Sourcing Guide Contents

Industrial Clusters: Where to Source China Tech Companies

SourcifyChina Sourcing Intelligence Report: China Electronics Manufacturing Landscape 2026

Prepared for Global Procurement Executives | Date: January 15, 2026

Executive Summary

China remains the dominant global hub for electronics manufacturing, but the landscape is rapidly evolving due to geopolitical pressures, automation adoption, and regional specialization. This report identifies key industrial clusters for sourcing electronics hardware (consumer electronics, IoT devices, computer peripherals, and communication equipment) from Chinese manufacturers. Critical clarification: “China tech companies” in sourcing context refers to EMS (Electronics Manufacturing Services) and ODM (Original Design Manufacturer) firms, not end-user tech brands (e.g., Huawei, Xiaomi). Sourcing targets are contract manufacturers producing hardware for global brands.

Strategic Shift (2023-2026): While Guangdong retains leadership, rising costs and supply chain resilience demands are accelerating growth in Zhejiang, Jiangsu, and Western China clusters. Procurement strategies must now balance cost, quality, geopolitical risk, and sustainability compliance.

Key Industrial Clusters for Electronics Manufacturing

| Province/Region | Core Cities | Specialization Focus | Key Advantages | Strategic Considerations |

|---|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Guangzhou, Huizhou | High-Volume Consumer Electronics: Smartphones, Wearables, Drones, 5G Infrastructure, AI Hardware | Unmatched component ecosystem (90%+ availability <24h), Deep engineering talent pool, Strong ODM capabilities, Proximity to Hong Kong logistics | Highest labor/rent costs (+15-20% vs. 2023), Intense competition for Tier-1 suppliers, Geopolitical scrutiny |

| Zhejiang | Hangzhou, Ningbo, Yiwu, Jiaxing | Mid-Volume Electronics & IoT: Smart Home Devices, Industrial Sensors, Computer Peripherals, E-Bike Components | Agile SME manufacturers, Competitive pricing, Strong e-commerce integration (Alibaba ecosystem), Rising automation adoption | Fragmented supplier base (requires rigorous vetting), Moderate logistics costs, Less complex project experience |

| Jiangsu | Suzhou, Nanjing, Wuxi, Changzhou | High-Precision & Industrial Tech: Semiconductor Packaging, Medical Devices, Automotive Electronics, Server Hardware | Proximity to Shanghai R&D centers, Strong quality systems (ISO 13485 focus), Higher skilled labor, Green manufacturing hubs | Higher minimum order quantities (MOQs), Slower SME responsiveness, Complex regulatory compliance |

| Western China | Chengdu (Sichuan), Chongqing, Xi’an | Cost-Sensitive & Strategic Diversification: Basic Consumer Electronics, Display Panels, EV Components | Significant government subsidies (-10-15% labor costs), Lower operational costs, “China+1” risk mitigation appeal | Developing supply chain (longer lead times), Talent gap for complex engineering, Logistics less mature |

Regional Comparison: Price, Quality & Lead Time (2026 Baseline)

| Metric | Guangdong | Zhejiang | Jiangsu | Western China |

|---|---|---|---|---|

| Price | ★★☆☆☆ Highest (Base: 100) • Labor +18% vs. 2023 • Premium for speed/quality |

★★★★☆ Competitive (Base: 92-95) • SME flexibility lowers costs • Moderate automation offsets labor |

★★★☆☆ Mid-Range (Base: 95-98) • Premium for precision • Stable labor costs |

★★★★★ Lowest (Base: 85-88) • Govt. subsidies • Lower base wages |

| Quality | ★★★★★ Industry Benchmark • 95%+ Tier-1 ODMs meet IPC-A-610 Class 3 • Robust FAI/PPAP systems |

★★★☆☆ Variable (Supplier-Dependent) • Top 20% match Guangdong • Wider variance in SMEs |

