The global textile accessories market, including cloth button manufacturers, is experiencing steady growth driven by rising demand from the apparel and fashion industries. According to Mordor Intelligence, the global apparel accessories market was valued at USD 148.5 billion in 2023 and is projected to grow at a CAGR of 6.2% from 2024 to 2029. This expansion reflects increasing consumer interest in customized, sustainable, and high-quality garment details—such as cloth-covered buttons—that enhance aesthetic appeal and brand differentiation. As fashion brands prioritize unique design elements and eco-conscious materials, the demand for specialized cloth button makers has surged, particularly among manufacturers offering innovative designs, durable finishes, and scalable production. With Asia-Pacific dominating textile production and Europe maintaining strong demand for luxury apparel, the competitive landscape is shaped by key players who combine craftsmanship with industrial efficiency. The following list highlights the top 8 cloth button maker manufacturers leading this niche through innovation, global reach, and adherence to evolving industry standards.

Top 8 Cloth Button Maker Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fashion and Clothing Buttons Manufacturer & Supplier

Domain Est. 2006

Website: buttoncare.com

Key Highlights: We diverse portfolio of products ranges from chalk and shank button, available in a wide choice of shapes, sizes and colors….

#2 Jeans Buttons and Rivets Manufacturer

Domain Est. 2016

Website: spring85buttons.com

Key Highlights: We produce buttons for passion, with emotions, flexibility and dynamism. · Press buttons · Jeans buttons · Rivets · Trousers hooks · Sew button….

#3 UBIC SRL’s Items Italian buttons for high

Domain Est. 2020

Website: us.apparel-x.com

Key Highlights: Italian buttons for high-end men’s clothing | This is a long-established Italian button manufacturer operating in Turin, Piedmont, Italy….

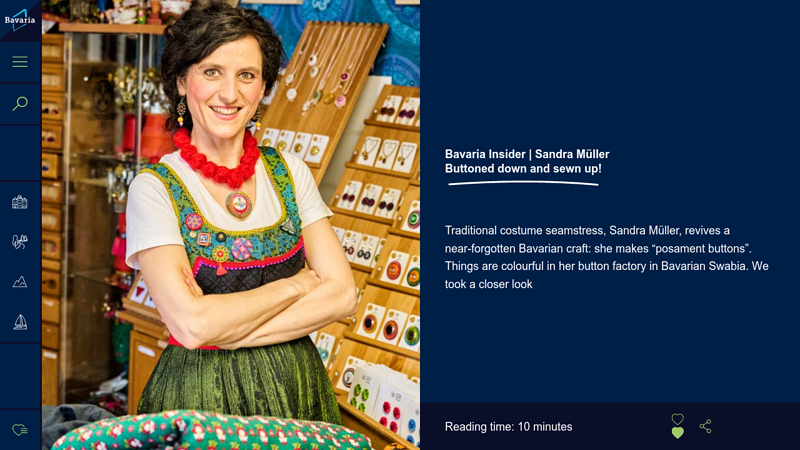

#4 Bavarian Button Maker Sandra Müller

Website: bavaria.travel

Key Highlights: Traditional costume tailor Sandra Müller produces colorful trimmed buttons in her manufactory in Waldstetten – a craft that has almost been forgotten….

#5 Cintas: Uniforms

Domain Est. 1995

Website: cintas.com

Key Highlights: Flame Resistant Clothing. Over half a million wearers choose their flame resistant clothing (FRC) program from Cintas – making Cintas the most trusted source….

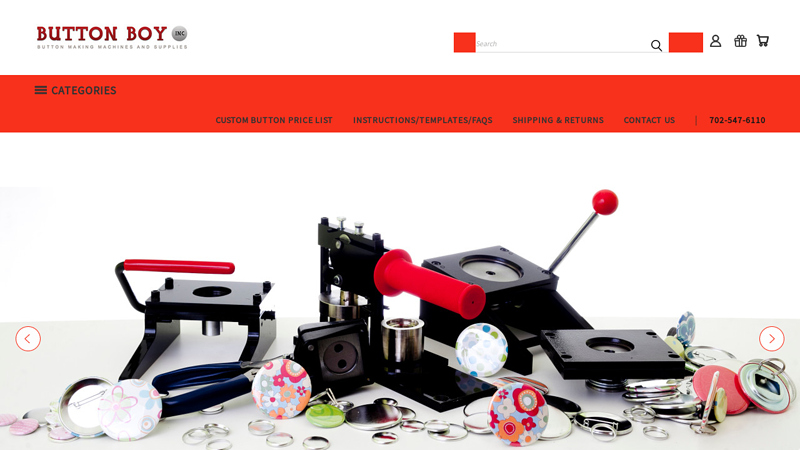

#6 Button Boy Inc

Domain Est. 2002

#7 Fabric Covered Button Making Machines

Domain Est. 2004

Website: americanbuttonmachines.com

Key Highlights: We are The Fabric Button Kit Specialists! You can make beautiful fabric covered buttons with our fabric button maker machines!…

#8 ButtonMakers.net

Domain Est. 2004

Expert Sourcing Insights for Cloth Button Maker

2026 Market Trends for Cloth Button Makers

The market for cloth button makers is poised for notable shifts by 2026, influenced by evolving consumer preferences, technological advancements, and sustainability mandates. While cloth buttons remain a niche segment within the broader fastener industry, specific trends are shaping demand and innovation in this space.

