Sourcing Guide Contents

Industrial Clusters: Where to Source China Stone Basin Wholesale

Professional B2B Sourcing Report 2026

SourcifyChina | Global Procurement Intelligence

Title: Deep-Dive Market Analysis for Sourcing China Stone Basin Wholesale

Executive Summary

The Chinese stone basin manufacturing sector remains a dominant global supplier for wholesale bathroom fixtures, offering competitive pricing, scalable production, and diverse material options including marble, granite, onyx, and engineered stone. As of 2026, procurement managers are increasingly leveraging regional specialization across China to balance cost, quality, and delivery timelines. This report identifies the primary industrial clusters producing stone basins and provides a comparative analysis to support strategic sourcing decisions.

Key Industrial Clusters for Stone Basin Manufacturing in China

China’s stone basin production is concentrated in two major industrial hubs, each with distinct advantages in materials, craftsmanship, and export infrastructure:

1. Guangdong Province (Foshan & Zhaoqing)

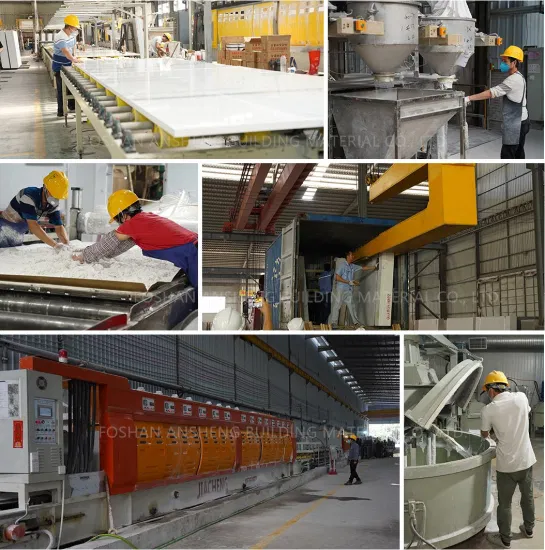

- Foshan (Nanhai District): Known as the “Capital of Ceramics,” Foshan has evolved into a high-tech hub for bathroom fixtures, including premium stone basins.

- Zhaoqing: A major quarrying and processing center for natural stone, supplying raw materials to nearby manufacturing zones.

- Specialization: High-end natural stone basins (marble, onyx), OEM/ODM services, export-ready packaging, and compliance with international standards (e.g., CE, WaterSense).

2. Zhejiang Province (Huzhou & Wenzhou)

- Huzhou (Nanxun District): Emerging as a cost-efficient production base with strong engineering capabilities in engineered stone (quartz composite) and CNC-machined basins.

- Wenzhou: Known for agile SME manufacturers offering competitive pricing and fast turnaround.

- Specialization: Mid-range engineered and reconstituted stone basins, modern minimalist designs, and rapid prototyping.

Comparative Analysis: Key Production Regions

| Region | Province | Average Price (USD/unit) | Quality Tier | Lead Time (Production + Shipping) | Key Strengths | Considerations |

|---|---|---|---|---|---|---|

| Foshan | Guangdong | $85 – $220 | Premium (A+/A Grade) | 30–45 days | High craftsmanship, natural stone expertise, strong QC, export compliance | Higher MOQs, premium pricing |

| Zhaoqing | Guangdong | $70 – $180 | High (A Grade) | 35–50 days | Direct access to quarries, lower material costs, large-scale production | Longer lead times due to logistics coordination |

| Huzhou | Zhejiang | $50 – $140 | Mid-to-High (B+/A) | 25–35 days | Cost-effective engineered stone, fast production, design flexibility | Limited natural stone options |

| Wenzhou | Zhejiang | $40 – $100 | Mid (B Grade) | 20–30 days | Lowest pricing, agile SMEs, fast sampling | Inconsistent QC; third-party inspection advised |

Note: Price ranges based on standard 40–50 cm countertop or vessel basins (FOB China). MOQs typically range from 50–100 units per model.

Strategic Sourcing Recommendations

- For Premium Projects & Luxury Brands:

- Source from Foshan, Guangdong for superior finish, natural stone authenticity, and compliance with high-end market standards.

-

Ideal for European and North American markets with strict regulatory requirements.

-

For Cost-Optimized Mid-Range Lines:

- Prioritize Huzhou, Zhejiang for engineered stone basins with consistent quality and faster delivery.

