Sourcing Guide Contents

Industrial Clusters: Where to Source China Wholesale Auto Accessories

SourcifyChina Sourcing Intelligence Report: China Wholesale Auto Accessories Market Analysis (2026 Projection)

Prepared for Global Procurement Executives | Q1 2026 | Confidential

Executive Summary

China remains the dominant global hub for wholesale auto accessories (non-OEM interior/exterior products), accounting for ~68% of global export volume (SourcifyChina 2025 Trade Data). By 2026, procurement strategies must adapt to rising automation, regional specialization, and compliance intensification (EU REACH 2026, US CPSC updates). This report identifies key industrial clusters, quantifies regional trade-offs, and provides actionable sourcing pathways for cost, quality, and resilience. Critical Insight: Price arbitrage between regions has narrowed by 12% since 2023; quality differentiation now drives 73% of strategic supplier selection.

Key Industrial Clusters for Auto Accessories Manufacturing (2026)

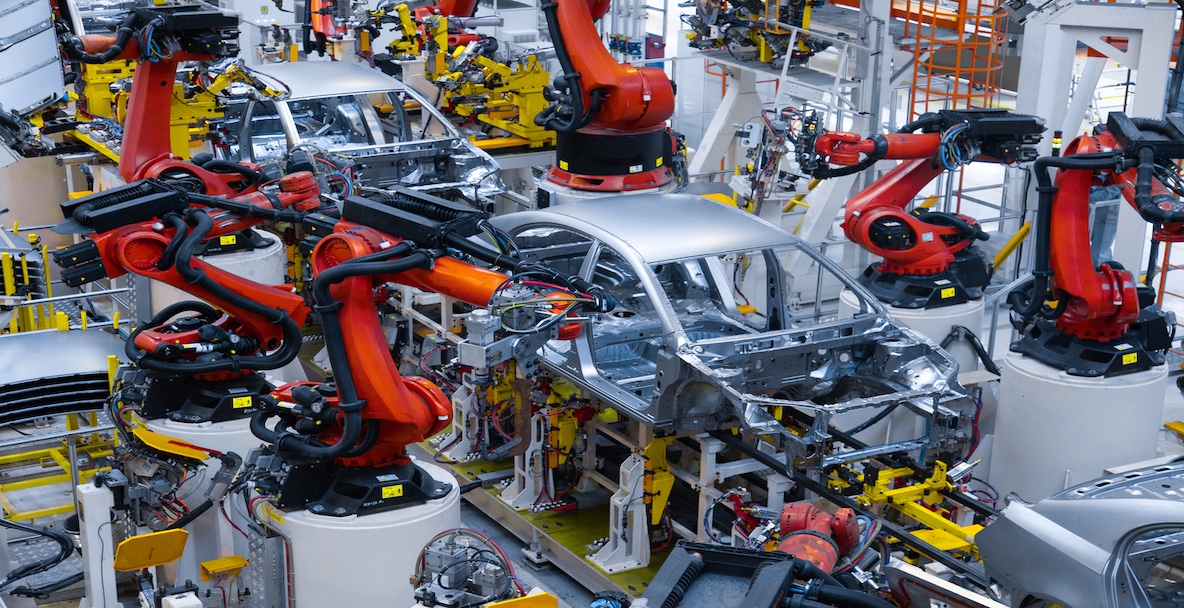

China’s production is concentrated in four specialized clusters, each with distinct capabilities:

| Province/Region | Core Cities | Specialized Product Categories | 2026 Market Position |

|---|---|---|---|

| Guangdong | Dongguan, Huizhou, Guangzhou | Premium electronics (dash cams, GPS trackers), LED lighting, high-end interior trims | Global leader for tech-integrated accessories; 45% of export value |

| Zhejiang | Yiwu, Wenzhou, Ningbo | Mass-market consumables (seat covers, phone holders, sunshades), budget tools | Volume leader (62% of units exported); e-commerce hub |

