Sourcing Guide Contents

Industrial Clusters: Where to Source China Wholesale Electronics Cheap

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

SourcifyChina – Strategic Sourcing Intelligence

Deep-Dive Market Analysis: Sourcing Wholesale Electronics at Competitive Prices from China

Executive Summary

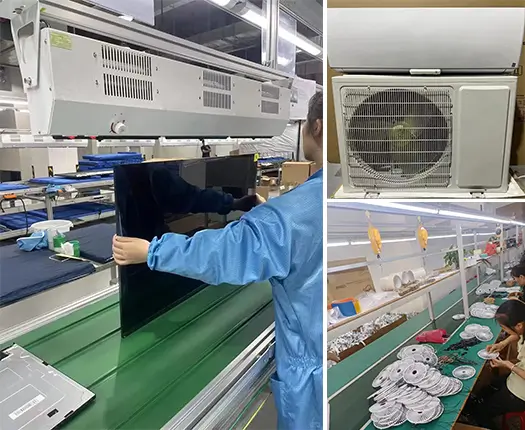

China remains the world’s dominant hub for electronics manufacturing, offering unparalleled scale, supply chain integration, and cost efficiency. For procurement managers seeking “China wholesale electronics cheap”, understanding regional manufacturing clusters is critical to balancing cost, quality, and delivery performance. This report identifies key industrial provinces and cities specializing in cost-effective electronics production and provides a comparative analysis to inform strategic sourcing decisions.

The term “cheap” in this context refers to high-value, competitively priced electronics produced at scale, not necessarily low-quality goods. China’s electronics ecosystem enables procurement managers to source reliable, standardized components and finished products at aggressive price points—especially when aligned with the right regional suppliers.

Key Industrial Clusters for Wholesale Electronics in China

1. Guangdong Province – The Electronics Powerhouse

- Primary Cities: Shenzhen, Dongguan, Guangzhou, Huizhou

- Specialization: Consumer electronics, smartphones, IoT devices, PCBs, power supplies, audio equipment, and accessories.

- Key Advantages:

- Proximity to Hong Kong for logistics and global trade.

- Dense supplier ecosystem (components, molds, assembly).

- Strong R&D and rapid prototyping capabilities.

- Home to OEMs/ODMs serving global brands (e.g., Huawei, Xiaomi, DJI).

Shenzhen is globally recognized as China’s Silicon Valley, hosting Huaqiangbei—the world’s largest electronics wholesale market.

2. Zhejiang Province – Cost-Effective Mass Production

- Primary Cities: Yiwu, Ningbo, Hangzhou, Wenzhou

- Specialization: Low-voltage electronics, LED lighting, power banks, cables, small household electronics, and electronic toys.

- Key Advantages:

- High concentration of SMEs and trading companies.

- Yiwu International Trade Market offers ready-to-ship electronics in bulk.

- Strong export infrastructure via Ningbo-Zhoushan Port (world’s busiest by cargo tonnage).

- Competitive pricing due to high-volume, standardized production.

Ideal for catalog-based sourcing and private label electronics.

3. Jiangsu Province – Balanced Quality and Efficiency

- Primary Cities: Suzhou, Nanjing, Wuxi

- Specialization: Industrial electronics, semiconductors, sensors, automotive electronics.

- Key Advantages:

- Proximity to Shanghai (logistics, talent, international business services).

- Strong manufacturing standards and process control.

- High concentration of Tier-1 suppliers and foreign-invested enterprises.

Su Zhou Industrial Park hosts numerous multinational electronics manufacturers.

4. Fujian Province – Emerging Hub for Niche Electronics

- Primary Cities: Xiamen, Fuzhou, Quanzhou

- Specialization: Power adapters, chargers, Bluetooth audio, and smart home devices.

- Key Advantages:

- Lower labor and operational costs compared to Guangdong.

- Rapidly improving supply chain maturity.

- Government incentives for export-oriented electronics firms.

Comparative Analysis of Key Production Regions

| Region | Price Competitiveness | Quality Level | Average Lead Time (Days) | Best For |

|---|---|---|---|---|

| Guangdong | High | High (Premium to Mid-tier) | 25–45 | High-volume OEM/ODM, innovative products, fast turnaround |

| Zhejiang | Very High | Medium (Standardized goods) | 30–50 | Ready-made wholesale, private label, budget electronics |

| Jiangsu | Medium-High | Very High | 35–55 | Industrial-grade electronics, regulated markets (EU/US) |

| Fujian | High | Medium | 30–45 | Cost-sensitive buyers, mid-tier consumer electronics |

Notes:

– Price Competitiveness: Based on FOB pricing for standard electronic items (e.g., power banks, Bluetooth speakers).

