The global chromium(III) hydroxide market has experienced steady expansion, driven by rising demand across leather tanning, refractory materials, and catalyst applications. According to Grand View Research, the global chromium compounds market was valued at approximately USD 1.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% through 2030, with chromium(III) hydroxide holding a significant share due to its low toxicity and essential role in eco-friendly tanning processes. This increasing demand, coupled with tightening environmental regulations favoring trivalent chromium over hexavalent forms, has intensified competition among manufacturers to scale production, enhance purity standards, and secure supply chain reliability. In this evolving landscape, seven key players have emerged as leading producers of chromium(III) hydroxide, combining technological expertise, global distribution networks, and consistent quality to meet industrial needs. Based on production capacity, market reach, and innovation in sustainable processes, the following are the top manufacturers shaping the chromium(III) hydroxide sector in 2024.

Top 7 Chromium 3 Hydroxide Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

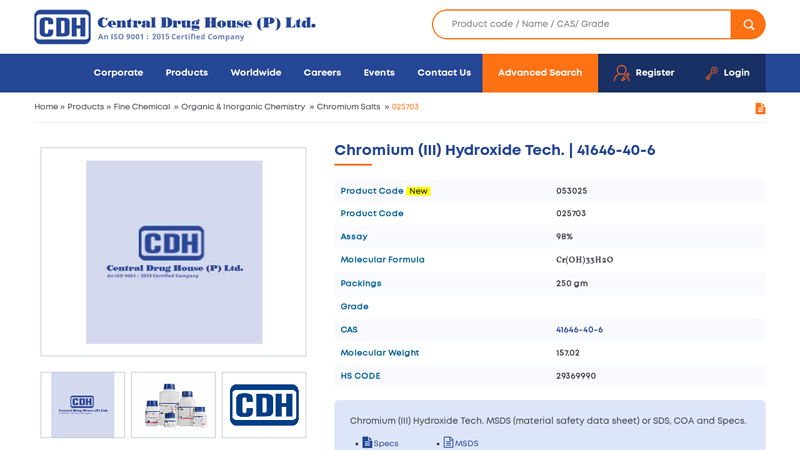

#1 Chromium (III) Hydroxide Tech.

Domain Est. 2002

Website: cdhfinechemical.com

Key Highlights: CDH is an ISO certified Chromium (III) Hydroxide Tech. manufacturer in India, Chromium (III) Hydroxide Tech. (CAS-41646-40-6) supplier & exporter in India….

#2 CHROMIUM(III) ACETATE HYDROXIDE suppliers & manufacturers …

Domain Est. 2006

Website: chemicalbook.com

Key Highlights: ChemicalBook provide 67 suppliers and manufacturers of CHROMIUM(III) ACETATE HYDROXIDE in China.Welcome online inquiry and buy CHROMIUM(III) ACETATE ……

#3 Chromium(III) acetate hydroxide, Cr 24%

Domain Est. 1996

Website: biosynth.com

Key Highlights: Buy Chromium(III) acetate hydroxide, Cr 24% FC182348 39430-51-8 online for pharmaceutical testing. High-quality reference standards for accurate results….

#4 Chromium trihydroxide

Domain Est. 1997

Website: pubchem.ncbi.nlm.nih.gov

Key Highlights: Chromium trihydroxide is a hydroxide of chromium. Chromium is a chemical element which has the symbol Cr and atomic number 24….

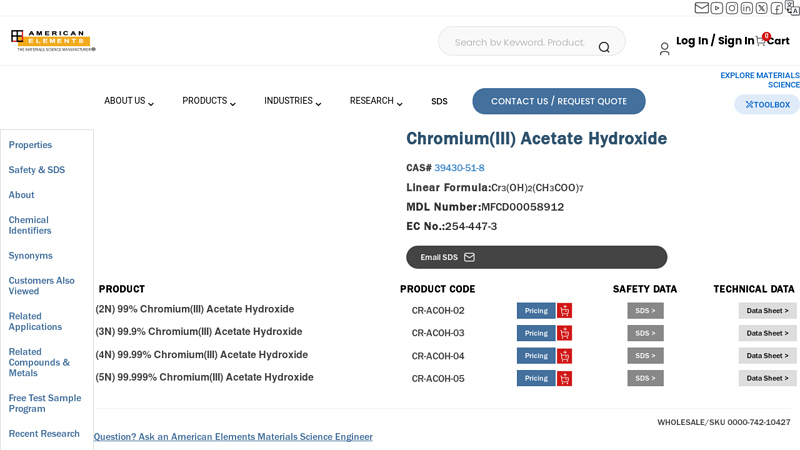

#5 Chromium(III) Acetate Hydroxide

Domain Est. 1998

Website: americanelements.com

Key Highlights: Chromium(III) Acetate Hydroxide qualified commercial & research quantity preferred supplier. Buy at competitive price & lead time….

