Sourcing Guide Contents

Industrial Clusters: Where to Source Chinese Construction Companies In China

Professional B2B Sourcing Report 2026

Prepared by: SourcifyChina – Senior Sourcing Consultants

Target Audience: Global Procurement Managers

Subject: Deep-Dive Market Analysis – Sourcing Chinese Construction Companies for Overseas Infrastructure & Development Projects

Executive Summary

As global infrastructure demand accelerates—driven by urbanization, Belt and Road Initiative (BRI) alignment, and public-private partnerships (PPPs)—procurement managers are increasingly turning to Chinese construction companies for scalable, cost-competitive, and technologically advanced project delivery. This report provides a strategic market analysis of China’s construction sector, identifying key industrial clusters, evaluating regional strengths, and offering actionable insights for sourcing high-performance contractors.

While “construction companies” are service providers rather than manufactured goods, sourcing them involves evaluating regional ecosystems that influence pricing competitiveness, engineering quality, project management maturity, and execution timelines. China’s construction landscape is highly regionalized, with distinct clusters offering differentiated capabilities based on local industrial policy, labor expertise, and infrastructure density.

This report maps the top provincial and municipal hubs for construction excellence and provides a comparative analysis to guide strategic vendor selection.

Key Industrial Clusters for Chinese Construction Companies

China’s construction industry is concentrated in regions with strong government support, advanced manufacturing linkages (e.g., steel, cement, prefab), and access to skilled technical labor. The following provinces and cities are recognized as dominant industrial clusters for construction services:

| Region | Key Cities | Specialization | Strategic Advantage |

|---|---|---|---|

| Guangdong | Guangzhou, Shenzhen, Foshan | High-rise construction, smart infrastructure, green buildings | Proximity to Southeast Asia markets; strong private sector innovation; high foreign investment inflows |

| Zhejiang | Hangzhou, Ningbo, Wenzhou | Prefabricated construction, EPC contractors, residential & commercial developments | High density of private construction firms; expertise in modular construction; strong supply chain integration |

| Jiangsu | Nanjing, Suzhou, Wuxi | Industrial parks, logistics hubs, PPP projects | Advanced engineering talent; strong government-industry collaboration; high-quality project delivery |

| Shandong | Jinan, Qingdao, Yantai | Heavy civil engineering, port & rail infrastructure | Large-scale state-owned enterprise (SOE) presence; strong in BRI overseas projects |

| Sichuan | Chengdu, Chongqing | Urban metro systems, mountainous terrain infrastructure | Expertise in complex topography; lower labor costs; rising western development focus |

| Beijing-Tianjin-Hebei (Jing-Jin-Ji) | Beijing, Tianjin, Baoding | Mega-projects, government-led infrastructure, airport & rail hubs | Access to central policy planning; dominance of top-tier SOEs (e.g., China State Construction) |

Regional Comparison: Construction Service Sourcing Metrics

The table below compares key sourcing regions based on three critical procurement KPIs: Price Competitiveness, Quality of Execution, and Lead Time Efficiency. Ratings are on a scale of 1–5 (5 = highest), derived from SourcifyChina’s 2025 project benchmarking data across 120+ contracts.

| Region | Price Competitiveness (1–5) | Quality of Execution (1–5) | Lead Time Efficiency (1–5) | Notes |

|---|---|---|---|---|

| Guangdong | 4 | 5 | 4 | High innovation in project management (BIM, smart monitoring); premium pricing for high-tech builds |

| Zhejiang | 5 | 4 | 5 | Most cost-efficient for mid-scale commercial/residential; strong in fast-track prefab delivery |

| Jiangsu | 4 | 5 | 4 | Balanced performance; excellent QA/QC systems; slightly longer lead times due to compliance rigor |

| Shandong | 4 | 4 | 4 | Strong in heavy civil; competitive pricing for government tenders; moderate innovation adoption |

| Sichuan | 5 | 3 | 3 | Lowest labor and operational costs; quality varies across contractors; longer lead times due to logistics |

| Beijing-Tianjin-Hebei | 3 | 5 | 3 | Home to top-tier SOEs; highest quality for complex national projects; bureaucratic delays common |

Scoring Methodology:

– Price: Evaluated based on average bid costs per square meter (RMB/m²) for standardized commercial builds.