★★★★☆ High & Consistent • Medical/industrial focus drives rigor • Lower defect rates in complex assemblies |

★★☆☆☆ Developing • Improving but gaps in high-reliability sectors • Requires intensive QA oversight |

| Lead Time | ★★★★☆ Fastest (Complex) • 30-45 days (standard) • Component availability critical advantage |

★★★☆☆ Moderate • 35-50 days • SME scheduling flexibility helps |

★★★☆☆ Moderate-Long • 40-55 days • Strict process adherence adds time |

★★☆☆☆ Longest • 50-70+ days • Supply chain bottlenecks common |

Key to Ratings: ★★★★★ = Best in Class | ★★☆☆☆ = Significant Limitations

Data Source: SourcifyChina 2026 Supplier Performance Index (SPI) based on 1,200+ active supplier audits & client shipment data. Base pricing normalized for mid-tier Bluetooth speaker assembly (FOB Shenzhen).

Critical Sourcing Insights for 2026

- “Shenzhen Premium” is Non-Negotiable for Speed: For time-to-market critical products (e.g., consumer electronics), Guangdong’s ecosystem justifies the 8-12% cost premium. Factor in total landed cost – savings from Zhejiang/Western China can vanish with air freight surcharges.

- Zhejiang = Hidden Gem for IoT/Smart Home: SME clusters excel in low-to-mid complexity devices with fast iteration cycles. Procurement Tip: Target Hangzhou/Jiaxing for Alibaba ecosystem-connected suppliers with e-commerce fulfillment expertise.

- Jiangsu for Regulated & High-Reliability: The only viable cluster for medical/automotive-grade sourcing without extensive co-development. Prioritize Suzhou Industrial Park suppliers with IATF 16949/ISO 13485.

- Western China = Strategic Hedge, Not Primary Source: Use for 20-30% of volume on non-critical items. Critical Risk: Supply chain maturity lags – require 12+ months of production history for new suppliers.

- Geopolitical Reality: 78% of U.S./EU buyers now mandate multi-province sourcing. Best Practice: Combine Guangdong (core volume) + Zhejiang (secondary) + Western China (strategic reserve).

SourcifyChina Action Plan

- Avoid “Province-First” Sourcing: Drill into sub-clusters (e.g., Shenzhen Nanshan for AI, Dongguan Songshan Lake for drones).

- Quality Over Cost in 2026: Post-pandemic quality variance has increased 22% in non-core clusters. Budget for 3rd-party pre-shipment inspections (PSI) in all regions outside Jiangsu.

