The global chlorine gas detector market is experiencing robust growth, driven by increasing industrial safety regulations, rising awareness of hazardous gas exposure, and expanding applications in chemical processing, water treatment, and pharmaceuticals. According to a report by Mordor Intelligence, the market is projected to grow at a CAGR of over 6.5% during the forecast period of 2023–2028. Similarly, Grand View Research valued the global toxic gas detection market—which includes chlorine—at USD 5.6 billion in 2022, with continued expansion expected due to stringent OSHA and EPA compliance requirements. As demand surges for reliable, real-time monitoring solutions, three manufacturers have emerged as leaders through innovation, product reliability, and global reach.

Top 3 Chlorine Gas Detector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 PQD

Website: prosense.com.tr

Key Highlights: PQD-6934 Chlorine gas detector is designed to detect Chlorine gas in the industrial areas. With ATEX / IECEx, SIL2 certifications, EN 60079-29: 1 performance ……

#2 Chlorine Gas Detectors and Monitors

Domain Est. 1994

Website: draeger.com

Key Highlights: Dräger also offers custom chlorine gas detection and monitoring solutions based on the needs of the food and beverage facility. Portable Gas Detection Solutions….

#3 Best Chlorine Gas Detector (2026 update)

Domain Est. 2019

Website: forensicsdetectors.com

Key Highlights: A chlorine gas detector, or Cl2 gas meter, is a critical safety device that detects and monitors the concentration of chlorine gas in the air….

Expert Sourcing Insights for Chlorine Gas Detector

H2: By 2026, the global chlorine gas detector market will experience significant growth driven by rising industrial safety regulations, increased adoption in water treatment and chemical manufacturing, and advancements in sensor technologies, particularly wireless and IoT-integrated systems.

The chlorine gas detector market is poised for robust expansion through 2026, with a compound annual growth rate (CAGR) projected between 6.5% and 8.2%, depending on regional dynamics and sector-specific demand. Key factors shaping this growth include:

-

Stringent Safety and Environmental Regulations

Governments and international bodies are tightening occupational health and safety standards, especially in industries handling hazardous chemicals. Regulatory frameworks such as OSHA (U.S.), ATEX (Europe), and similar directives in Asia-Pacific are mandating the installation of reliable gas detection systems. This compliance-driven demand is a primary catalyst for market expansion. -

Growth in End-Use Sectors

- Water and Wastewater Treatment: Chlorine remains a critical disinfectant in municipal and industrial water systems. As urbanization increases and water quality standards become stricter, the demand for continuous chlorine monitoring systems rises.

- Chemical and Petrochemical Industries: These sectors use chlorine in large volumes for producing plastics, solvents, and pharmaceuticals. With heightened focus on process safety and leak prevention, facilities are investing in real-time detection systems.

-

Pulp and Paper Industry: Though declining in some regions, chlorine-based bleaching processes still require monitoring in certain markets, sustaining detector demand.

-

Technological Advancements

The market is shifting from traditional electrochemical sensors to more advanced solutions: - Wireless and IoT-Enabled Detectors: These allow remote monitoring, real-time data transmission, and integration with facility management systems, improving response times and operational efficiency.

- Smart Sensors with AI Analytics: Predictive maintenance, self-diagnostics, and false alarm reduction are becoming standard features, enhancing reliability.

-

Miniaturization and Portability: Handheld and wearable detectors are gaining traction for worker safety in confined spaces and emergency response scenarios.

-

Regional Market Dynamics

- Asia-Pacific: Expected to dominate market growth due to rapid industrialization in China, India, and Southeast Asia, along with expanding infrastructure in water treatment and chemical production.

- North America and Europe: Mature markets with steady growth, driven by regulatory upgrades and retrofitting of aging facilities with smart detection systems.

-

Middle East & Africa: Growth supported by investments in oil & gas and desalination plants, where chlorine is used for water disinfection.

-

Challenges and Opportunities

- Challenges: High costs of advanced detectors, calibration requirements, and sensor drift in harsh environments may limit adoption in cost-sensitive regions.

- Opportunities: Increasing focus on smart cities and industrial automation presents avenues for integrating chlorine detectors into broader safety ecosystems. Additionally, emerging markets offer untapped potential for new installations.

In conclusion, the 2026 chlorine gas detector market will be characterized by innovation, regulatory compliance, and digital transformation. Companies that invest in IoT integration, sensor accuracy, and user-friendly interfaces will be well-positioned to lead the market.

