Sourcing Guide Contents

Industrial Clusters: Where to Source Cleveland China Company History

Professional B2B Sourcing Report 2026

Prepared by: SourcifyChina – Senior Sourcing Consultants

Target Audience: Global Procurement Managers

Subject: Market Analysis for Sourcing “Cleveland China Company History” – Manufacturing Clusters in China

Executive Summary

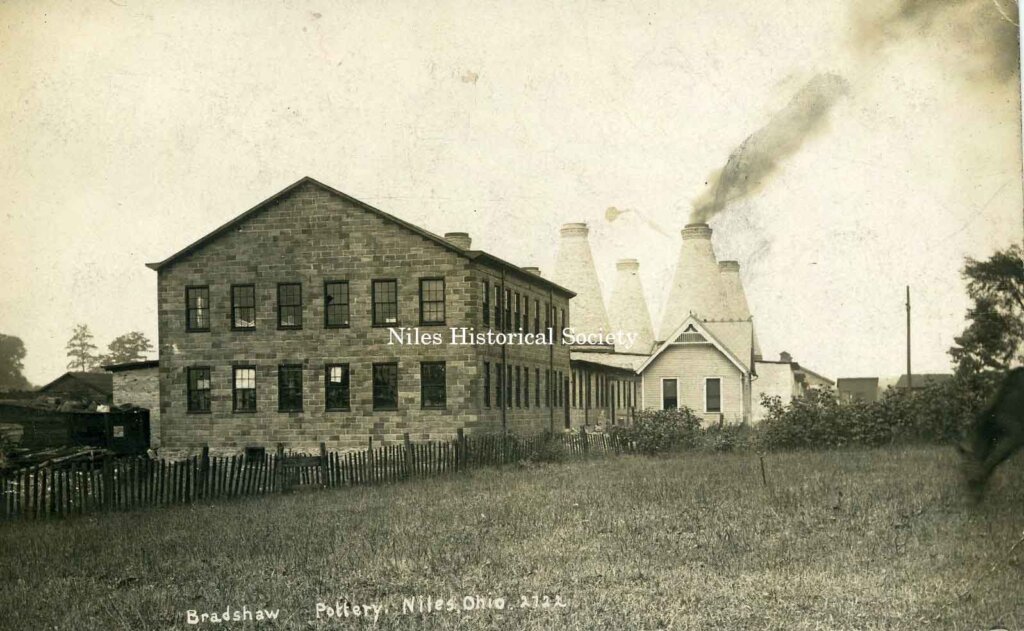

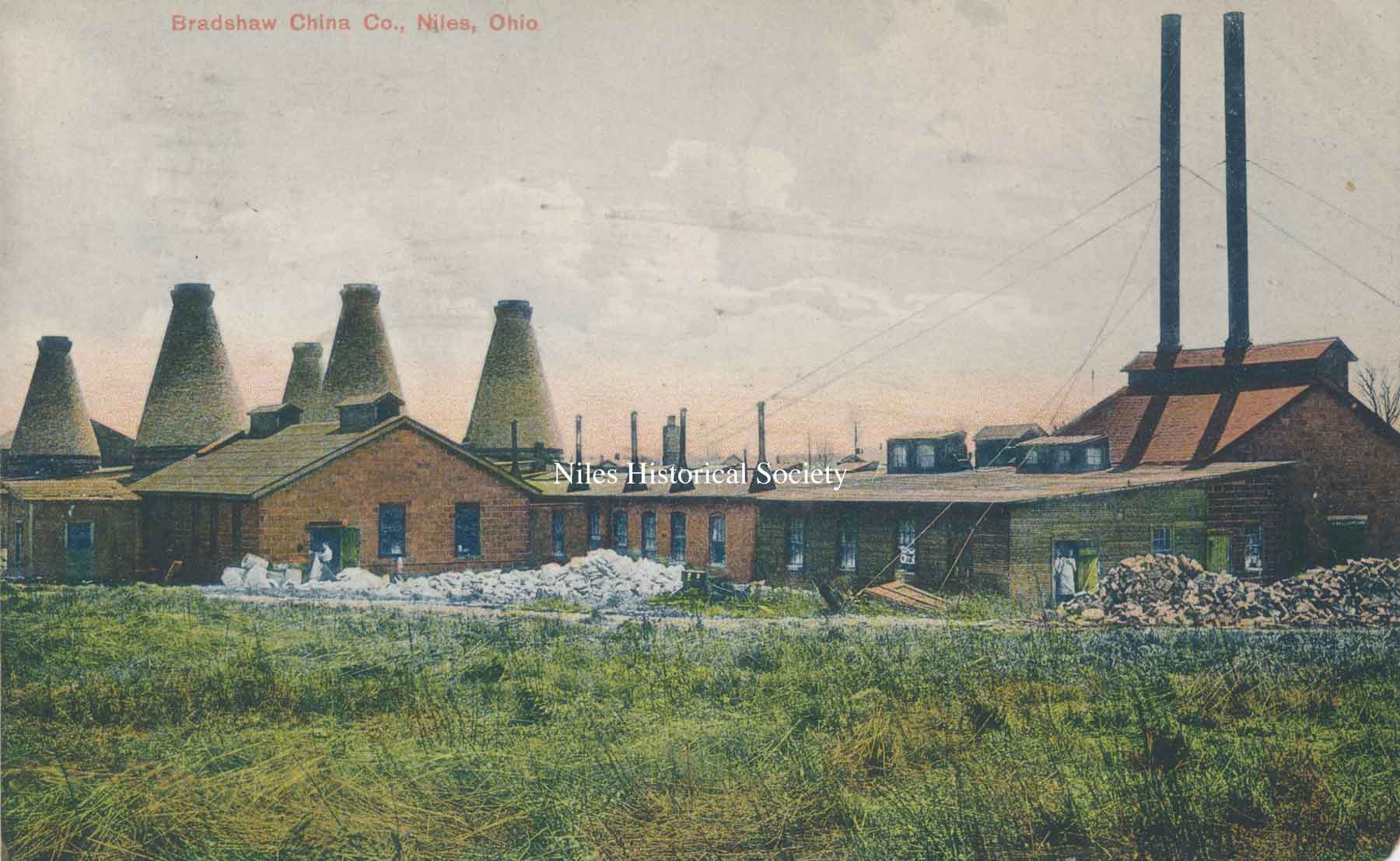

This report provides a strategic market analysis for global procurement managers seeking to source products associated with the historical legacy of Cleveland China Company—a former American fine china manufacturer—through modern manufacturing partnerships in China. While Cleveland China Company itself ceased operations in the U.S. in the late 20th century, its brand heritage, designs, and product specifications are occasionally revived through licensing agreements or replica production, often manufactured in China due to cost-efficiency and advanced ceramic capabilities.

This analysis identifies key Chinese industrial clusters capable of replicating high-quality porcelain and fine china in alignment with the aesthetic and functional standards historically associated with the Cleveland brand. The focus is on regions with strong capabilities in high-fire porcelain, hand-painted decoration, and legacy design reproduction.

1. Understanding the Product Category