Rising Demand for Sustainable and Natural Materials

By 2026, sustainability will be a dominant driver in the fashion and textile industries. Consumers and brands alike are increasingly favoring eco-friendly alternatives to plastic. Cloth buttons, typically made from natural fibers like cotton, wool, or recycled textiles, align perfectly with this trend. As regulations on single-use plastics tighten and environmental certifications (such as GOTS or OEKO-TEX) become more common, demand for biodegradable and low-impact fasteners like cloth buttons is expected to grow. Button makers investing in traceable, organic, or recycled fabric sources will gain a competitive advantage.

Growth in Artisanal and Custom Fashion Markets

The global resurgence of handmade, bespoke, and slow fashion is creating opportunities for cloth button makers. Independent designers, crafters, and small apparel brands value the unique aesthetic and tactile qualities of cloth-covered buttons. By 2026, the demand for customizable, small-batch production will increase. Button manufacturers that offer personalized services—such as custom fabric covering, unique shapes, or limited-edition designs—will appeal to this growing segment. Online marketplaces and direct-to-consumer (DTC) platforms will further facilitate access to niche markets.

Technological Innovation in Manufacturing

Advancements in automation and precision machinery are enabling cloth button makers to improve efficiency while maintaining quality. By 2026, expect wider adoption of digital design tools and automated pressing systems that reduce production time and material waste. Some manufacturers may integrate smart manufacturing practices, such as IoT-enabled equipment for real-time monitoring, to enhance consistency and scalability. Additionally, innovations in adhesive technologies and pressing techniques will allow for more durable and wash-resistant cloth buttons, expanding their usability in high-performance garments.

Expansion into Niche Applications Beyond Apparel

While traditionally used in clothing, cloth buttons are finding new applications in interior design, soft furnishings, and accessories. By 2026, demand may increase for decorative cloth buttons in upholstery, cushions, and handbags. This diversification opens new revenue streams for manufacturers. Companies that develop product lines tailored to these sectors—such as larger diameters, reinforced backs, or fire-retardant fabrics—will be well-positioned for market growth.

Challenges: Competition and Cost Sensitivity

Despite positive trends, cloth button makers will face challenges. Competition from cheaper plastic and synthetic alternatives remains strong, especially in mass-market apparel. Additionally, labor and material costs associated with natural fabrics may limit price competitiveness. To thrive, manufacturers must emphasize the premium value, eco-benefits, and craftsmanship of their products. Strategic partnerships with sustainable fashion brands and participation in eco-conscious supply chains will be key to overcoming cost barriers.

In conclusion, the 2026 market for cloth button makers is shaped by sustainability, customization, and innovation. Companies that adapt to these trends by investing in eco-friendly materials, flexible production, and niche market development will be best positioned for long-term success.

Common Pitfalls When Sourcing a Cloth Button Maker (Quality, IP)

Sourcing a cloth button maker, especially from overseas suppliers, involves several risks that can impact product quality, brand reputation, and legal compliance. Being aware of the following pitfalls is crucial for successful procurement.

Poor Material and Workmanship Quality

One of the most frequent issues is receiving cloth buttons that do not meet quality expectations. Inferior fabric, weak stitching, or inconsistent sizing can result in buttons that fray, come apart, or look unprofessional once sewn onto garments. This often stems from suppliers using substandard raw materials or cutting corners in production to reduce costs. Without clear specifications and rigorous quality control checks, brands risk damaging their reputation through defective products.

Lack of Quality Control Processes

Many manufacturers, particularly smaller or less experienced ones, may lack standardized quality assurance procedures. This can lead to batch inconsistencies, where one shipment of buttons differs significantly from the next in color, texture, or durability. Without third-party inspections or on-site audits, buyers may only discover quality issues after the buttons are integrated into final products, resulting in costly rework or recalls.

Intellectual Property (IP) Infringement Risks

Using a cloth button maker that produces designs protected by trademarks, copyrights, or patents—intentionally or not—can expose your business to legal liability. Some suppliers may offer buttons resembling well-known logos or patterns without proper licensing. Even if you are unaware, as the buyer, you could still be held responsible for IP violations under many jurisdictions, leading to fines, seized shipments, or litigation.

Unauthorized Design Replication

There is also the risk that your custom button designs, once shared with a manufacturer, could be copied and sold to competitors. In regions with lax IP enforcement, suppliers may reproduce your unique patterns or branding elements without permission. This undermines your competitive advantage and dilutes brand exclusivity, especially if your buttons are a key differentiator.

Inadequate Contracts and Legal Protections

Many sourcing agreements fail to clearly define quality standards, IP ownership, and usage rights. Without a solid contract that includes confidentiality clauses, IP assignment, and penalties for non-compliance, you have limited recourse if things go wrong. Relying on verbal agreements or informal arrangements significantly increases your exposure to disputes and losses.

