The global clamp nozzle market is experiencing steady expansion, driven by increasing demand across industrial, chemical, pharmaceutical, and food & beverage sectors. According to a 2023 report by Mordor Intelligence, the global industrial nozzle market—which includes clamp nozzles—is projected to grow at a CAGR of approximately 4.5% from 2023 to 2028. This growth is fueled by the need for efficient fluid handling solutions, enhanced process reliability, and rising automation in manufacturing environments. Clamp nozzles, known for their secure, leak-resistant connections and ease of maintenance, are becoming a preferred choice in high-purity and high-pressure applications. As industries prioritize operational efficiency and compliance with sanitary standards, the demand for high-performance clamp nozzles continues to rise—propelling innovation among key manufacturers. In this evolving landscape, six leading companies have emerged at the forefront, combining precision engineering, material excellence, and global reach to meet the expanding needs of modern industrial systems.

Top 6 Clamp Nozzle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Spray Nozzles

Domain Est. 2005

Website: industrialnozzles.co.za

Key Highlights: Leading industrial spray nozzle and spraying system manufacturer. We provide Nozzles and Systems to many different types of industries….

#2 clamp nozzle

Domain Est. 2018

Website: byspray.com

Key Highlights: We are China’s outstanding clamp nozzle suppliers, manufacturers and wholesalers,to provide you with high quality clamp nozzle products, as well as the cla….

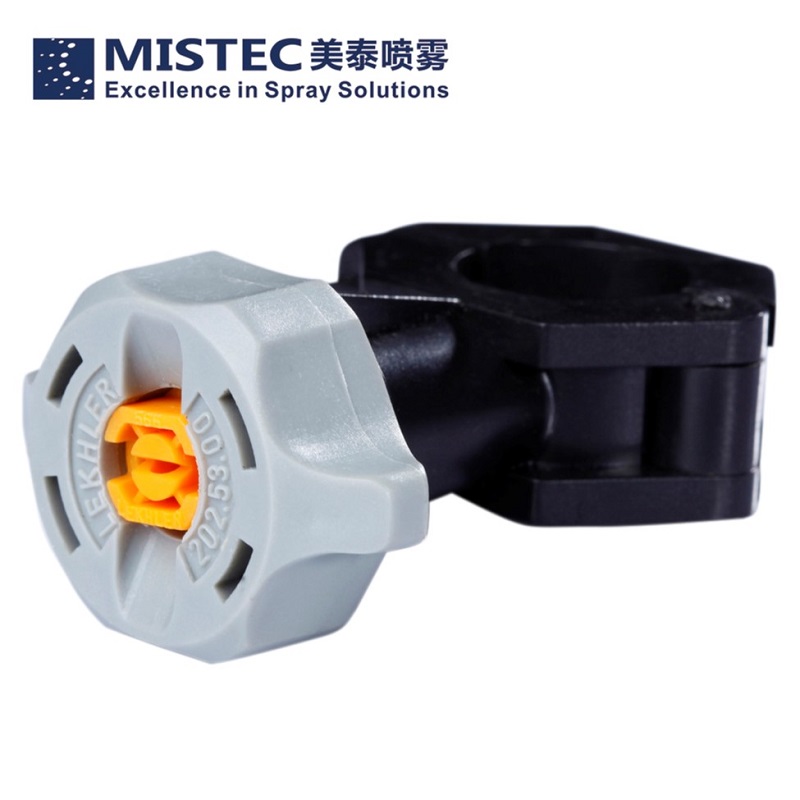

#3 Clamp spray nozzle manufacturers and suppliers

Domain Est. 2020

Website: xinhouspray.com

Key Highlights: The clamp Spray Nozzle is simple to use – just create a hole in the pipe, insert the exhaust nozzle, and secure it with a metal clamp….

#4 Clamp Spray Nozzles

Domain Est. 2022

Website: spraynozzlesonline.com

Key Highlights: Spray Nozzles Online is a leading manufacturer, supplier and exporters of Clamp Spray Nozzles in India. We design nozzles and manufactures exactly to customer ……

#5 Clamp Spray Nozzle

Domain Est. 2018

Website: ccnozzle.com

Key Highlights: Adjustable Ball-Type Clamp Nozzle have got two types: clamp connection type (26988/27988 series) and thread connection type (155 series)….

#6 Hose clamps for quick

Website: pnr.eu

Key Highlights: PNR Italia hose clamps can be swivel, cam, double- or single-spring and are designed to accommodate all types of quick-connect nozzles even those with discs….