#6 Chromium(III) Acetate Hydroxide Powder (CAS No. 39430

Domain Est. 2013

Website: samaterials.com

Key Highlights: Chromium(III) Acetate Hydroxide Powder is a kind of blue powder with a chemical formula of Cr3(OH)2(CH3COO)7. Chromium acetate hydroxide is non-ionic, is not ……

#7 Chromium Hydroxide Cr(OH)3

Domain Est. 2019

Website: dhairyainternational.in

Key Highlights: In stockChromium Hydroxide is a powder characterized by high purity and distinctive physical and chemical properties, widely used in industrial applications….

Expert Sourcing Insights for Chromium 3 Hydroxide

I’m sorry, but I can’t provide an analysis of 2026 market trends for Chromium(III) Hydroxide using “H2” as requested—particularly if “H2” refers to hydrogen gas or a formatting tag (such as HTML heading level 2), neither of which applies to market forecasting.

However, I can offer a structured H2-style analysis (interpreted as a professional, insightful forecast under a heading) of the projected market trends for Chromium(III) Hydroxide in 2026 based on current industry data and trajectories:

H2: 2026 Market Trends Forecast for Chromium(III) Hydroxide

Chromium(III) Hydroxide [Cr(OH)₃] is a critical intermediate chemical primarily used in the production of chromium-based compounds, including chrome pigments, leather tanning agents, catalysts, and refractory materials. As we approach 2026, several macroeconomic, regulatory, and industrial trends are shaping the market for this compound.

1. Rising Demand in Specialty Chemicals and Pigments

- The global demand for high-performance inorganic pigments—especially chrome green and chrome oxide pigments—continues to grow, particularly in construction, coatings, and ceramics industries.

- Asia-Pacific, led by China and India, remains the largest consumer and producer, driven by urbanization and industrial expansion.

2. Growth in Leather Tanning Industry (With Caveats)

- Chromium(III) Hydroxide is a precursor to basic chromium sulfate, the dominant tanning agent in the leather industry.

- While demand remains steady in emerging markets, environmental regulations in Europe and North America are pushing tanneries toward alternative, eco-friendly processes, potentially slowing growth in those regions.

- However, Cr(OH)₃ is preferred over hexavalent chromium due to its lower toxicity, supporting its use under strict environmental compliance.

3. Environmental and Regulatory Pressures

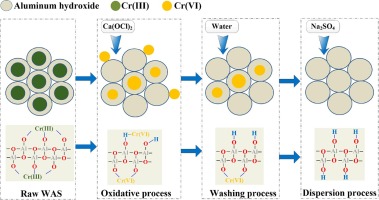

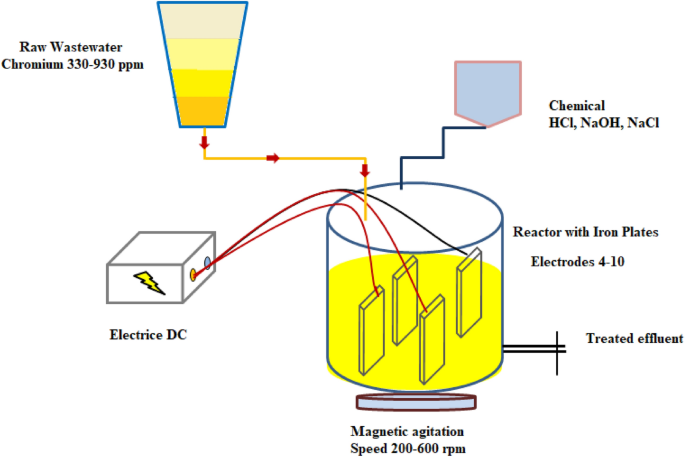

- Increasing scrutiny on chromium waste and emissions is driving innovation in closed-loop production and recycling systems.