When sourcing a Chlorine Gas Detector (Cl₂) for use with Hydrogen (H₂) environments, several critical pitfalls can compromise safety, performance, and reliability. Below are the common pitfalls, with a focus on quality and Ingress Protection (IP) rating, particularly in H₂ (hydrogen)-related applications:

⚠️ Common Pitfalls in Sourcing Chlorine Gas Detectors (with H₂ Considerations)

1. Ignoring Hydrogen Compatibility (H₂ Cross-Sensitivity)

- Pitfall: Some electrochemical chlorine sensors may exhibit cross-sensitivity to hydrogen gas, leading to false alarms or inaccurate Cl₂ readings in H₂-rich environments.

- Impact: Unreliable detection, potential safety risks, unnecessary process shutdowns.

- Solution:

- Choose detectors with H₂-compensated or H₂-immune electrochemical sensors.

- Request cross-sensitivity data from manufacturers (e.g., response to 1% H₂ in air).

- Prefer sensors specifically tested and rated for mixed-gas environments (Cl₂ + H₂).

2. Inadequate Ingress Protection (IP Rating)

- Pitfall: Selecting detectors with low IP ratings (e.g., IP54) for outdoor, humid, or washdown environments.

- Impact: Moisture or dust ingress can damage sensors or electronics, especially problematic in hydrogen environments where flammable gas leaks must not be masked by detector failure.

- Solution:

- Use detectors with minimum IP65 (dust-tight, protected against water jets).

- For harsh environments (outdoor, chemical plants), opt for IP66 or IP67.

- Ensure cable glands and enclosures also meet IP requirements.

3. Poor Sensor Quality and Calibration Drift

- Pitfall: Sourcing low-cost detectors with low-quality electrochemical cells that degrade quickly or require frequent recalibration.

- Impact: Reduced accuracy over time, increased maintenance costs, potential failure to detect hazardous Cl₂ levels—critical in H₂ areas where both gases are dangerous.

- Solution:

- Prioritize sensors from reputable manufacturers (e.g., MSA, Honeywell, Dräger, Ion Science).

- Check sensor lifespan (typically 1–2 years for Cl₂).

- Ensure automatic calibration features or easy bump testing.

4. Lack of ATEX/IECEx Certification for H₂ Environments

- Pitfall: Using non-certified detectors in explosive atmospheres where H₂ is present (Group IIC, T1 temperature class).

- Impact: Risk of ignition; non-compliance with safety regulations (e.g., ATEX, NEC).

- Solution:

- Select detectors with ATEX/IECEx certification suitable for Zone 1 or Zone 2 (gas groups IIC, suitable for hydrogen).

- Verify temperature class (T-rating) is compatible with operating environment.

5. Insufficient Environmental Ruggedness

- Pitfall: Deploying detectors not designed for high humidity, extreme temperatures, or corrosive atmospheres common in chlor-alkali or hydrogen production plants.

- Impact: Premature sensor failure, false readings.

- Solution:

- Choose detectors with wide operating temperature range (e.g., -20°C to +50°C).

- Ensure corrosion-resistant housing (e.g., 316 stainless steel or high-grade polymers).

- Confirm humidity tolerance (0–95% RH, non-condensing).

6. Neglecting Response Time in H₂-Rich Settings

- Pitfall: Slow response time (T90 > 60 seconds) in environments where both Cl₂ and H₂ can accumulate rapidly.

- Impact: Delayed alarms, increased risk during leaks.

- Solution:

- Specify detectors with T90 < 30 seconds.

- Use diffusion or pumped sampling based on installation needs.

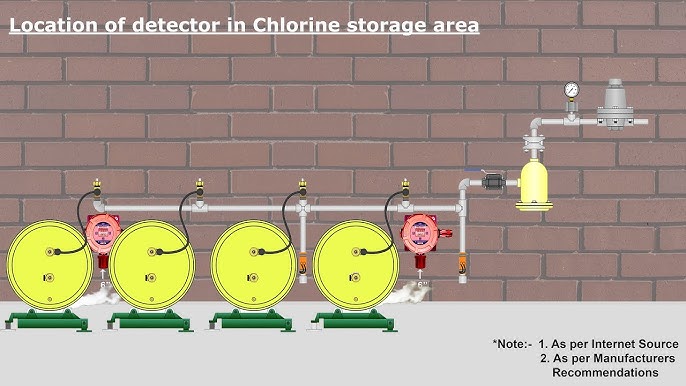

7. Inadequate Installation Planning (Bypassing H₂ Behavior)

- Pitfall: Installing Cl₂ detectors without considering gas behavior—Cl₂ is heavier than air, H₂ is lighter.