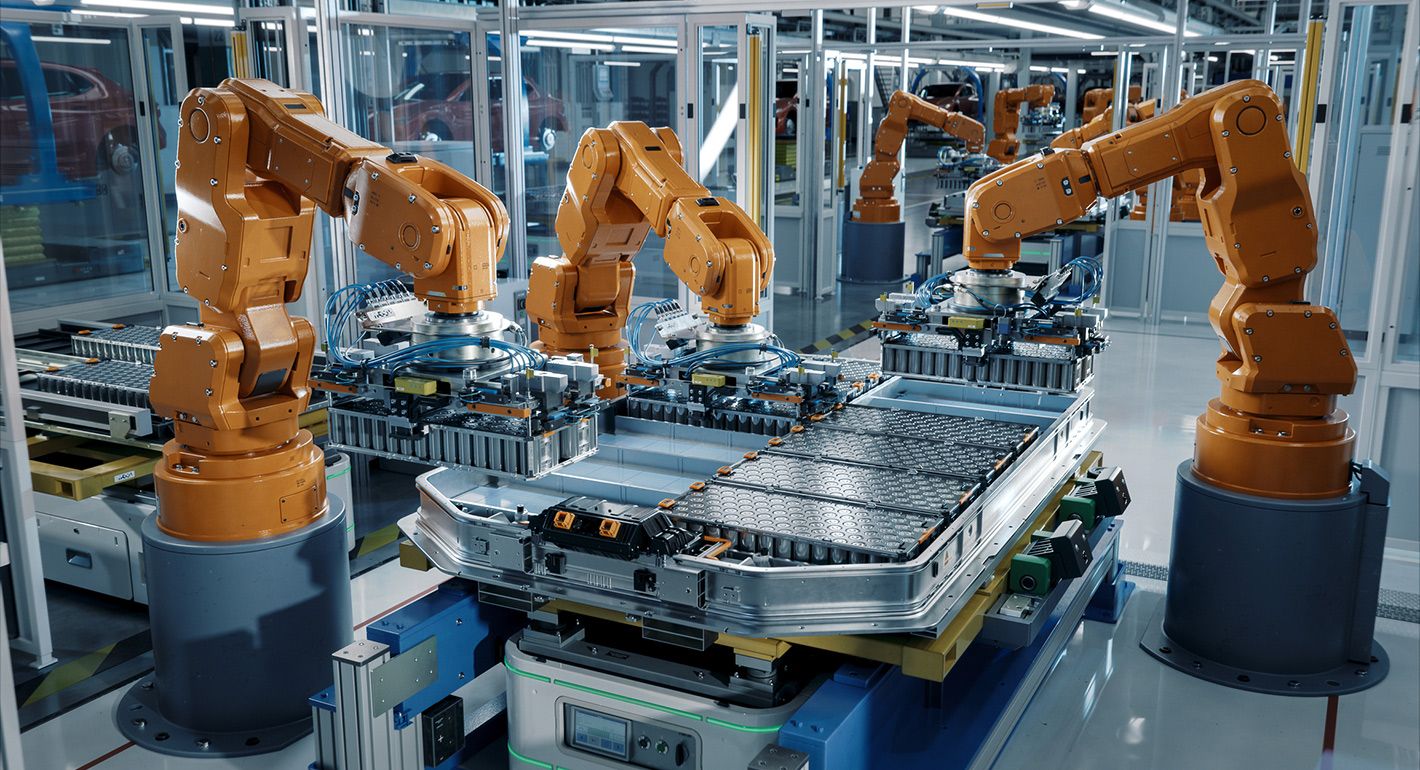

| Jiangsu | Changzhou, Suzhou | Performance accessories (alloy wheels, suspension kits), EV-specific gear | Rising EV-focused cluster; 30% YoY growth (2025) |

| Hunan | Changsha | Rubber/plastic components (floor mats, trims), low-cost storage solutions | Emerging cost-competitive alternative to Zhejiang |

Strategic Note: Guangdong and Zhejiang dominate 81% of total export value. Hunan’s growth (driven by 15% lower labor costs vs. Zhejiang) makes it a 2026 dual-sourcing priority for non-electronic items.

