The global automotive protective film market is experiencing robust growth, driven by increasing consumer demand for vehicle aesthetics, resale value preservation, and protection against environmental and mechanical damage. According to Grand View Research, the global car wrapping film market was valued at USD 5.4 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 8.7% from 2024 to 2030. This surge is fueled by rising adoption of clear protective wraps (CPW), also known as paint protection films (PPF), particularly in premium and luxury vehicle segments. Technological advancements—such as self-healing properties, enhanced durability, and improved optical clarity—are further accelerating market penetration. With North America and Europe leading adoption due to high vehicle ownership and awareness, and Asia-Pacific emerging as a fast-growing region, manufacturers are scaling innovation and production capacity. As demand intensifies, a select group of companies has risen to the forefront, setting industry benchmarks in clarity, resilience, and adhesion technology. Here’s a data-driven look at the top 10 clear protective wrap for cars manufacturers shaping this dynamic landscape.

Top 10 Clear Protective Wrap For Cars Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

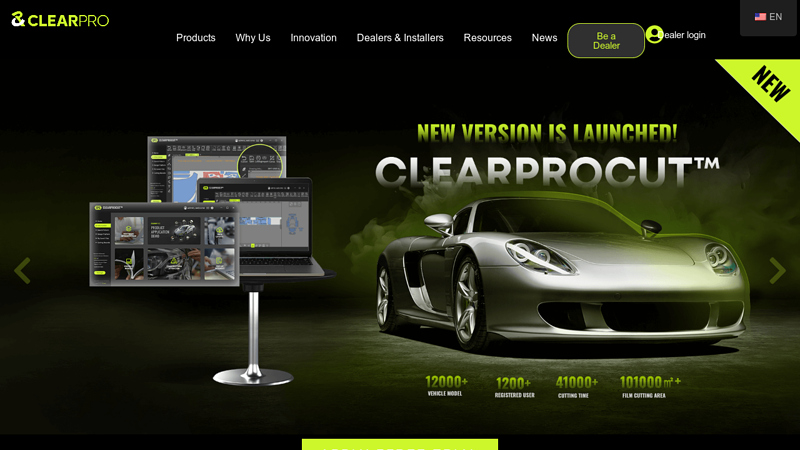

#1 ClearPro

Domain Est. 1998

Website: clearpro.com

Key Highlights: Using patented coating and adhesive technologies, our paint protection films protect the car from the headlamp to rear bumper while maintaining its glossy ……

#2 Top Paint Protection Film Manufacturer

Domain Est. 2023

Website: pureprotectionfilm.com

Key Highlights: Pure PPF is the Leading PPF Film Brand and Distributor of Automotive PPF Film Wraps in the USA. View Our Variety of Premium Colored and Clear PPF Films ……

#3 Scotchgard™ Paint Protection Film Pro Series

Domain Est. 1988

Website: 3m.com

Key Highlights: 3M™ Scotchgard™ Paint Protection Film Pro Series delivers superior protection to automotive surfaces against scratches, chips and weathering. Our Pro Series ……

#4 Paint Protection Film

Domain Est. 1993

Website: graphics.averydennison.com

Key Highlights: Avery Dennison Paint Protection Film protects painted vehicle surfaces from stone chips, bug splatters and scratches. It can be applied on the most exposed ……

#5 XPEL

Domain Est. 1999

Website: xpel.com

Key Highlights: XPEL’s self-healing paint protection film is designed to keep your vehicle looking brand new by protecting against rock chips, scratches, and scuffs….

#6 Paint Protection Film Ultra

Domain Est. 2003

Website: suntekfilms.com

Key Highlights: SunTek® PPF Ultra is scientifically formulated to help maintain the beauty and integrity of vehicle finishes—for many years in all kinds of weather….

#7 CLEAR PAINT PROTECTION FILM

Domain Est. 2012

#8 STEK USA: Hydrophobic Paint Protection Film

Domain Est. 2016

Website: stek-usa.com

Key Highlights: We offer paint protection films with hydrophobic and self-healing properties that boast extreme clarity and depth in a variety of finishes, colors, and ……

#9 Carlas USA

Domain Est. 2023

Website: carlasusa.com

Key Highlights: 30-day returnsDiscover the superior quality of our Elastic Polyurethane TPU car wraps, delivering a flawless paint-like finish without waviness or ‘orange peel’ texture….

