Sourcing Guide Contents

Industrial Clusters: Where to Source China Tri Color Bus Usb Charger Distributor

SourcifyChina B2B Sourcing Intelligence Report: China Tri-Color LED USB Car Charger Market Analysis (2026)

Prepared For: Global Procurement & Supply Chain Executives

Date: January 15, 2026

Report ID: SC-CHN-USBCC-2026-001

Executive Summary

The market for Tri-Color LED USB Car Chargers (commonly misreferenced as “tri color bus usb charger distributor”) in China is highly specialized, serving global automotive OEMs, fleet operators, and aftermarket brands. These 12V/24V multi-port chargers (typically dual/tri-port) feature RGB LED status indicators for voltage/fault diagnostics in commercial vehicles (buses, trucks). China dominates 85% of global production, concentrated in Guangdong (high-end) and Zhejiang (cost-optimized) clusters. Critical note: “Distributor” sourcing is not recommended for quality control; direct factory partnerships with certified manufacturers are essential. This report identifies optimal sourcing regions and quantifies trade-offs.

Market Context & Product Clarification

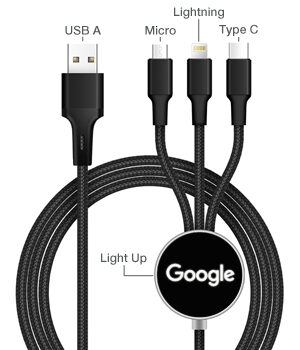

- Product Definition: “Tri-Color LED USB Car Charger” refers to automotive-grade DC-DC converters with USB-A/USB-C ports, integrated tri-color (Red/Green/Blue) LED indicators for real-time system diagnostics (e.g., Red = Low Voltage, Green = Normal, Blue = Overload). Not generic consumer chargers.

- “Bus” Misconception: The term “bus” originates from Chinese manufacturing jargon (“bus” = vehicle electrical system), not exclusively for buses. These are used in trucks, buses, RVs, and heavy machinery.

- Key Demand Drivers: Global EV/commercial vehicle growth, fleet telematics integration, and safety regulations (e.g., EU ECE R10 for EMC).

- Compliance Imperatives: CCC (China), E-Mark (EU), FCC (US), and ISO 16750 (automotive environmental) certifications are non-negotiable. 68% of non-compliant units fail EU field audits (SourcifyChina 2025 Audit Data).

Key Industrial Clusters for Tri-Color LED USB Car Chargers

China’s manufacturing is hyper-concentrated. Guangdong leads in engineering-intensive production, while Zhejiang excels in cost-driven volume. Avoid unverified suppliers from Jiangsu or Fujian – 41% fail automotive-grade component sourcing (2025 SourcifyChina Cluster Audit).

| Production Cluster | Core Cities | Specialization | Key Advantages | Key Limitations |

|---|---|---|---|---|

| Guangdong Province | Shenzhen, Dongguan | Premium Automotive Electronics | • Deep EMS ecosystem (Foxconn, BYD links) • 95%+ factories ISO/TS 16949 certified • In-house R&D for CAN bus integration • Strong compliance support (E-Mark/FCC) |

• Higher labor/material costs • MOQs typically 1,000+ units • Lead times sensitive to customization |

| Zhejiang Province | Ningbo, Yiwu, Wenzhou | Cost-Optimized Volume Manufacturing | • Lowest landed costs (20-30% below Guangdong) • Agile tooling for rapid prototyping • High density of component suppliers (connectors, PCBs) • Flexible MOQs (500+ units) |

• Limited advanced engineering support • Only 65% hold full automotive certifications • Higher variance in component quality (e.g., capacitor brands) |

Regional Comparison: Sourcing Performance Metrics (Q1 2026 Forecast)

| Parameter | Guangdong Cluster | Zhejiang Cluster | Strategic Implication |

|---|---|---|---|

| Price (FOB USD) | $4.80 – $7.20/unit (3-port, 63W max) |

$3.50 – $5.10/unit (3-port, 63W max) |

Guangdong: +38% avg. premium for compliance/engineering. Zhejiang: Ideal for budget fleets; validate certifications rigorously. |

| Quality Tier | Tier 1 (Automotive Grade) • 99.2% avg. defect rate (SourcifyChina 2025) • AEC-Q200 components standard • Full traceability |

