The global circular saw blade market is experiencing steady growth, driven by rising demand across construction, woodworking, and metal fabrication industries. According to Grand View Research, the global circular saw blade market size was valued at USD 1.27 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This expansion is fueled by increasing infrastructure development, technological advancements in blade materials such as carbide and diamond coatings, and a growing emphasis on precision and efficiency in industrial cutting applications. As demand for high-performance cutting solutions rises, manufacturers are investing in innovation and sustainable production methods to meet evolving industry standards. In this competitive landscape, a select group of leading companies have emerged as key players, setting benchmarks in quality, durability, and product diversity. This report highlights the top nine circular saw blade manufacturers shaping the market today.

Top 9 Circular Saw Blade Types Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tenryu America, Inc.

Domain Est. 1997

Website: tenryu.com

Key Highlights: Tenryu is known around the globe as the premier manufacturer of quality saw blades. Tenryu makes over 3,000 types of carbide blades for woodworking ……

#2 Industrial Circular Saw Blades for Sale

Domain Est. 2004

Website: doallsaws.com

Key Highlights: Free delivery 60-day returnsWe manufacture high-performance circular saw blades designed for applications where precision, long blade life, and reduced material waste are nonnegoti…

#3 Industrial Circular saw blades

Domain Est. 2010

Website: cmtorangetools.com

Key Highlights: Discover the CMT catalogue of Industrial Circular saw blades for cutting wood, melamine, laminate, non-ferrous materials, plastic, metal, steel….

#4 The M.K. Morse Company

Domain Est. 1997

Website: mkmorse.com

Key Highlights: Steel, stainless steel, and aluminum/non-ferrous blades partner with circular and chop saws to make faster, cooler, cleaner cuts with a smooth finish that needs ……

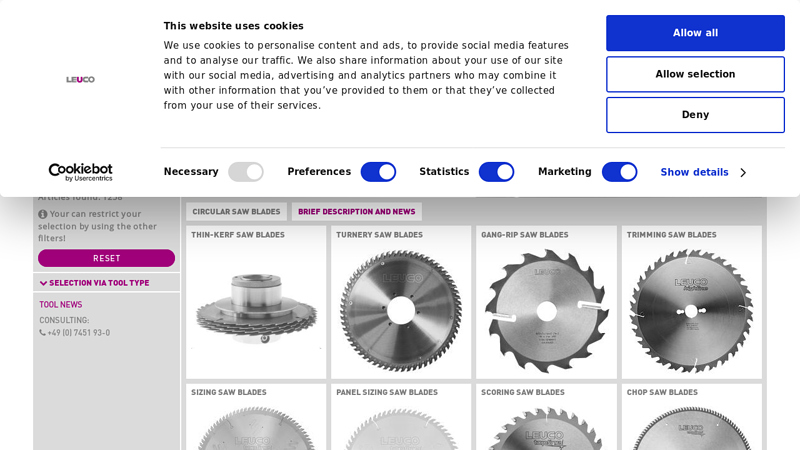

#5 Circular Saw Blades

Domain Est. 1997

Website: leuco.com

Key Highlights: Circular Saw Blades by LEUCO. Quality, Variety, Innovation. Thin-Kerf Saw Blades, Turnery Saw Blades, Gang-Rip Saw Blades, Trimming Saw Blades, Sizing Saw ……

#6 Saw Blades

Domain Est. 1998

Website: craftsman.com

Key Highlights: Product Type · Circular Saw Blade (7) · JIG SAW BLADE (4) · RECIPROCATING SAW BLADE (1) · SAW BLADE (2) · TABLE SAW BLADE (2) ……

#7 Evolution Blades

Domain Est. 2000

Website: store.evolutionpowertools.com

Key Highlights: Free delivery Free 45-day returnsExplore our selection of saw blades designed for a range of tools and purposes, such as chop saw blades, circular saw blades, jigsaw blades, miter …