#10 PPF Products

Website: uppf-usa.com

Key Highlights: UPPF’s advanced Paint Protection Film (PPF) delivers the industry’s leading combination of clarity, durability, and self-healing power….

Expert Sourcing Insights for Clear Protective Wrap For Cars

2026 Market Trends for Clear Protective Wrap for Cars: Key H2-Level Insights

The global market for Clear Protective Wrap for Cars (also known as Paint Protection Film – PPF) is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and broader automotive industry dynamics. Here are the critical H2-level trends shaping the market:

H2: Rising Consumer Demand for Vehicle Preservation and Aesthetic Enhancement

Consumers are increasingly viewing their vehicles as long-term investments, not just transportation. This mindset shift fuels demand for PPF to protect against scratches, stone chips, UV damage, and environmental contaminants, preserving resale value. Simultaneously, the desire for a pristine, “like-new” appearance drives adoption, especially among owners of premium, electric (EVs), and custom vehicles. The trend towards DIY culture and social media influence also amplifies visibility and desire for flawless vehicle aesthetics.

H2: Technological Advancements in Film Performance and Application

Innovation is a core market driver. By 2026, expect wider availability of PPFs featuring:

* Enhanced Self-Healing: Faster and more effective repair of swirl marks and minor scratches using heat (sunlight or warm water).

* Improved Hydrophobic & Oleophobic Properties: Superior water and oil beading for easier cleaning and enhanced gloss.

* Advanced Clarity & Gloss: Virtually invisible films with higher optical clarity and long-lasting high gloss finishes.

* Easier Installation: Thinner, more conformable films with improved adhesives (e.g., pressure-activated) reducing installation time, cost, and the risk of lifting or yellowing. Pre-cut “kits” for specific models will become more precise and comprehensive.

H2: Expansion of the Electric Vehicle (EV) Market as a Key Growth Segment

EVs are a major catalyst. Their high initial cost, smooth paint finishes (often more susceptible to damage), and association with premium technology make PPF a natural fit. EV owners prioritize protecting their significant investment and maintaining the vehicle’s futuristic aesthetics. The rapid growth of major EV manufacturers (Tesla, Rivian, Lucid, traditional OEMs) will significantly expand the addressable market for PPF, particularly on hoods, front bumpers, and wheel arches prone to stone chips.

H2: Growth of Premiumization and Full-Vehicle Coverage

While partial front-end protection remains popular, there’s a clear trend towards higher levels of coverage. “Full front,” “full wrap,” and even “full body” applications are becoming more common, especially in premium and luxury segments. Consumers are willing to pay more for comprehensive protection, viewing it as essential insurance. This shift boosts average revenue per installation (ARPU) for installers and distributors.

H2: Increasing Competition and Market Fragmentation

The market is attracting new players beyond traditional leaders (3M, XPEL, STEK). More regional and private-label brands are entering, offering competitive pricing. This intensifies competition, driving innovation but also potentially pressuring margins. Differentiation will increasingly rely on brand reputation, installer certification programs, warranty strength, and unique film properties.

H2: Emphasis on Installer Expertise and Certification Programs

As films become more advanced and consumers demand flawless results, the role of the installer is paramount. Reputable PPF brands will heavily invest in and promote rigorous installer certification programs. Consumer awareness of the importance of proper installation (preventing bubbles, lifting, damage) will grow, making certified installers a preferred choice and a key sales channel differentiator.

H2: Sustainability Concerns and Material Innovation

Environmental awareness is rising. While PPF offers long-term protection, concerns about the environmental impact of film production, installation (waste), and eventual disposal (non-biodegradable) are emerging. By 2026, expect increased R&D focus on:

* More Sustainable Materials: Development of films using bio-based polymers or recycled content.

* Improved Recyclability: Initiatives and technologies to facilitate end-of-life recycling of PPF.