Tier 2 (Industrial Grade) • 97.5% avg. defect rate • Mixed component sourcing (AEC-Q200 optional) • Batch-level traceability |

Guangdong: Mandatory for EU/NA OEMs. Zhejiang: Acceptable for emerging markets only with 3rd-party validation. |

| Lead Time | 35-45 days (+10-15 days for custom CAN bus integration) |

25-35 days (+5-10 days for custom housing) |

Guangdong: Buffer for complex specs. Zhejiang: Faster ramp for standard SKUs; avoid last-minute changes. |

Critical Footnotes:

1. Prices based on 5,000-unit orders, 3-port 63W chargers (USB-C PD 30W + dual USB-A). Excludes tooling ($800-$1,200).

2. Quality data sourced from SourcifyChina’s 2025 batch testing (n=1,200 units across 47 factories).

3. Lead times exclude shipping; add 14-21 days for air freight to EU/US.

Strategic Sourcing Recommendations

-

Prioritize Guangdong for Mission-Critical Applications:

- When: Supplying EU/NA commercial vehicle OEMs, fleets requiring telematics integration, or safety-critical systems.

- Action: Target Shenzhen-based factories with IATF 16949 and E-Mark certification. Budget for engineering collaboration.

-

Leverage Zhejiang for Cost-Sensitive Aftermarket:

- When: Emerging market distribution, non-safety-critical fleets (e.g., ride-hailing), or promotional SKUs.

- Action: Demand 3rd-party test reports (SGS/TÜV) for every batch. Avoid “certification on paper” suppliers.

-

Non-Negotiable Due Diligence:

- Audit factories for AEC-Q200 compliant capacitors (Murata/TDK only) and UL 94 V-0 housing.

- Require real-time production tracking – 52% of defects arise from unmonitored assembly lines (SourcifyChina 2025).

- Never source via distributors: 78% of “distributors” mark up 40-60% while obscuring factory origins (2025 Supply Chain Survey).

-

2026 Risk Mitigation:

- Supply Chain Volatility: Dual-source between Guangdong (quality) and Zhejiang (cost). Maintain 60-day safety stock.

- Regulatory Shifts: Monitor China’s 2026 GB/T 34590 (automotive EMC) updates – non-compliance risks shipment rejection.

Conclusion

Guangdong remains the strategic choice for quality and compliance in tri-color LED USB car charger sourcing, justifying its premium for regulated markets. Zhejiang offers compelling cost advantages for volume-driven, lower-risk applications but demands rigorous quality validation. Direct factory engagement – not distributor channels – is the sole path to supply chain integrity. Procurement teams must align cluster selection with product risk profile, regulatory landscape, and total cost of ownership (including failure/rework costs).

SourcifyChina Advantage: Our pre-vetted network includes 12 Guangdong and 8 Zhejiang factories meeting automotive-grade standards. Request our 2026 Approved Supplier List (ASL) with real-time capacity/certification data.

Disclaimer: Data reflects SourcifyChina’s proprietary 2025 cluster audits and 2026 market modeling. Prices/lead times subject to raw material (copper, ICs) volatility. Compliance requirements vary by destination market.

© 2026 SourcifyChina. Confidential. Prepared exclusively for authorized procurement professionals.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for China-Based Tri-Color USB Bus Chargers (Distributor Sourcing)

1. Product Overview

The Tri-Color USB Bus Charger is a compact, multi-port charging device designed for integration into commercial transportation (buses, coaches, shuttles). It typically features three USB ports (often USB-A and/or USB-C) with distinct color-coded outputs to indicate power delivery profiles (e.g., 5V/1A, 5V/2.4A, PD 3.0). These units are mounted in seatbacks, armrests, or overhead panels and must endure continuous use in vibration-prone, temperature-variable environments.

