The global clear epoxy coating market is witnessing steady expansion, driven by increasing demand across industrial, automotive, and construction sectors for durable, corrosion-resistant surface finishes. According to Grand View Research, the global epoxy coatings market size was valued at USD 12.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is underpinned by rising infrastructure investments and the need for protective coatings in harsh environments. Within this landscape, clear epoxy spray coatings have gained traction due to their ease of application, fast curing times, and superior finish quality—making them a preferred choice for both functional and aesthetic enhancements. As demand surges, a select group of manufacturers have emerged as leaders, combining innovation, scalability, and product consistency to dominate the segment. Based on market presence, technical capabilities, and product performance, here are the top 10 clear epoxy spray coating manufacturers shaping the industry today.

Top 10 Clear Epoxy Spray Coating Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

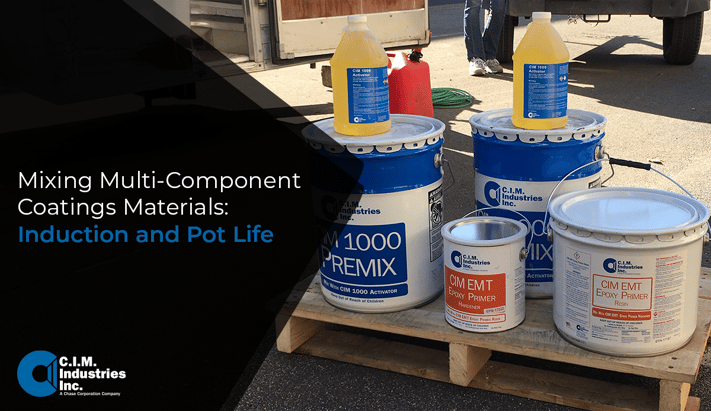

#1 Chase Corporation

Domain Est. 1996

Website: chasecorp.com

Key Highlights: Chase Corporation is a Global Manufacturer of Adhesives, Electronic Coatings, Industrial Tapes, Waterproofing and Corrosion Protection….

#2 Fasco Epoxies, Inc. > Industrial Epoxy Resins

Domain Est. 2000

#3 Endura Paint

Domain Est. 2002

Website: endurapaint.com

Key Highlights: Endura is a manufacturer of high performance polyurethane and epoxy industrial coatings. Product lines include, industrial paint systems, ……

#4 Epoxy Coatings Products

Domain Est. 1996

Website: miracote.com

Key Highlights: 100% solids clear epoxy with decorative colored quartz broadcast. MVERS Plus. A fluid-applied, one-coat epoxy moisture mitigation system. Protection of 24lbs/ …Missing: spray ma…

#5 Southern Polyurethanes: Automotive Refinishing

Domain Est. 1999

Website: southernpolyurethanes.com

Key Highlights: Southern Polyurethanes is a manufacturer of automotive coatings for the restoration, repair and custom markets. Epoxy Primers, Clear coats, Primers, Basecoat, ……

#6 POLYMERES TECHNOLOGIES

Domain Est. 2001

Website: polymerestechnologies.com

Key Highlights: 2–7 day delivery 14-day returns…

#7 3M Coatings

Domain Est. 1988

Website: 3m.com

Key Highlights: Primers, topcoats, polishing compounds and other coating materials for strengthening, protecting, and finishing cars, boats, planes, cabinets, pipes, ……

#8 Clear Coat

Domain Est. 1996

#9 Hentzen Coatings

Domain Est. 1997

Website: hentzen.com

Key Highlights: High-performance coatings for every challenge. From the moment you step through our doors, you’ll never look at liquid and powder coatings the same….

#10 FGCI

Domain Est. 1997

Website: fgci.com

Key Highlights: Fiberglass Coatings carries a complete line of polyester resin, epoxy resin gelcoats and fiberglass materials. Learn More. Featured Products….

Expert Sourcing Insights for Clear Epoxy Spray Coating

H2: Projected Market Trends for Clear Epoxy Spray Coating in 2026

By 2026, the global clear epoxy spray coating market is expected to experience robust growth, driven by increasing demand across key industries such as automotive, construction, marine, and industrial manufacturing. Several key trends are shaping the market landscape:

-

Rising Demand for Protective and Aesthetic Finishes

End-users are increasingly prioritizing coatings that offer both durability and visual appeal. Clear epoxy spray coatings provide excellent resistance to abrasion, chemicals, and UV degradation while enhancing the underlying material’s appearance—making them ideal for flooring, furniture, and metal surfaces. -

Expansion in the Construction and Infrastructure Sectors

Ongoing urbanization and infrastructure development, especially in Asia-Pacific and Latin America, are boosting demand for high-performance protective coatings. Clear epoxy sprays are widely used in concrete flooring for commercial and industrial spaces due to their quick application, rapid curing, and long-term resilience. -

Technological Advancements and Formulation Innovations

Manufacturers are investing in low-VOC (volatile organic compound) and water-based epoxy formulations to comply with tightening environmental regulations. Innovations in spray application technology are also improving coating uniformity and reducing material waste, increasing efficiency for contractors and OEMs. -

Growth in the Automotive and Marine Aftermarket

The automotive refinish market is adopting clear epoxy sprays for underbody protection and corrosion resistance. Similarly, in the marine industry, these coatings are being used to protect boat decks and interiors from saltwater exposure and wear. -

Sustainability and Regulatory Pressures

Environmental standards such as REACH (EU) and EPA regulations (U.S.) are pushing suppliers to develop greener alternatives. This is accelerating the shift toward bio-based epoxy resins and safer solvents, which may influence pricing and production strategies by 2026. -

Regional Market Dynamics

North America and Europe will remain key markets due to stringent quality standards and mature industrial sectors. However, the fastest growth is anticipated in the Asia-Pacific region, led by China, India, and Southeast Asia, where industrial expansion and infrastructure investments are driving demand.