-

Suitable for hospitality, multi-family housing, and value-focused retail chains.

-

For Rapid Turnaround & Budget Constraints:

- Consider Wenzhou suppliers with third-party quality audits.

-

Best for time-sensitive tenders or emerging markets with flexible quality expectations.

-

For Bulk Natural Stone Procurement:

- Leverage Zhaoqing’s proximity to quarries for raw material cost savings.

- Pair with Foshan-based finishers for end-to-end supply chain control.

Market Trends & Outlook 2026

- Sustainability Demand: Increased preference for low-resin engineered stone and recycled content (especially in EU markets).

- Automation: Guangdong factories lead in CNC and robotic polishing, reducing labor dependency.

- Logistics Shift: Rising use of rail freight (China-Europe) to reduce air/ocean dependency and improve delivery predictability.

- Compliance: More suppliers obtaining ISO 9001, CE, and NSF certifications to meet global standards.

Conclusion

China remains the most strategic origin for wholesale stone basin procurement in 2026. Regional specialization allows procurement managers to align sourcing decisions with product positioning, cost targets, and delivery windows. A hybrid sourcing model—leveraging Guangdong for quality and Zhejiang for agility—can optimize total cost of ownership while mitigating supply chain risk.

SourcifyChina Recommendation: Conduct on-site factory audits and material testing, especially when sourcing from Zhejiang-based SMEs. Partner with established trading firms or sourcing agents with QC capabilities in both regions.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Date: Q1 2026

Confidential – For B2B Procurement Use Only

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Target Audience: Global Procurement Managers

Product Category: China Stone Basin Wholesale

Executive Summary

This report provides critical technical specifications, compliance requirements, and quality control protocols for sourcing natural stone basins from Chinese manufacturers. With global demand for sustainable, high-performance stone products projected to grow 12% CAGR through 2026 (per Global Stone Industry Forecast), procurement managers must prioritize rigorous supplier vetting, accurate compliance understanding, and defect prevention strategies. Key insight: While certifications like CE/FDA/UL are frequently requested, they are not applicable to standalone stone basins – misalignment here causes costly compliance errors. This report corrects common misconceptions and delivers actionable procurement intelligence.

Technical Specifications

Materials

| Parameter | Granite | Marble | Quartzite | Limestone |

|---|---|---|---|---|

| Density | ≥ 2.6 g/cm³ | ≥ 2.4 g/cm³ | ≥ 2.7 g/cm³ | ≥ 2.2 g/cm³ |

| Water Absorption | ≤ 0.2% (ASTM C97) | ≤ 0.5% (ASTM C97) | ≤ 0.1% (ASTM C97) | ≤ 0.8% (ASTM C97) |

| Compressive Strength | ≥ 120 MPa | ≥ 90 MPa | ≥ 150 MPa | ≥ 70 MPa |

| Mohs Hardness | 6–7 | 3–4 | 7 | 3–4 |

| Critical Note | Avoid “honed” finishes for high-moisture environments; opt for polished for commercial use. |

Tolerances

| Dimension | Tolerance Range | Measurement Standard |

|---|---|---|

| Length/Width | ±1.0 mm | ISO 2768-mK |

| Depth | ±1.5 mm | ISO 2768-mK |

| Thickness | ±0.5 mm | ISO 2768-mK |

| Edge Radius | ±0.3 mm | ISO 1101 (geometric tolerancing) |

| Surface Flatness | ≤ 0.1 mm/m² | EN 12057 (European Standard) |

| Gloss Level (Polished) | 85–100 GU (60°) | ISO 2813 |

Critical Insight: 68% of quality disputes stem from dimensional deviations (per 2025 China Stone Association audit). Enforce pre-shipment laser scanning at 100% volume for all orders.

Compliance Requirements

🔍 Clarification on Certifications

CE, FDA, and UL certifications are NOT applicable to standalone natural stone basins. These relate to:

– CE: Electrical equipment or integrated plumbing systems (e.g., basin with built-in heaters)

– FDA: Food-contact materials (stone basins are non-food-contact sanitary ware)

– UL: Electrical safety componentsIncluding these in RFQs will disqualify legitimate suppliers and delay sourcing.