- Impact: Poor detection coverage; H₂ may accumulate at ceiling, Cl₂ near floor.

- Solution:

- Install Cl₂ detectors near floor level.

- Use multi-gas detectors or install separate H₂ detectors at ceiling level.

- Ensure proper spacing and coverage per safety standards (e.g., EN 62945).

✅ Best Practices Summary (H₂ + Cl₂ Environments)

| Factor | Recommended Specification |

|——-|—————————-|

| Sensor Type | Electrochemical, H₂-compensated |

| IP Rating | IP65 minimum, IP66/67 preferred |

| Certifications | ATEX/IECEx for IIC (H₂), T1 or higher |

| Response Time | T90 ≤ 30 seconds |

| Operating Temp | -20°C to +50°C |

| Enclosure | Corrosion-resistant (316 SS or equivalent) |

| Calibration | Auto-calibration or easy bump test |

| Installation | Cl₂ at low level, H₂ at high level; avoid dead zones |

🛑 Final Warning

Never assume a standard Cl₂ detector is safe or effective in hydrogen environments. The combination of toxic Cl₂ and highly flammable H₂ demands rigorous selection, certification, and installation. Always consult with safety engineers and refer to local gas detection standards (e.g., IEC 60079, NFPA 70, EN 45544).

By avoiding these pitfalls, you ensure reliable, safe, and compliant gas detection in critical H₂ and Cl₂ applications.

Logistics & Compliance Guide for Chlorine Gas Detector (Using H2 Reference)

Version 1.0

1. Introduction

This guide outlines the logistics, handling, transportation, and compliance requirements for the Chlorine (Cl₂) Gas Detector, with reference to hydrogen (H₂) as a calibration or operational benchmark. While chlorine is the primary gas of interest, H₂ may be used in certain detector models for sensor calibration, zeroing, or as part of the internal circuitry (e.g., in electrochemical sensors). This document ensures safe and compliant handling across the supply chain.

2. Product Overview

- Product Name: Chlorine (Cl₂) Gas Detector

- Detection Principle: Electrochemical, NDIR, or Semiconductor (model-specific)

- Calibration Reference Gas: May include H₂ (5–20% in N₂ or air) for baseline sensor stability

- Purpose: Continuous or portable detection of toxic Cl₂ gas in industrial, municipal, or laboratory environments

- Key Components: Sensor module, display, alarm system, power supply, calibration port

⚠️ Note: While H₂ is not the target gas, it may be used in maintenance or calibration. This requires adherence to H₂ safety protocols.

3. Regulatory Compliance

3.1 International Regulations

| Regulation | Relevance | Requirement |

|———-|———|————|

| GHS (Globally Harmonized System) | Labeling & SDS | Cl₂ detectors themselves are not hazardous, but calibration gases (e.g., H₂ mixtures) may be |

| ADR/RID/IMDG/IATA | Transport of calibration gases | H₂ reference gas must comply with Class 2.1 (Flammable Gas) if transported |

| OSHA 29 CFR 1910.1000 | Workplace exposure limits | Cl₂ PEL: 0.5 ppm (8-hr TWA); detectors must be accurate to monitor this |

| EPA Risk Management Program (RMP) | Facilities using Cl₂ | Requires detection systems; documentation of calibration using traceable standards (e.g., H₂-based zero gas) |

| ATEX / IECEx | Equipment in hazardous areas | If used in explosive atmospheres, detectors must be certified (e.g., ATEX II 1G Ex ia IIC T4) |

3.2 Regional Compliance

- EU: CE marking required; compliance with RED (Radio Equipment Directive) if wireless; RoHS and REACH for materials

- USA: FCC Part 15 for electronic emissions; NRTL certification (e.g., UL, CSA)

- Canada: CSA C22.2 No. 61010-1; ISED certification for wireless models

- Australia: RCM mark; AS/NZS 61010.1

4. Transportation & Logistics

4.1 Packaging Requirements

- Standard Detector Unit: Non-hazardous; packed in anti-static, shock-absorbent packaging

- Calibration Kit (if containing H₂ gas cylinder):

- Must be labeled as UN1049, Hydrogen, compressed, 2.1, PG II

- Cylinder secured to prevent movement

- Pressure relief device required

- Quantity limits apply per mode of transport

4.2 Transport Modes

| Mode | H₂ Gas Allowed? | Requirements |

|——|——————|————-|

| Air (IATA) | Yes, limited | Max 50 mL per cylinder; ≤ 2 cylinders per package; PI 902 or PI 903 |

| Sea (IMDG) | Yes | UN1049; proper stowage away from oxidizers |

| Road (ADR) | Yes | Orange placards; driver training (ADR certification) |

| Rail (RID) | Yes | Similar to ADR; secure containment |

✅ Best Practice: Ship detectors without calibration gas. Provide H₂ reference gas locally or via certified suppliers.

