The global clevis hooks market is experiencing steady growth, driven by increasing demand across construction, automotive, and material handling industries. According to a report by Mordor Intelligence, the rigging and lifting equipment market—of which clevis hooks are a critical component—is projected to grow at a CAGR of over 5.2% from 2023 to 2028. Similarly, Grand View Research valued the global lifting and rigging equipment market at USD 12.7 billion in 2022, with continued expansion expected due to infrastructure development and industrial automation. As safety and load-bearing precision become paramount, manufacturers of clevis hooks are focusing on high-strength materials, compliance with ISO and ASME standards, and innovative designs. In this evolving landscape, a select group of manufacturers has emerged as leaders through consistency, scalability, and technological advancement. Here’s a data-informed look at the top 9 clevis hooks manufacturers shaping the industry today.

Top 9 Clevis Hooks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Clevis Slip Hooks

Domain Est. 2018

Website: baronhardware.com

Key Highlights: Clevis Slip Hooks … We are a manufacturer and distributor of industrial snaps and all types of connecting products and accessories meeting global quality ……

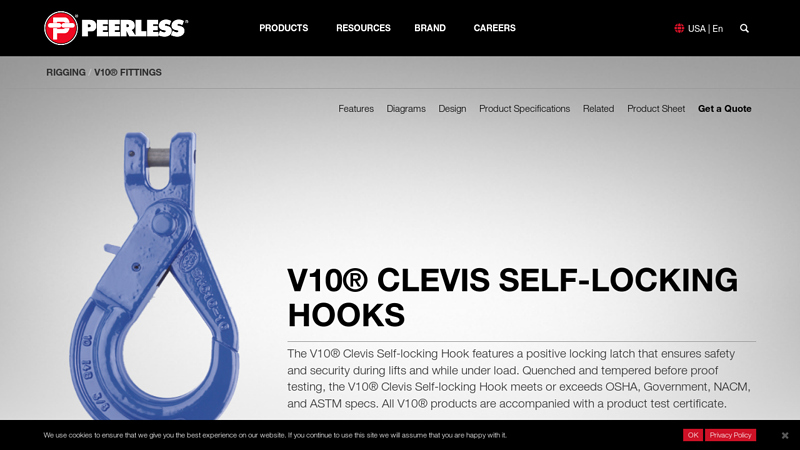

#2 V10® Clevis Self

Domain Est. 1995

Website: peerlesschain.com

Key Highlights: The V10 Clevis Self-locking Hook features a positive locking latch that ensures safety and security during lifts and while under load….

#3 Clevis Hooks for Secure, Durable, and Reliable Trailer Connections

Domain Est. 1996

#4 Clevis Hooks

Domain Est. 1997

Website: curtmfg.com

Key Highlights: We make our clevis hooks from heat-treated, forged steel to be strong and meet all the requirements for high-test chain….

#5 Laclede Chain

Domain Est. 1997

Website: lacledechain.com

Key Highlights: We offer a full line of chain hooks, fittings, and other accessories. Our Tire Chain division manufactures and imports several classifications of chains for ……

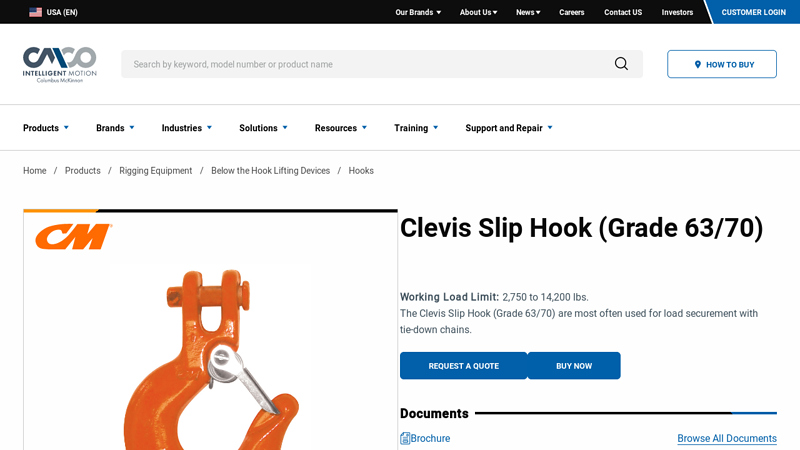

#6 CM Clevis Slip Hook (Grade 63/70)

Domain Est. 1997

Website: cmco.com

Key Highlights: Working Load Limit: 2,750 to 14,200 lbs. The Clevis Slip Hook (Grade 63/70) are most often used for load securement with tie-down chains. Request a Quote…

#7 Clevis Hooks Assembly

Domain Est. 1999

Website: swos.net

Key Highlights: SWOS offers a wide range of hooks, from drop forged carbon steel hooks to drop forged alloy steel swivel hooks, which are quenched and tempered….