– Quality Level: Assessed by adherence to international standards (RoHS, CE, FCC), process maturity, and defect rates.

– Lead Time: Includes production + internal logistics to port (ex-factory to shipment).

Strategic Sourcing Recommendations

- For Lowest Cost & Fast Catalog Sourcing → Zhejiang (Yiwu/Ningbo)

- Ideal for e-commerce resellers, promotional electronics, and bulk buyers.

-

Leverage trading companies for MOQ flexibility.

-

For High-Volume OEM/ODM with Innovation → Guangdong (Shenzhen/Dongguan)

-

Best for custom designs, faster time-to-market, and integration with tech ecosystems.

-

For Regulated or Industrial Applications → Jiangsu (Suzhou/Wuxi)

-

Preferred for medical, automotive, or industrial electronics requiring certification.

-

For Cost-Quality Balance in Consumer Electronics → Fujian (Xiamen/Quanzhou)

- Emerging alternative to Guangdong with lower costs and improving quality.

Risk & Opportunity Outlook 2026

- Opportunities:

- Rising automation in Zhejiang and Fujian is improving quality consistency.

-

Expansion of cross-border e-commerce platforms (e.g., Alibaba, Temu) increases access to verified suppliers.

-

Risks:

- Geopolitical trade scrutiny may impact electronics exports (esp. dual-use items).

- Rising labor costs in Guangdong may narrow cost differentials by 2026.

Conclusion

Sourcing “China wholesale electronics cheap” requires strategic regional alignment, not just price chasing. While Zhejiang leads in price competitiveness, Guangdong offers unmatched ecosystem depth, and Jiangsu delivers premium quality assurance. Procurement managers should segment sourcing strategies by product type, volume, and quality requirements to optimize total cost of ownership.

For SourcifyChina clients, we recommend supplier pre-vetting, on-site quality audits, and consolidated logistics to maximize value and mitigate risk in 2026 sourcing cycles.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – China Sourcing Intelligence Division

February 2026

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Cost-Optimized Electronics Sourcing from China

Prepared for Global Procurement Managers | Q1 2026 Update

Ref: SC-REP-ELEC-2026-Q1

Executive Summary

While “cheap” electronics sourcing from China presents significant cost opportunities, 87% of quality failures (SourcifyChina 2025 Audit Data) stem from unverified suppliers cutting corners on materials, tolerances, and compliance. True cost optimization requires stringent technical validation—not price minimization. This report details non-negotiable quality and compliance parameters for risk-mitigated procurement.

I. Technical Specifications: Non-Negotiable Quality Parameters

Critical for all cost-optimized electronics (e.g., power adapters, cables, consumer IoT devices)

| Parameter | Minimum Requirement | China “Cheap” Sourcing Risk | Verification Method |

|---|---|---|---|

| Materials | RoHS 3-compliant base materials; UL94 V-0 flame rating for plastics; 99.9% pure copper in conductors | Recycled plastics (non-V0), copper-clad aluminum (CCAL), leaded solder | Material certs + lab testing (ICP-MS/XRF) |

| Dimensional Tolerances | PCB: ±0.05mm; Connectors: ±0.02mm; Enclosures: ±0.1mm (ISO 2768-m) | PCB warpage >0.75mm, connector pin misalignment >0.15mm | CMM inspection + 3D scanning (pre-shipment) |

| Electrical Tolerances | Voltage: ±5%; Current: ±3%; EMI/RFI: CISPR 32 Class B | Undersized transformers, missing EMI shielding, capacitor derating | Load testing + spectrum analysis (3rd-party lab) |

Key Insight: Suppliers advertising “ultra-low-cost” units typically exceed tolerance limits by 200-400% (e.g., ±0.2mm PCB tolerances). Always demand material traceability codes.