In summary, the clear epoxy spray coating market in 2026 will be characterized by innovation, sustainability, and geographic expansion, with strong growth potential across multiple end-use sectors. Companies that adapt to regulatory changes and customer demands for high-performance, eco-friendly solutions are likely to gain a competitive edge.

Common Pitfalls When Sourcing Clear Epoxy Spray Coating (Quality & IP)

Sourcing a reliable clear epoxy spray coating requires careful attention to both quality and intellectual property (IP) concerns. Overlooking key pitfalls can lead to performance failures, compliance issues, supply chain disruption, or legal exposure. Below are critical considerations:

Inadequate Quality Verification

Many suppliers claim high-performance specifications, but actual product quality can vary significantly. Relying solely on datasheets without independent verification risks receiving subpar materials. Key quality pitfalls include inconsistent viscosity affecting spray application, poor UV resistance leading to yellowing, insufficient chemical or abrasion resistance, and inadequate adhesion to substrates. Always request batch-specific test reports and conduct in-house or third-party testing under real-world conditions before full-scale procurement.

Misleading or Incomplete Technical Data

Suppliers may provide incomplete or overly optimistic technical data, especially regarding cure times, temperature resistance, and film thickness. Some formulations require precise mixing ratios or environmental conditions (e.g., humidity, temperature) for optimal performance. Failure to account for these factors can result in incomplete curing, delamination, or poor finish. Ensure datasheets are comprehensive and include application guidelines, shelf life, and storage requirements.

Lack of Regulatory and Environmental Compliance

Clear epoxy coatings may contain volatile organic compounds (VOCs), hazardous air pollutants (HAPs), or restricted substances (e.g., under REACH, RoHS). Sourcing coatings without verifying compliance can lead to regulatory fines or market access issues. Confirm that the product meets all relevant environmental and safety regulations for your region and application, and request Safety Data Sheets (SDS) and compliance certifications.

Intellectual Property Risks and Reverse Engineering

Epoxy formulations are often proprietary, with specific performance attributes protected by patents or trade secrets. Sourcing from unverified or low-cost suppliers—particularly in regions with weak IP enforcement—risks receiving counterfeit or reverse-engineered products. These may mimic appearance but fail in durability or safety. Engage only with reputable manufacturers who can demonstrate IP ownership or proper licensing, and include IP indemnification clauses in contracts.

Supply Chain Instability and Raw Material Sourcing

Epoxy resins and hardeners depend on petrochemical feedstocks, making them vulnerable to price volatility and supply disruptions. Suppliers without secure raw material sourcing may face production delays or reformulations that alter coating performance. Assess supplier stability, ask about their supply chain transparency, and consider dual sourcing or long-term agreements to mitigate risk.

Inconsistent Batch-to-Batch Performance

Even with a qualified supplier, batch variability can occur due to process control issues. This inconsistency affects color clarity, gloss, and mechanical properties. Require suppliers to implement strict quality control protocols and provide Certificate of Analysis (CoA) for each batch.

Inadequate Support and Technical Collaboration

A supplier’s ability to provide technical support—such as troubleshooting application issues or optimizing curing parameters—is crucial. Sourcing from vendors with limited technical expertise can lead to field failures. Prioritize partners who offer application engineering support and collaborative development, especially for demanding or custom applications.

By proactively addressing these quality and IP-related pitfalls, buyers can ensure they source clear epoxy spray coatings that meet performance standards, regulatory requirements, and long-term business objectives.

Logistics & Compliance Guide for Clear Epoxy Spray Coating

Product Overview

Clear Epoxy Spray Coating is a two-component protective coating system designed to provide a durable, high-gloss finish with excellent resistance to chemicals, moisture, abrasion, and UV degradation (depending on formulation). It is commonly used on concrete, metal, wood, and composite surfaces in industrial, commercial, and residential applications.

1. Shipping & Transportation

a. Packaging & Labeling

– Shipped in pressurized aerosol cans or as separate component kits (resin and hardener) in non-leaking, UN-certified containers.

– Containers must display proper GHS (Globally Harmonized System) labeling, including:

– Product identifier

– Signal word (e.g., “Danger”)

– Hazard statements (e.g., H222, H319, H412)

– Pictograms (flame, exclamation mark, environment)

– Supplier contact information

b. Transport Classification

– UN Number: UN1950 (Aerosols, flammable)

– Hazard Class: 2.1 (Flammable Gas)

– Packing Group: II (Medium danger)

– Regulations: Complies with ADR/RID (road/rail Europe), IMDG (sea), IATA (air) for hazardous goods.

c. Storage & Handling During Transit

– Store and transport in a cool, dry, well-ventilated area.