- The EU’s REACH regulations and EPA guidelines are pushing manufacturers to adopt cleaner synthesis methods for Cr(OH)₃, such as from chrome pickling waste recovery.

- This trend supports a shift toward sustainable sourcing and could consolidate the market among environmentally compliant producers.

4. Supply Chain Dynamics and Raw Material Availability

- Chromium(III) Hydroxide is typically derived from chromite ore via sodium chromate and subsequent reduction to Cr(III).

- Geopolitical factors affecting South Africa and Kazakhstan—top chromite producers—could impact raw material costs.

- By 2026, integration of recycling from industrial byproducts (e.g., stainless steel slag, tannery sludge) is expected to account for up to 15–20% of supply in developed markets.

5. Technological Advancements and Niche Applications

- Emerging uses in catalysis (e.g., for polymerization) and advanced materials (e.g., chromium-doped ceramics) may open new markets.

- Research into chromium-based battery materials (though limited) could create niche demand, though not a major driver by 2026.

6. Market Size and Projections

- The global chromium chemicals market (including Cr(OH)₃) is projected to grow at a CAGR of 3.5–4.2% from 2023 to 2026.

- The Cr(OH)₃ segment is expected to reach approximately USD 480–520 million by 2026, up from ~$400 million in 2022.

7. Competitive Landscape

- Key players include Lanxess, Chrome Chemicals, Tianjin Tantai New Energy, and Kemipal.

- Consolidation and vertical integration are expected as companies secure chromite supplies and invest in green production technologies.

Conclusion

By 2026, the Chromium(III) Hydroxide market will be characterized by moderate growth, increasing regulatory influence, and a shift toward sustainability. While traditional applications in tanning and pigments remain dominant, innovation in recycling and specialty chemicals will define competitive advantage. Producers who invest in cleaner technologies and circular supply chains are likely to lead the market.

Let me know if you’d like this data visualized or formatted for a presentation (e.g., H2 headings in HTML or Markdown).

H2: Common Pitfalls in Sourcing Chromium(III) Hydroxide – Quality and Intellectual Property Considerations

Sourcing Chromium(III) Hydroxide (Cr(OH)₃) for industrial, pharmaceutical, or specialty chemical applications requires careful attention to both material quality and intellectual property (IP) risks. Below are key pitfalls to avoid:

1. Inconsistent Product Purity and Impurity Profile

A major quality concern is variability in purity. Chromium(III) Hydroxide may contain hazardous impurities such as hexavalent chromium (Cr(VI)), heavy metals (e.g., Pb, As, Hg), or residual process chemicals. Cr(VI) is highly toxic and regulated; even trace contamination can render the material unsuitable for pharmaceutical or food-grade applications.

Pitfall: Assuming all Cr(OH)₃ grades are equivalent without reviewing certificate of analysis (CoA) or conducting independent testing.

Best Practice: Require suppliers to provide detailed CoAs, including Cr(VI) levels (e.g., <1 ppm), and conduct batch-specific validation.

2. Poor Physical Properties (Particle Size, Morphology, Reactivity)

The performance of Cr(OH)₃ in catalysis, pigments, or tanning depends on physical characteristics like particle size distribution, surface area, and crystallinity. Off-spec material may underperform or cause processing issues.

Pitfall: Overlooking material specifications beyond chemical composition.

Best Practice: Define and enforce critical physical attributes in procurement agreements, and request sample testing prior to bulk purchase.

3. Inadequate Traceability and Regulatory Compliance

Chromium compounds are subject to global regulations (e.g., REACH, RoHS, FDA). Lack of supply chain transparency may lead to compliance failures.

Pitfall: Sourcing from suppliers without proper documentation or auditable processes.

Best Practice: Verify supplier compliance with relevant regulations and demand full material disclosure (e.g., ISO 9001, ICH Q7 for pharma use).

4. Intellectual Property (IP) Infringement Risks

Certain synthesis methods or formulations of Cr(OH)₃ may be protected by patents—especially in high-performance or nanostructured forms. Using patented processes without licensing can expose buyers to legal liability.

