The global truss manufacturing industry is experiencing steady growth, driven by rising demand in construction, event infrastructure, and industrial applications. According to Mordor Intelligence, the global construction equipment rental market—closely tied to truss usage—was valued at USD 66.7 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029, underlining increased reliance on modular and temporary structural systems. As truss applications expand, so does the need for reliable, high-performance clamps that ensure structural integrity, safety, and ease of assembly. From pipe-to-truss connections to multi-directional rigging, clamps are critical components in load distribution and system stability. With the market demanding greater precision and durability, truss manufacturers are prioritizing clamps engineered for repeatability, corrosion resistance, and compliance with safety standards. Based on performance metrics, material quality, load ratings, and field reliability, we’ve analyzed the most widely adopted clamping solutions to identify the top 7 clamps shaping modern truss systems today.

Top 7 Clamps For Truss Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Truss Clamps for Rigging, Tubes, Pipes, and Industrial Equipment

Domain Est. 2011

#2 Global Truss Clamps

Domain Est. 2003

Website: globaltruss.com

Key Highlights: Our aluminum clamps are made from 6061 aluminum, ensuring durability and corrosion resistance. Our diverse inventory covers various weight loads, truss sizes, ……

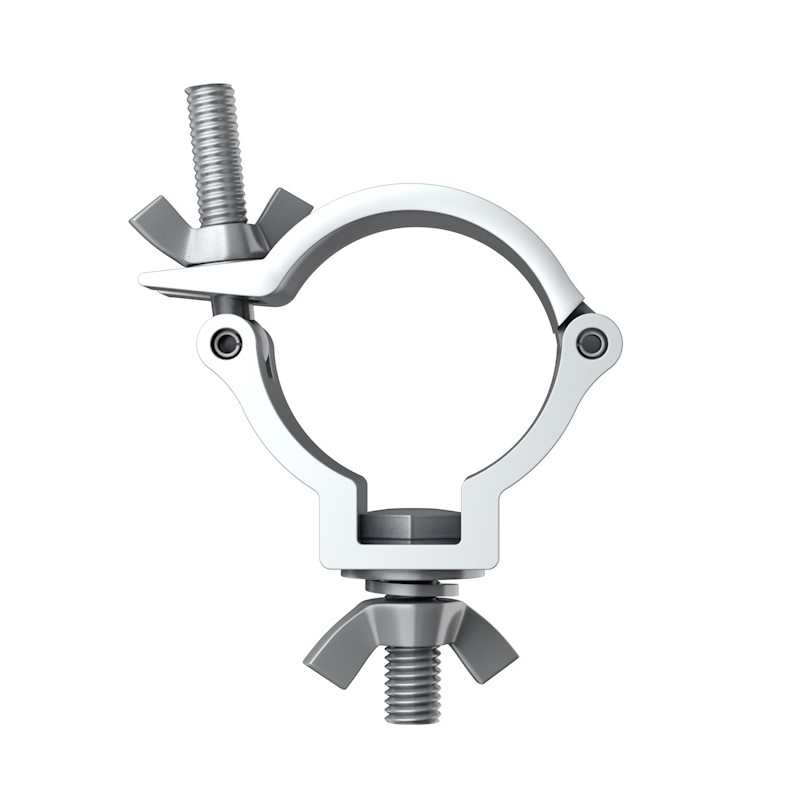

#3 M Pro Series Truss Clamp 45

Domain Est. 2004

Website: products.multibrackets.com

Key Highlights: This M Truss Clamp is designed to securely fit truss systems ranging from 45 to 51mm. Constructed from durable steel and finished in black, it provides a ……

#4 Truss Type Universal Hook Clamp

Domain Est. 2004

#5 ProX Truss

Domain Est. 2013

Website: proxdirect.com

Key Highlights: From the Live DJ to Large Format Concert Production, all Truss, Rigging & Lighting support Stage Roofing System….

#6 Truss Clamps

Domain Est. 2020

#7 Clamp

Domain Est. 2023

Website: neotrusssystem.dk

Key Highlights: Neo Clamp sets a new standard in structural performance, with TÜV certification up to 2300kg on an 8-meter span—surpassing the strength of traditional 40×40 ……

Expert Sourcing Insights for Clamps For Truss

H2: Market Trends for Clamps for Truss in 2026

The global market for clamps for truss systems is poised for significant evolution by 2026, driven by advancements in modular construction, increasing demand for temporary and permanent structural support in events and industrial applications, and a growing emphasis on safety and efficiency. Below is an analysis of key market trends expected to shape the clamps for truss sector in 2026:

1. Rising Adoption in Modular and Prefabricated Construction

The shift toward modular and prefabricated building techniques is accelerating worldwide due to faster project timelines and reduced labor costs. Truss clamps play a vital role in assembling lightweight, durable frameworks for roofs, ceilings, and support structures. By 2026, increasing investments in infrastructure and commercial real estate—especially in emerging economies—are projected to boost demand for high-performance truss clamps that offer ease of installation and reusability.