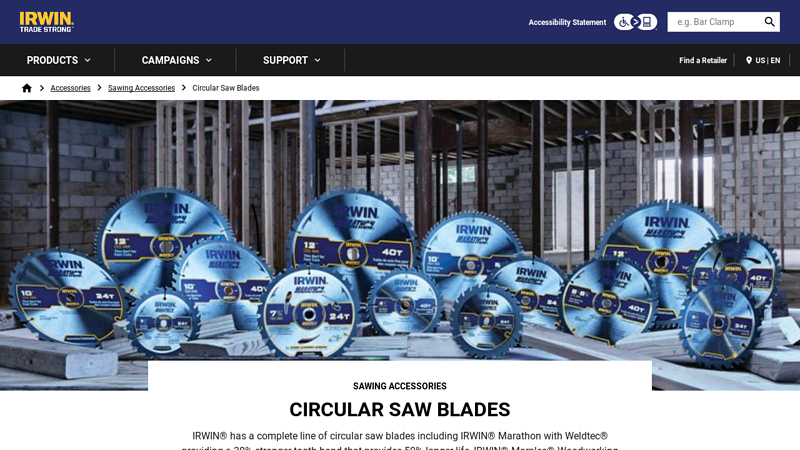

#8 Circular Saw Blades

Domain Est. 2002

Website: irwintools.com

Key Highlights: IRWIN has a complete line of circular saw blades including IRWIN Marathon with Weldtec providing a 30% stronger tooth bond that provides 50% longer life….

#9 LENOX®

Domain Est. 2017

Website: cutwithlenox.com

Key Highlights: Reciprocating Saw Blades · Portable Band Saw Blades · Jigsaw Blades · Circular Saw Blades · Step Drills Bits · Wood Drilling Bits · Auger Bits · Self Feed Bits ……

Expert Sourcing Insights for Circular Saw Blade Types

2026 Market Trends for Circular Saw Blade Types

The circular saw blade market in 2026 is poised for dynamic evolution, driven by technological advancements, sustainability imperatives, and shifting end-user demands. Here’s a detailed analysis of key trends shaping different blade types:

1. Dominance of Tungsten Carbide-Tipped (TCT) Blades Continues, But Evolves

TCT blades will maintain their market leadership due to their exceptional durability and versatility across materials like wood, plastic, and non-ferrous metals. However, by 2026, expect significant innovation in carbide formulations and tip geometry. Manufacturers are developing micro-grain carbide and wear-resistant coatings (e.g., titanium nitride, diamond-like carbon) to extend blade life and reduce downtime. Additionally, application-specific TCT blades—optimized for engineered wood, laminates, or aluminum—will gain traction, offering improved cut quality and reduced chipping.

2. High-Speed Steel (HSS) Blades Find Niche Applications

While gradually losing ground to TCT in heavy-duty applications, HSS blades will retain relevance in niche markets. Their superior flexibility and lower cost make them ideal for thin-kerf applications, intricate cuts, and DIY users. In 2026, premium HSS blades with advanced tempering and alloy compositions will cater to craftsmen and light industrial users who prioritize precision over extreme durability. The market for HSS blades will stabilize but remain smaller compared to carbide-based solutions.

3. Diamond Blades Experience Accelerated Growth

Diamond-tipped circular saw blades are set for the fastest growth, particularly in construction and masonry sectors. The rising demand for cutting reinforced concrete, asphalt, stone, and fiber-cement board drives this expansion. Innovations in diamond grit concentration, segment bonding, and wet/dry cutting capabilities will enhance performance and safety. By 2026, segmented and continuous-rim diamond blades will dominate infrastructure, renovation, and tile-cutting applications, supported by stricter building codes and urban development projects.

4. Rise of Specialized and Multi-Material Blades

As composite materials (e.g., cross-laminated timber, fiber-reinforced plastics) become more prevalent in construction and manufacturing, demand for multi-material blades will surge. These hybrid blades feature variable tooth designs and advanced coatings to handle transitions between wood, metal, and plastic without changing tools. In 2026, expect major brands to launch “universal” or “all-material” blades marketed toward renovators and industrial fabricators seeking efficiency and cost savings.

5. Sustainability and Circular Economy Influence Design

Environmental regulations and corporate ESG goals will increasingly shape blade manufacturing. By 2026, recyclable blade cores, reduced use of cobalt in carbide, and take-back programs for worn blades will become standard offerings. Laser-welded TCT blades with replaceable tips may emerge as a sustainable alternative to traditional brazed blades, minimizing waste. The circular economy model will gain momentum, especially in Europe and North America.