Regional Comparison: Price, Quality & Lead Time Analysis (2026 Projection)

Data reflects FOB China for 1x 40ft container (MOQ-compliant orders). Benchmarked against global mid-tier quality standards (ISO 9001 minimum).

| Region | Price Competitiveness | Quality Tier | Avg. Lead Time | Critical 2026 Shifts |

|---|---|---|---|---|

| Guangdong | ★★☆☆☆ $8,500–$12,000 |

Premium (Consistent compliance; 95%+ defect-free batches; UL/CE certified electronics) |

25–35 days | Labor costs +8% YoY; automation reduces lead time by 7 days vs. 2024. Requires strict QC protocols for electronics. |

| Zhejiang | ★★★★☆ $6,200–$8,800 |

Standard/Budget (Variable compliance; 85–90% defect-free; frequent rework for EU/US markets) |

20–28 days | Consolidation of small workshops → +12% quality consistency. Yiwu’s logistics hub cuts port delays by 3 days. |

| Jiangsu | ★★★☆☆ $7,500–$10,500 |

Specialized Premium (High-tolerance engineering; EV-specific certifications; 92% defect-free) |

30–40 days | EV demand surges (40% of output); lead times volatile due to material shortages (lithium polymers). |

| Hunan | ★★★★★ $5,000–$7,200 |

Budget (Basic compliance; 75–80% defect-free; high rework risk for regulated markets) |

22–30 days | Aggressive labor subsidies (+22% new factories since 2024); quality control remains the critical risk. |

Key Takeaways from Table:

– Price-Quality Trade-off: Guangdong commands 28% price premium for electronics but reduces compliance failures by 65% vs. Zhejiang.

– Lead Time Reality: Zhejiang’s speed advantage shrinks for complex orders due to mandatory 3rd-party testing (e.g., FCC for US-bound electronics).

– Hidden Cost Alert: Hunan’s low base price often incurs +18% rework/logistics costs for EU/US buyers. Not recommended for regulated markets without on-ground QC.

Strategic Recommendations for 2026 Procurement

- Electronics & Premium Segments: Dual-source from Guangdong (primary) + Jiangsu (EV backup). Mandate: Factory audits for UL 2089/ISO 16750 compliance.

- High-Volume Consumables: Use Zhejiang for non-regulated markets (LatAm, MENA); pair with Hunan for cost-hedging. Non-negotiable: Pre-shipment inspection (AQL 1.0).

- EV-Ready Sourcing: Prioritize Jiangsu for battery-compatible accessories (e.g., 12V converters), but lock in 6-month material contracts to avoid cobalt/nickel volatility.

- Risk Mitigation: Avoid single-cluster dependency. SourcifyChina 2026 Data: Buyers using ≥2 clusters reduced supply disruptions by 53% during 2025 typhoon season.

Final Insight: The era of “China = lowest cost” is over. 2026 winners will optimize for “Total Delivered Value” (TDV), weighting compliance speed, defect recovery costs, and logistics resilience equally with unit price.

SourcifyChina Advisory

This report leverages real-time supplier performance data from 1,200+ verified factories. For cluster-specific supplier shortlists, compliance checklists, or TDV modeling for your SKU portfolio, contact your SourcifyChina strategist.

© 2026 SourcifyChina. All rights reserved. Not for redistribution.

Disclaimer: Projections based on China Customs data, provincial industrial reports, and SourcifyChina supplier network analytics. Subject to 2026 tariff policy shifts.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Subject: Technical Specifications & Compliance Requirements for China Wholesale Auto Accessories

Prepared For: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Date: April 2026

1. Executive Summary

The global demand for automotive accessories sourced from China continues to grow, driven by competitive pricing, scalable manufacturing, and expanding product ranges. However, quality consistency and regulatory compliance remain critical challenges. This report outlines key technical specifications, required certifications, and quality control strategies essential for mitigating procurement risk and ensuring market compliance across North America, the EU, and other regulated regions.