Expert Sourcing Insights for Clamp Nozzle

H2: 2026 Market Trends for Clamp Nozzle

The global clamp nozzle market is projected to experience steady growth by 2026, driven by increasing demand across key industrial and commercial sectors. Emerging trends indicate a shift toward enhanced durability, precision engineering, and integration with automated fluid handling systems. Below are the primary market trends shaping the clamp nozzle industry in 2026:

-

Rising Demand in Industrial Automation

With the expansion of Industry 4.0, manufacturers are increasingly adopting automated fluid dispensing systems, where clamp nozzles play a critical role in ensuring accurate and leak-free connections. This trend is particularly strong in automotive, electronics, and pharmaceutical manufacturing, where precision and repeatability are paramount. -

Growth in Hygienic and Sanitary Applications

The food and beverage, biotechnology, and pharmaceutical industries are placing greater emphasis on hygiene and contamination control. Clamp nozzles with sanitary designs—often made from stainless steel and compliant with standards like 3A and FDA—are seeing increased adoption. The demand for clean-in-place (CIP) and sterilize-in-place (SIP) compatible components is a key driver. -

Material Innovation and Corrosion Resistance

By 2026, manufacturers are prioritizing advanced materials such as high-grade stainless steel (e.g., SS316L), PEEK, and engineered polymers to improve corrosion resistance and extend product lifespan. These materials cater to harsh operating environments, including high temperatures, acidic or alkaline media, and high-pressure applications. -

Regional Market Expansion

Asia-Pacific is emerging as a high-growth region due to rapid industrialization, infrastructure development, and expanding manufacturing bases in China, India, and Southeast Asia. Meanwhile, North America and Europe continue to lead in technological innovation and after-sales service integration, supporting market maturity and retrofitting of legacy systems. -

Sustainability and Leak Prevention

Environmental regulations and corporate sustainability goals are pushing industries to minimize fluid waste and emissions. Clamp nozzles with improved sealing technologies—such as silicone or EPDM gaskets—and low-drip designs are gaining favor to reduce leakage and enhance operational efficiency. -

Customization and Modular Design

End-users are increasingly seeking customizable clamp nozzle solutions tailored to specific flow rates, connection sizes (e.g., Tri-Clamp, DIN, SMS), and integration capabilities. Modular designs that allow quick assembly, maintenance, and scalability are becoming standard in fluid transfer systems. -

Digital Integration and Smart Monitoring

A nascent but growing trend involves integrating sensors and IoT-enabled monitoring into clamp nozzle systems. These “smart” nozzles can detect flow anomalies, pressure fluctuations, and seal degradation, enabling predictive maintenance and reducing downtime.

In summary, the 2026 clamp nozzle market is characterized by technological advancement, regulatory compliance, and sector-specific customization. As industries continue to prioritize efficiency, safety, and sustainability, clamp nozzles are evolving from simple connectors to critical components in intelligent fluid management ecosystems.

Common Pitfalls When Sourcing Clamp Nozzles (Quality and IP)

Sourcing clamp nozzles—critical components in fluid transfer systems across industries like food & beverage, pharmaceuticals, and chemicals—can present several challenges, particularly concerning quality consistency and intellectual property (IP) protection. Overlooking these aspects can lead to operational inefficiencies, compliance risks, and legal complications.

Quality-Related Pitfalls

Inconsistent Material Specifications

One of the most frequent quality issues arises when suppliers use substandard or non-compliant materials. For clamp nozzles used in hygienic applications, materials must meet strict standards (e.g., 316L stainless steel, FDA-compliant gaskets). Sourcing from vendors without proper material certifications can result in corrosion, contamination, or premature failure.

Poor Dimensional Tolerances and Fit

Clamp nozzles must adhere to precise dimensional standards (e.g., ISO 2852, SMS, or DIN) to ensure leak-free connections. Suppliers with inadequate quality control may deliver products with inconsistent thread pitch, flange diameter, or surface finish, leading to assembly problems and system leaks.

Inadequate Surface Finish

In sanitary environments, a smooth surface finish (e.g., Ra ≤ 0.8 µm) is essential to prevent bacterial growth. Sourcing from manufacturers that cut corners on polishing or electropolishing processes can compromise hygiene and lead to product recalls or regulatory non-compliance.

Lack of Traceability and Certifications

Reputable clamp nozzles should come with material test reports (MTRs), compliance certificates (e.g., 3.1 or 3.2), and lot traceability. Procuring from suppliers who cannot provide these documents increases the risk of receiving counterfeit or non-conforming parts.

Intellectual Property (IP)-Related Pitfalls

Unauthorized Replication of Patented Designs

Some high-performance clamp nozzles incorporate patented features (e.g., quick-connect mechanisms, sealing geometries). Sourcing from unlicensed manufacturers—especially in regions with weak IP enforcement—may result in the procurement of infringing products. This exposes the buyer to legal liability, shipment seizures, or forced equipment retrofits.

Misrepresentation of Brand and Origin

Counterfeit or “clone” clamp nozzles are often falsely labeled as products from reputable brands. Buyers may unknowingly purchase these, assuming they meet the original equipment manufacturer’s (OEM) performance standards. This misrepresentation can lead to system failures and void warranties.

Lack of Design Protection Agreements

When custom clamp nozzles are developed for specific applications, failure to secure proper IP agreements (e.g., work-for-hire contracts, non-disclosure agreements) with suppliers can result in loss of ownership over the design. The supplier may replicate or sell the design to competitors.