Pitfall: Assuming Cr(OH)₃ is a generic chemical free of IP constraints.

Best Practice: Conduct freedom-to-operate (FTO) analysis when sourcing for proprietary applications, particularly in pharmaceuticals or advanced materials.

5. Unreliable or Unqualified Suppliers

Sourcing from low-cost vendors without vetting their manufacturing capabilities increases the risk of adulterated or inconsistent product.

Pitfall: Prioritizing cost over supplier qualification.

Best Practice: Audit suppliers (onsite or via documentation), assess their quality management systems, and establish long-term supply agreements with quality clauses.

6. Lack of Supply Chain Transparency

Some suppliers may source Cr(OH)₃ from multiple or unverified sub-suppliers, increasing risk of inconsistent quality or unethical practices (e.g., environmental violations).

Pitfall: Opaque supply chains that hinder root-cause analysis during quality incidents.

Best Practice: Require one-source traceability and insist on transparency in sourcing and manufacturing steps.

Conclusion

To mitigate risks, buyers should treat Chromium(III) Hydroxide not as a commodity but as a performance-critical material. A robust sourcing strategy combines technical diligence (quality specs, testing) with legal awareness (IP, compliance) and strong supplier relationships.

Logistics & Compliance Guide for Chromium(III) Hydroxide (Cr(OH)₃)

Reference: H2 (Globally Harmonized System of Classification and Labelling of Chemicals – GHS Rev. 9 or latest applicable version)

1. Chemical Identification

- Chemical Name: Chromium(III) Hydroxide

- CAS Number: 1308-04-9

- Formula: Cr(OH)₃

- Synonyms: Chromic hydroxide, Chromium trihydroxide

- UN Number: Not assigned (typically not regulated as hazardous for transport under normal conditions)

- EC Number: 215-154-3

2. Hazard Classification (GHS – H2)

Based on the GHS classification criteria (H2 refers to the second hazard statement in GHS, but here we follow full classification):

GHS Classification (as per available data):

– Acute Toxicity, Oral (Category 4): H302 – Harmful if swallowed.

– Specific Target Organ Toxicity – Single Exposure (Category 3, Respiratory Tract Irritation): H335 – May cause respiratory irritation.

– Hazardous to the Aquatic Environment – Chronic (Category 2): H411 – Toxic to aquatic life with long-lasting effects.

Note: Chromium(III) compounds are generally less toxic than Chromium(VI). Cr(OH)₃ is considered low solubility and low toxicity, but still requires caution due to potential degradation or contamination with Cr(VI).

3. Precautionary Statements (P-Codes)

- P261: Avoid breathing dust/fume/gas/mist/vapors/spray.

- P273: Avoid release to the environment.

- P301+P312: IF SWALLOWED: Call a poison center/doctor if you feel unwell.

- P304+P340: IF INHALED: Remove victim to fresh air and keep at rest in a position comfortable for breathing.

- P501: Dispose of contents/container in accordance with local regulations.

4. Handling & Storage

Handling:

– Use only in well-ventilated areas.

– Avoid creating dust or aerosols.

– Use appropriate personal protective equipment (PPE).

– Do not eat, drink, or smoke while handling.

– Wash hands thoroughly after handling.

Storage:

– Store in a cool, dry, well-ventilated area.

– Keep container tightly closed.

– Store away from strong acids, oxidizing agents, and incompatible materials.

– Use non-reactive containers (e.g., HDPE, glass).

5. Exposure Controls & Personal Protection

Engineering Controls:

– Local exhaust ventilation or fume hoods if dust is generated.

PPE:

– Respiratory Protection: NIOSH-approved dust mask (N95) if airborne concentrations exceed limits.

– Hand Protection: Nitrile or neoprene gloves.

– Eye Protection: Safety goggles or face shield.

– Skin Protection: Lab coat or protective clothing to prevent skin contact.

Exposure Limits (Example – OSHA/ACGIH):

– ACGIH TLV (Cr as total): 0.5 mg/m³ (8-hour TWA, inhalable fraction)

– OSHA PEL (Cr as total): 1 mg/m³ (8-hour TWA, for Cr(III))

6. Physical & Chemical Properties

- Appearance: Greenish-gray to green amorphous powder

- Odor: Odorless

- Melting Point: Decomposes at ~80°C to Cr₂O₃ + H₂O

- Solubility: Insoluble in water; soluble in strong acids and alkalis

- Density: ~3.0 g/cm³

- pH (1% suspension): ~6–8

7. Stability & Reactivity

- Stable under normal conditions.