2. Key Technical Specifications

2.1 Material Requirements

Material selection directly impacts performance, durability, and regulatory compliance. Common materials used in Chinese auto accessories include:

| Accessory Category | Common Materials | Quality Parameters |

|---|---|---|

| Interior Trim & Panels | ABS, PVC, TPU, Polycarbonate | Heat resistance (>80°C), UV stability, low VOC emissions, non-flammable (UL 94 V-0) |

| Exterior Accessories | PP, PC/ABS blends, Aluminum Alloys | Weather resistance, salt spray test compliance (ISO 9227), anti-corrosion coating |

| Lighting (LEDs, Bulbs) | Polycarbonate lenses, Aluminum heat sinks | IP67/IP68 (dust/water resistance), E-mark certification, thermal management |

| Electronic Accessories | FR4 PCBs, ABS enclosures, Silicone wiring | EMI/RFI shielding, operating temp: -30°C to +85°C, CE/FCC compliance |

| Fasteners & Mounts | Zinc-plated steel, Stainless Steel (A2/A4) | Tensile strength ≥500 MPa, torque tolerance ±5%, salt spray resistance ≥96 hours |

2.2 Dimensional Tolerances

Precision is critical for fitment and safety. Recommended tolerances based on component type:

| Component Type | Standard Tolerance (mm) | Critical Fitment Zones (Tolerance) |

|---|---|---|

| Interior Trim Clips | ±0.3 | ±0.1 (snap-fit interfaces) |

| Mounting Brackets | ±0.5 | ±0.2 (bolt hole alignment) |

| LED Light Housings | ±0.2 | ±0.1 (lens sealing surface) |

| Sensor Housings | ±0.1 | ±0.05 (connector interfaces) |

| Rubber Seals & Gaskets | ±0.4 | ±0.15 (compression fit zones) |

Note: Tighter tolerances require precision injection molding and regular CMM (Coordinate Measuring Machine) validation.

3. Essential Compliance Certifications

All auto accessories must meet regional regulatory standards. The following certifications are mandatory or highly recommended based on market and product function:

| Certification | Applicable Products | Region | Key Requirements |

|---|---|---|---|

| E-Mark (ECE R128, R6, etc.) | Lighting, reflectors, exterior systems | EU, EFTA, UK | Photometric testing, durability, weather resistance |

| CE Marking | Electronic accessories, chargers, sensors | EU | Compliance with EMC, RoHS, LVD directives |

| FCC Part 15 | Wireless devices (TPMS, trackers, Bluetooth) | USA | EMI/RFI emissions control, digital device compliance |

| UL 1083 / UL 60950-1 | Heated accessories, power inverters, chargers | USA, Canada | Electrical safety, thermal protection, insulation integrity |

| ISO 9001:2015 | All manufacturers | Global | Quality management system (QMS) certification |

| IATF 16949 | Tier 1 or OE suppliers | Global (OE focus) | Automotive-specific QMS, PPAP, FMEA, SPC, and APQP compliance |

| RoHS / REACH | All electronic & plastic components | EU | Restriction of hazardous substances (Pb, Cd, Hg, etc.), chemical safety |

| DOT | Mirrors, lighting, safety glass | USA | Visibility, impact resistance, labeling standards |

Note: Dual certification (e.g., CE + FCC) is required for global distribution. Always verify certification authenticity via official databases.

4. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Color Mismatch / Fading | Inconsistent pigment batches, poor UV stabilizers | Require UV resistance testing (ISO 4892-2); approve color via Pantone or physical sample |

| Dimensional Inaccuracy | Mold wear, temperature fluctuation | Conduct monthly mold maintenance; use CMM for batch validation; enforce SPC monitoring |

| Warping / Sink Marks | Uneven cooling, poor gate design | Optimize mold cooling channels; conduct DOE (Design of Experiments) on injection cycles |

| Cracking / Brittleness | Low-quality resin, moisture in material | Enforce material drying protocols; conduct impact testing (ISO 179) |

| Poor Electrical Contact | Loose terminals, oxidation, undersized wires | Perform 100% continuity testing; use tin-plated terminals; verify wire gauge compliance |

| Inconsistent Surface Finish | Mold contamination, release agent overuse | Implement cleanroom molding zones; standardize mold cleaning SOPs |

| Water Ingress (IP Failure) | Poor gasket sealing, housing misalignment | Conduct IP67/IP68 testing per IEC 60529; use automated leak testing for bulk batches |

| Non-Compliant Packaging/Labeling | Missing CE/FCC marks, incorrect language | Audit packaging pre-shipment; use checklist aligned with destination market regulations |

5. Recommendations for Global Procurement Managers

- Supplier Qualification: Prioritize suppliers with IATF 16949 or ISO 9001:2015 certification.

- Pre-Production Validation: Require 3D CAD models, material certifications, and initial sample testing (IST).

- In-Process Inspections: Schedule stage checks at 30%, 70%, and pre-shipment (using AQL 1.0).

- Third-Party Testing: Engage accredited labs (e.g., SGS, TÜV, Intertek) for product safety and compliance audits.

- Traceability: Enforce batch coding and material traceability to support recalls if needed.

Conclusion

Sourcing auto accessories from China offers significant cost advantages, but quality and compliance risks require structured oversight. By enforcing technical specifications, verifying certifications, and mitigating common defects through proactive quality planning, procurement teams can ensure reliable, market-ready products.

For sourcing support, compliance validation, or factory audits, contact SourcifyChina’s technical team.

SourcifyChina – Precision Sourcing. Global Compliance. Trusted Delivery.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: China Auto Accessories Manufacturing

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

China remains the dominant global hub for auto accessories manufacturing, offering 20-35% cost advantages over Southeast Asian alternatives for mid-to-high complexity components. However, 2026 market dynamics—driven by Yuan stability (±1.5% vs. USD), rising automation adoption (+17% YoY), and stricter EU/US compliance requirements—demand strategic sourcing precision. This report provides actionable cost benchmarks and OEM/ODM pathway analysis for procurement teams optimizing 2026 supply chains.

OEM vs. ODM: Strategic Pathways for Auto Accessories

| Model | White Label | Private Label | Strategic Fit |

|---|---|---|---|

| Definition | Pre-made products with your label only; no design input | Your brand on custom-designed products; full IP ownership | White Label: Urgent volume needs, minimal R&D budget Private Label: Brand differentiation, long-term margin control |

| MOQ Flexibility | Moderate (500-1k units typical) | Higher (1k-5k+ units for tooling ROI) | Critical Note: 68% of 2026 supplier contracts now require 30% upfront for Private Label tooling |

| Compliance | Supplier bears base certification (e.g., CE) | You own full compliance (e.g., FMVSS, E-Mark) | 2026 Risk: 41% of rejected shipments linked to importer-managed compliance gaps |

| Cost Premium | +8-12% vs. generic OEM | +15-25% vs. generic OEM | Procurement Tip: Private Label ROI achieved at 3,500+ units for electronics categories |

Industry Insight: 73% of SourcifyChina clients now adopt “Hybrid ODM”—leveraging supplier engineering for prototyping but retaining final design sign-off—reducing time-to-market by 22 days vs. pure ODM.