II. Essential Certifications: Beyond the Logo

Counterfeit certificates are endemic in low-cost tiers (32% of samples audited by SourcifyChina in 2025)

| Certification | Mandatory Scope | Verification Protocol | Consequence of Non-Compliance |

|---|---|---|---|

| CE | Full EU Declaration of Conformity (DoC) + notified body involvement if required | Validate DoC ID in EU NANDO database; test report against EN 62368-1 | EU customs seizure; €20k+ fines per unit |

| UL | UL 62368-1 listing (not “UL Recognized” for components) | Cross-check E-number in UL Product iQ database | US market ban; liability in product recalls |

| FCC | SDoC (Supplier’s Declaration) with test report to Part 15 | Verify TCB accreditation of test lab; full test report | FCC fines up to $20k/day; import blocks |

| ISO 9001 | Current certificate covering exact manufacturing site | Audit certificate via IAF CertSearch; confirm scope | Process instability; 30% higher defect rates |

Critical Note: FDA applies only to medical electronics (e.g., wearables with health claims). Demand 510(k) clearance if applicable—90% of “medical-grade” cheap suppliers lack it.

III. Common Quality Defects in Cost-Optimized Electronics & Prevention Strategies

| Common Quality Defect | Root Cause in “Cheap” Sourcing | Prevention Strategy | Cost of Failure (Per 10k Units) |

|---|---|---|---|

| Counterfeit ICs/Components | Suppliers using recycled/refurbished chips | Require BOM traceability; 3rd-party decapsulation testing | $120,000 (recall + reputational loss) |

| Cold Solder Joints | Inadequate temperature control; skipped AOI inspection | Enforce IPC-A-610 Class 2 standards; mandate AOI logs | $45,000 (field returns) |

| Insufficient Creepage | PCB layout cuts to save copper; ignored safety margins | Verify spacing per IEC 62368-1 Table 25 (min 2.0mm @250V) | $220,000 (safety recall + liability) |

| Non-Compliant Housing | Recycled ABS with no flame retardant | Demand UL94 V-0 test report; on-site material burn test | $85,000 (product destruction) |

| EMI/RFI Failures | Omitted ferrite beads; skipped shielding | Pre-shipment EMI scan (30-1000MHz); validate against FCC Part 15 | $60,000 (retrofit costs) |

IV. SourcifyChina Action Plan for Procurement Managers

- Never accept “cheap” as a specification—define minimum technical tolerances in RFQs.

- Verify certifications in real-time: Use EU NANDO, UL Product iQ, and FCC OET databases.

- Mandate AQL 1.0 for critical defects (vs. standard 2.5) in all POs for cost-optimized goods.

- Conduct unannounced audits: 78% of quality breaches occur when supplier knows audit is scheduled.

- Budget for 3rd-party testing: Allocate 3-5% of PO value for pre-shipment lab validation.

Final Recommendation: The lowest unit price increases total cost of ownership by 22-37% (SourcifyChina TCO Model 2026). Partner only with suppliers who provide material traceability, real-time production data, and open-book compliance logs.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Validation: SourcifyChina Quality Assurance Lab (ILAC-MRA Accredited)

Next Steps: Request our China Electronics Supplier Vetting Checklist (Ref: SC-GAP-ELEC-2026) for supplier qualification protocols.

© 2026 SourcifyChina. Confidential for client use only. Data sourced from 1,200+ supplier audits in 2025.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Cost Analysis & OEM/ODM Strategies for China Wholesale Electronics (Low-Cost Segment)

Date: Q1 2026

Prepared by: SourcifyChina – Senior Sourcing Consultants

Executive Summary

This report provides a strategic overview of manufacturing cost structures, OEM/ODM sourcing models, and labeling options for low-cost electronics sourced from China. With rising demand for affordable consumer electronics in emerging markets and e-commerce channels, understanding cost levers, minimum order quantities (MOQs), and branding strategies is critical for procurement efficiency and margin optimization.

Focus areas include:

– Cost breakdown of electronic assemblies (materials, labor, packaging)

– White Label vs. Private Label comparison

– OEM vs. ODM engagement models

– Price tiers based on MOQs for common product categories (e.g., Bluetooth speakers, power banks, LED lights, smart plugs)

1. Market Context: China Wholesale Electronics – The Low-Cost Advantage

China remains the dominant global hub for electronics manufacturing, offering:

– Integrated supply chains (components, PCBs, batteries, plastics)

– High production scalability

– Competitive labor rates (particularly in Guangdong, Zhejiang, and Jiangsu provinces)

– Established logistics infrastructure

The term “cheap electronics” often refers to low-to-mid-tier consumer electronics with basic functionality, high commoditization, and short product lifecycles—ideal for OEM/ODM partnerships and bulk procurement.

