The global clamp-on current transformer market is experiencing robust growth, driven by rising demand for energy efficiency, predictive maintenance, and real-time power monitoring across industrial, commercial, and utility sectors. According to Grand View Research, the global current transformer market size was valued at USD 8.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. A key contributor to this expansion is the increasing adoption of non-invasive sensing solutions like clamp-on current transformers, which offer ease of installation, minimal downtime, and accurate current measurement in retrofit and monitoring applications. Mordor Intelligence further supports this trend, highlighting accelerated deployment in renewable energy systems, smart grids, and building automation as primary growth drivers. With the industrial IoT ecosystem expanding and energy management becoming a strategic priority, demand for reliable, high-precision clamp-on CTs is surging—spurring innovation among manufacturers. In this competitive landscape, seven companies have emerged as leaders, setting benchmarks in accuracy, durability, and smart integration capabilities.

Top 7 Clamp On Current Transformer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Current Transformer Manufacturer/Supplier, Clamp on …

Domain Est. 2021

Website: acrelenergy.com

Key Highlights: Acrel, a Chinese current transformer manufacturer, offers ct current transformers and flexible ct clamps at a reasonable price. CT clamps are developed from ……

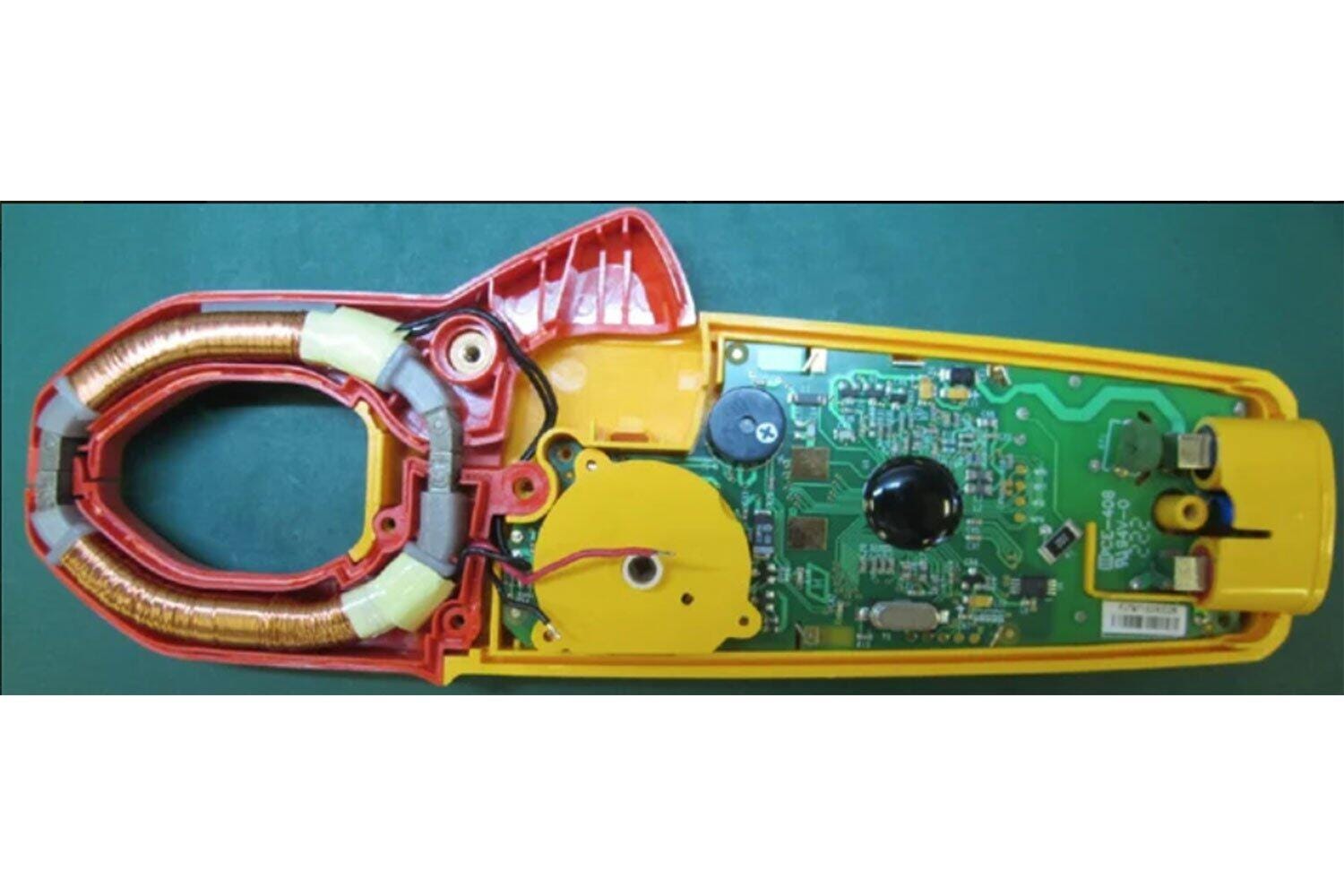

#2 Inside Current Transformer (ac) Clamp Meters

Domain Est. 1986

#3 Clamp-On Current Transformers

Domain Est. 1997

Website: flex-core.com

Key Highlights: Below is a list of all clamp-on current transformers including AC, micro clamp and clamp-on CT accessories available through Flex-Core….

#4 LEM

Domain Est. 1997

Website: lem.com

Key Highlights: LEM sensors, transducers and ICS cover all your current and voltage measurement needs from 10 to 2,000 A, and from 10 to 4,200 V. We manufacture thousands of ……

#5 Current Transformers (CT’s)

Domain Est. 1998

Website: mecoinst.com

Key Highlights: Current Transformers (CT’s) ; Flexible Current Transformer (Model : FCT Series) ; Clamp – On AC Transformer (Model : CCT50)…

#6 Consumption Monitoring Clamp CT

Domain Est. 2003

Website: enphase.com

Key Highlights: Consumption Clamp Current Transformer · Includes 13 ft, 18 AWG wire · Enables whole-home consumption metering with an accuracy of +/- 2.5% · Residential use only….

#7 Current Transformer Products

Domain Est. 2009

Website: ctlsys.com

Key Highlights: Continental Control Systems sells several different series of current transformers (CTs) in various window sizes, current ranges, and accuracy grades….

Expert Sourcing Insights for Clamp On Current Transformer

H2: 2026 Market Trends for Clamp-On Current Transformers