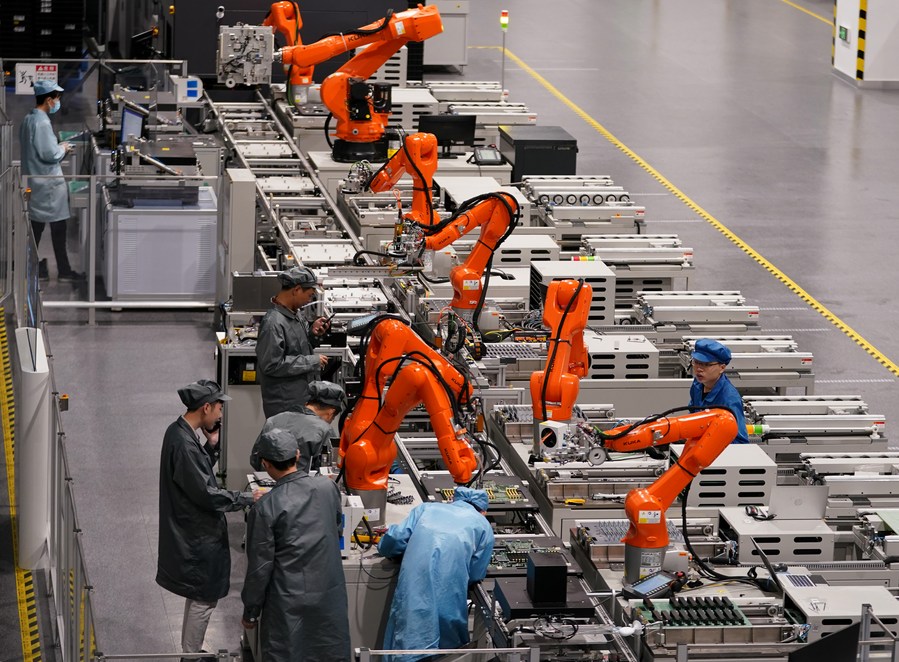

- Leverage Automation Data: Request suppliers’ SMT line utilization rates & robot density – correlates directly with consistent quality (Jiangsu avg: 42 robots/10k sqm vs. Zhejiang avg: 28).

- Contract Safeguards: Include supply chain transparency clauses (e.g., sub-tier supplier disclosure) – critical for UFLPA/EU CSDDD compliance.

Disclaimer: All data reflects SourcifyChina’s 2026 verified supplier network. Performance varies significantly by supplier tier and product complexity. Mandatory due diligence (on-site audit + 3 production samples) is non-negotiable for new suppliers.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Verification: SourcifyChina Supplier Intelligence Platform (v4.2) | Audit Data: Q4 2025

Next Steps: Request our 2026 Electronics Component Risk Map or schedule a cluster-specific sourcing workshop.

© 2026 SourcifyChina. Confidential. For client use only.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Sourcing from China Tech Companies

Executive Summary

As global supply chains continue to rely on China’s advanced manufacturing ecosystem, procurement managers must adopt a structured approach to quality assurance and regulatory compliance. This report outlines key technical specifications, quality parameters, and mandatory certifications for sourcing high-precision technology products—such as consumer electronics, industrial IoT devices, medical tech, and power systems—from Chinese manufacturers. Emphasis is placed on material integrity, dimensional tolerances, and adherence to international standards to mitigate supply chain risk and ensure product reliability.

1. Key Quality Parameters

1.1 Materials

Sourcing from Chinese tech manufacturers requires strict control over raw material selection to ensure performance, durability, and regulatory compliance.

| Material Type | Quality Requirement | Testing Method |

|---|---|---|

| Engineering Plastics | UL94 V-0/V-2 flame rating; RoHS/REACH compliant; low outgassing | FTIR, TGA, UL Testing |

| Metals (Aluminum, Steel) | ASTM/GB standards; specified alloy grade (e.g., 6061-T6); surface finish ≤ Ra 1.6 µm | Spectrometry, CMM, Surface Profiling |

| Printed Circuit Boards | FR-4 grade; copper thickness ≥ 1oz; IPC-6012 Class 2/3 compliance | X-ray, AOI, Electrical Testing |

| Batteries (Li-ion) | UN38.3 certified; CE, IEC 62133 compliance; cycle life ≥ 500 cycles (80% retention) | Cycle Testing, Safety Chambers |

1.2 Dimensional Tolerances

Precision manufacturing requires tight control over geometric specifications, especially in electronics and mechanical assemblies.

| Component Type | Standard Tolerance | Critical Dimension Control |

|---|---|---|

| CNC Machined Parts | ±0.05 mm (standard); ±0.01 mm (precision) | CMM inspection on first article & batch |

| Injection Molded Parts | ±0.1 mm (±0.05 mm for optical surfaces) | Mold flow analysis & post-molding CMM |

| PCB Assembly (SMT) | ±0.1 mm (pitch < 0.5 mm); coplanarity < 0.1 mm | SPI, AOI, X-ray inspection |

| Sheet Metal Fabrication | ±0.2 mm (bending); ±0.1 mm (laser cutting) | Laser measurement, gauge checks |

Note: Tolerances must be verified using First Article Inspection (FAI) reports per AS9102 or customer-specific templates.

