The global acrylic sheet market, which includes clear Perspex panels, was valued at USD 7.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2030, according to Grand View Research. Rising demand across construction, retail displays, transportation, and safety barriers—accelerated by post-pandemic hygiene infrastructure needs—has driven significant expansion in the Perspex manufacturing sector. Additionally, Mordor Intelligence forecasts steady regional growth, particularly in Asia-Pacific and North America, fueled by urbanization and increased investments in sustainable, lightweight materials. As demand for high-clarity, impact-resistant transparent sheets intensifies, manufacturers with advanced extrusion technologies, rigorous quality control, and scalable production capacity are emerging as key market players. Below is a data-informed analysis of the top nine clear Perspex panel manufacturers shaping this growing landscape.

Top 9 Clear Perspex Panels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Clear Acrylic Plexiglass Sheets

Domain Est. 1997

Website: acplasticsinc.com

Key Highlights: $30 deliveryBuy clear acrylic sheets online at A&C Plastics Inc. Our clear plexiglass acrylic sheets are ideal for POP displays, store fixtures, glazing, ……

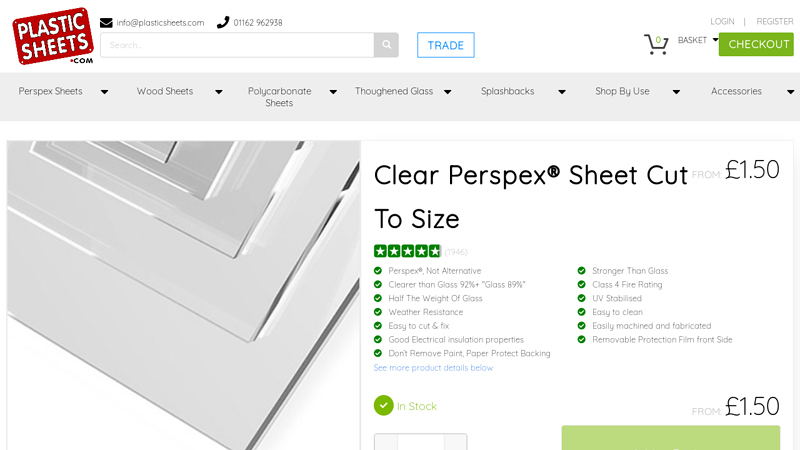

#2 Clear Perspex® Sheet, Disc, Shape Cut To Size

Domain Est. 1999

Website: plasticsheets.com

Key Highlights: 30-day returnsAll Perspex® sheeting comes with a 10-year manufacturer’s guarantee. Cut to size clear plastic panels are available in many thickness options and are ……

#3 Bemis Manufacturing

Website: bemismfg.com

Key Highlights: We are a leading toilet seat manufacturer that owns respected brands including Bemis, Bio Bidet by Bemis and Mayfair by Bemis. CONSUMERS · PROFESSIONALS ……