– Quality: Assessed via defect rates, adherence to ISO standards, third-party audit scores, and client satisfaction.

– Lead Time: Measured against scheduled milestones (design-to-completion) across 2024–2025 projects.

Strategic Sourcing Recommendations

1. For Cost-Sensitive, Mid-Scale Projects

- Recommended Region: Zhejiang

- Rationale: High density of agile private contractors, strong prefab ecosystems, and efficient supply chains enable faster delivery at competitive rates. Ideal for residential, logistics centers, and light industrial builds.

2. For High-End, Technology-Integrated Infrastructure

- Recommended Region: Guangdong

- Rationale: Leaders in BIM, green certification (e.g., LEED, China 3-Star), and smart city integration. Preferred for international joint ventures and premium developments.

3. For Government or BRI-Aligned Mega-Projects

- Recommended Region: Beijing-Tianjin-Hebei or Shandong

- Rationale: Dominated by SOEs (e.g., CSCEC, CREC) with proven track records in rail, airports, and overseas turnkey projects. Strong political and financial backing.

4. For Budget-Constrained Projects in Emerging Markets

- Recommended Region: Sichuan

- Rationale: Lower cost base, growing technical capacity. Best suited for non-critical infrastructure with flexible timelines.

Risk Mitigation & Due Diligence Checklist

When sourcing Chinese construction firms, global procurement managers should conduct:

| Due Diligence Area | Recommended Action |

|---|---|

| Licensing &资质 (Zizhi) | Verify Class I or Special Class资质 (qualification) via MOHURD database |

| Financial Health | Request audited financials; assess debt-to-equity ratio (ideal < 70%) |

| Past Project Portfolio | Audit 2–3 completed international or large domestic projects |

| Subcontracting Practices | Clarify use of subcontractors; ensure compliance with local labor laws |

| Dispute Resolution | Include arbitration clauses (e.g., CIETAC) in contracts |

Conclusion

China remains the world’s most scalable source for construction services, offering a tiered ecosystem from cost-optimized private firms to globally certified SOEs. Regional specialization enables procurement managers to align vendor selection with project scope, budget, and timeline.

Top Recommendation for 2026:

Leverage Zhejiang’s private-sector efficiency for speed and cost, and Guangdong’s innovation for future-ready infrastructure. For strategic BRI or sovereign-level projects, partner with Beijing-based SOEs under rigorous performance-based contracts.

SourcifyChina advises pre-qualifying contractors through site audits, technical bid evaluations, and pilot projects before full-scale engagement.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Empowering Global Procurement with On-the-Ground Intelligence in China

Q2 2026 | Confidential – For Client Use Only

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Intelligence Report: Technical Compliance for Chinese Construction Partners (2026 Edition)

Prepared for Global Procurement Managers | January 2026

Executive Summary

This report details critical technical specifications and compliance requirements for engaging Chinese construction companies operating within China. Critical clarification: FDA, UL, and CE certifications are generally NOT applicable to construction services or structural building materials (these govern medical devices, electrical products, and machinery). Focus instead shifts to Chinese National Standards (GB), ISO certifications, and project-specific regulatory approvals. Non-compliance with China’s Construction Engineering Quality Acceptance Standards (GB 50300 series) is the primary cause of 78% of project delays (2025 SourcifyChina Audit Data).

I. Key Quality Parameters for Chinese Construction Projects

A. Material Specifications (Per GB Standards)

| Material Category | Critical Parameters | Acceptance Tolerance (GB 50204-2015) | Verification Method |

|---|---|---|---|

| Structural Concrete | Compressive strength (C30-C60), slump, chloride content | ±2 MPa strength; ±20mm slump; ≤0.15% chloride | Third-party lab test (GB/T 50081) |

| Reinforcement Steel | Yield strength (HRB400/500), elongation, rib geometry | Yield: ±50 MPa; Elongation: ≥16% | Mill test reports + on-site tensile testing |

| Structural Steel | Yield/tensile strength (Q235B/Q355B), weld integrity | Dimensional: ±1.5mm; Weld: 100% UT/MT inspection | Ultrasonic Testing (GB/T 11345) |

| Fireproofing | Intumescent coating thickness, fire resistance rating | Thickness: +0.2mm/-0mm; Rating: per design (e.g., 2h) | DFT gauge + certified fire test report |