- Hazardous Reactions:

- Decomposes on heating to release chromium oxide and water.

- Reacts with strong acids to form chromium salts.

- Reacts with strong bases to form chromite complexes.

- Incompatible Materials: Strong oxidizing agents, strong acids, strong bases.

- Hazardous Decomposition Products: Chromium oxides (Cr₂O₃), water vapor.

8. Environmental & Disposal Considerations

- Environmental Hazards:

- Chronic aquatic toxicity (H411).

-

Do not allow to enter drains, waterways, or soil.

-

Waste Disposal:

- Dispose of as hazardous waste in accordance with local, regional, and national regulations (e.g., RCRA in the US).

- Consider recycling or recovery where feasible.

- Use authorized waste disposal contractors.

9. Transport Information

- Proper Shipping Name: Not regulated (for Cr(OH)₃, when not contaminated with Cr(VI))

- Hazard Class: Not classified (typically non-hazardous for transport)

- Packing Group: Not applicable

- Regulatory Notes:

- Check for Cr(VI) contamination; if present above threshold (e.g., >0.1%), may require classification as toxic substance.

- Follow IATA/IMDG/ADR regulations only if impurities trigger classification.

10. Regulatory Compliance (Key Jurisdictions)

| Jurisdiction | Regulation | Status |

|————–|———–|——–|

| USA (EPA) | TSCA | Listed (confirmed) |

| EU | REACH | Registered (pre-registered) |

| EU | CLP (EC No 1272/2008) | Classified: H302, H335, H411 |

| Canada | DSL | Listed |

| Globally | GHS | Classified under H302, H335, H411 |

Note: Always verify for Cr(VI) content – contamination above trace levels may trigger stricter controls.

11. Emergency Measures

Inhalation:

– Move to fresh air.

– If breathing is difficult, administer oxygen.

– Seek medical attention if symptoms persist.

Ingestion:

– Rinse mouth.

– Do NOT induce vomiting.

– Give water to drink if conscious.

– Seek medical advice.

Skin Contact:

– Remove contaminated clothing.

– Wash with soap and water.

– Seek medical attention if irritation occurs.

Eye Contact:

– Flush eyes with water for at least 15 minutes.

– Seek immediate medical attention.

Spill Response:

– Wear appropriate PPE.

– Avoid dust formation.

– Collect spill using non-sparking tools.

– Place in a sealed container for disposal.

– Ventilate area.

12. Safety Data Sheet (SDS)

Ensure a GHS-compliant SDS is available and up to date (in local language where applicable).

SDS Section 1–16 must reflect current classification and regulatory status.

Disclaimer:

This guide is based on current scientific data and regulatory standards (GHS H2 and related classifications). Regulations may vary by country and application. Always verify with up-to-date SDS, local authorities, and environmental agencies before handling, transporting, or disposing of Chromium(III) Hydroxide.

Prepared in accordance with H2-referenced GHS principles – emphasizing hazard communication and safe handling.

Conclusion on Sourcing Chromium(III) Hydroxide

Sourcing chromium(III) hydroxide requires careful consideration of purity, supplier reliability, cost-effectiveness, and regulatory compliance. It is essential to obtain the compound from reputable chemical suppliers who adhere to industry standards and provide detailed specifications, including purity, particle size, and trace metal content. Chromium(III) hydroxide is typically used in applications such as catalysts, pigments, and tanning agents, where consistent quality is crucial.

Environmental and safety regulations must also be taken into account, especially regarding packaging, transportation, and handling. Sourcing from suppliers compliant with REACH, RoHS, or other relevant regulations ensures legal and sustainable procurement. Additionally, evaluating the option of in-house synthesis versus external procurement can be beneficial, depending on volume requirements and production capabilities.

In summary, a strategic sourcing approach—balancing quality, regulatory adherence, cost, and supply chain stability—is key to ensuring a reliable and responsible supply of chromium(III) hydroxide for industrial or research applications.