Supply Chain Transparency Gaps

Complex or opaque supply chains make it difficult to verify whether a supplier is the legitimate manufacturer or merely a reseller of potentially IP-infringing goods. Without direct oversight, buyers risk supporting unethical or illegal production practices.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct thorough supplier audits and request full compliance documentation.

– Prioritize vendors with recognized quality certifications (e.g., ISO 9001, ASME BPE).

– Perform incoming inspections, including material verification and dimensional checks.

– Engage legal counsel to review contracts and ensure IP rights are protected.

– Use trusted procurement channels and avoid unusually low-cost offers that may indicate IP violations or substandard quality.

By proactively addressing both quality and IP concerns, organizations can ensure the reliability, safety, and legal compliance of their clamp nozzle supply chain.

Logistics & Compliance Guide for Clamp Nozzle

Product Overview

The Clamp Nozzle is a specialized fluid transfer component designed for secure, leak-proof connections in industrial, chemical, or fuel handling applications. Its clamp-based attachment mechanism ensures compatibility with standard hose fittings and compliance with industry safety standards. This guide outlines key logistics and regulatory considerations for the safe transport, handling, and use of Clamp Nozzles.

Regulatory Compliance

Clamp Nozzles must adhere to regional and international regulations governing industrial components and fluid handling equipment. Key compliance standards include:

– ISO 7241: Specifies dimensions and performance requirements for quick-connect couplings, relevant to nozzle interface design.

– REACH (EU): Requires disclosure of substances of very high concern (SVHC) in materials used; ensure no restricted chemicals are present in seals or housing.

– RoHS (EU): Restricts hazardous substances such as lead, cadmium, and mercury in electrical and electronic components if applicable.

– ATEX/IECEx (for hazardous environments): If used in explosive atmospheres, confirm certification for safe operation in designated zones.

– OSHA & ANSI Standards (USA): Compliance with workplace safety and mechanical integrity standards for equipment in industrial settings.

Packaging & Labeling Requirements

Proper packaging and labeling are critical to prevent damage during shipping and ensure regulatory compliance:

– Use durable, anti-static packaging to protect against physical impact and electrostatic discharge.

– Clearly label each unit with part number, material composition, manufacturer details, and compliance marks (e.g., CE, UKCA, RoHS).

– Include multilingual safety and handling instructions if destined for international markets.

– For bulk shipments, use pallets secured with stretch wrap and moisture barriers; include hazard labels if applicable (e.g., “Fragile,” “Do Not Stack”).

Transportation & Storage

Follow these guidelines to maintain product integrity:

– Temperature Control: Store and transport between -10°C to 50°C; avoid prolonged exposure to extreme heat or cold.

– Humidity: Keep in dry environments (<70% RH) to prevent corrosion, especially for metal components.

– Orientation: Ship upright when possible to prevent internal component displacement.

– Stacking Limits: Adhere to manufacturer-specified stacking heights to prevent crushing.

– Hazard Classification: Clamp Nozzles are generally non-hazardous; however, verify if packaged with lubricants or sealants that may require special handling.

Import/Export Documentation

Ensure all shipments include:

– Commercial invoice with HS Code (e.g., 8481.80 for taps, valves, and similar appliances).

– Packing list detailing quantity, weight, and dimensions.

– Certificate of Conformity (CoC) confirming compliance with target market regulations.

– Material Safety Data Sheet (MSDS/SDS) if requested, particularly for elastomeric seals or coated surfaces.

Quality Assurance & Traceability

Maintain full traceability through:

– Batch or serial number tracking for each unit.

– Regular audits of manufacturing and packaging processes to meet ISO 9001 standards.

– Supplier declarations confirming raw material compliance (e.g., FDA-approved materials for food-grade variants).

End-of-Life & Environmental Compliance

Dispose of or recycle Clamp Nozzles in accordance with local environmental laws:

– Separate metal (e.g., stainless steel, aluminum) and plastic components for recycling.

– Follow WEEE directives in the EU for proper electronic waste handling if integrated sensors are present.

– Avoid landfill disposal where prohibited by regional regulations.

Contact & Support

For compliance inquiries, logistics support, or documentation requests, contact:

Global Compliance Team

Email: [email protected]

Phone: +1 (800) XXX-XXXX

Website: www.yourcompany.com/compliance

Conclusion for Sourcing Clamp Nozzle:

After a thorough evaluation of technical specifications, supplier reliability, cost-efficiency, material quality, and lead times, sourcing clamp nozzles from the selected suppliers presents a viable and strategic solution for ensuring operational efficiency and system compatibility. The chosen options meet industry standards for performance and durability, offering secure connections, leak-free operation, and ease of maintenance. Furthermore, establishing partnerships with reputable suppliers ensures consistent quality, timely delivery, and potential for long-term cost savings through volume agreements. It is recommended to proceed with the shortlisted vendors, initiate pilot procurement, and implement ongoing performance monitoring to ensure sustained supply chain integrity and optimal equipment functionality.