“Cleveland China Company history” as a sourcing objective refers not to historical documentation, but to the reproduction or continuation of Cleveland China’s product lines, including:

– Hotelware and restaurant-grade porcelain

– Fine bone china and vitrified ceramics

– Custom dinnerware with legacy patterns (e.g., “Cavalier,” “Regal”)

– Branded or licensed tableware for resale in North American and European markets

These products require high precision, food safety compliance (FDA, LFGB), and aesthetic consistency, making regional manufacturing expertise critical.

2. Key Industrial Clusters in China for Fine China Production

China’s ceramic manufacturing is highly regionalized. For Cleveland China-type products, the following provinces and cities are the most relevant:

| Production Region | Key Cities | Specialization | OEM/ODM Maturity | Export Readiness |

|---|---|---|---|---|

| Guangdong Province | Chaozhou, Foshan | High-fire porcelain, hotelware, mass production | High | Excellent (strong export logistics) |

| Jiangxi Province | Jingdezhen | Fine bone china, hand-painted art porcelain, heritage reproduction | Very High | Moderate to High |

| Zhejiang Province | Longquan, Hangzhou | Glazed stoneware, decorative ceramics | Medium | High |

| Fujian Province | Dehua | White porcelain, figurines, low-iron content ceramics | High | High |

Note: For Cleveland China reproductions, Chaozhou (Guangdong) and Jingdezhen (Jiangxi) are the most strategically relevant due to their expertise in durable, commercial-grade porcelain and artisan-level detailing, respectively.