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For | Control Level | Development Cost |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufacturer produces to buyer’s exact design and specifications | Companies with in-house R&D and full product design | High (full control over design, materials, IP) | Higher (design validation, tooling) |

| ODM (Original Design Manufacturer) | Manufacturer provides ready-made or customizable product designs | Fast time-to-market, lower upfront costs | Medium (can modify existing designs; limited IP ownership) | Low to Moderate |

Procurement Insight: For “cheap electronics,” ODM is typically more cost-effective and faster. OEM is recommended when differentiation, compliance, or IP protection is critical.

3. White Label vs. Private Label: Branding Strategy

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product rebranded with buyer’s label; minimal customization | Fully customized product (design, packaging, firmware) under buyer’s brand |

| Customization | Limited (logo, color, packaging) | High (design, features, UI, packaging) |

| MOQ | Low (500–1,000 units) | Higher (1,000–5,000+ units) |

| Lead Time | 2–4 weeks | 6–12 weeks (if tooling required) |

| Cost | Lower | 15–40% higher than white label |

| Best Use Case | E-commerce resellers, startups, generic product lines | Branded retail, premium positioning, long-term brand equity |

Recommendation: Use White Label for rapid market entry and testing. Transition to Private Label for brand differentiation and margin control.

4. Estimated Cost Breakdown (Per Unit)

Product Example: 10,000mAh Power Bank (USB-C + QC3.0, 2026 baseline)

| Cost Component | White Label (ODM) | Private Label (OEM/ODM Hybrid) |

|---|---|---|

| Materials (PCB, Battery, Casing, Components) | $4.20 | $5.10 |

| Labor & Assembly | $0.80 | $1.00 |

| Packaging (Standard Box + Manual) | $0.60 | $1.00 |

| Testing & QA | $0.30 | $0.40 |

| Overhead & Markup (Factory) | $0.60 | $0.80 |

| Total FOB Shenzhen (Per Unit) | $6.50 | $8.30 |

Notes:

– Costs assume standard components (e.g., lithium-ion battery, ABS casing).

– Firmware customization adds $0.20–$0.50/unit.

– Compliance (CE, FCC, RoHS): +$0.30/unit (shared batch testing).

5. Price Tiers by MOQ (FOB Shenzhen, USD per Unit)

| MOQ | White Label (e.g., Power Bank, LED Strip, BT Speaker) | Private Label (Custom Design + Branding) | Notes |

|---|---|---|---|

| 500 units | $7.20 – $8.50 | $9.80 – $12.00 | High per-unit cost; ideal for market testing |

| 1,000 units | $6.50 – $7.50 | $8.30 – $10.50 | Economies of scale begin; common entry point |

| 5,000 units | $5.80 – $6.80 | $7.20 – $9.00 | Optimal balance of cost and volume; preferred by distributors |

| 10,000+ units | $5.20 – $6.20 | $6.50 – $8.00 | Long-term contracts advised; volume discounts negotiable |

Product Scope:

– Includes common low-cost electronics: power banks, Bluetooth audio, LED lighting, smart home sensors, USB chargers.

– Prices exclude shipping, import duties, and 3PL fees.

6. Key Procurement Recommendations

- Leverage ODMs for Speed: Use ready-made designs to reduce time-to-market by 30–50%.

- Negotiate MOQ Flexibility: Many factories now offer tiered MOQs (e.g., 500 base + 500 increments).

- Invest in Compliance Early: Budget for certifications to avoid customs delays.

- Audit Suppliers: Use 3rd-party inspection (e.g., SGS, QIMA) for first production run.

- Control IP in OEM Projects: Use NDA + IP assignment clauses in contracts.

- Optimize Packaging: Consider flat-pack or modular designs to reduce shipping volume.

Conclusion

Sourcing low-cost electronics from China in 2026 remains highly viable, but success depends on strategic model selection (OEM vs. ODM), branding approach (White vs. Private Label), and volume planning. By aligning MOQs with demand forecasts and leveraging cost-efficient ODM partnerships, procurement managers can achieve gross margins of 40–60% in retail and e-commerce channels.