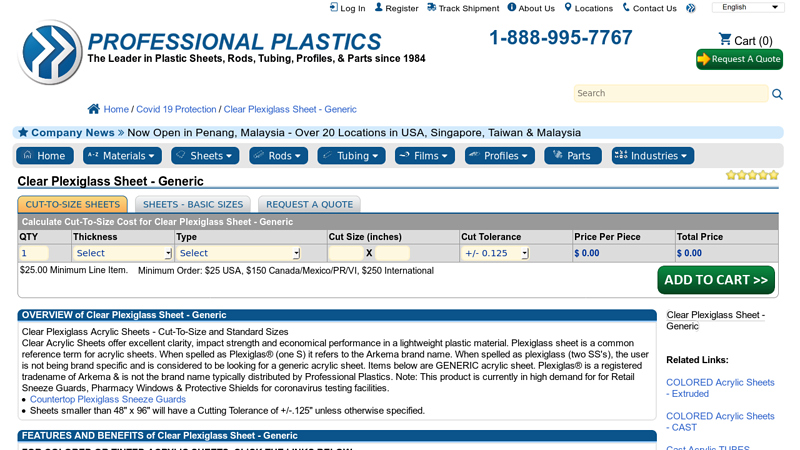

#4 Clear Plexiglass Sheet

Domain Est. 1997

#5 Clear Cast Acrylic Sheets

Domain Est. 1997

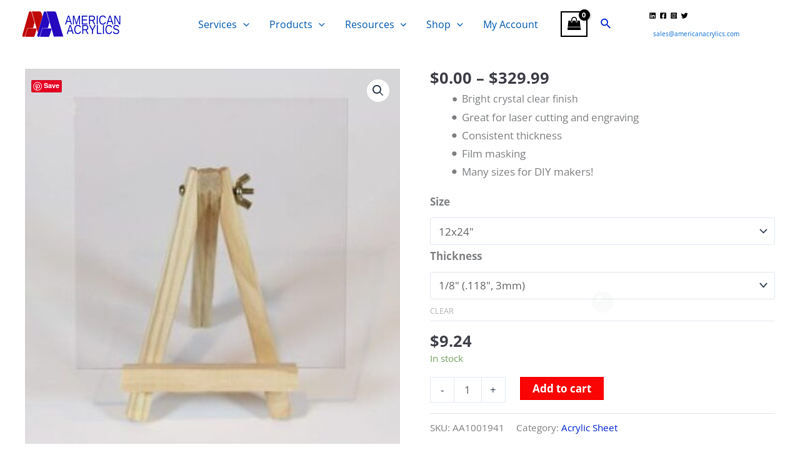

#6 Clear Acrylic Sheet 0001

Domain Est. 1997

#7 Manufacturing Plastics, Chemicals & More

Domain Est. 1997

Website: primexplastics.com

Key Highlights: Primex Plastics is a worldwide leader in trading, distribution, marketing, and manufacturing, primarily of chemicals, plastics, and related products….

#8 PERSPEX® XT CLEAR (1067)

Domain Est. 2010

Website: display.3acomposites.com

Key Highlights: PERSPEX® XT clear transparent acrylic sheets. The material is easy to process, can be used for a wide range of different indoor and outdoor applications….

#9 ASTARIGLAS®

Domain Est. 2016

Website: astariglas.com

Key Highlights: Produce cast acrylic sheet, recycle cast acrylic sheet and extruded acrylic sheet with various thicknesses, sizes, and colors….

Expert Sourcing Insights for Clear Perspex Panels

H2: Projected Market Trends for Clear Perspex Panels in 2026

By 2026, the global market for clear Perspex (acrylic) panels is expected to experience steady growth, driven by evolving consumer preferences, sustainability imperatives, and technological advancements. Key trends shaping the sector include:

1. Sustained Demand in Safety and Hygiene Applications:

Post-pandemic habits will continue to influence demand. Clear Perspex panels will remain essential in healthcare, retail, education, and hospitality as physical barriers for infection control. The emphasis on hygiene and visible safety measures will support long-term installations in high-traffic public spaces.

2. Growth in Architectural and Design Innovation:

Architects and interior designers will increasingly favor Perspex for its versatility, light transmission, and modern aesthetic. Expect wider adoption in residential and commercial projects for skylights, partitions, balustrades, and decorative elements. Demand for large-format, custom-cut, and curved panels will rise to meet design-specific requirements.

3. Sustainability and Circular Economy Pressure:

Environmental concerns will drive demand for recyclable and bio-based acrylic alternatives. Manufacturers investing in closed-loop recycling systems and transparent sourcing will gain a competitive edge. Regulatory pressures in regions like the EU (e.g., Green Deal) may favor sustainable materials, pushing the industry toward greener production methods.

4. Technological Integration and Smart Features:

Innovation will focus on functional enhancements. Integration with touch-sensitive surfaces, anti-microbial coatings, anti-fog treatments, and UV-blocking properties will expand use cases. Smart acrylic panels with embedded sensors or display capabilities could emerge in high-end retail and tech environments.

5. Supply Chain Resilience and Regionalization:

Ongoing geopolitical and logistical challenges will encourage regional production and sourcing. Companies may diversify suppliers or invest in local manufacturing to reduce dependency on single markets and mitigate disruptions, particularly in North America and Europe.

6. Competitive Pricing and Material Substitution:

While demand grows, competition from alternative transparent materials like polycarbonate (for impact resistance) and glass (for premium aesthetics) will persist. Price volatility in raw materials (e.g., propylene) may pressure margins, pushing innovation in cost-efficient production.

Conclusion:

The 2026 market for clear Perspex panels will be defined by a balance between functional utility and aesthetic innovation, underpinned by sustainability and supply chain adaptability. Companies that prioritize eco-friendly practices, customization, and value-added features are best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing Clear Perspex Panels (Quality and Intellectual Property)

Sourcing clear Perspex® panels—especially for high-end or precision applications—requires attention to both material quality and intellectual property (IP) considerations. Falling into common pitfalls can result in substandard performance, legal risks, or supply chain disruptions. Below are key issues to watch for:

Confusing Generic Acrylic with Genuine Perspex®

Perspex® is a registered trademark of Lucite International for a specific brand of acrylic (polymethyl methacrylate or PMMA). Many suppliers offer generic acrylic sheets labeled as “Perspex,” which can mislead buyers. These generic alternatives often lack the optical clarity, UV resistance, impact strength, and consistency of genuine Perspex®. Always verify the material specification and request proof of origin or certification.

Overlooking Optical Clarity and Surface Quality

High-quality applications—such as display cases, optical instruments, or architectural glazing—demand exceptional clarity and minimal distortion. Low-grade acrylic may exhibit haze, waviness, or surface imperfections. Insist on samples and test for light transmission (ideally ≥92%) and minimal refractive distortion before bulk ordering.