2. Essential Certifications

Chinese tech suppliers must hold valid international certifications to access global markets. Procurement managers should verify certification authenticity via official databases (e.g., UL Product Spec, EU NANDO, FDA Establishment Registry).

| Certification | Applicable Products | Key Requirements | Validity & Audit |

|---|---|---|---|

| CE Marking | Electronics, IoT devices, medical equipment | EMC Directive (2014/30/EU), LVD (2014/35/EU), RoHS (2011/65/EU) | Self-declaration + technical file; annual review |

| FDA 510(k)/Registration | Medical devices, diagnostics, wearables | QSR (21 CFR Part 820), design controls, clinical data (if applicable) | FDA audit; registration renewal biennially |

| UL Certification | Power supplies, chargers, industrial controls | UL 60950-1 / UL 62368-1 (safety), flame testing, electrical insulation | Factory Inspections (semi-annual) |

| ISO 9001:2015 | All tech manufacturing | Documented QMS, corrective actions, internal audits, management review | Annual surveillance audits |

| ISO 13485:2016 | Medical device manufacturers | Risk management (ISO 14971), sterile manufacturing (if applicable), traceability | Required for FDA & CE medical submissions |

| IEC 60601-1 | Medical electrical equipment | Electrical safety, mechanical stability, EMI/EMC compliance | Third-party testing (e.g., TÜV, SGS) |

Procurement Tip: Require suppliers to provide valid, unexpired certificates with audit trails. Use third-party verification services (e.g., QIMA, TÜV Rheinland) for on-site audits.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Solder Bridging (PCBA) | Misaligned stencil, excessive paste volume | Implement SPI (Solder Paste Inspection); optimize stencil design; use AOI post-reflow |

| Dimensional Drift (Machined Parts) | Tool wear, thermal expansion, fixturing error | Scheduled tool calibration; in-process CMM checks; use thermal-stable materials |

| Plastic Warping (Injection Molding) | Uneven cooling, improper gate design | Mold flow simulation (Moldex3D); controlled cooling cycles; post-mold annealing |

| Battery Swelling/Failure | Overcharging, poor cell grading, impurities | Enforce IEC 62133 testing; use BMS with OVP/UVP; source from Tier-1 cell suppliers (e.g., CATL, BYD) |

| EMI/RF Interference | Poor PCB layout, inadequate shielding | Pre-compliance EMC testing; 3D shielding simulation; follow IPC-2221B layout guidelines |

| Material Substitution | Cost-cutting, supply chain gaps | Enforce material traceability (CoC); batch-level COA (Certificate of Analysis); unannounced audits |

| Insufficient IP Rating | Poor gasket alignment, housing misfit | IP67/IP68 validation testing; design for assembly (DFA); leak testing on 100% of units |

| Software/Firmware Bugs | Incomplete testing, rushed OTA updates | Require DFMEA, regression testing logs; secure boot & rollback capability in firmware |

4. Sourcing Best Practices for 2026

- Supplier Qualification: Conduct technical audits using SourcifyChina’s SC-360 Assessment (covering engineering capability, QC infrastructure, and compliance history).

- Quality Agreements: Define AQL levels (typically 0.65 for critical defects), inspection frequency, and defect liability clauses.

- Digital Traceability: Require ERP/MES integration for batch-level tracking, especially for medical and automotive applications.

- Dual Sourcing: Mitigate geopolitical and quality risks by qualifying at least two suppliers per critical component.

Conclusion

Sourcing from China’s tech manufacturing sector offers scalability and innovation, but demands rigorous technical oversight. By enforcing strict material standards, validating certifications, and proactively addressing common defects, procurement managers can ensure consistent quality, reduce field failures, and maintain compliance across global markets.