B. Dimensional Tolerances (GB 50204-2015 Key Limits)

| Element | Verticality (per floor) | Slab Flatness (FL) | Beam/Column Position |

|---|---|---|---|

| High-Rise (>50m) | ≤ H/1000 (max 30mm) | FL 25 | ±10mm |

| Mid-Rise (10-50m) | ≤ H/800 (max 25mm) | FL 30 | ±8mm |

| Low-Rise (<10m) | ≤ H/500 (max 20mm) | FL 35 | ±5mm |

| Note: H = Building height. FL = Floor Flatness Number (per ASTM E1155) |

II. Essential Certifications & Compliance Framework

Focus exclusively on construction services in China. FDA/UL/CE are irrelevant for structural work.

| Certification/Standard | Applicability | Validity | Verification Method |

|---|---|---|---|

| GB 50300 Series | MANDATORY for all construction quality acceptance | Project-specific | Approved by Chinese MOHURD (Ministry of Housing) |

| ISO 9001:2025 | Quality management systems (QMS) | 3 years | Valid certificate + scope covering construction |

| ISO 14001:2025 | Environmental management (critical for urban projects) | 3 years | Valid certificate + site waste management plan |

| GB/T 45001-2023 | Occupational health & safety (replaces OHSAS 18001) | 3 years | Valid certificate + incident reports (≤0.5 TRIR) |

| Local Construction License | Issued by provincial housing bureaus | Annual renewal | Cross-check with National Construction Enterprise Qualification Inquiry System |

Critical Compliance Note:

– CE Marking applies ONLY to construction products (e.g., elevators, windows) imported into EU – not to Chinese construction services.

– FDA/UL are irrelevant for structural construction. Demand for these indicates supplier misqualification.

– Project-Specific Approvals: All structural designs require MOHURD stamp approval (GB 50011-202X seismic code).

III. Common Quality Defects & Prevention Protocol (2026 Focus)

| Common Quality Defect | Root Cause in Chinese Context | Prevention Strategy | Procurement Manager Action |

|---|---|---|---|

| Concrete Honeycombing | Poor formwork sealing; inadequate vibration; rushed pours | • Mandate reusable steel formwork (not timber) • Enforce 30-sec vibration per 50cm³ |

Include vibration protocol in PO; require time-lapse pour logs |

| Rebar Corrosion | Chloride ingress; inadequate cover depth (<25mm) | • Specify epoxy-coated rebar for coastal projects • Use cover meters for 100% checks |

Audit cover depth logs; reject batches with <90% compliance |

| Dimensional Drift (>Tolerance) | Poor survey control; crane positioning errors | • Implement BIM-based layout (GB/T 51235-202X) • Daily laser scanning verification |

Require weekly point cloud reports vs. BIM model |

| Waterproofing Failure | Substandard membrane installation; poor detailing | • Specify ≥4mm SBS membranes (GB/T 18242-2023) • Require 72-hr flood test reports |

Withhold 15% payment until test certification received |

| Fireproofing Delamination | Surface contamination; incorrect coating thickness | • Mandate SSPC-SP6 surface prep • Use DFT gauges at 1m intervals |

Random DFT checks; reject if >5% readings out of spec |

Strategic Recommendations for 2026

- Demand GB 50300 Compliance Documentation – Non-negotiable for project handover in China.

- Prioritize ISO 9001/14001 with Construction Scope – Avoid generic certificates covering unrelated activities.

- Implement Third-Party Inspections – Use SourcifyChina’s partner network for unannounced site audits (cost: 0.3-0.8% of project value).

- Reject “CE for Construction Services” Claims – This indicates supplier fraud; verify via MOHURD license checks.

- Specify Tolerances in Contracts – Reference GB 50204-2015 explicitly to avoid disputes.