Ignoring UV and Weather Resistance Requirements

Standard acrylic yellows and becomes brittle under prolonged UV exposure. Genuine Perspex® offers UV-stabilized grades designed for outdoor use. If the application involves sunlight exposure, ensure the panels are specifically rated for weather resistance; otherwise, premature degradation can occur.

Failing to Verify Technical Specifications

Not all acrylic sheets meet the same standards. Properties like thickness tolerance, tensile strength, and thermal expansion vary between manufacturers. Always request technical data sheets (TDS) and confirm compliance with relevant standards (e.g., ISO 7823 for acrylic sheets).

Supply Chain and IP Infringement Risks

Using or sourcing counterfeit Perspex® panels infringes on Lucite International’s trademark rights. Unauthorized use of the Perspex® name in procurement or marketing can lead to legal disputes. Ensure suppliers are authorized distributors and can provide traceable documentation to mitigate IP risks.

Inadequate Quality Control from Suppliers

Some suppliers, particularly low-cost offshore manufacturers, may lack rigorous quality control. This can result in inconsistent thickness, surface scratches, or internal stresses that lead to cracking. Conduct factory audits or require third-party inspection reports for larger orders.

Not Considering Processing Compatibility

Perspex® behaves differently during cutting, drilling, or thermoforming compared to generic acrylic. Poorly sourced materials may craze or crack during fabrication. Confirm compatibility with your intended manufacturing processes and consult with material experts when necessary.

By addressing these pitfalls proactively—through supplier vetting, material verification, and IP compliance—you can ensure reliable performance and legal safety when sourcing clear Perspex® panels.

Logistics & Compliance Guide for Clear Perspex Panels

Clear Perspex panels (a brand name for acrylic sheets, also known as PMMA) require careful handling and compliance with regulations throughout the supply chain. This guide outlines key logistics and compliance considerations to ensure safe, legal, and efficient transportation and use.

Product Identification and Specifications

Ensure accurate documentation of the material. Clear Perspex is polymethyl methacrylate (PMMA), a thermoplastic. Key specifications include thickness, dimensions, grade (e.g., optical, impact-resistant), and compliance certifications (e.g., ISO, ANSI, or fire ratings if applicable). Proper identification avoids regulatory issues and ensures suitability for intended use.

Packaging and Handling Requirements

Clear Perspex panels are susceptible to scratching, cracking, and static buildup. Use protective films on both sides and wrap panels in bubble wrap or foam between sheets. Secure stacking with edge protectors prevents chipping. Always handle with clean gloves to avoid surface contamination. Label packages as “Fragile” and “This Side Up” to minimize damage during transit.

Transportation and Storage

Use flatbed trucks or enclosed vehicles with adequate support to prevent flexing during transport. Secure loads with straps, avoiding direct pressure on edges. Store vertically in a dry, temperature-controlled environment away from direct sunlight to prevent warping or yellowing. Avoid stacking heavy items on stored panels. Maximize airflow to reduce condensation risks.

Regulatory Compliance

Adhere to regional and international regulations. In the EU, ensure compliance with REACH and RoHS directives regarding chemical content. In the US, follow OSHA guidelines for workplace handling and any applicable building codes (e.g., fire safety under IBC if used in construction). For exports, verify customs documentation and import requirements, including Material Safety Data Sheets (MSDS/SDS).

Fire Safety and Building Codes

While PMMA is combustible, certain grades meet fire safety standards (e.g., BS 476, UL 94). Verify fire rating requirements if panels are used in public buildings, partitions, or safety barriers. Always supply documentation proving compliance with relevant fire codes to end users and authorities.

Environmental and Disposal Considerations

PMMA is recyclable (plastic #7). Encourage end-of-life recycling through certified facilities. Avoid incineration without proper emissions controls, as burning can release harmful fumes. Follow local waste disposal regulations and provide disposal guidance to customers.

Documentation and Traceability

Maintain batch traceability and quality certificates. Provide Safety Data Sheets (SDS) detailing handling, storage, and emergency procedures. Include compliance labels and product specifications with shipments to support audits and customer requirements.

Conclusion

Proper logistics and compliance management for clear Perspex panels safeguards product integrity, ensures regulatory adherence, and supports customer safety. Implement standardized procedures across packaging, transport, and documentation to minimize risks and enhance supply chain reliability.

In conclusion, sourcing clear Perspex panels requires careful consideration of factors such as panel thickness, size, quality, UV resistance, and intended application—whether for signage, display, protective barriers, or architectural use. It is essential to select a reputable supplier who can provide consistent material quality, proper certifications (such as BS or ISO standards), and reliable delivery times. Comparing quotes from multiple suppliers, evaluating customization options like laser cutting or edge polishing, and factoring in shipping and handling will help ensure cost-effectiveness and project suitability. By prioritizing both material performance and supplier reliability, you can successfully source clear Perspex panels that meet your functional and aesthetic requirements.