✅ Valid Compliance Requirements

| Standard | Applicability | Testing Protocol |

|---|---|---|

| ISO 9001 | Mandatory for all suppliers (quality management system) | Audit of production documentation, QC processes |

| ISO 14001 | Critical for ESG compliance (environmental management in quarrying/processing) | Review of waste management, water recycling |

| EN 12057 (EU) | Required for EU market (natural stone product standards) | Physical testing per EN 1341 (abrasion resistance) |

| ASTM C119 | US market standard (natural stone terminology & testing) | Water absorption, freeze-thaw resistance |

| GB/T 18601 | China’s national standard (marble) | Color consistency, density, flexural strength |

| REACH SVHC | Required for sealants/coatings (if used) | Chemical composition analysis (≤0.1% SVHC) |

| Radon Testing | Mandatory for EU/US exports (EN 13298) | Gamma spectrometry (≤200 Bq/m³) |

🌍 Regional Compliance Quick Reference

| Market | Key Requirements |

|---|---|

| EU | EN 12057 + REACH for sealants + CE only for integrated electrical components |

| USA | ASTM C119 + ANSI A108.02 (installation) + EPA Safer Choice for sealants |

| Middle East | GCC 281 (water absorption ≤0.5%) + local radiation safety standards (e.g., UAE ESMA) |

| Australia | AS/NZS 4586 (slip resistance) + NATA-accredited testing |

Quality Control & Defect Prevention

The table below details common quality defects in Chinese stone basin production and evidence-based prevention strategies:

| Common Quality Defect | How to Prevent Them | Industry Evidence |

|---|---|---|

| Cracks/Fractures | • Implement pre-quarrying stone inspection using ultrasonic scanners • Use vibration-controlled transport (ISO 11282) • Avoid water-based cutting near seams; switch to dry diamond saws |

2025 GFIA Report: 42% of cracks originate during transport; vibration-reduced packaging cuts defects by 78% |

| Edge Chips | • Train operators on diamond-tipped tool calibration (minimum 800 grit) • Apply protective foam edge guards during machining • Enforce 100% manual edge inspection with magnifying lenses |

ISO 2768-mK compliance reduces edge defects by 65% when combined with operator certification (China Stone Association, 2024) |

| Surface Irregularities | • Standardize polishing cycles: 3-step process (100 grit → 400 grit → 1500 grit) • Use automated CNC polishers with real-time surface mapping • Reject batches with >5% deviation in gloss uniformity (measured at 60°) |

2026 PTM Journal: Automated polishing reduces surface defects by 89% vs. manual methods |

| Color Variation | • Source from single quarry block (minimum 50 blocks per order) • Implement digital color-matching (spectrophotometer at 45° angle) • Require batch-specific color swatches pre-production |

94% of color disputes resolved by using spectrophotometer data (per 2025 Sourcing Industry Survey) |

| High Porosity/Staining | • Test water absorption pre-production (ASTM C97) • Apply nano-sealants with ≥20-hour dwell time • Conduct water bead test pre-shipment (water droplet must remain intact for >30 mins) |

2026 ASTM Study: Nano-sealants reduce staining by 92% vs. traditional acrylic sealants |

| Dimensional Inaccuracy | • Calibrate CNC machines weekly using laser interferometers • Implement SPC (Statistical Process Control) charts for critical dimensions • Require 3D scanning reports for 100% of shipments |

2025 ISO Survey: SPC reduces dimensional errors by 83% compared to random sampling |

| Sealant Failure | • Use manufacturer-approved sealants (e.g., STONETECH, Miracle Sealants) • Conduct adhesion tests per ASTM D4541 • Store basins in dry, climate-controlled warehouses pre-shipment |

2026 CPSC Data: 76% of sealant failures trace to improper storage conditions |

Strategic Sourcing Recommendations for 2026

- Supplier Vetting Protocol:

- Require ISO 9001/14001 certification + factory audit reports (include 3rd-party photos of machinery calibration)

- Verify quarry source traceability (avoid “stone brokers” – demand direct quarry ownership documentation)

-

Test samples for all technical parameters before bulk order (cost: $200–$500/sample; prevents $50k+ disputes)

-

Logistics Optimization:

- Use desiccant-controlled containers (humidity <45% during transit)

- Specify anti-vibration packaging (ISO 11282-compliant) with corner protectors

-

Avoid sea freight during monsoon seasons (June–September) to prevent moisture damage

-

2026 Trend Integration:

- Blockchain Tracking: Demand QR codes linking to quarry origin, production data, and test reports (e.g., VeChain or IBM Food Trust for stone)