2. Growth in Entertainment and Event Industries

The live events, concerts, exhibitions, and film production sectors continue to recover and expand post-pandemic, fueling demand for reliable truss systems used in lighting, sound, and stage rigging. Truss clamps are essential for secure, rapid assembly and disassembly. Innovations in quick-connect and tool-free clamp designs are expected to gain traction by 2026, meeting the industry’s need for speed and safety.

3. Emphasis on Lightweight and High-Strength Materials

Manufacturers are increasingly adopting aerospace-grade aluminum alloys and composite materials to produce truss clamps that are both lightweight and capable of bearing high loads. This trend aligns with the broader industry push for energy-efficient transport and handling. By 2026, clamps made from corrosion-resistant, durable materials will dominate premium market segments, particularly in outdoor and marine environments.

4. Technological Integration and Smart Clamps

Emerging smart construction technologies are beginning to influence truss clamp design. While still in early stages, research into sensor-integrated clamps that monitor load stress, alignment, and structural integrity could see pilot adoption by 2026. These “smart clamps” may appeal to high-risk industrial applications such as offshore platforms or large-scale temporary roofs.

5. Sustainability and Circular Economy Practices

Environmental regulations and corporate sustainability goals are prompting manufacturers to focus on recyclable materials and longer product lifecycles. Reusable and modular truss clamp systems reduce waste and support circular economy models. By 2026, companies offering eco-certified or recyclable clamp solutions are likely to gain competitive advantage, especially in Europe and North America.

6. Regional Market Expansion

Asia-Pacific is expected to emerge as the fastest-growing market for truss clamps by 2026, driven by urbanization, infrastructure development, and the expansion of the entertainment industry in countries like China, India, and Southeast Asian nations. Meanwhile, North America and Europe will maintain strong demand due to high safety standards and recurring renovation projects.

7. Competitive Landscape and Customization

The market is becoming increasingly competitive, with key players focusing on product differentiation through customization, improved ergonomics, and compatibility with international truss standards (e.g., ISO and ANSI). By 2026, vendors offering modular clamp systems that support multiple truss geometries (square, circular, triangular) will hold a strategic edge.

In conclusion, the clamps for truss market in 2026 will be shaped by innovation, sustainability, and sector-specific demands. Companies that invest in R&D, embrace digital integration, and respond to regional construction dynamics are best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Clamps for Truss (Quality and IP)

Sourcing clamps for truss systems involves more than just finding a low price—quality and intellectual property (IP) concerns can lead to significant operational, safety, and legal risks. Below are key pitfalls to watch for:

Poor Material Quality and Workmanship

Low-cost clamps may use substandard materials such as inferior-grade steel or poorly machined components, leading to reduced load capacity, premature wear, or catastrophic failure under stress. Look for signs like inconsistent welds, rough finishes, or dimensional inaccuracies, which indicate poor manufacturing control.

Lack of Load Certification and Testing

Many generic clamps lack proper load ratings or third-party testing documentation. Without certified performance data, users risk using clamps beyond safe limits, endangering structures and personnel—especially in entertainment, event, or industrial rigging applications.

Incompatibility with Truss Profiles

Clamps designed for one truss size or shape (e.g., box truss vs. ladder truss) may not fit others securely. Using mismatched clamps can result in slippage, misalignment, or structural instability. Always verify compatibility with your specific truss system.

Counterfeit or IP-Infringing Products

Many reputable clamp designs (e.g., from Global Truss, Eurotruss, or Prolyft) are protected by patents and trademarks. Sourcing counterfeit or knockoff clamps not only violates intellectual property rights but often results in lower performance and reliability due to reverse-engineered designs.

Absence of Traceability and Manufacturer Accountability

Unbranded or no-name clamps frequently lack batch traceability, making it difficult to address defects or recalls. Reputable suppliers provide clear manufacturer information, warranties, and customer support—critical for long-term reliability and liability protection.

Overlooking Safety Standards and Compliance

In some regions, truss clamps must comply with safety standards like CE, EN, or OSHA guidelines. Sourcing non-compliant products can lead to failed inspections, project delays, or legal liability in the event of an accident.