The global clamp-on current transformer (Clamp CT) market is poised for steady growth and significant transformation by 2026, driven by evolving energy demands, technological advancements, and regulatory pressures. Here’s a breakdown of the key trends shaping the market:

1. Accelerated Demand in Renewable Energy & Grid Modernization:

The global push toward decarbonization and energy resilience will significantly boost demand for clamp-on CTs. As solar and wind installations proliferate, both during commissioning and ongoing maintenance, Clamp CTs offer non-intrusive, safe current measurement crucial for monitoring inverter performance, grid synchronization, and fault detection. Concurrently, investments in smart grid infrastructure, including advanced metering infrastructure (AMI) and distribution automation, will drive the need for reliable, temporary, and permanent current monitoring solutions—areas where Clamp CTs excel.

2. Rise of High-Accuracy, Smart Clamp CTs with Digital Integration:

The market will shift towards higher-precision Clamp CTs (e.g., Class 0.2, 0.5) capable of supporting energy auditing, power quality analysis, and revenue-grade measurements in industrial and commercial settings. Integration with digital platforms is critical: expect wider adoption of Clamp CTs with Bluetooth/Wi-Fi connectivity, enabling seamless data transfer to smartphones, tablets, or cloud-based energy management systems (EMS). This trend supports predictive maintenance, real-time monitoring, and remote diagnostics.

3. Expansion in Industrial Energy Management & ESG Compliance:

With increasing focus on energy efficiency and ESG (Environmental, Social, Governance) reporting, industries will deploy Clamp CTs for granular energy consumption tracking across machinery, production lines, and facilities. This data is essential for identifying energy waste, verifying energy-saving initiatives, and meeting regulatory sustainability targets. Clamp CTs provide a cost-effective, retrofit-friendly solution for comprehensive energy audits without disrupting operations.

4. Growth in EV Infrastructure and Data Center Applications:

The rapid expansion of electric vehicle (EV) charging stations—especially high-power DC fast chargers—creates a need for reliable current monitoring for billing, safety, and load management. Clamp CTs offer a safe, non-contact solution for these high-current applications. Similarly, the exponential growth of data centers demands precise power monitoring for critical IT loads, UPS systems, and cooling units. Clamp CTs are ideal for adding monitoring points in densely packed, high-availability environments.

5. Technological Advancements and Miniaturization:

Innovation will focus on improving performance and usability. Key developments include:

* DC Current Measurement: Wider availability and improved accuracy of Clamp CTs capable of measuring DC current (using Hall effect or fluxgate technology), critical for solar PV systems, EVs, and battery storage.