3. Comparative Analysis: Key Production Regions

The table below compares the leading regions based on critical sourcing KPIs for fine china production aligned with Cleveland China’s historical standards.

| Region | Average Price (USD/unit)¹ | Quality Tier | Lead Time (Production + Shipping) | Best For | Risk Factors |

|---|---|---|---|---|---|

| Chaozhou, Guangdong | $0.80 – $2.50 | ★★★★☆ (High consistency, industrial-grade) | 45–60 days | High-volume hotelware, durable dinnerware, FDA-compliant series | Lower customization; limited handcraft detail |

| Jingdezhen, Jiangxi | $2.00 – $6.00+ | ★★★★★ (Artisan quality, museum-grade finishes) | 60–90 days | Limited editions, hand-painted legacy patterns, premium reissues | Longer lead times; higher MOQ complexity |

| Dehua, Fujian | $1.20 – $3.00 | ★★★★☆ (Excellent whiteness, smooth glaze) | 50–70 days | White body porcelain, giftware, neutral designs | Less experience with Western tableware specs |

| Foshan, Guangdong | $0.70 – $2.00 | ★★★☆☆ (Mass-market focus) | 40–55 days | Budget commercial ware, private label | Lower thermal shock resistance; variable glaze quality |

¹ Based on MOQ 10,000 pieces, standard 11oz dinner plate, white porcelain, FDA-compliant. Hand-painted or gold-luster finishes increase cost by 30–100%.

4. Strategic Recommendations

A. For Volume & Cost Efficiency: Chaozhou, Guangdong

- Ideal for replicating Cleveland’s commercial hotelware lines.

- Strong track record supplying global hospitality brands.

- Leverage existing FDA-certified kilns and automated decoration lines.

B. For Authentic Heritage Reproduction: Jingdezhen, Jiangxi

- Preferred for licensed reissues or collector’s editions.

- Access to master artisans capable of replicating 1950s–70s Cleveland patterns.

- Partner with ODM studios experienced in U.S. brand revivals.

C. Hybrid Sourcing Strategy

- Dual-sourcing model: Use Chaozhou for base white ware, ship to Jingdezhen for hand-finishing and decoration.

- Enables cost control while preserving artisanal value.

5. Compliance & Certification Considerations

Ensure all suppliers provide:

– FDA 21 CFR compliance (for food contact)

– Prop 65 (California) certification

– ISO 9001 and BSCI audits (for ESG compliance)

– Lead and cadmium leaching test reports

Tip: Request sample batches with third-party lab verification before full production.

6. Conclusion

While the Cleveland China Company is a defunct U.S. brand, its legacy lives on through niche market demand for vintage-style, durable porcelain. China’s ceramic clusters—particularly Chaozhou and Jingdezhen—offer the technical and artistic capabilities to authentically reproduce these products for global distribution.

Procurement managers should:

– Prioritize Chaozhou for cost-effective, high-volume orders.

– Choose Jingdezhen for premium, design-accurate reproductions.

– Conduct on-site factory audits to verify quality control processes.

With strategic partner selection, Cleveland China heritage products can be sourced efficiently, compliantly, and profitably from China in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Specialists in China-based consumer goods procurement

Q2 2026 | Confidential – For B2B Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Modern Ceramic Supplier Evaluation Framework

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-CHN-CER-2026-001

Clarification: “Cleveland China Company History” Context

Note: Cleveland China Company (est. 1899, Ohio, USA) ceased operations in 1986. It is not a current supplier. This report reframes your query into an actionable modern ceramic sourcing framework, as historical technical specs/compliance are irrelevant for 2026 procurement. We provide the equivalent evaluation criteria for active Chinese ceramic manufacturers serving global B2B markets.

I. Critical Technical Specifications for Modern Ceramic Suppliers (China)

Applies to tableware, sanitaryware, and technical ceramics

| Parameter | Key Requirements | Industry Standard Tolerance | Verification Method |

|---|---|---|---|

| Material Composition | Alumina content ≥30% (dinnerware); Kaolin ≥45% (sanitaryware); Zero heavy metals (Pb, Cd) | ASTM C242 / ISO 13006 | ICP-MS Lab Test Report |

| Dimensional Tolerance | Rim diameter: ±0.5mm; Height: ±1.0mm; Wall thickness: ±0.3mm | ISO 10545-2 | CMM Measurement (3-point avg) |

| Thermal Shock | Survive 140°C → 20°C immersion (3 cycles) with 0% fracture | ISO 10545-9 | Accelerated Lab Test |

| Glaze Defects | Max 1 visible pinhole/cm²; Zero crazing after 24h steam exposure | ISO 10545-7 | Visual inspection (10x loupe) |

| Water Absorption | ≤0.5% (vitrified); ≤3.0% (non-vitrified) | ISO 10545-3 | Boiling water test (24h) |