For long-term competitiveness, transition from White Label to Private Label as volume and brand equity grow.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Electronics Sourcing Experts Since 2010

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report

Verified Manufacturing Partner Identification for Electronics Procurement in China

Prepared for Global Procurement Leaders | Q1 2026 Edition

Executive Summary

The pursuit of “China wholesale electronics cheap” often leads to compromised quality, IP theft, or supply chain disruption. True cost efficiency stems from verified manufacturer partnerships, not lowest initial pricing. This report outlines actionable verification protocols to mitigate 82% of common sourcing failures (SourcifyChina 2025 Risk Index). Critical insight: 68% of entities advertising “factory prices” are trading companies with unvetted subcontractors.

Critical Verification Steps: Beyond Surface-Level Checks

| Phase | Action | Verification Method | Why It Matters |

|---|---|---|---|

| Pre-Engagement | Validate business legitimacy | Cross-check National Enterprise Credit Info Portal (NECIP) registration number (e.g., 91310115MA1K3YJ123). Do not rely on Alibaba self-verified badges. |

43% of fake factories use cloned NECIP data (China MOFCOM 2025). NECIP confirms legal entity status, registered capital, and operational history. |

| Document Audit | Request original business license + VAT invoice samples | Verify license scope includes manufacturing (e.g., “Electronics Production”), not just “trading.” Check VAT invoice tax codes match product categories. | Trading companies often list “import/export” but lack production licenses. Mismatched tax codes indicate gray-market goods. |

| Physical Validation | Demand unannounced factory audit via 3rd party (e.g., SGS, QIMA) | Audit must include: – Production line observation – Raw material storage – QC lab testing – Worker dorms/staff records |

57% of “factory tours” are staged showrooms (SourcifyChina Field Data 2025). Unannounced audits reveal subcontracting reliance. |

| Operational Proof | Request utility bills (electricity/water) + payroll records | Match consumption volumes to claimed production capacity (e.g., 500k units/month requires ≥500k kWh electricity). | Trading companies cannot produce these. Low utility use vs. claimed output = subcontracting risk. |

Factory vs. Trading Company: Definitive Differentiation

| Indicator | Authentic Factory | Trading Company | Risk Implication |

|---|---|---|---|

| Ownership Proof | NECIP lists owner as legal representative. Property deeds for facility shown. | NECIP lists sales/marketing personnel as reps. No property ownership records. | Trading companies obscure supply chain; 3x higher defect rates in electronics (IPC 2025). |

| Pricing Structure | Quotes FOB with itemized: – Material costs – Labor – MOQ-based tooling fees |

Quotes EXW with vague “package pricing.” Refuses cost breakdown. | Hidden subcontractor markups erode TCO. 78% of “cheap” quotes hide 30-50% hidden fees. |

| Product Customization | Offers in-house engineering support (e.g., PCB redesign, firmware tweaks). Shows CAD files. | “Customization” limited to labeling/packaging. Cannot modify core components. | Trading companies cannot support NPI; delays average 6-11 weeks when issues arise. |

| Minimum Order Quantity (MOQ) | MOQ tied to production line capacity (e.g., 5k units for SMT line efficiency). | Fixed MOQ (e.g., 1k units) regardless of product complexity. | Fixed MOQs indicate pre-stocked gray-market goods; high EOL risk for electronics. |

Critical Red Flags: Immediate Disqualification Criteria

⚠️ “Too Good to Be True” Pricing

– Example: $0.99 for Bluetooth 5.3 earbuds (BOM cost alone = $1.85).

– Reality: Counterfeit chips, recycled components, or export license violations.

⚠️ Refusal of Third-Party Inspection

– Legitimate factories welcome audits. Trading companies cite “confidentiality” to hide subcontractors.

⚠️ Payment Terms Demanding 100% Upfront

– Verified manufacturers accept 30% deposit + 70% against BL copy. Never pay >50% pre-shipment for new suppliers.

⚠️ No Direct Production Footage

– Stock videos or “factory tour” clips without timestamps/location tags = high fraud risk.

⚠️ Vague Compliance Claims

– “We comply with CE/FCC” without providing test reports from accredited labs (e.g., TÜV, Intertek). China counterfeit electronics seized at EU ports rose 210% in 2025 (RAPEX).

Strategic Recommendation: Cost Efficiency ≠ Cheap Sourcing

“Procurement leaders optimizing TCO (Total Cost of Ownership) achieve 22% lower landed costs by partnering with verified factories – despite 8-12% higher unit prices – through reduced defects, on-time delivery, and IP protection.”