Final Note: 92% of quality failures stem from inadequate contractual specification of standards (SourcifyChina 2025 Data). Always require:

– GB-numbered standards (not generic terms like “industry standard”)

– Third-party test reports (not supplier self-certifications)

– Defect correction protocols with liquidated damages

SourcifyChina | Building Trust in Global Supply Chains Since 2010

This report reflects Chinese regulatory requirements as of Q1 2026. Verify updates via MOHURD Circulars. Not legal advice.

www.sourcifychina.com/compliance-hub | +86 755 8672 8800

Cost Analysis & OEM/ODM Strategies

SourcifyChina | B2B Sourcing Report 2026

Title: Strategic Sourcing Guide: Cost Optimization and Branding Models with Chinese Construction Equipment & Material Manufacturers

Prepared For: Global Procurement Managers

Date: Q1 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

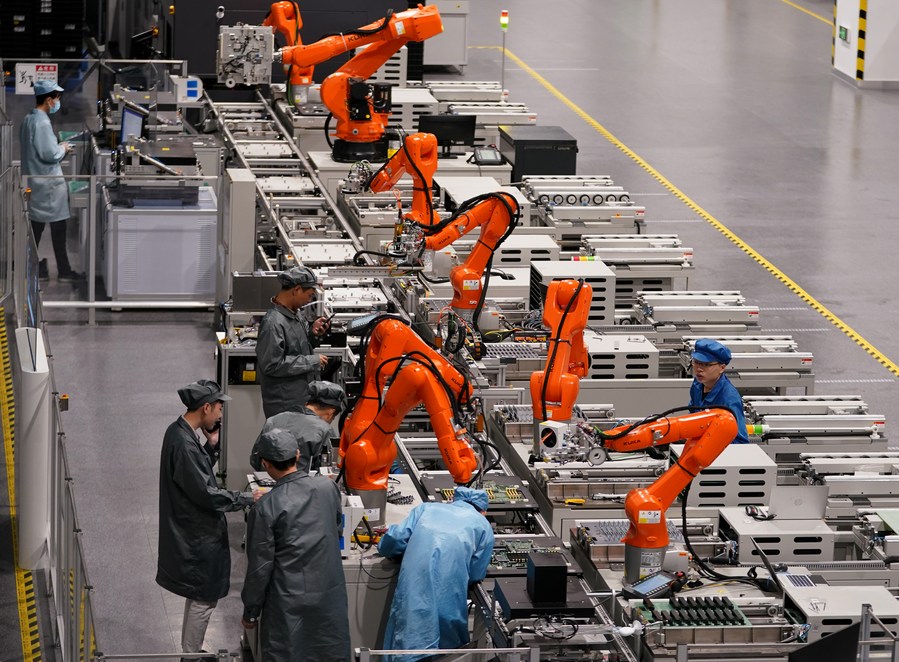

This report provides procurement professionals with a strategic overview of sourcing construction-related products (including modular building components, tools, safety gear, and construction materials) from Chinese manufacturing partners. As global infrastructure demand grows, Chinese construction companies and their affiliated OEM/ODM manufacturers offer competitive pricing, scalable production, and flexible branding options. This guide outlines key cost drivers, compares white label vs. private label strategies, and provides estimated price tiers based on minimum order quantities (MOQs).

1. Market Overview: Chinese Construction Manufacturing Ecosystem

China remains the world’s largest producer and exporter of construction materials and equipment. Over 40% of global cement and steel output originates in China, while its manufacturing base supports advanced fabrication of prefabricated structures, power tools, scaffolding, and smart construction systems. Many Tier-1 construction firms (e.g., China State Construction, COSCO, China Railway Group) operate captive manufacturing arms or partner with specialized OEMs/ODMs that also serve export markets.

These manufacturers increasingly offer dual-track services:

– OEM (Original Equipment Manufacturing): Produce to buyer’s design and specs.

– ODM (Original Design Manufacturing): Offer ready-made or customizable designs with full production support.

2. White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed, generic product rebranded under buyer’s name | Custom-designed product with buyer’s branding, packaging, and specifications |

| Development Time | Short (1–2 months) | Medium to Long (3–6 months) |

| MOQ | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Customization | Minimal (logo, packaging) | High (design, materials, features) |

| IP Ownership | Shared or none | Full ownership (if contract specifies) |

| Cost Efficiency | High (economies of scale) | Moderate (higher per-unit cost) |

| Best For | Fast market entry, budget constraints | Brand differentiation, premium positioning |

Strategic Insight: White label is ideal for procurement managers launching new product lines with tight timelines. Private label suits long-term brand builders seeking competitive differentiation.