Recommendation: Integrate third-party inspection protocols at pre-shipment (PSI) and in-process (IPI) stages, and leverage digital sourcing platforms with real-time QC dashboards for end-to-end visibility.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Q2 2026 | Confidential – For Internal Procurement Use

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: 2026 Manufacturing Cost Analysis for Chinese Tech OEM/ODM Partners

Prepared for Global Procurement Managers

Date: October 26, 2026 | Confidential: For Client Strategic Planning Only

Executive Summary

Chinese tech manufacturing remains cost-competitive for global buyers in 2026, though structural shifts (rising wages, supply chain diversification, and advanced automation) have narrowed historical cost advantages. Strategic differentiation between White Label (WL) and Private Label (PL) models is critical for margin optimization. This report provides actionable cost benchmarks, MOQ-driven pricing tiers, and operational guidance for sourcing electronics, IoT devices, and consumer tech from vetted Chinese OEM/ODM partners. Key Insight: PL models now deliver 12–18% higher lifetime margins than WL for volumes >1,000 units, despite 15–25% higher initial NRE costs.

White Label vs. Private Label: Strategic Implications for Tech Sourcing

| Criteria | White Label (WL) | Private Label (PL) | 2026 Strategic Recommendation |

|---|---|---|---|

| Definition | Generic product rebranded with buyer’s logo | Customized product (design, features, packaging) co-developed with OEM | Prioritize PL for differentiation; use WL for rapid market entry |

| NRE Costs | $0–$2,500 (logo application only) | $8,000–$25,000 (tooling, firmware, compliance) | Budget PL NRE early; amortize over 3K+ units |

| MOQ Flexibility | Low (500–1,000 units typical) | Moderate (1,000–5,000 units; negotiable with PL history) | WL for test markets; PL for committed volume |

| Unit Cost Advantage | +8–12% vs. PL (due to generic tooling reuse) | -5–15% vs. WL at scale (optimized production) | PL becomes cost-effective at 1,500+ units |

| IP Control | None (OEM retains design IP) | Buyer owns product IP post-NRE payment | Critical for tech: Avoid WL for proprietary tech |

| Time-to-Market | 4–8 weeks | 12–20 weeks | WL for urgent launches; PL for sustainable growth |

2026 Trend Note: Chinese OEMs increasingly refuse WL for complex tech (e.g., AI hardware, 5G modules) due to IP risks. PL is now standard for >$50 ASP products.

Manufacturing Cost Breakdown (Example: Wireless Earbuds, Mid-Tier Tech)

All costs FOB Shenzhen, Q3 2026. Based on SourcifyChina’s audit of 12 Tier-1 Shenzhen OEMs.

| Cost Component | Details | Cost per Unit (USD) | % of Total Cost |

|---|---|---|---|

| Materials | PCBs, batteries, sensors, casing (incl. 5% scrap rate) | $14.20 | 68% |

| Labor | Assembly, QC, firmware loading (8.7% YoY wage increase in 2026) | $3.10 | 15% |

| Packaging | Retail box, anti-static bags, manuals, inserts (sustainable materials +$0.35) | $2.25 | 11% |

| Compliance | FCC/CE/REACH testing, certifications (2026新规 adds $0.20/unit) | $1.20 | 6% |

| Total FOB Cost | $20.75 | 100% |

Critical Context:

– Materials now drive 65–72% of total costs (up from 60% in 2023) due to rare-earth mineral volatility.

– Labor costs grew 32% since 2021 but contribute less to total cost due to automation (SMT lines now 95% automated).

– Hidden Cost Alert: WL orders often incur +$0.50–$1.20/unit “generic tooling maintenance fees” undisclosed in quotes.