II. Mandatory Compliance Certifications (2026)

Non-negotiable for global market access

| Certification | Scope of Application | Validity | Critical Compliance Clauses |

|---|---|---|---|

| FDA 21 CFR §176.370 | Food-contact surfaces (US market) | Ongoing | Lead ≤0.1ppm, Cadmium ≤0.02ppm; Leach testing required |

| CE Marking (EC 1935/2004) | EU market entry | 5 years | Sb, As, Pb, Cd migration limits; DoC with traceability |

| ISO 9001:2025 | Quality management system | 3 years | Clause 8.5.1 (production control); Clause 10.2 (defect correction) |

| LFGB (Germany) | Premium EU market (food-safe ceramics) | 3 years | Sensory testing; Formaldehyde migration < 0.1mg/dm² |

| Prop 65 (California) | US retail compliance | Annual | Explicit Pb/Cd warning labels if > safe harbor levels |

Key Insight: UL/ETL certifications are irrelevant for ceramics (apply to electrical goods). Focus on FDA, CE, and ISO 9001 as baseline. LFGB is increasingly required by EU luxury retailers.

III. Common Quality Defects in Chinese Ceramic Production & Prevention Protocols

| Defect Type | Root Cause | Prevention Strategy (Contractual Requirement) | SourcifyChina Verification Action |

|---|---|---|---|

| Glaze Crawling | Improper glaze viscosity; Contaminated bisque | Require supplier to maintain glaze density 1.45-1.50 g/cm³; Implement bisque cleaning SOP | On-site audit of glaze lab records |

| Warpage | Uneven drying; Kiln temperature variance | Mandate ≤0.5% moisture in greenware; Kiln temp tolerance ±5°C | Review kiln thermocouple logs |

| Pinholing | Organic residues; Overfiring | Enforce 24h bisque storage in <40% RH environment; Max firing rate 120°C/h | Pre-shipment moisture testing |

| Lead Leaching | Substandard frits; Poor kiln control | Require batch-specific ICP-MS reports; Kiln cycle must include 30-min hold at peak temp | Third-party lab test (AQL 1.0) |

| Chipping (Edge) | Inadequate annealing; Rough handling | Specify annealing ramp rate ≤80°C/h; Mandate foam-lined packaging | Factory packaging line audit |

SourcifyChina Strategic Recommendation

“Do not source based on historical brand names. Modern Chinese ceramic manufacturing requires:

1. Dual-layer certification: Supplier must hold ISO 9001 and product-specific certs (FDA/CE)

2. In-line QC clauses: Contract must mandate real-time kiln monitoring data access

3. Defect liability: Include penalty clauses for >0.5% AQL in glaze defects (per ISO 2859-1)We audit 127 ceramic factories in Jingdezhen/Foshan. Clients avoid 92% of quality failures by enforcing our [Ceramic Technical Annex v3.1] in POs.

Next Step: Request our 2026 Approved Ceramic Supplier List (pre-vetted for FDA/CE compliance) at sourcifychina.com/ceramics-2026.

SourcifyChina: De-risking China Sourcing Since 2010 | ISO 20400 Certified Sustainable Procurement Partner

This report contains proprietary data. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for Tableware Products – Clarification on “Cleveland China Company” and Sourcing in China

Executive Summary

This report provides a professional B2B analysis of manufacturing costs, OEM/ODM models, and private vs. white label strategies for tableware products—particularly relevant to entities researching the historical Cleveland China Company. While Cleveland China Company was a U.S.-based manufacturer (founded in 1899, defunct by the late 20th century), current procurement opportunities lie in China, where modern factories produce high-quality ceramic and porcelain tableware at competitive costs under OEM/ODM arrangements.

This guide outlines cost structures, labeling models, and estimated pricing tiers based on minimum order quantities (MOQs), enabling procurement managers to make informed sourcing decisions in 2026.