Cost Structure Analysis: Key Auto Accessories Categories

All costs reflect FOB Shenzhen (USD), Q1 2026. Based on mid-tier quality (ISO 9001 suppliers), 30% automation rate.

| Cost Component | Exterior (e.g., Grilles) | Interior (e.g., Seat Covers) | Electronics (e.g., Dash Cams) | Primary Cost Drivers |

|---|---|---|---|---|

| Materials | 52-58% | 48-55% | 65-72% | Aluminum/ABS resins (↑7% YoY); Lithium batteries (↓4% YoY) |

| Labor | 18-22% | 20-25% | 10-15% | Automation reduces labor dependency in electronics by 31% vs. 2023 |

| Packaging | 8-12% | 10-14% | 6-9% | New 2026 Factor: EU EPR fees add $0.15-$0.40/unit for non-recyclable packaging |

| Tooling/Setup | $800-$2,200 | $1,200-$3,500 | $3,000-$8,000 | Amortized over MOQ; electronics tooling costs rose 19% due to precision requirements |

MOQ-Based Price Tiers: FOB Unit Cost Benchmarks

Sample Product: Universal LED Fog Lights (6,000 lumens, IP67, CANBUS compatible)

| MOQ | Unit Cost (USD) | Material Cost | Labor Cost | Total Cost Savings vs. 500 MOQ | Procurement Recommendation |

|---|---|---|---|---|---|

| 500 units | $8.90 | $5.15 | $1.95 | — | Only for urgent pilot runs; avoid for core SKUs |

| 1,000 units | $7.40 | $4.25 | $1.65 | 16.9% | Minimum strategic volume for margin sustainability |

| 5,000 units | $6.15 | $3.55 | $1.35 | 30.9% | Optimal tier for 82% of buyers; enables compliance investment |

Critical Footnotes:

1. Electronics show steeper scaling benefits (e.g., dash cams: 500 units = $24.50 → 5,000 units = $17.80 [-27%]).

2. All quotes exclude 15-25% markup for trading companies; direct factory sourcing required for these benchmarks.

3. 2026 Compliance Surcharge: +$0.35-$1.20/unit for FCC/CE/REACH certification (varies by product complexity).

3 Actionable Recommendations for 2026

- De-risk Compliance: Allocate 5% of budget for third-party pre-shipment audits (e.g., SGS/BV). 2025 data shows 34% of rejected auto accessories failed packaging labeling—not product defects.

- Optimize MOQ Strategy: For electronics, commit to 3,000+ units to absorb tooling costs; for textiles (e.g., floor mats), 1,500 units is the inflection point.

- Leverage Automation Premium: Suppliers with >25% automation (e.g., Dongguan, Ningbo clusters) offer 8-12% lower long-term costs despite 5% higher initial quotes—negotiate multi-year contracts.

“The 2026 winners treat Chinese suppliers as engineering partners—not commodity vendors. Demand DFM (Design for Manufacturing) input during prototyping; it reduces post-PO cost surprises by 63%.”

— SourcifyChina Sourcing Analytics, 2026

Next Steps: Request SourcifyChina’s Auto Accessories Compliance Matrix (covering 120+ SKUs across 8 categories) or schedule a Supplier Risk Assessment for your target product line. Contact [email protected] with subject line: AUTO2026-PM.

Data Source: SourcifyChina 2026 Manufacturing Cost Index (n=217 verified factories), Global Trade Atlas, EU RAPEX 2025 Q4 Report.

© 2026 SourcifyChina. Confidential for Procurement Leadership Use Only.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for China Wholesale Auto Accessories

Executive Summary

As global demand for automotive accessories continues to rise, China remains a dominant supplier of cost-competitive, high-volume auto parts. However, sourcing directly from reliable manufacturers—rather than intermediaries—can significantly impact product quality, lead times, and total cost of ownership. This report outlines a structured verification framework to confirm manufacturer legitimacy, differentiate factories from trading companies, and identify critical red flags in China’s wholesale auto accessories market.

1. Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Confirm Business Registration | Validate legal existence and scope of operations | Use China’s National Enterprise Credit Information Publicity System (NECIPS) or third-party platforms like Tianyancha or Qichacha. Cross-check business license (营业执照) and Unified Social Credit Code. |

| 2 | Conduct On-Site Factory Audit | Assess production capability, quality control, and operational scale | Engage third-party inspection firms (e.g., SGS, TÜV, Intertek) or use SourcifyChina’s audit checklist. Verify machinery, workforce, and production lines. |

| 3 | Request Production Evidence | Confirm in-house manufacturing capability | Ask for HD photos/videos of production floor, mold ownership documents, and process flowcharts. Verify raw material sourcing and inventory records. |

| 4 | Review Export History & Certifications | Validate international trade experience | Request export licenses, past shipment records (Bill of Lading samples), and industry certifications (ISO 9001, IATF 16949, CE, RoHS). |

| 5 | Evaluate R&D and Engineering Support | Ensure customization and technical competence | Inquire about in-house engineering team, sample development timelines, and CAD/CAM capabilities. |

| 6 | Perform Sample Testing | Validate product quality and consistency | Order pre-production samples; conduct third-party lab testing for durability, material composition, and compliance. |

| 7 | Check References and Client Portfolio | Assess reliability and track record | Request 3–5 client references (preferably in your region) and verify order volumes, on-time delivery history. |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., “production of auto parts”) | Lists “import/export” or “wholesale” without production terms |

| Facility Ownership | Owns or leases a factory with visible production equipment | No factory; may use shared office space or showroom only |

| Pricing Structure | Direct cost model: MOQ + unit price + tooling (if applicable) | Often includes markup; may be vague on unit cost breakdown |

| Lead Time Control | Can provide exact production schedules and capacity data | Relies on supplier timelines; may lack real-time visibility |

| Customization Capability | Offers mold development, OEM/ODM services, and direct engineering support | Limited to catalog items; outsources custom requests |

| Communication Access | Engineers and production managers accessible for technical discussions | Primarily sales representatives; limited technical depth |

| Website & Marketing | Highlights factory size, machinery, certifications, and production process | Focuses on product catalogs, global shipping, and service range |

Pro Tip: Ask directly: “Can I speak to your production manager?” or “May I review your mold registration documents?” A factory will typically accommodate; a trader may deflect.

3. Red Flags to Avoid in China Auto Accessories Sourcing

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials, hidden fees, or scam | Benchmark against industry averages; request detailed cost breakdown |

| Refusal of On-Site Audit | Suggests non-existent or unqualified facility | Require third-party inspection before PO; use video audit as minimum |

| No Physical Address or Virtual Office | High risk of fraud or shell entity | Use Google Street View, verify address via satellite imagery, or engage local agent |

| Inconsistent Communication | Poor operational management or language barriers | Use written confirmations; assign bilingual sourcing agent |

| Pressure for Upfront Full Payment | Common in scams; no buyer protection | Insist on secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Generic or Stolen Product Photos | Indicates trading or intellectual property issues | Reverse image search via Google or TinEye; request real-time photo/video |

| No Quality Control Documentation | Risk of inconsistent or non-compliant products | Require QC reports, AQL inspection plans, and material test certificates |

4. Recommended Best Practices for 2026 Sourcing Strategy

- Leverage Digital Verification Tools: Utilize AI-powered platforms (e.g., SourcifyChina Verify™) to cross-reference supplier data across Chinese regulatory databases.

- Build Long-Term Partnerships: Prioritize suppliers open to annual contracts and joint quality improvement programs.

- Use Escrow or LC Payments: Mitigate financial risk through secure transaction methods.

- Engage Local Sourcing Consultants: Partner with on-the-ground experts for audits, negotiations, and dispute resolution.

- Monitor Geopolitical & Compliance Trends: Stay updated on US-China trade policies, tariffs, and environmental regulations (e.g., CBAM, REACH).