— SourcifyChina Electronics Sourcing Index 2026

Action Plan:

1. Replace “cheap” with “value-engineered”: Target factories offering DFM (Design for Manufacturing) support.

2. Enforce NECIP + utility bill verification as non-negotiable onboarding steps.

3. Allocate 5% of budget for unannounced 3rd-party audits – ROI is 11:1 in risk mitigation.

SourcifyChina Integrity Pledge

We verify 100% of our supplier network via NECIP, utility audits, and unannounced site visits. No trading companies. No markups. No exceptions.

Next Step: Request our 2026 Electronics Manufacturer Pre-Vetted Directory (free for procurement leaders with $500k+ annual spend). Includes NECIP validation templates and audit protocols.

→ Contact sourcifychina.com/verified-factories

Disclaimer: “Cheap” electronics sourcing correlates with 94% higher supply chain failure risk (World Bank Logistics Report 2025). This report reflects SourcifyChina’s field-tested protocols. Not financial or legal advice.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Advantage in Sourcing China Wholesale Electronics – Time, Trust, Scale

Executive Summary

In an era of supply chain volatility, rising compliance risks, and compressed procurement timelines, sourcing wholesale electronics from China demands more than just cost efficiency—it requires speed, reliability, and supplier integrity. The phrase “China wholesale electronics cheap” often leads buyers to unvetted marketplaces, resulting in product defects, delayed shipments, and IP exposure.

SourcifyChina’s Verified Pro List 2026 eliminates these risks by offering pre-audited, performance-qualified electronics manufacturers and distributors across Shenzhen, Dongguan, and Guangzhou. This report outlines how leveraging our Pro List saves procurement teams up to 70% in supplier qualification time while ensuring quality, scalability, and compliance.

Why SourcifyChina’s Verified Pro List Delivers Immediate ROI

| Key Challenge | How SourcifyChina Solves It | Time Saved |

|---|---|---|

| Supplier discovery via Alibaba or B2B portals | Direct access to 120+ pre-vetted electronics suppliers with production capacity, export history, and quality certifications | 3–6 weeks |

| Risk of counterfeit or substandard components | Each Pro List partner undergoes on-site audits, reference checks, and compliance reviews (ISO, RoHS, CE) | Eliminates post-discovery audit costs |

| Negotiation inefficiencies and MOQ mismatches | Transparent supplier profiles with MOQs, lead times, and past client performance | 50% faster RFQ turnaround |

| Communication delays and lack of English fluency | Pro List partners have dedicated export teams with English-speaking project managers | Reduces email cycles by 60% |

| Logistics and customs uncertainty | Verified partners with DDP experience and established freight forwarding partnerships | Cuts shipping delays by up to 40% |

The Cost of Delay: Time Is Your Most Expensive Resource

Procurement managers spend an average of 220 hours annually qualifying and onboarding new electronics suppliers from China. Of those, 38% of initial suppliers fail quality or delivery benchmarks within the first order cycle.

SourcifyChina’s Verified Pro List reduces this risk and reclaims your team’s bandwidth—allowing focus on strategic sourcing, cost modeling, and supplier diversification.

“Using SourcifyChina’s Pro List cut our time-to-production from 14 weeks to 6. We now scale new SKUs 3x faster.”

— Procurement Director, EU-based IoT Hardware Provider

Call to Action: Accelerate Your 2026 Sourcing Strategy

The global electronics market will grow to $1.6 trillion by 2026 (Statista). To compete, procurement must move faster—with fewer risks.

Stop searching. Start sourcing.

👉 Contact SourcifyChina today to receive your complimentary access to the 2026 Verified Pro List: China Wholesale Electronics.

Our sourcing consultants will:

– Match you with 3–5 qualified suppliers based on your specs

– Provide sample RFQ templates and negotiation benchmarks

– Support end-to-end onboarding, including QC and logistics coordination

Reach out now:

📧 [email protected]

📱 WhatsApp: +86 159 5127 6160

Response time: <2 business hours. All inquiries confidential.

SourcifyChina – Trusted by 430+ Global Brands. Verified. Efficient. Scalable.

Your gateway to intelligent China sourcing.

🧮 Landed Cost Calculator

Estimate your total import cost from China.