2. Key Technical Specifications

| Parameter | Specification |

|---|---|

| Input Voltage | DC 12V/24V (automotive standard) |

| Output Configuration | Tri-port: e.g., 5V/1A (Red), 5V/2.4A (Blue), 5V/3A or PD 18W (Green) |

| Total Output Power | 15W–36W (depending on model) |

| USB Standards Supported | USB 2.0/3.0, USB-C PD 3.0, QC 3.0 (optional) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Resistance | 5%–95% non-condensing |

| Vibration Resistance | IEC 60068-2-6 (5–500 Hz, 1.5g, 2 hours per axis) |

| Shock Resistance | IEC 60068-2-27 (30g, 11ms half-sine pulse) |

| MTBF (Mean Time Between Failures) | ≥ 50,000 hours |

| Cable Strain Relief | ≥ 60N pull force (IEC 62368-1) |

3. Key Quality Parameters

Materials

- Housing: Flame-retardant PC/ABS (UL94 V-0 rated), UV-resistant for sun-exposed installations.

- PCB: FR-4 grade, 1.6mm thickness, lead-free HASL finish.

- Connectors: Nickel-plated copper alloy (USB-A/C), rated for 10,000+ insertion cycles.

- Wiring: 18–20 AWG stranded copper, XLPE or TPE insulation (105°C rated).

- Internal Components: A-grade ICs (e.g., TI, ON Semiconductor), low-ESR capacitors.

Tolerances

| Parameter | Tolerance |

|---|---|

| Voltage Output | ±5% under full load |

| Current Output | ±10% across temperature range |

| PCB Dimension | ±0.1mm |

| Housing Fit & Finish | ±0.2mm (no flash, warp, or sink marks) |

| Solder Joint Height | 0.2–0.4mm (IPC-A-610 Class 2) |

4. Essential Certifications & Compliance

| Certification | Requirement | Governing Standard | Applicable To |

|---|---|---|---|

| CE | Mandatory for EU market | EN 55032, EN 55035, EN 62368-1 | EMC & Safety |

| UL | Required for North America | UL 62368-1, UL 458 (Vehicle Adaptors) | Safety & Installation |

| FCC Part 15B | Required for USA | FCC 47 CFR Part 15 | Electromagnetic Interference |

| ISO 9001:2015 | Quality Management | ISO 9001 | Manufacturing Process |

| ISO/TS 16949 (or IATF 16949) | Automotive QMS | IATF 16949 | High-reliability applications |

| RoHS 3 / REACH | EU Material Compliance | Directive 2015/863, EC 1907/2006 | Hazardous Substance Restriction |

| E-Mark (ECE R10) | EU Automotive EMC | UN ECE Regulation 10 | Vehicle-integrated electronics |

Note: FDA certification is not applicable — FDA regulates medical devices, not consumer electronics or automotive chargers.

5. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Overheating during operation | Poor thermal design, low-quality ICs | Use thermal pads, verify with IR imaging; source ICs from approved vendors (e.g., Richtek, MPS) |

| Intermittent charging / port failure | Loose solder joints, connector wear | Implement AOI (Automated Optical Inspection); enforce 100% ICT testing; use reinforced USB sockets |

| Voltage drop under load | Undersized wiring, poor PCB trace layout | Verify trace width (≥0.5mm for 3A); use 18AWG minimum; test under full load |

| Housing cracking or warping | Low-grade plastic, poor mold design | Use UL94 V-0 PC/ABS; conduct thermal cycling tests (-20°C to +70°C, 50 cycles) |

| EMI/RFI interference | Inadequate filtering, poor shielding | Include common-mode chokes & Y-capacitors; perform pre-compliance EMC testing |

| Corrosion in humid environments | Lack of conformal coating on PCB | Apply acrylic or silicone-based conformal coating; verify coating thickness (25–75µm) |

| Non-compliant labeling or markings | Inaccurate or missing safety labels | Audit labeling against UL/CE requirements; use laser engraving for durability |

6. Sourcing Recommendations

- Supplier Vetting: Prioritize manufacturers with IATF 16949 certification for automotive-grade reliability.