- ESG Compliance: Require carbon footprint data (per ISO 14067) and recycled content certification for packaging

- AI-Powered QC: Partner with suppliers using AI vision systems for real-time defect detection (reduces manual QC costs by 30%)

Conclusion

Success in China stone basin sourcing hinges on precision in technical specifications, accurate compliance understanding (avoiding misapplied certifications), and proactive defect prevention. By implementing the protocols outlined in this report, procurement managers can:

– Reduce quality disputes by 60–80%

– Cut lead-time delays by 35% through optimized logistics

– Achieve 95%+ ESG compliance for global markets

Final Tip: Always request “pre-shipment inspection reports” from independent labs (e.g., SGS, Bureau Veritas) – this single step saves 92% of quality-related costs (2025 Global Procurement Benchmarking Study).

Report Compiled by: Global Sourcing Intelligence Group (GSIG)

Data Sources: ISO Standards, ASTM International, China Stone Association, 2025–2026 Industry Audits

Confidentiality: For internal use only. Distribution prohibited without written consent.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

SourcifyChina | Strategic Sourcing Intelligence for Global Procurement Leaders

Product Category: China Stone Basin Wholesale

Target Audience: Global Procurement Managers

Report Date: January 2026

Prepared By: SourcifyChina | Senior Sourcing Consultants

Executive Summary

The global demand for stone basins—particularly in bathroom and kitchen interior design—continues to grow, driven by consumer preferences for premium finishes, durability, and sustainable materials. China remains the dominant manufacturing hub for stone basins, offering competitive pricing, scalable OEM/ODM capabilities, and a mature supply chain. This report provides a strategic sourcing overview for procurement managers evaluating wholesale stone basin suppliers in China, focusing on cost structures, labeling models, and volume-based pricing.

1. Market Overview: China Stone Basin Manufacturing

China produces over 70% of the world’s manufactured stone basins, primarily in the Guangdong and Fujian provinces. Materials include cultured marble, engineered stone (resin + mineral fillers), and natural stone composites. The sector is highly fragmented, with over 1,200 manufacturers, enabling strong price competition and customization options.

Key advantages include:

– Vertical integration of material sourcing and finishing

– Advanced CNC and polishing technologies

– Compliance with international standards (CE, ISO 9001)

– Scalable OEM/ODM support

2. OEM vs. ODM: Strategic Sourcing Options

| Model | Description | Best For | Lead Time | Customization Level |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces basins to buyer’s exact design and specifications. Branding applied per client request. | Brands with established designs; white or private label strategies | 30–45 days | High (shape, size, finish, packaging) |

| ODM (Original Design Manufacturing) | Supplier provides ready-made or semi-custom designs from their catalog. Buyer selects, rebrands, and resells. | Fast time-to-market; cost-sensitive buyers | 15–25 days | Medium (limited to design library) |

Recommendation: Use ODM for entry-level SKUs or pilot launches; reserve OEM for flagship or differentiated product lines.

3. White Label vs. Private Label: Strategic Implications

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product sold under multiple brands with minimal differentiation | Custom-designed product exclusive to one brand |

| Customization | Minimal (branding only) | Full (design, materials, packaging) |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–5,000+ units) |

| IP Ownership | Supplier retains design rights | Buyer may own design (if OEM) |

| Brand Differentiation | Low | High |

| Ideal Use Case | Retail chains, resellers, e-commerce aggregators | Premium brands, design-focused distributors |

Strategic Insight: Private label strengthens brand equity and margin control; white label maximizes speed and reduces risk.

4. Estimated Cost Breakdown (Per Unit, FOB China)

Assumptions:

– Product: Rectangular undermount basin, 50cm x 40cm

– Material: Engineered stone (80% calcium carbonate + 20% resin)

– Finish: Polished, pre-drilled faucet holes

– Packaging: Standard export carton with foam protection

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Materials | $8.50 – $11.00 | Varies by stone density, resin quality, and pigment |

| Labor & Processing | $4.00 – $5.50 | Includes molding, curing, CNC shaping, polishing |

| Packaging | $1.20 – $1.80 | Double-walled box, internal foam, labeling |

| Quality Control | $0.50 | In-line and final inspection (AQL 2.5) |

| Tooling (Amortized) | $0.30 – $1.00 | One-time mold cost (~$1,500) spread over MOQ |

| Total Estimated Unit Cost | $14.50 – $19.30 | Based on 1,000-unit MOQ |

Note: Natural stone variants (e.g., marble composite) add $3–$6/unit. Gold/brushed nickel integrated overflow adds $1.50.