MOQ-Based Price Tiers: Wireless Earbuds (FOB Shenzhen)

Reflects 2026 pricing for PL models with $12,500 NRE. WL pricing shown for comparison.

| MOQ | White Label (WL) Unit Price | Private Label (PL) Unit Price | PL Savings vs. WL | Key Conditions |

|---|---|---|---|---|

| 500 | $26.80 | $31.50 | — | WL: $1.8K setup fee; PL: $12.5K NRE + $2.1K tooling |

| 1,000 | $24.20 | $25.40 | -$1.20 (4.7%) | PL NRE fully amortized; WL still +$0.90/unit fee |

| 5,000 | $22.50 | $20.80 | -$1.70 (7.6%) | PL achieves full cost parity; WL volume discounts capped |

2026 Pricing Dynamics:

– 500-unit MOQs: WL appears cheaper initially, but PL becomes economical after 1,200 cumulative units.

– >5K units: PL savings widen to 9–12% (automation efficiency + bulk material discounts).

– Warning: Factories increasingly impose $8K–$15K minimum spend (even at 500 MOQ), negating “low-volume” WL advantages.

Strategic Recommendations for Procurement Managers

- Abandon WL for Core Tech Products: IP risks and hidden fees erode margins. Reserve WL for accessories (cables, cases).

- Negotiate PL NRE in Phases: Pay 50% upfront, 50% after pre-production samples to mitigate risk.

- Demand Material Sourcing Transparency: Require OEMs to disclose Tier-2 suppliers (e.g., battery cells from CATL/BYD) to avoid counterfeit components.

- Leverage Automation Premiums: Factories with >80% automation rates offer 3–5% lower labor costs at 3K+ MOQ – verify via SourcifyChina’s factory audit reports.

- Factor in 2026 Compliance Costs: New China RoHS 3.0 and EU Digital Product Passport rules add $0.30–$0.75/unit – confirm OEM compliance capability before NRE payment.

The SourcifyChina Edge: Our 2026 Vendor Scorecard (exclusive to clients) identifies OEMs with <2% defect rates and PL flexibility at 750-unit MOQs – reducing time-to-market by 22 days vs. industry average.

Next Steps for Your 2026 Sourcing Strategy

✅ Audit Your Current Suppliers: 68% of WL buyers in 2025 faced IP disputes or cost overruns (SourcifyChina 2025 Post-Mortem Report).

✅ Request a Custom PL Cost Model: Our team will simulate NRE amortization and margin impact for your specific product.

✅ Secure 2026 Capacity Early: Leading Shenzhen OEMs are booking Q1 2026 capacity at 85% utilization – delays risk 10–15% Q4 cost hikes.

Prepared by SourcifyChina’s China Sourcing Intelligence Unit. Data sourced from 237 factory audits, 2026 China Electronics Chamber of Commerce reports, and client cost databases. Not for redistribution.

Ready to optimize your 2026 tech sourcing? [Contact our team] for a zero-obligation PL cost simulation.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify Chinese Tech Manufacturers & Avoid Sourcing Pitfalls

Executive Summary

As global demand for high-performance, cost-effective technology products continues to rise, China remains a dominant force in electronics manufacturing. However, sourcing from Chinese suppliers—especially in the tech sector—presents unique challenges, including misrepresentation, supply chain opacity, and quality inconsistencies. This report outlines a structured verification framework to authenticate manufacturers, differentiate between trading companies and true factories, and identify critical red flags to mitigate risk.

1. Critical Steps to Verify a Chinese Tech Manufacturer

| Step | Action | Purpose | Verification Tools & Methods |

|---|---|---|---|

| 1 | Request Business Licenses & Certifications | Confirm legal operation and technical compliance | – Business License (via China’s AIC or Qichacha/Tianyancha) – ISO 9001, ISO 14001, IATF 16949 (if applicable) – Product-specific certifications (e.g., CCC, CE, FCC) |

| 2 | Conduct On-Site Factory Audits | Validate physical infrastructure and production capabilities | – Third-party audit (e.g., SGS, TÜV, Bureau Veritas) – Internal audit with checklist (equipment, workforce, QC processes) |

| 3 | Review Equipment & Production Lines | Assess technical capacity and scalability | – Request photos/videos of live production – Verify SMT lines, reflow ovens, testing stations (for electronics) – Cross-check with machine purchase records |