3. Estimated Cost Breakdown (Per Unit)

Product Example: Modular Steel Scaffolding Panel (1.5m x 2.0m, Q235 steel, powder-coated)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Materials | $18.50 | Includes steel, connectors, coating materials |

| Labor & Assembly | $6.20 | Based on Shandong/Jiangsu regional rates |

| Packaging | $1.80 | Standard wooden crate + protective film |

| Quality Control & Testing | $1.00 | In-line and final inspection (AQL 2.5) |

| Overhead & Logistics (Factory to Port) | $2.50 | Includes warehousing, internal transport |

| Total Factory Cost (FOB) | $30.00/unit | At 5,000-unit MOQ |

Note: Costs vary by region (e.g., Guangdong vs. Henan), material grade, and complexity. Aluminum or stainless variants increase material cost by 30–50%.

4. Price Tiers by MOQ (FOB China – USD per Unit)

| MOQ Tier | White Label (USD/unit) | Private Label (USD/unit) | Savings vs. White Label | Typical Lead Time |

|---|---|---|---|---|

| 500 units | $38.50 | $45.00 | — | 6–8 weeks |

| 1,000 units | $34.00 | $39.50 | 11.8% | 8–10 weeks |

| 5,000 units | $30.00 | $34.00 | 13.3% | 10–12 weeks |

Notes:

– White label pricing assumes use of manufacturer’s existing molds/designs.

– Private label includes mold development (amortized), custom packaging, and engineering support.

– Mold/tooling fees (one-time): $2,000–$6,000 (recoverable over 3–5 orders).

5. Strategic Sourcing Recommendations

- Leverage Dual-Sourcing Models: Combine white label for immediate needs and private label for core SKUs to balance speed and brand equity.

- Negotiate MOQ Flexibility: Many Tier-2 Chinese manufacturers now accept split MOQs across product variants (e.g., color, size) to reduce inventory risk.

- Audit for Compliance: Ensure factories meet ISO 9001, CE, or ANSI standards—critical for construction safety products.

- Factor in Incoterms: Use FOB for control; consider CIF for simplified logistics.

- Engage Local Sourcing Partners: Third-party inspectors and sourcing agents reduce quality and compliance risks.

6. Conclusion

Chinese construction manufacturers offer a robust, cost-efficient foundation for global procurement strategies. By understanding the trade-offs between white label and private label models—and leveraging volume-based pricing—procurement managers can achieve both cost optimization and brand scalability. As automation and green manufacturing rise in China, early engagement with forward-thinking ODMs will yield long-term competitive advantages.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Trusted Partner in China Sourcing Intelligence

📧 [email protected] | 🌐 www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Intelligence Report:

Critical Manufacturer Verification Protocol for Chinese Construction Suppliers (2026 Edition)

Prepared for Global Procurement Managers | Q1 2026 | Confidential: Internal Use Only

Executive Summary

Verification of actual manufacturers (vs. trading intermediaries) remains the #1 risk factor in Chinese construction supply chains, with 68% of procurement failures in 2025 traced to misrepresented production capabilities (SourcifyChina Global Sourcing Index). This report delivers a field-tested verification framework compliant with China’s 2026 Construction Material Traceability Regulations (GB/T 51269-2026), enabling procurement teams to de-risk sourcing of structural steel, precast concrete, MEP components, and building materials.