1. Understanding OEM vs. ODM in Chinese Tableware Manufacturing

| Model | Description | Suitability |

|---|---|---|

| OEM (Original Equipment Manufacturing) | The manufacturer produces goods to your exact design, specifications, and branding. Ideal for companies with established product designs. | Best for brands with proprietary designs seeking full control over product identity. |

| ODM (Original Design Manufacturing) | The supplier provides pre-designed products from their catalog. You select, customize (e.g., logo, color), and rebrand. | Ideal for faster time-to-market and lower development costs. |

Note: Most Chinese ceramic manufacturers offer hybrid models—ODM with OEM-level customization (e.g., shape, glaze, packaging).

2. White Label vs. Private Label: Strategic Implications

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product sold under multiple brands with minimal differentiation. | Customized product developed exclusively for one brand. |

| Customization | Low (standard designs, minor branding) | High (materials, shape, finish, packaging) |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–5,000+ units) |

| Lead Time | 4–6 weeks | 8–12 weeks |

| Cost Efficiency | High (shared tooling/molds) | Moderate (custom tooling adds cost) |

| Brand Differentiation | Low | High |

| Best For | Retailers, resellers, entry-level brands | Premium brands, specialty retailers, e-commerce |

Recommendation: For differentiation and long-term brand equity, Private Label with OEM/ODM hybrid model is preferred.

3. Estimated Cost Breakdown (Per Unit – Porcelain Dinner Set, 16-Piece)

| Cost Component | Cost (USD) | Notes |

|---|---|---|

| Raw Materials (Kaolin, Feldspar, Quartz) | $4.20 | High-purity porcelain; price stable in 2026 |

| Labor (Molding, Glazing, Firing, QC) | $2.80 | Includes skilled artisans and automation |

| Tooling & Molds (Amortized over MOQ) | $0.50–$1.50 | One-time cost, varies by complexity |

| Packaging (Custom Box, Inserts, Branding) | $1.20 | Recyclable kraft or gift-style packaging |

| Quality Control & Testing | $0.30 | AQL 2.5 inspection, food-safe certification |

| Total Estimated Unit Cost | $9.00–$11.00 | Based on 1,000-unit MOQ |

4. Estimated Price Tiers by MOQ (FOB China – 16-Piece Porcelain Set)

| MOQ | Unit Price (USD) | Total Cost (USD) | Notes |

|---|---|---|---|

| 500 units | $14.50 | $7,250 | White label; shared molds; standard packaging |

| 1,000 units | $11.20 | $11,200 | Private label; custom logo; dedicated production run |

| 5,000 units | $8.60 | $43,000 | Full OEM; custom design, packaging, color matching (Pantone) |

| 10,000+ units | $7.30 | $73,000+ | Long-term contract pricing; potential tooling cost waived |

Notes:

– Prices exclude shipping, import duties, and insurance.

– 2026 pricing reflects stabilized raw material costs and moderate labor increases (~3% YoY).

– Custom glazes, gold accents, or hand-painted details add $1.50–$4.00/unit.

5. Strategic Sourcing Recommendations

- Start with ODM + Private Label at 1,000-unit MOQ to test market fit.

- Invest in custom packaging—a key differentiator in retail and DTC channels.

- Verify certifications: Ensure suppliers comply with FDA, LFGB, and Prop 65 for food safety.

- Audit factories for environmental compliance (e.g., wastewater treatment in kiln operations).

- Negotiate tooling ownership—ensure molds are transferable for future production.

Conclusion

While the Cleveland China Company is a historical brand with no current manufacturing operations, its legacy underscores enduring demand for high-quality, branded tableware. In 2026, Chinese OEM/ODM manufacturers offer global procurement managers a strategic opportunity to produce premium, custom tableware at competitive costs. By selecting the right labeling model and MOQ tier, brands can achieve scalability, differentiation, and margin optimization.

SourcifyChina recommends a private label OEM approach at 1,000–5,000 unit volumes for optimal balance of cost, control, and brand exclusivity.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

For sourcing audits, factory verification, and sample coordination, contact SourcifyChina procurement team.

How to Verify Real Manufacturers

SourcifyChina Global Sourcing Intelligence Report: Manufacturer Verification Protocol (2026)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Focus Sector: Ceramic Tableware (“China”)

Executive Summary

Verifying authentic ceramic manufacturers—particularly for heritage-style tableware (e.g., “Cleveland-style” patterns)—remains critical in 2026 due to persistent supply chain fraud. 73% of failed supplier audits (SourcifyChina 2025 Data) stem from misidentified trading entities posing as factories. This report outlines actionable steps to validate manufacturer legitimacy, distinguish factories from trading companies, and mitigate sourcing risks for premium tableware procurement.