* Wider Jaw Apertures & Higher Current Ratings: To accommodate larger conductors in industrial and utility applications.

* Enhanced Safety Features: Improved insulation, CAT safety ratings, and anti-slip designs for harsh environments.

* Smaller Form Factors: For use in tight spaces within control panels and distribution boards.

6. Competitive Landscape and Regional Dynamics:

Asia-Pacific (especially China and India) will remain the fastest-growing market due to massive infrastructure development, industrialization, and renewable energy targets. North America and Europe will see strong growth driven by grid modernization, energy efficiency programs, and ESG mandates. Competition will intensify, with established players (Fluke, Hioki, Keysight) focusing on high-end digital solutions, while regional manufacturers offer cost-effective options, increasing market accessibility.

In conclusion, by 2026, the clamp-on current transformer market will be characterized by smarter, more accurate, and digitally connected devices. Growth will be fueled primarily by the energy transition, digitalization of infrastructure, and the imperative for energy efficiency across industrial, commercial, and utility sectors.

Common Pitfalls When Sourcing Clamp-On Current Transformers (Quality, IP)

Sourcing clamp-on current transformers (CTs) involves navigating several potential pitfalls, particularly concerning quality and intellectual property (IP). Overlooking these can lead to performance issues, safety risks, legal complications, and increased total cost of ownership.

Inadequate Quality Control and Performance Verification

Many low-cost or unverified suppliers may provide clamp-on CTs that fail to meet stated accuracy, linearity, or temperature specifications. Buyers often assume published specs are reliable, but without independent testing or certifications, performance can vary significantly. Poorly manufactured CTs may exhibit high phase errors, saturation at lower currents, or inconsistent output, leading to inaccurate energy measurements or protection system malfunctions.

Lack of Compliance with International Standards

A frequent oversight is sourcing CTs that do not comply with relevant standards such as IEC 61869 or IEEE C57.13. Non-compliant units may lack proper insulation ratings, safety clearances, or mechanical durability, increasing risks in high-voltage environments. Devices not certified by recognized bodies (e.g., UL, CE, TÜV) may fail regulatory inspections or void system warranties.

Misleading IP Ratings and Environmental Protection

Suppliers may advertise high IP (Ingress Protection) ratings (e.g., IP67) without valid testing or certification. In reality, the enclosure seals, materials, or design may not withstand dust, moisture, or harsh industrial conditions. This can result in premature failure, safety hazards, or unreliable operation in outdoor or wet environments.

Counterfeit or Reverse-Engineered Designs

Some manufacturers produce CTs that closely mimic branded models but use inferior materials or reverse-engineered designs. These products may infringe on intellectual property rights, exposing the buyer to legal liability. Additionally, counterfeit units often lack traceability, proper documentation, or technical support, complicating maintenance and compliance audits.

Insufficient Long-Term Reliability and Durability

Clamp-on CTs are often expected to operate reliably for years in demanding conditions. Sourcing from vendors without proven track records can result in units with poor mechanical hinges, degraded magnetic cores, or substandard output cables. These issues lead to drift, calibration loss, or physical failure over time.

Absence of Technical Support and Documentation

Low-cost suppliers may provide inadequate technical documentation, calibration certificates, or application support. Missing or inaccurate datasheets, installation guides, or safety instructions increase the risk of improper use, incorrect installation, and measurement errors.

Hidden Total Cost of Ownership

While initial purchase price may be low, poor-quality CTs can incur higher long-term costs due to frequent recalibration, maintenance, downtime, or replacement. Investing in higher-quality, certified products from reputable suppliers typically results in better accuracy, longevity, and reduced lifecycle costs.

Logistics & Compliance Guide for Clamp On Current Transformer

This guide outlines essential logistics considerations and compliance requirements for the transportation, handling, and use of Clamp On Current Transformers (CTs). Adhering to these guidelines ensures product integrity, regulatory compliance, and user safety.

Regulatory Compliance

Clamp On Current Transformers must meet various international and regional standards to ensure electrical safety, electromagnetic compatibility (EMC), and environmental responsibility.

- Electrical Safety Standards: Devices should comply with IEC/EN 61010-1 for safety requirements for electrical equipment used in measurement, control, and laboratory use. This includes insulation, dielectric strength, and protection against electric shock.

- EMC Standards: Compliance with IEC/EN 61326-1 ensures the device operates without interference in industrial environments and does not emit excessive electromagnetic disturbances.

- RoHS Compliance: Products must adhere to the Restriction of Hazardous Substances (RoHS) Directive (2011/65/EU and updates), limiting the use of lead, mercury, cadmium, and other hazardous materials.