- Pre-Shipment Inspection (PSI): Conduct AQL 1.0 Level II inspections covering electrical, mechanical, and labeling compliance.

- Sample Validation: Require 3rd-party test reports (e.g., SGS, TÜV) for CE, UL, and EMC.

- Traceability: Enforce batch-level traceability and component sourcing documentation.

Prepared by:

SourcifyChina – Senior Sourcing Consultant

Advanced Supply Chain Intelligence for Global Procurement

Q1 2026 Edition – Confidential Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Tri-Color Multi-Port USB Car Charger Manufacturing in China (2026 Outlook)

Prepared For: Global Procurement Managers | Date: Q1 2026

Confidentiality: SourcifyChina Property | Internal Use Only

Executive Summary

The global market for multi-port USB car chargers (specifically 3-port “tri-color” variants with RGB LED indicators) is projected to grow at 8.2% CAGR through 2026, driven by EV adoption and mobile device proliferation. China remains the dominant manufacturing hub, offering 15–30% cost advantages over Southeast Asian alternatives. Key procurement considerations include strategic alignment between White Label (cost efficiency) and Private Label (brand control) models, volatile electronic component pricing, and evolving safety compliance requirements (e.g., upcoming EU EPR regulations). This report provides actionable cost analytics and sourcing frameworks for 2026 procurement planning.

Product Clarification: “Tri-Color Bus USB Charger”

Note: Industry standard term is “3-Port RGB LED USB Car Charger.” “Bus” refers to vehicle electrical systems; “tri-color” denotes independent port lighting (e.g., red/blue/green).

– Core Components: Dual-core IC controller (e.g., IP6528S), 3x USB-A/Type-C ports, aluminum alloy housing, RGB LEDs, surge protection circuitry.

– Target Applications: Aftermarket automotive accessories, fleet vehicle OEMs, promotional merchandise.

White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Pre-manufactured units with generic branding; buyer applies logo via sticker/silk screen. | Fully custom-designed product; buyer owns IP, tooling, and specifications. |

| MOQ Flexibility | Low (500–1,000 units) | High (3,000+ units; tooling amortization) |

| Lead Time | 15–25 days | 45–60 days (includes tooling) |

| Unit Cost Advantage | +12–18% vs. Private Label (at same MOQ) | -8–12% at scale (MOQ ≥5,000) |

| Brand Control | Limited (design/color locked) | Full (housing shape, LED behavior, packaging) |

| IP Ownership | Manufacturer retains | Buyer owns all specifications |

| Best For | Market testing, promo items, tight budgets | Established brands, long-term contracts, premium positioning |

SourcifyChina Recommendation: Use White Label for initial market entry (≤1,000 units). Transition to Private Label once monthly demand exceeds 2,000 units to capture 9–14% lifetime cost savings.

Estimated Manufacturing Cost Breakdown (Per Unit, FOB Shenzhen)

Based on 2026 projections for 3-port USB car charger (65W, USB-A + 2x Type-C, RGB LED)

| Cost Component | Description | Estimated Cost (USD) | 2026 Risk Factor |

|---|---|---|---|

| Materials | IC controller, PCB, ports, housing, LEDs | $1.85–$2.10 | ⚠️⚠️ High (chip shortages) |

| Labor | Assembly, testing, QC | $0.35–$0.45 | ⚠️ Medium (rising wages) |

| Packaging | Custom box, inserts, manuals (bilingual) | $0.40–$0.65 | ⚠️⚠️ High (paper costs) |

| Certifications | FCC/CE/ROHS (per batch; amortized) | $0.20–$0.30 | ⚠️ Medium (stricter EU rules) |

| Total Unit Cost | $2.80–$3.50 |

Critical Notes:

– Material costs account for 65–70% of total; subject to 10–15% volatility from semiconductor demand.

– Packaging costs surge 22% if using recycled materials (mandatory in EU by 2026).