Short-Term Savings Leading to Long-Term Costs

While budget clamps may appear cost-effective upfront, poor durability, frequent replacements, and potential safety incidents often result in higher total cost of ownership. Investing in quality, IP-respecting clamps typically delivers better value over time.

Avoiding these pitfalls requires due diligence: verify certifications, inspect samples, source from reputable suppliers, and ensure products respect intellectual property rights. Prioritizing quality and compliance safeguards both people and projects.

Logistics & Compliance Guide for Clamps For Truss

This guide provides essential information for the safe, efficient, and compliant handling, transportation, and use of clamps for truss systems in construction, event production, and industrial applications.

1. Product Overview

Clamps for truss systems are mechanical fasteners designed to securely connect truss sections, lighting, rigging equipment, or other accessories. Common types include C-clamps, beam clamps, truss-to-truss connectors, and safety cable clamps. These components are typically made from high-strength steel or aluminum alloys and must meet specific load and safety standards.

2. Regulatory & Safety Compliance

Ensure all clamps comply with relevant international and local standards, including:

– EN 795:2012 – Safety of protection systems against falls

– OSHA 1926.502 – Fall protection systems (U.S.)

– AS/NZS 1891.4 – Industrial fall-arrest systems (Australia/New Zealand)

– CE Marking – Required for sale within the European Economic Area

– Load Rating Certification – Each clamp must be clearly marked with working load limit (WLL) and safety factor (typically 5:1 or higher)

Verify that clamps are supplied with test certificates and traceability documentation (e.g., batch numbers, material certifications).

3. Packaging & Labeling Requirements

– Package clamps in durable containers to prevent damage during transit.

– Label each package with:

– Product name and model number

– Weight and dimensions

– WLL and safety factor

– Manufacturer name and contact information

– CE or other compliance marks

– Handling symbols (e.g., “Do Not Stack,” “Fragile”)

– Include user manuals and safety instructions in local languages where applicable.

4. Storage & Handling

– Store clamps in a dry, temperature-controlled environment to prevent corrosion.

– Keep away from chemicals, moisture, and extreme temperatures.

– Use protective coatings or rust inhibitors for metal components.

– Handle with care; avoid dropping or impact that may compromise structural integrity.

– Inspect regularly for wear, cracks, deformation, or stripped threads.

5. Transportation Guidelines

– Secure loads to prevent shifting during transit.

– Use pallets or crates to organize and protect clamps.

– Comply with international freight regulations (e.g., IMDG for sea, IATA for air, ADR for road in Europe).

– Declare weights accurately for customs and freight calculations.

– For international shipments, ensure proper Harmonized System (HS) code classification (e.g., 7326.90 for other articles of iron or steel).

6. Import & Export Compliance

– Determine applicable tariffs and import duties based on destination country.

– Prepare commercial invoice, packing list, bill of lading, and certificate of origin.

– Verify if product requires special permits or notifications (e.g., REACH, RoHS in the EU).

– Confirm compliance with local building or safety codes in the destination market.

7. On-Site Use & Inspection

– Only trained personnel should install and use truss clamps.

– Conduct pre-use inspections for damage or wear.

– Torque bolts to manufacturer specifications using calibrated tools.

– Never exceed the WLL; account for dynamic loads in live events or high-wind areas.

– Use secondary safety measures (e.g., safety cables) where required.

8. Maintenance & Record Keeping

– Implement a regular inspection and maintenance schedule.

– Keep detailed logs including:

– Inspection dates

– Findings and repairs

– Retirement of damaged components

– Retire clamps showing signs of fatigue, deformation, or corrosion.

9. Disposal & Sustainability

– Recycle metal components through certified scrap metal processors.

– Follow local environmental regulations for disposal of non-reusable parts.

– Consider supplier take-back programs for end-of-life equipment.

10. Support & Documentation

Maintain access to:

– Manufacturer technical support

– Product manuals and installation guides

– Compliance certifications

– Warranty information

Following this guide ensures safe, compliant, and efficient logistics for clamps used in truss applications across global markets.

In conclusion, sourcing clamps for truss systems requires careful consideration of compatibility, material quality, load requirements, and adherence to safety standards. It is essential to select clamps that are specifically designed for the type of truss in use—whether standard, touring, or architectural—to ensure secure connections and structural integrity. Sourcing from reputable suppliers with proven track records in providing certified and durable components will minimize risks associated with failure under load. Additionally, evaluating factors such as ease of assembly, corrosion resistance, and long-term maintenance needs will contribute to operational efficiency and cost-effectiveness. Ultimately, a well-informed sourcing strategy ensures reliable performance, safety compliance, and longevity in truss-based installations.