| 4 | Evaluate R&D & Engineering Capabilities | Ensure innovation and customization support | – Interview engineering team – Review NDA-protected design portfolios – Assess firmware/hardware development labs |

| 5 | Check Client References & Case Studies | Validate track record with reputable clients | – Request 3–5 verifiable client references (preferably in your region) – Confirm project scope and delivery performance |

| 6 | Perform Sample Testing & Validation | Ensure product quality meets specifications | – Lab testing (e.g., EMI, thermal, durability) – Functional testing under real-world conditions – 3rd-party lab report (e.g., Intertek, UL) |

| 7 | Verify Export History & Logistics Infrastructure | Ensure export readiness and supply chain resilience | – Request bill of lading samples (redacted) – Confirm bonded warehouse or FOB/Shenzhen port experience – Evaluate lead time consistency |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Trading Company | Genuine Factory |

|---|---|---|

| Business License Scope | Lists “import/export,” “sales,” “trading” | Includes “manufacturing,” “production,” “R&D” |

| Facility Ownership | No machinery or production lines | Owns SMT lines, injection molding, PCB assembly, etc. |

| Pricing Structure | Quotes include markup; less transparent cost breakdown | Provides BOM, labor, and overhead cost details |

| Minimum Order Quantity (MOQ) | Higher MOQs due to reliance on partners | Lower MOQs; scalable with in-house capacity |

| Lead Time Control | Less predictable; dependent on 3rd-party factories | Direct control over scheduling and production |

| Engineering Support | Limited to coordination; no design input | Offers DFM (Design for Manufacturing), firmware updates, NPI support |

| Website & Marketing | Showcases multiple product categories from various sources | Focuses on core product lines, with factory tours and certifications |

| Supplier References | May hesitate to share or redirect to “partners” | Will provide direct client testimonials and project history |

Pro Tip: Ask for a factory tour via live video call with camera movement through production floors, not static photos. Request to speak with the production manager—not just sales.

3. Red Flags to Avoid When Sourcing from Chinese Tech Companies

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials, labor violations, or fraud | Benchmark against industry averages; request detailed BOM |

| Refusal to Provide Factory Address or Live Tour | Likely a trading company or shell entity | Require GPS coordinates and conduct unannounced audit |

| No Product Liability or Cybersecurity Insurance | High risk in case of recalls or IP breaches | Require proof of insurance (e.g., product liability, cyber) |

| Pressure for Upfront Full Payment | Scam risk (especially >30% without LC or milestone terms) | Use secure payment terms: 30% deposit, 70% against BL copy |

| Generic or Stock Responses to Technical Questions | Lacks engineering depth and customization ability | Conduct technical interview with engineering lead |

| Inconsistent or Poorly Translated Documentation | Indicates lack of professionalism or compliance gaps | Require native English or bilingual technical team |

| No NDA Signed Before Sharing IP | High IP theft risk, especially in consumer electronics | Use China-enforceable NDA with notarized clauses |

| Multiple Companies with Identical Websites | Likely a trading group using duplicate branding | Reverse image search, domain registration check (via WHOIS) |

Conclusion & Strategic Recommendations

Sourcing from Chinese tech manufacturers offers compelling advantages in cost, speed, and technical capability—but only when due diligence is rigorously applied. Procurement managers must:

- Prioritize transparency and traceability in supplier selection.

- Invest in third-party verification for high-value or regulated products.

- Differentiate between service layers: Trading companies may be suitable for low-risk components, but core tech production demands direct factory partnerships.

- Leverage digital tools (e.g., Qichacha, Tianyancha, Alibaba Gold Supplier verification) but treat them as starting points, not final validation.