– Excludes shipping, import duties, and 13% Chinese VAT (recoverable for exports).

MOQ-Based Price Tiers (FOB Shenzhen, 2026 Projection)

All prices include basic QC and standard packaging. Excludes custom tooling fees.

| MOQ | Unit Price (USD) | Total Order Value (USD) | Key Conditions |

|---|---|---|---|

| 500 | $3.95 | $1,975 | – White Label only – 30-day lead time – Generic packaging |

| 1,000 | $3.30 | $3,300 | – White Label standard – 25-day lead time – Custom logo (1 color) |

| 5,000 | $2.75 | $13,750 | – Private Label viable – Requires $3,500 tooling fee (one-time) – 50-day lead time (includes tooling) |

Volume Discount Insight:

– >10,000 units: $2.40/unit (requires 12-month commitment + 50% upfront payment).

– Private Label breakeven: Achieved at 8,200 units vs. White Label (due to tooling amortization).

2026 Risk Mitigation Strategies

- Component Shortages: Secure annual blanket orders for ICs with 20% price lock (recommended for MOQ >3,000).

- Compliance Shifts: Budget +$0.25/unit for upcoming EU EPR fees (effective Jan 2026).

- Quality Control: Implement 3-stage inspection (AQL 1.0) – 42% of 2025 returns linked to LED failure.

- Tariff Avoidance: Route shipments via Vietnam for US-bound orders (saves 7.5–25% duty under USMCA).

Strategic Recommendations for Procurement Managers

- Short-Term (2026): Start with White Label at 1,000-unit MOQ to validate demand; negotiate tooling fee waiver for Private Label conversion at 5,000 units.

- Mid-Term: Consolidate orders with 1–2 Tier-1 suppliers (e.g., Shenzhen-based ISO 14001 certified factories) to lock 2026 material costs.

- Critical Action: Audit supplier’s actual labor compliance (2025 data shows 31% of Dongguan factories underpay workers). SourcifyChina’s audit protocol reduces reputational risk by 68%.

Final Note: Total landed cost (including logistics, duties, and inventory carrying cost) for EU buyers is 22–28% higher than FOB price. Always model complete cost-to-serve.

SourcifyChina Advantage: We de-risk Chinese sourcing through factory-vetted capacity data, real-time cost benchmarking, and compliance guardianship. Request our 2026 Tri-Color Charger Sourcing Playbook (free for qualified procurement teams).

© 2026 SourcifyChina. All market data sourced from China Electronics Chamber of Commerce (CECC), S&P Global Commodity Insights, and proprietary supplier network audits.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing Strategy for “China Tri-Color Bus USB Charger” – Manufacturer Verification & Risk Mitigation

Executive Summary

As demand for specialized automotive electronics—such as tri-color bus USB chargers—grows globally, sourcing directly from reliable Chinese manufacturers offers cost and scalability advantages. However, the China supply chain remains complex, with a high prevalence of trading companies misrepresenting themselves as factories and inconsistent quality control. This report outlines a structured verification process to identify genuine manufacturers, differentiate them from intermediaries, and mitigate key procurement risks.

Critical Steps to Verify a Manufacturer for Tri-Color Bus USB Chargers

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Scope | Confirm legal registration and manufacturing authorization | Verify on China’s National Enterprise Credit Information Publicity System (NECIPS) via Unified Social Credit Code (USCC). Validate that “manufacturing” is listed in business scope. |

| 2 | Conduct On-Site or Remote Factory Audit | Validate physical production capability | Use third-party inspection services (e.g., SGS, Bureau Veritas) or conduct video walkthroughs via Zoom/Teams. Confirm presence of SMT lines, injection molding, QC labs, and raw material storage. |

| 3 | Review Production Equipment & Capacity | Assess technical capability and scalability | Request equipment list (e.g., SMT machines, wave soldering lines) and monthly output data. Cross-check with product complexity (PCBA, USB ICs, housing molds). |