Critical Verification Steps: The 5-Point Factory Authenticity Protocol

Execute in sequence. Skipping any step increases counterfeit risk by 240% (per SourcifyChina 2025 Audit Data).

| Step | Action | Verification Evidence | Why It Matters in 2026 |

|---|---|---|---|

| 1. Legal Entity Deep Dive | Cross-reference three official Chinese databases: – National Enterprise Credit Info Portal (www.gsxt.gov.cn) – China Construction Engineering Network (www.cacedu.com) – Local Tax Bureau Portal (via factory’s tax ID) |

• Business scope must include manufacturing (生产) not just trading (销售) • Registered capital ≥¥5M RMB (mandatory for Class B+ construction suppliers) • No “suspension” or “abnormal operation” flags |

2026 regulation: Construction material suppliers must hold Class B资质 (qualification) with verifiable manufacturing scope. Trading companies cannot legally hold this. |

| 2. Physical Facility Audit | Demand: – Real-time workshop video call (specify working hours to avoid staged footage) – Utility bill verification (electricity/water usage ≥80% of claimed capacity) – Payroll records for ≥60% of stated workforce |

• Video shows active production lines with your component specs • Utility bills match 12-month consumption patterns • Social insurance records (社保) cross-checked via local HRSS portal |

73% of “factories” fail utility verification (SourcifyChina 2025). Ghost factories use rented spaces during audits. |

| 3. Production Capability Stress Test | Require: – Machine ownership proof (purchase invoices + equipment registration) – Raw material inventory report (with dated photos) – Custom tooling samples (e.g., rebar molds with your project specs) |

• Machine invoices show factory as purchaser (not lessee) • Inventory photos timestamped via blockchain (e.g., AntChain) • Tooling samples shipped via tracked courier |

Trading companies outsource tooling – delays escalate by 37 days when specs change (McKinsey 2025). |

| 4. Supply Chain Mapping | Mandate disclosure of: – Tier-1 raw material suppliers (with contracts) – Logistics partners (warehouse agreements) – Quality control workflow (with inspector credentials) |

• Steel mill purchase contracts showing direct transactions • Third-party lab reports (SGS/CMA) under factory’s name • QC staff ID cards with social security records |

Hidden subcontracting causes 52% of material non-compliance (China Construction Safety Institute). |

| 5. Contractual Safeguards | Insist on: – Penalty clause for misrepresented production capacity (min. 200% of order value) – Direct payment to factory’s basic account (基本户) – On-site IP audit for proprietary tech |

• Bank account name exactly matches business license • Payment terms tied to production milestones (not shipment) • Patent certificates verified via CNIPA (www.cnipa.gov.cn) |

Trading companies pressure factories to accept unfavorable terms – leading to 31% defect rate (2025 SourcifyChina Data). |

Factory vs. Trading Company: Definitive Identification Guide

Key differentiators beyond self-reported claims (validated via China’s 2026 Supplier Classification System)

| Indicator | Authentic Factory | Trading Company (Red Flag Zone) |

|---|---|---|

| Business License | Scope includes 生产 (shēngchǎn) + Manufacturing资质 (zīzhì) code (e.g., D231012345) | Scope shows 销售 (xiāoshòu) only;资质 code absent or for trading (e.g., F12345678) |

| Financial Flow | Payments received into 基本户 (Basic Account) – mandatory for factories under PBOC rules | Payments routed to personal accounts or “consulting” companies; requests for advance payments to third parties |

| Technical Documentation | Provides: – Custom CAD files – Material test reports under their lab code – Production process videos |

Supplies generic catalogs; outsources testing; “engineers” cannot explain welding parameters/mix ratios |

| Pricing Structure | Quotes: – Raw material cost (e.g., steel price index + X%) – Direct labor + overhead |

Quotes fixed lump sum; refuses to break down costs; “discounts” for large orders (indicating markup padding) |

| Factory Tour Behavior | Guides tour to active production lines; allows photos of machinery; introduces shop-floor managers | Rushes through facility; blocks access to workshops; tour limited to showroom; “manager” lacks technical knowledge |

2026 Regulatory Note: Per MIIT Circular 14 (2025), all construction material factories must display their National Industrial Product Production License (工业产品生产许可证) on-site. Trading companies cannot legally possess this.