#8 Clevis Hooks, Chain Accessories

Domain Est. 2003

Website: imperialsupplies.com

Key Highlights: Free delivery over $400 365-day returns…

#9 Clevis Hooks

Domain Est. 2008

Website: horizoncableinc.com

Key Highlights: Clevis Hooks are a hooks with or without a snapping lock or pin to secure it’s load to the hook. Clevis Hooks can be attached with brackets or a chain depending ……

Expert Sourcing Insights for Clevis Hooks

2026 Market Trends for Clevis Hooks

The global clevis hook market is poised for steady growth and transformation by 2026, driven by infrastructure development, industrial automation, and evolving safety standards. As essential components in lifting, rigging, and load-bearing applications, clevis hooks are seeing shifts in demand, materials, and innovation that will define the market landscape in the coming years.

Rising Demand from Infrastructure and Construction Sectors

Continued global investment in infrastructure—particularly in emerging economies—will drive demand for durable rigging hardware. Urbanization, transportation projects (bridges, railways), and renewable energy installations (wind turbines, solar farms) require reliable lifting solutions, positioning clevis hooks as critical components. Governments and private sectors increasing capital expenditure on construction will directly benefit the market.

Focus on Safety and Compliance Standards

Regulatory bodies worldwide are tightening safety regulations for lifting equipment. Clevis hooks must comply with standards such as ASME B30.26, OSHA, and ISO 2308. By 2026, manufacturers will increasingly prioritize certifications, load testing, and traceability to meet compliance demands. This trend will favor suppliers offering documented quality assurance and smart hooks with integrated load monitoring.

Growth in Material Innovation and Lightweighting

Demand for high-strength, corrosion-resistant materials like alloy steel, stainless steel, and advanced composites will rise, especially in marine, offshore, and chemical environments. Lightweight yet durable designs will gain traction to improve handling efficiency and reduce fatigue in repetitive operations. Innovations in heat treatment and surface coatings (e.g., galvanization, powder coating) will enhance longevity and performance.

Expansion in Automation and Industry 4.0 Integration

As industries adopt smart manufacturing and automated material handling systems, there will be growing interest in intelligent rigging components. While clevis hooks remain largely mechanical, future iterations may incorporate sensors for load measurement, wear detection, and connectivity to IoT platforms. This shift supports predictive maintenance and improves operational safety in automated warehouses and production lines.

Regional Market Dynamics

Asia-Pacific will remain the dominant market due to rapid industrialization and construction growth in China, India, and Southeast Asia. North America and Europe will see steady demand driven by infrastructure renewal and strict safety regulations. Meanwhile, the Middle East and Africa will present emerging opportunities linked to oil & gas and large-scale development projects.

Sustainability and Circular Economy Considerations

Environmental concerns will influence material sourcing and manufacturing processes. By 2026, manufacturers may emphasize recyclable materials, energy-efficient production, and end-of-life product recovery. Customers in regulated industries will increasingly favor suppliers with sustainable practices and transparent supply chains.

In conclusion, the clevis hook market in 2026 will be shaped by safety, technological adaptation, and regional economic trends. Companies that innovate in materials, ensure compliance, and align with sustainability goals will be best positioned for growth in this mature yet evolving segment.

Common Pitfalls When Sourcing Clevis Hooks (Quality and Intellectual Property)

Sourcing clevis hooks may appear straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to significant operational, safety, and legal risks. Below are common pitfalls to avoid:

Inadequate Material and Manufacturing Standards

Many suppliers offer clevis hooks made from substandard materials or using outdated manufacturing processes. Without adherence to recognized standards such as ASME B30.26, ASTM A391, or ISO 2415, the hooks may lack the necessary strength, durability, or resistance to corrosion, increasing the risk of failure under load.

Lack of Proper Load Ratings and Certification

A frequent issue is the absence of verifiable Working Load Limits (WLL) or third-party certification. Some suppliers may overstate load capacities without proper testing. Always insist on certified test reports and traceable documentation to ensure the clevis hook can safely perform under specified conditions.

Poor Surface Finish and Defects

Low-quality clevis hooks often exhibit surface imperfections such as cracks, porosity, or incomplete threading. These defects can act as stress concentrators and lead to premature failure. Visual inspection alone is insufficient—require non-destructive testing (NDT) like magnetic particle inspection (MPI) for critical applications.

Counterfeit or Non-Compliant Products

Sourcing from unauthorized or unverified suppliers increases the risk of receiving counterfeit products that mimic reputable brands but fail to meet safety and performance criteria. These items may bear fake certifications or misleading markings, posing serious safety hazards.

Intellectual Property Infringement Risks

Manufacturers sometimes replicate patented designs, such as unique locking mechanisms or geometry, without licensing. Purchasing such products—even unknowingly—can expose your company to legal liability, especially in regions with strong IP enforcement. Always verify that the supplier has the right to produce and sell the design.

Insufficient Traceability and Documentation

Without proper lot traceability, heat numbers, or material test reports, it becomes difficult to investigate failures or comply with regulatory audits. Reliable suppliers provide full documentation to support quality assurance and accountability throughout the supply chain.

Choosing Solely on Price

Opting for the lowest-cost option often leads to compromised quality. Cheaper clevis hooks may use inferior alloys, skip essential heat treatments, or lack rigorous quality control. The long-term costs of downtime, accidents, or liability far outweigh initial savings.