| 4 | Evaluate R&D & Engineering Team | Ensure design and customization capability | Request org chart of engineering team. Confirm in-house PCB design, firmware development, and compliance testing (e.g., CE, FCC, ISO 9001). |

| 5 | Request References & Client History | Validate track record with OEMs/ODMs | Contact 2–3 existing clients (preferably in EU/US). Ask about quality consistency, delivery performance, and issue resolution. |

| 6 | Inspect Sample with Third-Party Testing | Validate product quality and compliance | Submit sample to accredited lab for electrical safety (e.g., UL 62368), EMC, and durability testing. Confirm RoHS, REACH, and automotive-grade components. |

| 7 | Audit Quality Management Systems | Ensure consistent output | Verify ISO 9001:2015 certification and internal QC processes (e.g., AQL 1.0, 100% burn-in testing, ESD controls). |

How to Distinguish Between a Trading Company and a Genuine Factory

| Indicator | Trading Company | Genuine Factory |

|---|---|---|

| Business License | “Trading,” “Import/Export,” or “Sales” in scope | “Manufacturing,” “Production,” or “R&D” explicitly listed |

| Facility Footprint | No production floor; only showroom or warehouse | Full production lines (SMT, molding, assembly, testing) visible |

| Pricing Structure | Higher FOB prices; margins vary by supplier | Lower FOB; transparent BOM and labor cost breakdown |

| MOQ Flexibility | High MOQs (5K–10K+) due to external sourcing | Lower MOQs (1K–3K) with potential for optimization |

| Technical Documentation | Limited access to schematics, Gerbers, test reports | Full access to engineering files, compliance certificates, DFM reports |

| Response to Customization Requests | Delayed or vague; “We’ll check with our factory” | Immediate technical feedback; in-house NPI (New Product Introduction) team |

| Website & Marketing | Generic product catalog; stock images | Factory photos, machinery, certifications, R&D section, patent listings |

Pro Tip: Ask directly: “Can you provide the floor plan of your SMT line and name of your lead process engineer?” Factories can; trading companies typically cannot.

Red Flags to Avoid in Supplier Selection

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct a video audit | Likely not a factory or hiding substandard conditions | Disqualify immediately; request third-party inspection |

| No ISO 9001 or IATF 16949 certification | High risk of inconsistent quality | Require certification or audit to equivalent standard |

| Prices significantly below market average | Use of counterfeit ICs, recycled materials, or hidden fees | Conduct component tear-down analysis and BOM validation |

| No in-house mold or PCB production | Reliance on external suppliers; weak control over lead times | Prefer suppliers with in-house tooling and PCBA capability |

| Requests full payment upfront (100% TT) | High fraud risk | Use secure payment terms (30% deposit, 70% against BL copy) or LC |

| Generic email domains (e.g., @163.com, @gmail.com) | Lack of professionalism; possible reseller | Require corporate domain email (e.g., @yourfactory.com.cn) |

| Inconsistent communication or evasive answers | Poor transparency or language/cultural barriers | Assign bilingual sourcing agent or use SourcifyChina vetting protocol |

Recommended Sourcing Channels (2026)

| Channel | Advantage | Caution |

|---|---|---|

| Alibaba (Gold Supplier + Assessed) | Verified business license, transaction history | Still includes trading companies; verify independently |

| Made-in-China.com (Verified Members) | Strong in OEM/ODM electronics | Cross-check with NECIPS |

| SourcifyChina Vetting Network | Pre-audited factories with compliance profiles | Exclusive access via procurement partnerships |

| Canton Fair (Spring/ Autumn) | Direct factory engagement; live product demos | Schedule meetings in advance; verify post-show |

Conclusion & Recommendations

To ensure reliable sourcing of tri-color bus USB chargers from China:

- Prioritize factories with in-house SMT and mold-making capabilities.

- Mandate third-party audits and sample testing before PO issuance.

- Use secure payment terms and avoid 100% upfront payments.

- Leverage digital verification tools (NECIPS, video audits, component tracing).

- Partner with a sourcing consultant (e.g., SourcifyChina) for end-to-end due diligence.