6. Smart Blades and Digital Integration Begin to Emerge

While still in early stages, smart circular saw blades embedded with sensors to monitor wear, temperature, and vibration could debut in 2026. These IoT-enabled blades will integrate with power tools and workshop management systems, providing predictive maintenance alerts and optimizing cutting performance. Adoption will initially be limited to high-end industrial applications but signal a future shift toward connected tool ecosystems.

Conclusion

By 2026, the circular saw blade market will be characterized by material-specific innovation, sustainability integration, and a growing appetite for specialized, high-performance solutions. While TCT blades remain dominant, diamond and multi-material blades will gain significant share, driven by construction trends and advanced composites. Smart technologies and circular economy principles will begin to reshape product design, setting the stage for a more efficient and sustainable future in cutting tools.

Common Pitfalls When Sourcing Circular Saw Blade Types (Quality, IP)

Sourcing the right circular saw blade is critical for achieving clean cuts, ensuring operator safety, and maximizing tool life. However, several pitfalls—especially related to quality and intellectual property (IP)—can lead to poor performance, increased costs, or even legal risks. Avoiding these issues requires awareness and due diligence.

Overlooking Blade Material and Build Quality

One of the most frequent mistakes is focusing solely on price while ignoring the blade’s core components—such as the carbide grade, steel core quality, and manufacturing precision. Low-cost blades often use inferior carbide inserts that dull quickly or poorly tensioned steel cores that warp under heat. This leads to rough cuts, excessive vibration, and reduced blade lifespan. Always verify material specifications and opt for reputable manufacturers known for strict quality control.

Ignoring Application-Specific Design Requirements

Circular saw blades vary significantly based on the material being cut—wood, metal, masonry, or composites. Using a general-purpose blade for a specialized task (e.g., cutting aluminum with a wood-optimized blade) results in poor performance and safety hazards. Ensure blades are engineered for the intended material and cutting conditions, including tooth geometry, hook angle, and gullet size.

Falling for Counterfeit or IP-Infringing Products

The market is flooded with counterfeit blades that mimic well-known brands, often bearing fake logos or packaging. These violate intellectual property rights and typically deliver substandard performance and safety. Sourcing from unauthorized distributors increases the risk of receiving such products. Always purchase through authorized channels and verify product authenticity through batch numbers, holograms, or direct supplier confirmation.

Assuming All Blades Meet Safety and Certification Standards

Not all blades comply with international safety standards (e.g., ANSI, CE, or ISO). Non-compliant blades may lack proper labeling, safety testing, or quality certifications, increasing the risk of breakage or kickback. Confirm that blades meet relevant safety regulations and are certified by recognized bodies before procurement.

Underestimating the Importance of Coatings and Treatments

High-performance blades often feature specialized coatings (e.g., titanium nitride or anti-vibration damping) that enhance durability and cut quality. Skipping blades with such treatments to cut costs can lead to faster wear, increased friction, and overheating. Evaluate whether advanced coatings offer long-term savings through extended blade life and better cutting efficiency.

Failing to Verify Supplier Credibility and Traceability

Working with unknown or unverified suppliers—especially in online marketplaces—increases exposure to low-quality or IP-infringing products. Lack of traceability makes it difficult to address defects or recalls. Conduct supplier audits, request references, and ensure they can provide documentation on material sourcing and manufacturing processes.

By addressing these common pitfalls, buyers can ensure they source high-quality, legally compliant circular saw blades that meet performance and safety standards. Prioritizing quality over upfront cost and respecting intellectual property rights protects both operational efficiency and brand reputation.

Logistics & Compliance Guide for Circular Saw Blade Types

Understanding the logistics and compliance requirements associated with circular saw blades is essential for manufacturers, distributors, importers, and end-users. This guide outlines key considerations related to transportation, storage, regulatory standards, and safety compliance across different blade types.