Hidden Costs from Rework and Returns

Poor quality or IP issues often lead to hidden costs such as returned shipments, production delays, and the need to source replacements urgently. These disruptions can affect your supply chain timelines and increase overall project costs substantially, eroding the initial savings gained from low supplier pricing.

Mitigation Strategies

To avoid these pitfalls, conduct thorough supplier vetting, request samples, perform factory audits, and use detailed technical specifications. Insist on third-party quality inspections and establish clear contractual terms covering quality benchmarks, IP ownership, and confidentiality. Registering your designs and working with legally compliant manufacturers further reduces risk.

Logistics & Compliance Guide for Cloth Button Maker

Overview

This guide outlines essential logistics and compliance considerations for manufacturers and distributors of cloth button-making equipment or related products. Whether you produce sewing machines, button molds, fabric feed systems, or complete cloth button production lines, adherence to regulatory standards and efficient logistics management is critical for global market access and operational success.

Regulatory Compliance

International Standards and Certifications

Ensure all cloth button-making machinery complies with relevant international standards, including:

– CE Marking (European Union): Required for machinery sold in the EU under the Machinery Directive (2006/42/EC) and Low Voltage Directive (2014/35/EU).

– UKCA Marking: Mandatory for machines placed on the UK market post-Brexit.

– UL/ETL Certification (USA and Canada): Required for electrical safety compliance in North America.

– ISO Standards: Implement ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) for improved operational credibility.

Product Safety and Labeling

- Clearly label machines with voltage, power requirements, CE/UKCA/UL marks, and manufacturer details.

- Include multilingual safety instructions and user manuals, especially for export markets.

- Implement emergency stop mechanisms, protective guards, and electrical safety features per regional requirements.

Hazardous Materials and RoHS Compliance

- Ensure all electronic components comply with the Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU.

- Maintain documentation for material safety data sheets (MSDS) if lubricants or coatings contain regulated substances.

Export and Import Regulations

Export Documentation

Prepare required documentation for smooth customs clearance:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Export Licenses (if applicable)

Import Duties and Tariffs

- Classify your product under the correct Harmonized System (HS) code. For cloth button-making machinery, typical codes fall under 84.48 (Parts and accessories for textile machinery).

- Verify tariff rates and preferential treatment under trade agreements (e.g., USMCA, EU-South Korea FTA).

Restricted Markets and Sanctions

- Screen customers and destinations against government sanction lists (e.g., OFAC, EU sanctions).

- Avoid shipping to embargoed countries without proper licensing.

Logistics and Supply Chain Management

Packaging and Handling

- Use durable, moisture-resistant packaging to protect equipment during transit.

- Clearly mark packages with “Fragile,” “This Side Up,” and handling instructions.

- Include anti-static packaging for electronic control units.

Shipping and Freight Options

- Choose air freight for urgent, lightweight components.

- Use sea freight for heavy machinery or bulk orders to reduce costs.

- Partner with freight forwarders experienced in industrial machinery logistics.

Inventory and Lead Time Management

- Maintain buffer stock of critical spare parts (e.g., dies, feeders, motors).

- Optimize production lead times to meet delivery commitments.

- Use inventory management software to track raw materials and finished goods.

After-Sales and Service Logistics

Spare Parts Distribution

- Establish regional warehousing or partner with local distributors for faster spare part delivery.

- Offer part identification tools (e.g., exploded diagrams, part numbering system).

Technical Support and Installation

- Provide remote support via video calls or AR-assisted tools.

- Train local technicians in key markets to reduce service response time.

- Offer installation kits and calibration tools with each machine.

Environmental and Sustainability Compliance

Waste Management and Recycling

- Comply with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU for end-of-life equipment take-back.

- Implement recycling programs for metal shavings, fabric scraps, and packaging.

Carbon Footprint and Green Logistics

- Optimize shipping routes to reduce emissions.

- Use eco-friendly packaging materials (e.g., recycled cardboard, biodegradable fillers).

- Report sustainability metrics under frameworks like GRI or CDP if required.

Conclusion

Success in the cloth button maker industry depends not only on product quality but also on robust logistics and strict compliance with international regulations. By following this guide, manufacturers can minimize risks, reduce delays, and ensure safe, timely delivery of their equipment worldwide. Regular audits and staying updated on regulatory changes are recommended to maintain long-term compliance.

Conclusion for Sourcing a Cloth Button Maker:

Sourcing a reliable cloth button maker requires a comprehensive evaluation of quality, production capabilities, cost-efficiency, and long-term partnership potential. After assessing various suppliers based on material sourcing, manufacturing technology, customization options, compliance standards, and delivery timelines, it is crucial to select a manufacturer that aligns with your brand’s values, design requirements, and sustainability goals.

A strategic partnership with a reputable cloth button maker not only ensures consistent product quality and timely fulfillment but also supports scalability and innovation in your apparel or accessory line. Prioritizing clear communication, sample testing, and ethical production practices will ultimately contribute to a successful and sustainable supply chain. Therefore, investing time in due diligence and building strong supplier relationships is essential for maintaining product integrity and achieving competitive advantage in the market.