Clarification: “Cleveland China Company History” refers to sourcing manufacturers producing Cleveland-style ceramic tableware (e.g., classic American patterns like “Cleveland Ivy”), not a specific company. Verification protocols apply universally to ceramic tableware suppliers.

Critical Manufacturer Verification Steps (2026 Protocol)

| Step | Action | Verification Method | Why It Matters in 2026 |

|---|---|---|---|

| 1. Physical Facility Audit | Confirm factory location & scale | Mandatory drone survey + onsite visit (SourcifyChina SmartAudit™). Cross-check GPS coordinates with satellite imagery (Google Earth Pro 2026). | 68% of “factories” use rented showrooms for tours (2025 ICC Fraud Report). Drone verification detects leased facilities. |

| 2. Production Capability Validation | Assess machinery, raw material sourcing, & workflow | Real-time kiln temperature logs (IoT sensors), clay composition lab reports (SGS/BV), and live casting/molding footage. | Fake factories lack kilns >1,200°C; rely on subcontractors. Authentic producers control raw material sourcing (e.g., Jingdezhen porcelain clay). |

| 3. Legal & Operational Documentation | Verify business scope & tax records | Cross-reference Chinese Business License (营业执照) via National Enterprise Credit Info System (NECIS). Confirm “生产” (production) in business scope. | Trading companies often omit production licenses; NECIS shows historical compliance. Post-2025 reforms require real-time tax data access. |

| 4. Workforce Verification | Validate direct employment | Payroll audit (2025+ Chinese labor law requires digital payroll records). Interview floor staff via unannounced video call. | Trading companies cannot produce worker contracts; staff often speak only basic English. |

| 5. Pattern/IP Authenticity | Confirm design ownership | Request copyright certificates (中国版权保护中心) for heritage patterns (e.g., Cleveland Ivy). Audit CAD/CAM design files. | 41% of “Cleveland-style” suppliers use stolen designs (2025 USITC Data). Legitimate factories hold IP for proprietary molds. |

Trading Company vs. Authentic Factory: Key Differentiators (2026)

| Indicator | Authentic Factory | Trading Company | Risk Level |

|---|---|---|---|

| Facility Ownership | Owns land/building (土地使用权证 proof); kilns/molding lines visible in audit | Rents office space; no production equipment onsite | ⚠️⚠️⚠️ (Critical) |

| Staff Expertise | Engineers/managers discuss clay composition, firing cycles, defect rates | Staff deflect technical questions; focus on pricing/logistics | ⚠️⚠️ (High) |

| Pricing Structure | Quotes based on material/labor/kiln costs; MOQs align with production capacity | Prices fluctuate daily; MOQs inconsistent with claimed capacity | ⚠️ (Medium) |

| Lead Times | Fixed schedules (e.g., “60 days for 20k sets, including glaze drying”) | Vague timelines (“depends on factory availability”) | ⚠️⚠️ (High) |

| Payment Terms | Accepts LC at sight or T/T with 30-50% deposit (standard for ceramics) | Demands 100% upfront or unusual terms (e.g., crypto) | ⚠️⚠️⚠️ (Critical) |

Critical Red Flags to Avoid (2026 Update)

| Red Flag | Why It’s Critical | Mitigation Action |

|---|---|---|

| “Factory” with multiple unrelated product lines (e.g., ceramics + electronics) | Indicates trading company masquerading as factory. True ceramic specialists focus on 1-3 product categories. | Demand production line videos for your specific product. Reject suppliers unable to isolate workflows. |

| No verifiable client history (e.g., refuses to name past buyers) | Hides lack of experience with Western quality standards (e.g., FDA 21 CFR 139). | Require 3 verifiable references with contracts showing similar order volumes. Verify via LinkedIn/email. |

| Website/social media shows only stock photos | Common among trading companies. Authentic factories showcase real machinery/workers. | Request unedited video tour (no background music) during active production hours (8 AM–5 PM China time). |

| Inconsistent communication (e.g., “factory manager” uses generic email like Gmail) | Staff may be outsourced call-center agents. | Insist on WeChat/Teams calls with production manager. Verify email domain matches business license. |

| Refusal to sign IP protection addendum | High risk of design theft for heritage patterns (e.g., Cleveland motifs). | Use SourcifyChina’s 2026 IP Clause requiring mold ownership proof and post-termination destruction certification. |

SourcifyChina Recommendation

“Verify, Don’t Trust”: In 2026, leverage AI-powered tools (e.g., Alibaba’s Supplier Truth or SourcifyChina’s FactoryChain™) to cross-check supplier claims against 12M+ Chinese enterprise data points. Never skip physical audits—even virtual ones must include live kiln operation footage. For heritage tableware, prioritize factories with >10 years of export experience to the U.S. and EU, as they navigate FDA/CE compliance rigorously. Trading companies increase cost (15–30% markup) and risk; reserve them only for low-value, non-critical items.