Blade Classification and Regulatory Standards

Circular saw blades are categorized based on material, design, and intended application—such as wood-cutting, metal-cutting, masonry, and combination blades. Each type may be subject to different regulatory frameworks depending on the region:

- United States: The Occupational Safety and Health Administration (OSHA) regulates blade safety under 29 CFR 1910.213, mandating guards, arbor size compliance, and maximum operating speeds.

- European Union: Compliant with the Machinery Directive (2006/42/EC) and CE marking requirements. Blades must meet EN 847-1 standards for safety and performance.

- Canada: Subject to Canadian Standards Association (CSA) standards such as CSA M404 for portable power tools and associated accessories.

- Australia/New Zealand: Must comply with AS/NZS 60745.1 for hand-held motor-operated tools and relevant blade performance standards.

Ensure all blades are accompanied by technical documentation, including declarations of conformity and safety data sheets where applicable.

Packaging and Labeling Requirements

Proper packaging and labeling are critical for compliance and safe handling:

- Mandatory Labeling: Include blade type, diameter, bore size, maximum RPM, material compatibility, and manufacturer details. CE, UKCA, or CSA marks must be visibly displayed where required.

- Hazard Communication: Blades with coatings (e.g., carbide-tipped or diamond segments) may require labeling under GHS (Globally Harmonized System) if hazardous materials are present.

- Packaging Integrity: Use durable, non-abrasive packaging to prevent edge damage during transit. Individual blister packs or cardboard sleeves are recommended for retail distribution.

Transportation and Shipping Logistics

Circular saw blades may be subject to specific transportation regulations, especially for international shipments:

- Dangerous Goods Classification: While most blades are not classified as hazardous, those with cobalt-binder in carbide tips may fall under Class 9 (Miscellaneous Dangerous Goods) due to environmental concerns under IATA/IMDG regulations. Confirm material composition before shipping.

- Air and Sea Freight: Declare contents accurately on commercial invoices and packing lists. Sharp blades must be securely packaged to prevent punctures and comply with carrier policies.

- Customs Clearance: Provide Harmonized System (HS) codes (e.g., 8202.20 for circular saw blades) and country-specific certifications to avoid delays. Import duties and taxes vary by jurisdiction.

Storage and Handling Best Practices

Safe storage ensures blade longevity and compliance with workplace safety standards:

- Environment: Store in a dry, temperature-controlled area to prevent corrosion—especially critical for high-speed steel (HSS) and tungsten carbide blades.

- Orientation: Keep blades flat or vertically hung to avoid warping. Avoid stacking heavy items on top.

- Access Control: Store in locked cabinets if required by site safety policies, particularly in industrial or educational environments.

End-of-Life and Environmental Compliance

Disposal and recycling of saw blades must adhere to environmental regulations:

- Recycling Programs: Carbide-tipped and diamond blades contain recoverable materials. Partner with certified metal recyclers or take-back programs.

- Waste Classification: Blades may be classified as industrial metal waste. Comply with local regulations (e.g., RCRA in the U.S., WEEE in the EU).

- Documentation: Maintain records of disposal or recycling to support corporate sustainability and compliance reporting.

Summary

Adhering to logistics and compliance standards for circular saw blades ensures operational safety, regulatory conformity, and efficient supply chain management. Always verify regional requirements, maintain accurate documentation, and use appropriate handling and packaging methods for each blade type.

In conclusion, sourcing the appropriate circular saw blade type is crucial for achieving optimal cutting performance, precision, and tool longevity across various materials and applications. With a wide range of blade types—such as rip blades, crosscut blades, combination blades, plywood blades, and specialized blades for metals, masonry, or laminates—selecting the right one depends on factors like tooth count, tooth geometry (ATB, FT, TCG, etc.), blade diameter, arbor size, and the material being cut.

High-quality blades from reputable manufacturers ensure durability, reduced vibration, cleaner cuts, and greater safety. When sourcing, consider balancing cost with performance, especially for professional vs. DIY use. Additionally, proper maintenance and correct installation further enhance blade efficiency.

Ultimately, understanding your cutting needs and matching them with the right blade specifications will lead to better results, increased productivity, and long-term savings in both time and material costs. Careful selection and sourcing of circular saw blades are therefore essential steps in any woodworking, metalworking, or construction project.