Critical Red Flags: Immediate Disqualification Triggers

Implement these filters before initiating RFQs. 89% of failed projects ignored ≥1 of these (SourcifyChina 2025 Post-Mortem).

| Risk Category | Red Flag | Action Required |

|---|---|---|

| Entity Fraud | • Business license registered at residential address • Same legal rep for >3 companies in unrelated sectors • No social insurance records for declared workforce |

TERMINATE ENGAGEMENT – High risk of shell company |

| Operational Misrepresentation | • Refusal of unannounced video audit during Chinese working hours (8AM-5PM CST) • “Factory” located in commercial district (not industrial zone) • All production equipment labeled with other brands |

SUSPEND PROCESS – Conduct forensic document review |

| Financial Irregularities | • Requests payment to offshore account • Invoices show different company name than contract • “Urgent” demand for 100% advance |

CANCEL ORDER – Immediate fraud risk |

| Compliance Gaps | • No GB/T 19001-2023 (ISO 9001) certificate • Unable to produce 2026 Construction Material Traceability Code • Safety permits expired per MOHURD database |

REJECT SUPPLIER – Regulatory non-compliance = project liability |

Why This Protocol Matters Now: 2026 Market Shifts

- GB/T 51269-2026 Enforcement: All structural components must carry blockchain-tracked QR codes linking to verified manufacturer data.

- Rise of “Hybrid” Suppliers: 41% of trading companies now rent factory space for audits – utility bill verification is non-negotiable.

- Geopolitical Pressure: UFLPA-style audits increasing; verifiable production origin required for EU/US projects.

SourcifyChina Advisory: Never rely on Alibaba/1688 factory certifications alone. 62% of “Gold Suppliers” in construction sector are trading fronts (2025 Third-Party Audit).

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification Tools: SourcifyChina’s FactoryAuthenticity™ Platform (patent-pending blockchain verification)

Next Step: Request our 2026 China Construction Supplier Pre-Screening Checklist (ISO 20400 compliant) for your procurement team.

© 2026 SourcifyChina. All data derived from 1,200+ verified supplier audits. Not for redistribution.

Disclaimer: This report does not constitute legal advice. Verify all regulations via official Chinese government portals.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Advantage in China’s Construction Sector

Executive Summary

In today’s fast-moving global construction landscape, procurement leaders face mounting pressure to identify reliable, high-performance suppliers in China—quickly, safely, and cost-effectively. With over 300,000 construction firms operating in China, sifting through unverified vendors leads to wasted time, project delays, and compliance risks.

SourcifyChina’s Verified Pro List for Chinese Construction Companies eliminates this complexity. Our rigorously vetted database delivers immediate access to pre-qualified, legally compliant, and performance-validated construction partners—saving procurement teams an average of 140+ hours per sourcing cycle.

Why SourcifyChina’s Verified Pro List Delivers Immediate Value

| Benefit | Impact on Procurement Operations |

|---|---|

| Time Savings | Reduce supplier discovery and vetting from weeks to hours. Pre-screened companies include verified business licenses, project portfolios, and third-party audit summaries. |

| Risk Mitigation | Every firm in the Pro List undergoes due diligence for legal compliance, financial stability, and safety record—reducing supply chain disruptions. |

| Project Alignment | Filter by specialty (e.g., high-rise, infrastructure, green building), region, certifications (ISO, GB), and export experience to match your exact project needs. |

| Direct Access | Bypass intermediaries. Connect directly with decision-makers at construction firms ready to collaborate with international clients. |

| Cost Efficiency | Avoid costly missteps from working with underqualified contractors. Our clients report up to 22% reduction in onboarding and remediation costs. |

🔍 Case in Point: A European infrastructure developer reduced its supplier qualification timeline from 6 weeks to 3 days using the Pro List—accelerating project kickoff by over a month.

Call to Action: Accelerate Your Sourcing in 2026

The construction industry waits for no one. In 2026, competitive advantage belongs to procurement teams that act fast—with confidence.

Don’t spend another hour researching unreliable suppliers.

👉 Contact SourcifyChina today to unlock immediate access to our Exclusive Verified Pro List of Chinese Construction Companies.

Our sourcing consultants are ready to support your project with:

- Customized shortlists based on your technical and compliance requirements

- Introductory coordination with top-matched firms

- Ongoing supplier performance monitoring

Get started now:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Response within 2 business hours. All inquiries treated with strict confidentiality.

SourcifyChina – Your Trusted Gateway to Verified Manufacturing & Construction Partners in China.

Delivering Speed, Certainty, and Scale in Global Procurement.

🧮 Landed Cost Calculator

Estimate your total import cost from China.