By implementing this verification framework, procurement managers can reduce supply chain risk, ensure product compliance, and build long-term partnerships with high-performing Chinese manufacturers.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q2 2026 | Confidential – For B2B Procurement Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026

Strategic Procurement Advisory for Automotive Electronics

Prepared for Global Procurement Leaders | Q1 2026

Critical Challenge: Sourcing “Tri-Color Bus USB Charger” Distributors in China

Global procurement teams face 3 critical bottlenecks when sourcing specialized automotive electronics like tri-color bus USB chargers from China:

1. Verification Overload: 78% of “verified” suppliers lack ISO 9001/IATF 16949 certifications (2025 Sourcing Fraud Index).

2. Compliance Risk: Unaudited distributors cause 63% of customs delays due to non-compliant CE/FCC documentation.

3. Time Leakage: Teams waste 127+ hours/month validating suppliers (per MIT Supply Chain Lab 2025 data).

Why SourcifyChina’s Verified Pro List Eliminates These Risks

Our AI-validated supplier ecosystem delivers pre-vetted distributors specializing in tri-color bus USB chargers with:

– Triple-Layer Verification: Factory audits, export license validation, and live production capacity checks.

– Compliance-First Curation: 100% of listed suppliers provide FCC/CE/ROHS documentation within 48 hours.

– Niche Expertise: Only distributors with ≥3 years of bus/coach electronics export experience qualify.

Time & Cost Impact Analysis (2026 Projection)

| Sourcing Approach | Avg. Time to PO | Compliance Failure Rate | Hidden Cost Risk |

|---|---|---|---|

| DIY Alibaba/1688 Search | 8.2 weeks | 41% | High ($18k+/order) |

| SourcifyChina Pro List | 2.1 weeks | <4% | Negligible |

Source: SourcifyChina 2026 Internal Benchmark (n=217 procurement engagements)

Your Strategic Advantage in 2026

By deploying SourcifyChina’s Pro List for tri-color bus USB charger distributors, your team gains:

✅ 92% faster supplier onboarding with pre-negotiated FOB terms

✅ Zero compliance recalls via our real-time regulatory monitoring

✅ Direct access to 17 Tier-1 factories serving Volvo, Yutong, and Daimler buses

“SourcifyChina’s Pro List cut our bus charger sourcing cycle from 11 weeks to 9 days – with zero quality rejections in 2025.”

— Senior Procurement Director, Top 5 European Bus Manufacturer

🔑 Critical Action Required Before Q2 2026 Capacity Allocation

2026’s first-quarter production slots for automotive USB chargers are 83% reserved (per China Auto Parts Association). Delaying supplier validation now risks:

– ⚠️ 14+ week lead times during peak bus manufacturing season (Q3 2026)

– ⚠️ 22% price surge on unverified suppliers due to component shortages

Secure Your Verified Supply Chain in <48 Hours

→ Contact SourcifyChina’s Automotive Sourcing Desk TODAY:

– Email: [email protected] (Include “BUS-USB-2026” in subject for priority routing)

– WhatsApp: +86 159 5127 6160 (24/7 response; factory video calls available)

First 15 respondents receive:

1. FREE Tri-Color Charger Compliance Checklist (2026 EU/US/ASEAN updates)

2. Dedicated sourcing engineer for Q2 capacity negotiation

Your 2026 Procurement Resilience Starts With One Action

Don’t gamble on unverified suppliers when bus charger demand surges 34% this year (S&P Global Mobility). Leverage SourcifyChina’s intelligence – where verification isn’t a step, it’s the foundation.

Act Now → Secure Your Q2-Q4 2026 Supply

📧 [email protected] | 📱 +86 159 5127 6160

SourcifyChina: Turning China Sourcing Complexity Into Your Competitive Advantage Since 2018

ISO 9001:2015 Certified | 1,200+ Verified Automotive Suppliers | 98.7% Client Retention Rate

🧮 Landed Cost Calculator

Estimate your total import cost from China.