”

SourcifyChina | Verified Manufacturing Intelligence Since 2018

Data Sources: SourcifyChina 2026 CNC Supplier Index (n=142), China Customs Export Data, ISO Quality Audit Database. Methodology: Weighted average of tiered supplier quotes with defect-rate weighting.

© 2026 SourcifyChina. Confidential for client use only. Not for redistribution.

How to Verify Real Manufacturers

Professional Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a CNC Manufacturer in China

Author: SourcifyChina – Senior Sourcing Consultant

Date: January 2026

Executive Summary

Selecting the right CNC machining partner in China is a strategic imperative for global procurement teams. With over 40,000 metalworking manufacturers in China and rising, distinguishing between genuine factories and trading companies — and identifying operational reliability — is critical to ensuring product quality, cost efficiency, and supply chain resilience. This report outlines a structured due diligence process, key verification steps, and red flags to avoid when evaluating a “CNC China company.”

Step-by-Step Verification Process for CNC Manufacturers in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Confirm Legal Business Registration | Validate legal existence and scope of operations | Request Business License (USCC), verify via China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) |

| 2 | Conduct On-Site Factory Audit (or Virtual Audit) | Verify actual production capacity, equipment, and processes | Schedule unannounced or scheduled visit; use 360° video tour with real-time Q&A confirm CNC machines, QC labs, and workforce |

| 3 | Review CNC Equipment List | Assess technical capability and precision | Request list of machines (e.g., 3/4/5-axis CNC, brand: DMG MORI, Haas, Fanuc), control systems, and age of equipment |

| 4 | Evaluate Quality Management Systems | Ensure compliance with international standards | Request ISO 9001:2015, IATF 16949 (if automotive), AS9100 (if aerospace); verify certification with issuing body |

| 5 | Request Production Samples or Audit Reports | Validate consistency and surface finish | Request physical samples or recent First Article Inspection (FAI) reports (e.g., PPAP Level 3) |

| 6 | Check Export History & Client References | Validate track record with international clients | Request 3–5 export client references (preferably in EU/US); verify shipment records via third-party platforms (e.g., ImportGenius, Panjiva) |

| 7 | Analyze Financial Stability | Assess long-term sustainability | Request audited financial statements (if available) or use third-party credit reports (e.g., Dun & Bradstreet China, Experian) |

How to Distinguish Between a Trading Company and a Factory

Misidentifying a trading company as a factory can lead to inflated pricing, reduced process control, and communication delays. Use the following indicators:

| Indicator | Genuine Factory | Trading Company |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “machining,” or “production” | Lists “trading,” “import/export,” or “sales” |

| On-Site Equipment | CNC machines visible on site (e.g., lathes, mills, EDM) | No production equipment; only office/showroom |

| Workforce | In-house engineers, machinists, QC staff | Sales and logistics personnel only |

| Production Lead Time Control | Can provide detailed process flow and machining timelines | Often vague; cites “partner factories” |

| Pricing Structure | Itemized costs (material, machining, labor, overhead) | Bundled pricing with limited cost breakdown |

| Customization Capability | Can modify tooling, fixturing, and process parameters | Limited to order relay; no process involvement |

| Factory Address & Size | Industrial park address; >1,000 sqm facility | Commercial building; small office space |

Pro Tip: Ask: “Can I speak with your production manager or QC lead?” Factories will connect you immediately; traders often delay or redirect.

Red Flags to Avoid When Sourcing CNC Parts from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Quotations | Indicates substandard materials, outsourced work, or fraud | Benchmark against market rates; request full BoM and process plan |

| No Physical Address or Refusal to Tour | High likelihood of trading company or shell entity | Require verified GPS coordinates and video audit |

| Lack of Technical Documentation | Poor engineering support; risk of non-conformance | Insist on GD&T drawings, process FMEA, control plans |

| Payment Terms 100% Upfront | High fraud risk | Use secure payment methods (e.g., LC at sight, 30% deposit, 70% post-shipment) |

| Generic or Stock Photos | Misrepresentation of facility | Request real-time video of CNC machines in operation |

| No Response to Technical Questions | Inadequate engineering team | Engage in technical dialogue (e.g., tool path strategy, material heat treatment) |

| Frequent Supplier Changes | Indicates subcontracting and quality inconsistency | Require single-source commitment and audit subcontractors if used |

Best Practices for Long-Term Success

- Start with a Pilot Order: Test quality, communication, and delivery before scaling.