* Reduced VOC Adhesives: Healthier installation environments. Brands emphasizing sustainability will gain a competitive edge with eco-conscious consumers.

H2: Integration with OEM and Aftermarket Distribution Channels

PPF is moving beyond purely aftermarket specialist shops:

* OEM Partnerships: Potential for factory-installed PPF options on high-end or EV models.

* Dealership Integration: More dealerships offering PPF as a value-added accessory during vehicle purchase.

* Online DTC Models: Growth of direct-to-consumer sales of DIY kits, competing with professional installers but expanding market reach. Omnichannel strategies will be crucial.

Overall, the 2026 Clear Protective Wrap for Cars market will be characterized by sophisticated products meeting heightened consumer expectations for protection and perfection, fueled by the EV revolution and underpinned by advancing technology and evolving distribution. Success will depend on innovation, quality, installer partnerships, and addressing sustainability.

Common Pitfalls When Sourcing Clear Protective Wrap for Cars (Quality & IP)

Sourcing clear protective wrap—also known as paint protection film (PPF) or clear bra—for cars involves significant risks if quality and intellectual property (IP) considerations are overlooked. Failing to address these pitfalls can lead to poor product performance, customer dissatisfaction, legal complications, and reputational damage.

Poor Material Quality and Performance

One of the most frequent issues is receiving wraps made from substandard materials. Low-quality films may yellow, crack, or delaminate within months due to inadequate UV resistance or poor adhesive formulation. These films often lack self-healing properties and scratch resistance, which are hallmarks of premium PPF. Buyers may unknowingly purchase products with inconsistent thickness or inferior clarity, leading to visible seams, hazing, or reduced vehicle aesthetics.

Lack of Authentic Certification and Testing

Many suppliers claim compliance with industry standards (e.g., ISO, ASTM, or OEM specifications) without providing verifiable test reports or third-party certifications. Without proper documentation, it’s difficult to confirm whether the film meets durability, clarity, and elongation requirements. This lack of transparency increases the risk of sourcing counterfeit or non-compliant materials.

Intellectual Property Infringement Risks

Sourcing PPF from unauthorized manufacturers or suppliers increases the risk of IP violations. Reputable brands like 3M, XPEL, and STEK invest heavily in R&D and hold patents on film structures, adhesive technologies, and manufacturing processes. Purchasing knock-offs or unlicensed copies—even if labeled generically—can expose buyers to legal liability, including cease-and-desist orders, fines, or import seizures, especially in regulated markets.

Misrepresentation of Product Origin and Branding

Some suppliers falsely advertise their films as “equivalent to” or “OEM-grade” without legal rights to make such claims. Others rebrand generic films with misleading names or packaging to mimic well-known brands. This not only undermines brand integrity but also misleads end customers, potentially damaging trust and inviting legal scrutiny.

Inconsistent Batch-to-Batch Quality

Low-cost manufacturers may lack strict quality control, resulting in variations in gloss level, thickness, or adhesive strength across production batches. This inconsistency makes installation difficult and affects long-term performance, leading to customer complaints and increased warranty claims.

Inadequate Warranty and Support

Many off-brand or unlicensed films come with weak or non-transferable warranties, or none at all. In contrast, premium PPFs include comprehensive warranties covering yellowing, delamination, and bubbling—backed by manufacturer support. Sourcing without warranty coverage shifts all risk to the buyer and limits recourse in case of failure.

Supply Chain and Compliance Gaps

Unverified suppliers may source raw materials from regions with lax environmental and labor regulations, raising ethical and compliance concerns. Additionally, films may contain restricted substances (e.g., phthalates, heavy metals) that violate REACH, RoHS, or other regional regulations, jeopardizing market access.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, request material data sheets and test reports, verify IP rights, and prioritize partners with transparent sourcing and proven quality control.

Logistics & Compliance Guide for Clear Protective Wrap For Cars

Product Classification and HS Code

Clear protective wrap for cars, also known as paint protection film (PPF) or clear bra, typically falls under specific Harmonized System (HS) codes for international shipping. The most applicable HS code is 3919.10, which covers self-adhesive plates, sheets, film, foil, tape, and other flat shapes of plastics, non-cellular and not reinforced, laminated, or supported. Accurate classification is essential for customs clearance, duty calculation, and regulatory compliance across borders.