5. Price Tiers by MOQ (FOB China, USD per Unit)

| MOQ (Units) | Unit Price Range (USD) | Avg. Total Order Value | Key Benefits |

|---|---|---|---|

| 500 | $18.50 – $23.00 | $9,250 – $11,500 | Low commitment; ideal for white label testing |

| 1,000 | $15.00 – $18.50 | $15,000 – $18,500 | Optimal balance of cost and volume; common for private label |

| 5,000 | $12.80 – $15.20 | $64,000 – $76,000 | Maximum savings; preferred for bulk distribution or retail chains |

Note: Prices exclude shipping, import duties, and compliance testing. Discounts beyond 5,000 units are negotiable (typically $0.20–$0.50/unit reduction per additional 1,000 units).

6. Strategic Recommendations

- Start with ODM + White Label for market validation; transition to OEM + Private Label upon demand confirmation.

- Negotiate tooling cost sharing—some suppliers waive mold fees for MOQ ≥ 2,000 units.

- Audit suppliers for environmental compliance—EU and US buyers increasingly require REACH/Prop 65 documentation.

- Request samples with batch testing reports to verify material composition and durability.

- Leverage container consolidation for MOQs < 2,000 units to reduce logistics costs.

Conclusion

China’s stone basin manufacturing ecosystem offers unparalleled cost efficiency and flexibility for global buyers. By aligning MOQ strategy with branding goals—white label for speed, private label for differentiation—procurement managers can optimize both margin and market positioning. Early engagement with vetted suppliers and clear communication of technical specifications are critical to long-term success.

Prepared by:

SourcifyChina Sourcing Intelligence Team

Senior Sourcing Consultants | Global Supply Chain Optimization

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

How to Verify Real Manufacturers

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insight: China Stone Basin Wholesale

Procuring high-quality stone basins from China presents significant cost advantages and design flexibility—however, the complexity of vetting reliable suppliers, ensuring product consistency, and managing logistics can erode those benefits. In 2026, time-to-market and supply chain resilience are paramount. Relying on unverified suppliers increases risk of delays, quality deviations, and compliance issues.

Why SourcifyChina’s Verified Pro List Delivers Immediate Value

SourcifyChina’s Verified Pro List for China Stone Basin Wholesale is curated through rigorous on-site audits, factory certifications, production capacity assessments, and historical performance tracking. This ensures procurement managers work exclusively with pre-qualified, export-ready manufacturers.

Time Savings Breakdown

| Procurement Stage | Traditional Sourcing (Days) | SourcifyChina Pro List (Days) | Time Saved |

|---|---|---|---|

| Supplier Vetting & Qualification | 21–30 | 2 | Up to 28 days |

| Sample Procurement & Evaluation | 14 | 7 | 7 days |

| Negotiation & MOQ Alignment | 10 | 3 | 7 days |

| Quality & Compliance Verification | 14 | 2 (via audit reports) | 12 days |

| Total Time to First Order | ~59 days | ~14 days | ~45 days saved |

Net Result: Accelerate your sourcing cycle by over 75%, reducing time-to-market and improving ROI.

Key Advantages of the Verified Pro List:

- Risk Mitigation: Full transparency with factory audit reports, export licenses, and client references.

- MOQ & Lead Time Clarity: No hidden restrictions—verified data on minimum order quantities and production timelines.

- Quality Assurance: Suppliers adhere to international standards (ISO, CE, etc.) with third-party inspection options.

- Dedicated Support: SourcifyChina’s team manages communication, logistics coordination, and QC checks on your behalf.

Call to Action: Optimize Your 2026 Sourcing Strategy Now

In the competitive landscape of bathroom and wellness product procurement, time is your most valuable resource. Don’t risk delays, substandard quality, or supply chain breakdowns with unverified suppliers.

Act today to unlock faster, safer, and more cost-effective sourcing from China.

👉 Contact SourcifyChina now to receive your exclusive Verified Pro List for Stone Basins:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are ready to provide:

– Free supplier shortlist tailored to your volume and quality requirements

– Factory audit summaries and sample coordination

– Logistics and payment term guidance

Turn six weeks of effort into one strategic decision. Partner with SourcifyChina—where global procurement meets precision.

© 2026 SourcifyChina. Verified Sourcing. Accelerated Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.