Ignoring Environmental and Application-Specific Needs

Clevis hooks used in corrosive, high-temperature, or dynamic load environments require special materials (e.g., stainless steel, galvanized coatings) and design features. Standard off-the-shelf hooks may degrade quickly if not suited for the operational context.

By proactively addressing these pitfalls—prioritizing certified quality, verifying IP legitimacy, and partnering with reputable suppliers—organizations can ensure the safety, reliability, and legal compliance of their clevis hook procurement.

Logistics & Compliance Guide for Clevis Hooks

Clevis hooks are essential lifting and rigging components used across industries such as construction, transportation, and manufacturing. Ensuring their proper logistics handling and compliance with relevant standards is crucial for safety, legal adherence, and operational efficiency. This guide outlines key considerations for the safe transport, storage, inspection, and regulatory compliance of clevis hooks.

Regulatory Standards and Certifications

Clevis hooks must comply with nationally and internationally recognized standards to ensure structural integrity and safety. Key regulations include:

- ASME B30.26: Governs the design, manufacture, marking, and testing of below-the-hook lifting devices, including clevis hooks. Requires identification markings, load ratings, and periodic inspections.

- OSHA 29 CFR 1910.184: OSHA’s regulation for slings and rigging hardware mandates that all components, including clevis hooks, be inspected before each shift and removed from service if damaged or deformed.

- EN 13889 (European Standard): Applies to forged steel lifting hooks with latch, specifying requirements for design, testing, and marking within the European Union.

- CE Marking: Required for clevis hooks sold in the EU, indicating conformity with health, safety, and environmental protection standards.

Manufacturers and suppliers must provide certification documentation (e.g., material test reports, load test certificates) and ensure traceability through serial numbers and batch tracking.

Load Capacity and Marking Requirements

Each clevis hook must be permanently marked with critical information, including:

- Rated load capacity (in tons or kilograms)

- Manufacturer’s name or trademark

- Size or model number

- Working Load Limit (WLL)

- Manufacture date or code

These markings must be legible and indelible. Overloading or using clevis hooks beyond their rated capacity is a violation of safety regulations and poses serious risks.

Inspection and Maintenance Protocols

Regular inspection is mandatory to maintain compliance and safety:

- Pre-Use Inspection: Conduct a visual check for cracks, deformation, wear, or missing latches before each use.

- Periodic Inspection: Formal inspections should be performed by a qualified person at intervals defined by usage frequency and environmental conditions (e.g., monthly or quarterly).

- Documentation: Maintain inspection logs that record findings, corrective actions, and equipment status.

Damaged or suspect clevis hooks must be immediately removed from service and either repaired by authorized personnel or condemned.

Packaging and Transportation

Proper packaging and handling during logistics reduce the risk of damage:

- Protective Packaging: Use padded containers, crates, or bulk bins to prevent impact damage during transit.

- Segregation: Store and transport clevis hooks separately from corrosive or abrasive materials.

- Labeling: Clearly label packages with handling instructions (e.g., “Fragile,” “Do Not Stack”), contents, and WLL.

- Secure Loading: When shipping in bulk, secure loads to prevent shifting that could cause deformation or surface damage.

Storage Conditions

Optimal storage preserves the integrity of clevis hooks:

- Dry Environment: Store indoors in a dry, climate-controlled area to prevent rust and corrosion.

- Elevated Storage: Use racks or shelves to keep hooks off the floor and away from moisture.

- Ventilation: Ensure adequate airflow to reduce condensation in storage areas.

- Organization: Sort by size and capacity to prevent misapplication and streamline inventory management.

Import/Export Compliance

For international movement of clevis hooks, additional compliance steps apply:

- Customs Documentation: Provide commercial invoices, packing lists, and certificates of conformity.

- Material Declarations: Comply with REACH (EU) or TSCA (USA) if applicable, especially for coated or treated metals.

- Tariff Classification: Use correct HS codes (e.g., 7312.10 for iron or steel hooks) to avoid delays or fines.

Training and Documentation

Personnel involved in handling, using, or inspecting clevis hooks must be trained on:

- Proper attachment and disengagement techniques

- Recognition of wear and damage

- Compliance with site-specific safety protocols

Maintain training records and ensure workers have access to manufacturer instructions and safety data.

Conclusion

Adhering to logistics and compliance standards for clevis hooks ensures workplace safety, regulatory alignment, and asset longevity. By following established guidelines for certification, inspection, handling, and documentation, organizations can minimize risk and maintain high operational standards in lifting and rigging operations.

Conclusion for Sourcing Clevis Hooks:

Sourcing clevis hooks requires a careful evaluation of material quality, load capacity, compliance with industry standards, and supplier reliability. By prioritizing reputable suppliers who provide certified materials, consistent manufacturing processes, and transparent product specifications, organizations can ensure the safety, durability, and performance of clevis hooks in critical lifting and rigging applications. Additionally, considering cost-effectiveness without compromising on quality allows for optimized procurement decisions. Ultimately, a strategic sourcing approach—balancing technical requirements, quality assurance, and supplier partnerships—leads to enhanced operational efficiency and safety across industrial operations.