Import/Export Regulations

When shipping clear protective wrap internationally, ensure compliance with the import and export regulations of both origin and destination countries. Key considerations include:

– Customs Documentation: Prepare commercial invoices, packing lists, and certificates of origin.

– Restricted Substances: Verify that the film does not contain hazardous or restricted chemicals (e.g., certain plasticizers or flame retardants) as regulated under REACH (EU), TSCA (USA), or other regional frameworks.

– Labeling Requirements: Product labels must include relevant safety information, batch numbers, and compliance markings (e.g., CE marking in Europe if applicable).

Packaging and Shipping Requirements

Proper packaging ensures the film arrives undamaged and meets carrier standards:

– Roll Protection: Wrap film rolls in durable outer packaging (e.g., cardboard tubes and shrink-wrapped ends) to prevent edge damage and moisture exposure.

– Palletization: Secure multiple rolls on pallets using stretch wrap and corner boards. Label pallets with handling instructions (e.g., “Fragile,” “This Side Up”).

– Shipping Modes: Choose appropriate freight methods—air for urgent orders, sea for bulk shipments—based on lead times and cost.

– Temperature Control: Avoid extreme temperatures during transit, as high heat can cause adhesive degradation or film warping.

Storage Conditions

Maintain optimal storage conditions to preserve product integrity:

– Temperature: Store between 10°C and 30°C (50°F–86°F).

– Humidity: Keep relative humidity below 65% to prevent adhesive issues.

– Light Exposure: Protect from direct sunlight and UV radiation, which may degrade film properties over time.

– Shelf Life: Observe manufacturer-recommended shelf life (typically 1–2 years); rotate stock using FIFO (First In, First Out) principles.

Regulatory Compliance

Ensure adherence to regional and international regulations:

– REACH & RoHS (EU): Confirm that the film is free from SVHCs (Substances of Very High Concern) and restricted heavy metals.

– EPA & DOT (USA): Comply with hazardous materials regulations if shipping in bulk; most PPFs are non-hazardous but verify with SDS (Safety Data Sheet).

– Country-Specific Approvals: Some markets may require certification (e.g., INMETRO in Brazil, KC in South Korea). Verify requirements before entry.

Documentation and Traceability

Maintain comprehensive records for compliance and quality control:

– Batch Tracking: Assign unique batch/lot numbers for traceability in case of recalls or quality issues.

– Certificates of Conformance (CoC): Provide CoC with shipments to confirm product specifications and regulatory alignment.

– Safety Data Sheets (SDS): Supply updated SDS compliant with GHS standards for workplace safety and emergency response.

Environmental and Disposal Compliance

Follow environmental guidelines for waste management:

– Recyclability: Inform customers if the film or packaging is recyclable; some polyurethane-based films may require specialized recycling.

– Waste Disposal: Advise proper disposal methods in line with local regulations—do not incinerate without proper filtration due to potential emissions.

Carrier and Insurance Considerations

- Freight Partner Selection: Work with carriers experienced in handling sensitive materials.

- Cargo Insurance: Insure shipments against damage, loss, or delay, especially for high-value or international deliveries.

Adhering to this logistics and compliance guide ensures smooth distribution, minimizes regulatory risks, and maintains the quality of clear protective wrap for automotive applications.

In conclusion, sourcing a clear protective wrap for cars requires careful consideration of several key factors to ensure optimal performance, durability, and value. High-quality materials such as thermoplastic polyurethane (TPU) offer superior resistance to scratches, UV rays, and environmental contaminants, preserving the vehicle’s paint and resale value. It is essential to choose a reputable supplier that provides authentic, warrantied products and consistent thickness and clarity standards. Additionally, ease of installation, self-healing properties, and hydrophobic features can significantly enhance the wrap’s effectiveness and long-term benefits. By evaluating cost against quality, verifying compliance with industry standards, and considering professional installation options, consumers and businesses can make informed decisions that protect their vehicles while maintaining a pristine, factory-like finish.