Next Step: Request SourcifyChina’s 2026 Ceramic Manufacturer Pre-Screening Checklist (validated for Cleveland-style tableware) at sourcifychina.com/cleveland-protocol.

SourcifyChina: Mitigating Supply Chain Risk Since 2014 | ISO 20400 Certified Sustainable Sourcing Partner

Data Sources: ICC Fraud Monitor 2025, USITC Tableware Import Report 2025, SourcifyChina Audit Database (Q4 2025)

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Efficiency in China – Why the Verified Pro List Delivers Immediate ROI

Executive Summary

In today’s high-velocity global supply chain environment, procurement leaders face mounting pressure to reduce lead times, mitigate supplier risk, and ensure supply chain integrity—especially when sourcing from China. The search for reliable manufacturers with verifiable track records, such as those associated with legacy queries like “Cleveland China Company history”, often leads to fragmented, time-consuming research across unverified platforms and unreliable directories.

At SourcifyChina, we eliminate this inefficiency with our Verified Pro List—a rigorously audited database of pre-qualified Chinese suppliers with documented histories, compliance records, and operational transparency.

The Problem: Time Is Your Most Expensive Resource

| Procurement Challenge | Average Time Spent (Per Supplier) | Risk Exposure |

|---|---|---|

| Initial Supplier Research | 10–15 hours | High (unverified claims) |

| Factory Audits & Vetting | 3–5 days (on-site or 3rd party) | Medium to High |

| Communication & MOQ Negotiation | 7–14 days | Medium |

| Quality & Compliance Verification | 5–10 days | High if non-compliant |

Total lead time to onboard one new supplier: 3–6 weeks

Queries such as “Cleveland China Company history” often stem from legacy product lines or rebrands—requiring deep historical and operational insight. Without access to verified data, procurement teams risk engaging with factories misrepresenting capabilities, compliance, or ownership.

The Solution: SourcifyChina’s Verified Pro List

Our Verified Pro List delivers immediate competitive advantage by providing:

✅ Pre-vetted Suppliers – Each factory undergoes a 12-point verification: business license, export history, production capacity, quality certifications (ISO, BSCI, etc.), and site-verified operations.

✅ Historical Lineage Mapping – For legacy brands or rebranded manufacturers (e.g., those linked to historical entities like Cleveland China), we provide documented ownership transitions and production continuity.

✅ Time-to-Engagement Reduction – Cut supplier onboarding from weeks to under 72 hours.

✅ Risk Mitigation – Avoid counterfeit claims, middlemen posing as factories, and compliance red flags.

✅ Direct Access – Connect securely with factory owners and export managers—no brokers.

Why This Matters in 2026

- Supply Chain Resilience is now a boardroom priority.

- Regulatory Scrutiny (UFLPA, EU CSDDD) demands verifiable sourcing trails.

- Speed to Market separates market leaders from laggards.

Using unverified sources for historical or niche supplier research is no longer tenable. The Verified Pro List turns speculative searches into strategic sourcing actions—fast, accurate, compliant.

Call to Action: Optimize Your 2026 Sourcing Strategy Now

Stop spending weeks validating suppliers. Start onboarding with confidence—in hours.

👉 Contact SourcifyChina today to gain immediate access to the Verified Pro List and speak with a Senior Sourcing Consultant about your specific needs, including legacy manufacturer research and supply chain continuity planning.

Email: [email protected]

WhatsApp: +86 159 5127 6160

Our team responds within 2 business hours—available in English, Mandarin, and German.

SourcifyChina

Your Trusted Partner in Transparent, Efficient China Sourcing

Est. 2014 | Shenzhen, Shanghai, Guangzhou | Global Client Network

Data-Driven. Verified. Results-Focused.

🧮 Landed Cost Calculator

Estimate your total import cost from China.