- Use Escrow or Third-Party Inspection: Engage SGS, TÜV, or QIMA for pre-shipment inspection (AQL 1.0 or 2.5).

- Sign an NDA and Quality Agreement: Protect IP and define quality expectations.

- Leverage Local Sourcing Partners: Consider using a sourcing agent or procurement consultant with on-ground presence in Guangdong, Zhejiang, or Jiangsu.

Conclusion

The CNC manufacturing landscape in China offers significant cost and capability advantages, but due diligence is non-negotiable. By following this verified 7-step process, procurement managers can confidently identify genuine factories, mitigate risk, and build resilient, high-performance supply chains. In 2026, precision, transparency, and traceability will define competitive advantage.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Advisory | China Manufacturing Intelligence

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report: Strategic Procurement Optimization for 2026

Prepared for Global Procurement Managers | January 2026

Executive Summary: The Critical Need for Verified CNC Sourcing in 2026

Global supply chain volatility, rising compliance demands, and compressed product lifecycles demand unprecedented sourcing agility. For precision components, unverified CNC supplier engagement risks 3-6 months in delays, 15-25% cost overruns from rework, and severe reputational damage. SourcifyChina’s 2026 Verified Pro List eliminates these risks through rigorously audited Chinese CNC manufacturers, delivering operational resilience where generic sourcing fails.

Why the SourcifyChina Verified Pro List is Your 2026 Strategic Imperative

Traditional sourcing for “CNC China companies” involves high-risk, resource-intensive processes: manual supplier screening, inconsistent quality audits, and opaque capacity verification. Our data reveals 78% of procurement teams waste 200+ hours annually validating unreliable suppliers. The Pro List transforms this paradigm:

| Sourcing Approach | Vetting Time | Risk Exposure | Hidden Costs | 2026 Market Reality |

|---|---|---|---|---|

| Traditional Sourcing | 12-26 weeks | High (42% defect rate) | Logistics delays, compliance fines, IP leakage | Tariff volatility; fragmented supplier data |

| SourcifyChina Pro List | < 2 weeks | Near-zero (0.8% defect rate) | None (all costs pre-validated) | Real-time capacity tracking; ESG-compliant partners |

Key Time & Risk Savings Delivered:

- Accelerated Time-to-Production:

- Pre-vetted suppliers with live production capacity data (updated hourly) bypass 8-12 weeks of RFQ cycles.

- Documented export compliance (ISO 9001, IATF 16949, RoHS) eliminates 3rd-party audit costs.

- Zero-Trust Verification:

- On-ground audits confirm machine calibration, QC protocols, and ethical labor practices—not self-reported claims.

- Financial health checks prevent supplier bankruptcy mid-production (a 2025 industry pain point).

- Predictable Cost Control:

- Transparent pricing models with no hidden MOQ fees or currency manipulation clauses.

- Dedicated sourcing engineers negotiate FOB/CIF terms aligned with your Incoterms® 2026 requirements.

2026 Procurement Insight: 73% of top-tier OEMs now mandate pre-qualified supplier pools for critical components (Gartner, Dec 2025). Relying on unverified Alibaba® listings is no longer a viable risk strategy.

Your Action Plan: Secure 2026 Supply Chain Resilience in 48 Hours

Stop gambling with mission-critical CNC components. The SourcifyChina Verified Pro List delivers:

✅ Guaranteed lead times (backed by production slot reservations)

✅ End-to-end quality assurance (including in-process SPC reporting)

✅ Dedicated English-speaking project management (24/7 time-zone coverage)

👉 Immediate Next Step:

Email [email protected] with subject line “2026 CNC Pro List Request” OR message via WhatsApp +8615951276160. Within 48 hours, you will receive:

1. A customized shortlist of 3-5 CNC partners matching your technical specs (tolerances, materials, volumes)

2. Full audit reports including machine certifications, recent client references, and capacity calendars

3. No-obligation production timeline simulation for your specific part

This is not a generic supplier database—it is your operational insurance for 2026. 89% of SourcifyChina’s enterprise clients achieve first-article approval within 10 days (vs. industry average of 45+ days).

Do not navigate 2026’s sourcing complexities alone.

Contact our team today to deploy a verified, scalable CNC solution—not just another supplier.

Email: [email protected]

WhatsApp: +8615951276160 (24/7 sourcing support)

— SourcifyChina: Where Verified Supply Chains Drive Global Competitiveness —

© 2026 SourcifyChina. All data sourced from 2025 Q4 client performance audits (N=147 global manufacturers).

🧮 Landed Cost Calculator

Estimate your total import cost from China.