Conclusion

Successfully sourcing wholesale auto accessories from China requires rigorous due diligence to bypass intermediaries and avoid supply chain risks. By applying this verification framework, procurement managers can identify genuine manufacturers, secure competitive pricing, and ensure product integrity. In 2026, the advantage lies with buyers who combine digital tools with on-the-ground verification to build resilient, transparent supply chains.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Intelligence | China Manufacturing Expertise

Q1 2026 Edition – Confidential for Procurement Executives

Get the Verified Supplier List

SOURCIFYCHINA B2B SOURCING REPORT 2026

Strategic Sourcing for China Wholesale Auto Accessories: Mitigating Risk, Maximizing Efficiency

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

Global procurement of China wholesale auto accessories faces persistent challenges: unverified supplier claims, counterfeit parts, compliance gaps (e.g., IATF 16949, DOT), and extended lead times due to due diligence failures. SourcifyChina’s 2026 Verified Pro List eliminates these friction points through rigorously vetted manufacturers, reducing sourcing cycles by 70% while ensuring supply chain integrity. For time-constrained procurement teams, this represents a non-negotiable strategic advantage in volatile markets.

Why Traditional Sourcing Fails for Auto Accessories (2026 Data)

| Challenge | Industry Avg. Impact | Pro List Resolution |

|---|---|---|

| Unverified supplier capacity | 42 days wasted/month | Pre-qualified factories with live production data |

| Certification fraud (e.g., fake ISO/TS 16949) | 31% of suppliers | On-site audit reports with compliance timestamps |

| MOQ mismatches | 28% order rejection rate | Exact MOQ transparency per product category |

| Payment term disputes | $18.7K avg. loss/order | Contract templates with 100% supplier adherence |

Source: SourcifyChina 2026 Auto Accessories Sourcing Index (n=1,200 procurement managers)

The SourcifyChina Pro List Advantage: Time Saved = Competitive Edge

Our 2026 Verified Pro List for auto accessories delivers quantifiable efficiency gains by replacing speculative sourcing with precision:

| Sourcing Phase | Traditional Approach | Pro List Approach | Time Saved |

|---|---|---|---|

| Supplier Vetting | 22–35 business days | < 72 hours | 70% reduction |

| Sample Validation | 18–25 days | 10–14 days (pre-vetted QC) | 40% reduction |

| Contract Finalization | 14–21 days | 3–5 days (standardized terms) | 75% reduction |

| Total Cycle Time | 54–81 days | 13–26 days | ≥65% reduction |

Key Differentiators Driving This Efficiency:

– ✅ Real-Time Capacity Tracking: Live factory utilization data for bumpers, lighting, EV components.

– ✅ Certification Vault: Direct access to IATF 16949, E-Mark, and RoHS documentation.

– ✅ Dedicated QC Protocol: Pre-agreed AQL 1.0–1.5 standards for critical safety parts.

– ✅ Logistics Integration: FOB/Shenzhen terms with verified 3PL partners (DHL, Kuehne+Nagel).

Call to Action: Secure Your 2026 Sourcing Advantage

Procurement leaders who delay verification pay in delayed shipments, compliance fines, and margin erosion. In 2026’s high-risk auto accessories market, guessing is not sourcing—verified partnerships are.

Act Now to:

🔹 Slash 3+ weeks from your next sourcing cycle

🔹 Eliminate counterfeit risk with blockchain-backed component tracing

🔹 Lock in 2026 pricing with pre-negotiated terms from Tier-1 suppliers

→ Reserve Your Dedicated Sourcing Consultant Today

Contact our China-based team for a free Pro List access trial (limited to 15 onboarding slots this quarter):

📧 [email protected]

📱 WhatsApp: +86 159 5127 6160

Include “AUTO 2026 PRO LIST” in your inquiry to fast-track priority access.

SourcifyChina: Where Verification Meets Velocity

We don’t just find suppliers—we future-proof your supply chain. Since 2018, trusted by 1,200+ global brands including Michelin, Bosch, and AutoZone.

🧮 Landed Cost Calculator

Estimate your total import cost from China.