- CE Marking: Required for sale in the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- UKCA Marking: Required for products placed on the market in Great Britain (England, Wales, Scotland), replacing CE marking in certain cases post-Brexit.

- NRTL Certification (North America): In the U.S. and Canada, certification by a Nationally Recognized Testing Laboratory (e.g., UL, CSA) to standards such as UL 61010-1 is typically required.

Packaging & Handling

Proper packaging and handling are critical to prevent damage during shipping and storage.

- Protective Packaging: Use shock-absorbent materials (e.g., molded foam, bubble wrap) to secure the clamp-on CT and accessories (test leads, carrying case, manual) inside a sturdy outer box.

- Labeling: Clearly label packages with:

- Product name and model number

- Fragile and handle-with-care symbols

- Orientation arrows (if applicable)

- Regulatory markings (CE, UKCA, RoHS, etc.)

- Environmental Conditions: Store and transport within specified temperature (-10°C to +50°C) and humidity (≤80% RH, non-condensing) ranges to avoid damage to electronic components.

- Static Protection: Use anti-static bags or containers if the device contains sensitive electronics.

Shipping & Transportation

Ensure safe and compliant movement of units across domestic and international channels.

- Domestic Shipping (e.g., US, EU):

- Use carriers compliant with national regulations.

- Include commercial invoice and packing list.

-

Follow carrier-specific requirements for electronic test equipment.

-

International Shipping:

- Prepare accurate export documentation, including commercial invoice, packing list, and certificate of origin.

- Verify import regulations in destination countries (e.g., customs duties, conformity assessment).

- Comply with IATA/ICAO regulations if shipping by air, especially for lithium batteries (if applicable).

- Declare goods correctly under HS Code 9030.89 (measuring and checking instruments).

Import & Customs Clearance

Facilitate smooth customs processing to avoid delays.

- Accurate Classification: Use correct HS/ECCN codes (e.g., 9030.89.0000 for most clamp meters).

- Declaration of Compliance: Provide copies of CE, UKCA, or other relevant certificates upon request.

- RoHS & REACH Documentation: Supply compliance declarations for hazardous substances.

- Battery Regulations: If the device includes a rechargeable battery, comply with UN 38.3 testing certification for lithium cells.

End-of-Life & Environmental Responsibility

Follow environmentally responsible disposal and recycling practices.

- WEEE Directive (EU): Label products with the crossed-out wheeled bin symbol. Ensure availability of take-back programs for end-of-life equipment.

- Recycling: Encourage users to return old units to authorized collection points for proper recycling of plastics, metals, and electronics.

- Battery Disposal: Instruct users to remove and recycle batteries separately according to local regulations (e.g., under IEC 62619 or national battery laws).

User Documentation & Training

Provide comprehensive materials to ensure safe and compliant use.

- User Manual: Include safety instructions, operating procedures, technical specifications, and compliance statements.

- Safety Warnings: Highlight risks of high-voltage environments and correct usage on live circuits.

- Calibration Requirements: Recommend periodic calibration per ISO/IEC 17025 standards to maintain measurement accuracy.

- Training: Advise users to undergo electrical safety training (e.g., NFPA 70E or equivalent) before using clamp-on CTs in industrial settings.

Adherence to this logistics and compliance guide ensures that Clamp On Current Transformers are safely transported, legally marketed, and responsibly managed throughout their lifecycle.

Conclusion for Sourcing Clamp-On Current Transformers

In conclusion, sourcing clamp-on current transformers (CTs) requires careful consideration of several key factors including accuracy, current range, compatibility with measurement devices, physical dimensions, safety certifications, and environmental conditions. Clamp-on CTs offer a non-invasive, convenient solution for AC current measurement and monitoring in industrial, commercial, and energy management applications, minimizing downtime and installation complexity.

When selecting a supplier, it is essential to prioritize reputable manufacturers or distributors that provide reliable product specifications, technical support, and compliance with international standards such as IEC or UL. Evaluating features like split-core design, frequency response, output signal type (analog or digital), and integration capabilities with data loggers or energy meters further ensures optimal performance.

Additionally, cost-effectiveness should be balanced with long-term reliability and accuracy. Investing in high-quality clamp-on CTs from trusted sources not only enhances measurement precision but also contributes to improved system monitoring, energy efficiency, and predictive maintenance strategies.

Ultimately, a well-informed sourcing decision will support accurate current monitoring, ensure operational safety, and deliver sustained value across electrical systems and applications.