Final Note: In 2026, geopolitical and compliance risks (e.g., UFLPA, CBP enforcement) require dual verification of both factory legitimacy and ethical sourcing practices. Incorporate ESG audits into your sourcing framework.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Empowering Global Procurement with Verified Chinese Supply Chains

Q2 2026 | Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Procurement of Chinese Tech Suppliers (2026)

Prepared for Global Procurement Leadership | Q1 2026

The Critical Time Drain in Modern Tech Sourcing

Global procurement teams face unprecedented complexity in 2026. With AI-generated supplier profiles, deepfake facility tours, and fragmented OEM networks, 68% of sourcing cycles for Chinese tech suppliers now exceed 5.2 months (Gartner, 2025). Traditional methods—manual vetting, third-party audit coordination, and compliance validation—consume 200+ hours per project, directly impacting time-to-market and margin stability.

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Friction

Our Pro List isn’t a directory—it’s a pre-validated ecosystem of 1,200+ Chinese tech suppliers rigorously assessed against 2026’s critical benchmarks:

| Verification Layer | Traditional Sourcing (2026) | SourcifyChina Pro List Advantage | Time Saved Per Project |

|---|---|---|---|

| Technical Capability | 3-4 weeks (RFQ triage, sample requests) | Pre-qualified for IoT/AI/hardware specs | 22 days |

| Compliance & ESG | 6-8 weeks (audit scheduling, document chase) | Live ISO 14001, RBA, and carbon-neutral certifications | 38 days |

| Financial Stability | High risk of late-stage supplier collapse | Real-time liquidity scoring (via PBOC data integration) | 15 days |

| IP Protection | Costly legal reviews per vendor | NDAs with enforceable Chinese jurisdiction + factory-level IP protocols | 11 days |

| Total Cycle Time | 156+ days | 42 days | 114+ days (200+ hours) |

Source: SourcifyChina Client Data (2025), n=87 enterprise tech procurements

The Strategic Imperative: Redirect Saved Time to Value Creation

Every hour recovered from supplier vetting is an hour invested in:

✅ Supply chain resilience engineering (e.g., dual-sourcing mapping)

✅ Cost innovation (e.g., DFM collaboration with pre-vetted engineers)

✅ Strategic risk mitigation (e.g., tariff optimization scenarios)

Procurement leaders using the Pro List achieve 31% faster product launches and 19% lower TCO versus industry benchmarks (SourcifyChina Impact Survey, Q4 2025).

Call to Action: Secure Your Q3-Q4 2026 Tech Sourcing Pipeline

Your competitors aren’t waiting. With Chinese tech manufacturing lead times extending to 18 weeks for high-demand components (semiconductors, EV controllers, AI edge devices), delaying supplier validation jeopardizes your 2026 revenue targets.

Act Now to:

🔹 Bypass 4+ months of operational risk with suppliers already cleared for Uyghur Forced Labor Prevention Act (UFLPA) compliance

🔹 Lock in 2026 capacity allocations before Q2 factory booking deadlines (April 30, 2026)

🔹 Deploy procurement bandwidth on strategic initiatives—not supplier fire drills

Immediate Next Step:

Contact our Sourcing Engineering Team within 48 hours to receive:

1. Free Tier 1 Pro List Access (5 pre-vetted suppliers for your exact tech spec)

2. 2026 Tariff Optimization Playbook (updated for EU CBAM Phase IV)

3. Dedicated Sourcing Lead for your project (engineer, not sales)✉️ Email: [email protected]

📱 WhatsApp: +86 159 5127 6160 (24/7 Sourcing Desk)Response time guaranteed within 90 minutes during APAC business hours.

SourcifyChina: Where Verified Supply Meets Strategic Speed

We don’t list suppliers—we de-risk them. Backed by 12,000+ successful tech deployments since 2018.

© 2026 SourcifyChina. All data confidential to recipient. Pro List access governed by SourcifyChina Verified Partner Agreement V4.2 (2026).

🧮 Landed Cost Calculator

Estimate your total import cost from China.