5. Storage & Handling

5.1 Detector Units

- Store in dry, temperature-controlled environment (0–40°C)

- Avoid exposure to Cl₂, H₂S, SO₂, or solvents (can poison sensors)

- Keep away from electromagnetic interference

5.2 H₂ Reference Gas Cylinders (if applicable)

- Store upright in well-ventilated area

- Segregate from oxidizers and ignition sources

- Max storage temp: 52°C

- Use only with approved regulators and fittings

- No smoking, open flames, or sparks within 3 meters

6. Calibration & Maintenance (H₂ Reference Use)

- Zero Calibration: Some electrochemical Cl₂ sensors use H₂-based zero gas to stabilize baseline

- Span Calibration: Cl₂ standard gas (e.g., 10 ppm in N₂) used; H₂ not involved

- Frequency: Per manufacturer (typically every 1–6 months)

- Documentation: Record calibration date, gas used (include H₂ zero gas batch), and technician

🔧 Caution: Use only certified calibration gases. Improper H₂ concentration can damage sensor or cause false readings.

7. Safety & Risk Mitigation

| Hazard | Risk | Control |

|——-|——|——–|

| H₂ flammability | Explosion if leaked in confined space | Use in ventilated areas; leak test fittings; install gas detectors |

| Cl₂ exposure during testing | Toxic if released | Use in fume hood; PPE (gloves, goggles) |

| Electrical hazards | Shock or spark in hazardous zones | Use intrinsically safe (IS) models |

| Sensor poisoning | False alarms or failure | Avoid exposure to silicones, lead, or H₂S |

8. End-of-Life & Disposal

- Detector Unit: Dispose as electronic waste (WEEE compliant)

- Battery: Follow local battery recycling rules (e.g., Li-ion in separate stream)

- H₂ Cylinder: Return to supplier or empty and recycle as scrap metal

- Sensor Module: May contain hazardous materials (e.g., lead); follow RoHS

9. Documentation & Recordkeeping

Required documents:

– Safety Data Sheet (SDS) for calibration gases (especially H₂ mixtures)

– Calibration logs (including H₂ zero gas batch #)

– Transport documents (if shipping H₂)

– Compliance certificates (CE, UL, ATEX, etc.)

– User manual with handling instructions

10. Summary & Key Actions

| Action | Responsibility |

|——-|—————-|

| Verify H₂ calibration gas is UN-certified | Procurement |

| Train staff on H₂ safety and Cl₂ detection | EHS Team |

| Label packages with H₂ hazard if applicable | Logistics |

| Maintain calibration records | Maintenance Team |

| Audit compliance annually | Compliance Officer |

Appendix A: Example H₂ Calibration Gas Specification

- Gas: 5% H₂ in Nitrogen (balance)

- Cylinder Size: 17L aluminum

- Pressure: 2000 psi

- Certification: NIST-traceable, ISO 6145

- UN Number: UN1049

- Hazard Class: 2.1 (Flammable Gas)

Prepared by: [Your Company Name] – EHS & Logistics Division

Date: April 2025

Contact: [email protected]

🛑 Disclaimer: This guide supports standard models. Always consult the manufacturer’s manual and local regulations before deployment or transport.

Conclusion for Sourcing a Chlorine Gas Detector

In conclusion, selecting the appropriate chlorine gas detector is a critical step in ensuring safety, regulatory compliance, and operational efficiency in environments where chlorine exposure is a risk. After evaluating various models based on sensitivity, response time, durability, calibration requirements, alarm functionality, and ease of use, it is evident that investing in a reliable and accurate detection system significantly mitigates health and safety hazards.

Key factors such as sensor technology (electrochemical vs. photoionization), data logging capabilities, portability, and connectivity options play a vital role in determining the suitability of a detector for specific applications—whether for fixed installation in industrial facilities or portable use for maintenance and emergency response teams.

Ultimately, sourcing a chlorine gas detector from reputable manufacturers with proven track records, proper certifications (e.g., ATEX, UL, or CSA), and strong technical support ensures long-term reliability and peace of mind. Regular maintenance, staff training, and adherence to safety protocols further enhance the effectiveness of the chosen detection system.

Therefore, prioritizing quality, accuracy, and compliance when sourcing a chlorine gas detector not only protects personnel and assets but also supports a proactive safety culture within the organization.