– Keep away from direct sunlight, heat sources, and open flames.

– Do not puncture, incinerate, or expose to temperatures >50°C (122°F).

– Keep upright to prevent leakage.

2. Storage Requirements

- Temperature: Store between 10°C and 30°C (50°F–86°F). Avoid freezing.

- Ventilation: Store in a flammable liquids cabinet or designated hazardous storage area with explosion-proof ventilation.

- Segregation: Keep away from oxidizers, acids, and strong bases.

- Shelf Life: Typically 12–24 months from manufacture date when unopened and stored properly. Check manufacturer’s label.

3. Handling & Use

a. Personal Protective Equipment (PPE)

– Wear nitrile gloves, chemical-resistant apron, safety goggles, and respiratory protection (NIOSH-approved N95 or half-face respirator with organic vapor cartridges).

– Use in well-ventilated areas or with local exhaust ventilation.

b. Application Precautions

– Do not spray near ignition sources (sparks, open flames, hot surfaces).

– Ensure surfaces are clean, dry, and properly prepared before application.

– Follow manufacturer’s mixing ratio (if applicable) and induction time.

– Avoid prolonged or repeated skin contact; wash hands thoroughly after use.

4. Regulatory Compliance

a. GHS Hazard Statements (H-Statements)

– H222: Extremely flammable aerosol.

– H229: Pressurized container: may burst if heated.

– H315: Causes skin irritation.

– H319: Causes serious eye irritation.

– H336: May cause drowsiness or dizziness (if solvents present).

– H411: Toxic to aquatic life with long-lasting effects.

b. Safety Data Sheet (SDS) Compliance

– Maintain a current SDS (Section 16) for each product batch.

– SDS must comply with OSHA HazCom 2012 (U.S.), CLP Regulation (EU), or local equivalents.

– Ensure SDS includes first-aid, firefighting, accidental release, and disposal measures.

c. Environmental Regulations

– VOC (Volatile Organic Compound) content must comply with regional limits (e.g., U.S. EPA, EU Directive 2004/42/EC).

– Do not release into sewers or waterways.

– Follow local regulations for hazardous waste disposal.

5. Spill & Emergency Response

a. Spill Containment

– Stop leak if safe to do so.

– Contain spill with absorbent materials (e.g., sand, vermiculite, or commercial absorbents).

– Avoid creating dust; do not flush with water.

b. Fire Response

– Extinguishing Media: Use dry chemical, CO₂, or foam. Water may be ineffective.

– Hazard: Aerosol cans may explode if exposed to fire. Cool containers with water from a safe distance.

– Evacuate area and call emergency services.

c. First Aid Measures

– Inhalation: Move to fresh air. Administer oxygen if breathing is difficult. Seek medical attention.

– Skin Contact: Wash with soap and water. Remove contaminated clothing.

– Eye Contact: Rinse thoroughly with water for at least 15 minutes. Seek medical help.

– Ingestion: Do not induce vomiting. Rinse mouth and seek immediate medical attention.

6. Disposal & Recycling

- Empty Containers: May still contain flammable residue. Dispose of as hazardous waste.

- Waste Material: Collect used absorbents, rags, or overspray as hazardous waste.

- Regulatory Compliance: Follow EPA, RCRA (U.S.), or local waste disposal regulations.

- Recycling: Check with local authorities or manufacturer for aerosol can recycling programs.

7. Training & Documentation

- Train all personnel on:

- SDS review

- Safe handling and storage

- Emergency procedures

- PPE requirements

- Maintain records of training, SDS access, and incident reports.

- Conduct periodic safety audits.

8. Supplier & Regulatory Contacts

- Manufacturer/Supplier: [Insert Supplier Name, Address, Phone, Email]

- Emergency Hotline: [Insert 24/7 Emergency Number]

- Regulatory Agencies:

- U.S.: OSHA, EPA

- EU: ECHA, national CLP enforcers

- Canada: Health Canada, WHMIS

Note: Always refer to the specific product’s Safety Data Sheet and local regulations for the most accurate and up-to-date compliance information.

Conclusion for Sourcing Clear Epoxy Spray Coating:

Sourcing a high-quality clear epoxy spray coating requires careful consideration of performance requirements, application methods, environmental conditions, and compliance standards. After evaluating various suppliers and product options, it is evident that selecting the right coating involves balancing durability, clarity, UV resistance, and ease of application. Premium formulations offer superior protection against corrosion, abrasion, and weathering, making them ideal for industrial, marine, and automotive applications. Additionally, ensuring compatibility with substrates and adherence to environmental regulations—such as low VOC content—is essential for both performance and sustainability. Ultimately, partnering with reputable suppliers who provide technical support, consistent product quality, and certification documentation will ensure reliable results and long-term project success. A well-informed sourcing decision enhances product longevity, reduces maintenance costs, and delivers a professional, high-gloss finish that meets both aesthetic and functional expectations.