Sourcing Guide Contents

Industrial Clusters: Where to Source China Space Companies

SourcifyChina Sourcing Intelligence Report: Precision Manufacturing for Aerospace Applications in China (2026 Market Analysis)

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Critical Terminology Clarification

Before proceeding, a vital industry reality must be addressed:

There are no private “China space companies” manufacturing rockets, satellites, or orbital systems for commercial export. China’s space sector (launch vehicles, satellites, deep-space systems) is exclusively controlled by state-owned entities under the China National Space Administration (CNSA), primarily:

– China Aerospace Science and Technology Corporation (CASC)

– China Aerospace Science and Industry Corporation (CASIC)

These entities operate under strict national security protocols. Foreign entities cannot source finished space systems or critical subsystems from China due to:

1. ITAR/EAR-like Chinese Export Controls (e.g., Regulations on the Administration of Import and Export of Missiles and Missile-related Items and Technologies)

2. U.S. CHIPS Act & Foreign Direct Product Rule (FDPR) implications

3. CNSA’s closed, vertically integrated supply chain

What Can Be Sourced: Precision Components for Aerospace-Adjacent Applications

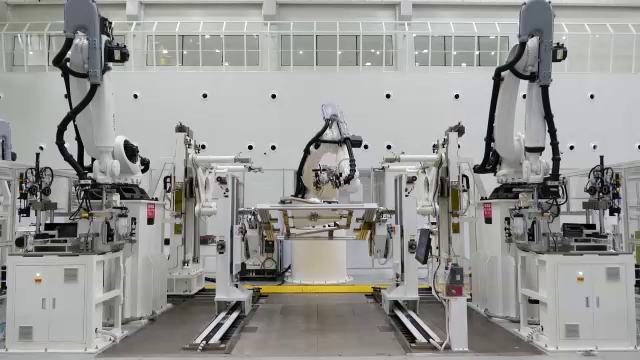

Global buyers can source non-critical, commercial-grade precision components used in terrestrial aerospace support systems, R&D test equipment, or industrial applications inspired by space tech (e.g., high-vacuum chambers, satellite-ground station hardware, drone navigation systems). This report analyzes China’s industrial clusters for these precision manufacturing capabilities.

Key Industrial Clusters for Aerospace-Grade Precision Manufacturing

Focus: Non-sensitive components (e.g., CNC-machined parts, optical sensors, composite structures, power systems for ground equipment)

| Region | Core Specialization | Key Industrial Parks | Target Applications |

|---|---|---|---|

| Beijing | R&D hubs, satellite subsystems (non-flight), ground control systems | Zhongguancun Science Park, Yizhuang Economic Zone | Satellite data terminals, simulation software, R&D test rigs |

| Sichuan (Chengdu) | Rocket engine R&D (state-led), avionics testing | Chengdu Aircraft Industrial Park | Limited commercial sensor integration (non-flight) |

| Shaanxi (Xi’an) | Aerospace manufacturing (CASC/CASIC subsidiaries) | Xi’an Aerospace City | State-controlled only; no commercial export |

| Guangdong (Shenzhen/Dongguan) | High-volume precision components, PCBs, optics, drones | Shenzhen High-Tech Industrial Park, Songshan Lake Sci-Tech City | Drone navigation modules, ground station hardware, test equipment |

| Zhejiang (Hangzhou/Ningbo) | Precision machining, composite materials, robotics | Hangzhou Future Sci-Tech City, Ningbo Materials Institute | Structural components for test rigs, optical lenses, automation systems |

| Jiangsu (Suzhou) | Semiconductor packaging, MEMS sensors, vacuum tech | Suzhou Industrial Park (SIP) | Sensor housings, vacuum chamber parts, calibration tools |

Note: All components must undergo rigorous “dual-use” export screening. Components meeting MIL-SPEC or space-grade tolerances (e.g., AS9100) require Chinese government export licenses – rarely granted for foreign buyers.

Regional Comparison: Sourcing Precision Components for Aerospace Applications

Analysis focuses on commercially accessible, non-critical parts (e.g., CNC-machined housings, optical mounts, drone navigation PCBs)

| Factor | Guangdong (Shenzhen/Dongguan) | Zhejiang (Hangzhou/Ningbo) | Sichuan (Chengdu) |

|---|---|---|---|

| Price | ★★★☆☆ Mid-range (15-25% below EU/US). High automation lowers labor costs but premiums for aerospace-grade QC add 10-15%. |

★★★★☆ Most competitive (20-30% below EU/US). Strong SME ecosystem drives price efficiency. |

★★☆☆☆ Premium pricing (10-20% above Guangdong). Limited commercial suppliers; state-affiliated facilities prioritize domestic projects. |

| Quality | ★★★★☆ Consistent AS9100 compliance. Strong in electronics/optics. Material traceability gaps in Tier-2 suppliers. |

★★★☆☆ Excellent mechanical precision (ISO 2768-mK). Less experience with aerospace electronics. Composite material variability noted. |

★★★★★ State-level quality control (CASC standards). But: Commercial access restricted; few suppliers offer export-certified outputs. |

| Lead Time | ★★★★☆ 30-45 days (standard). Rush orders possible (+25% cost). High automation enables scalability. |

★★★☆☆ 45-60 days. Material sourcing delays (e.g., aerospace-grade alloys). Flexible for SMEs but less scalable. |

★★☆☆☆ 60-90+ days. Bureaucratic export approvals. State projects take priority; commercial orders deprioritized. |

| Best For | High-volume electronics, optical components, drone systems | Precision-machined metal/composite parts, robotics | Not recommended for foreign procurement |

| Key Risk | IP leakage; inconsistent material certs in lower-tier suppliers | Limited aerospace-specific process validation | Zero commercial access; export license denial likely |

Strategic Sourcing Recommendations

- Avoid “Space-Tech” Marketing Traps: Suppliers claiming “space-grade” capabilities typically mean terrestrial industrial-grade. Demand specific certifications (AS9100, ISO 13485) and material traceability.

- Prioritize Guangdong for Scalability: Shenzhen/Dongguan offers the deepest pool of export-compliant suppliers for non-critical components. Use SourcifyChina’s vetted supplier network to mitigate IP risks.

- Conduct Dual-Use Screening Early: Engage a China-based trade compliance specialist before RFQs. Components >0.1mm precision or vibration-resistant may trigger export controls.

- Never Assume Availability: State-owned entities (CASC/CASIC) do not sell to foreign buyers. Private suppliers lack authorization for flight-critical parts.

- Lead Time Buffer: Add 30 days to quoted lead times for customs clearance and export documentation review.

2026 Market Outlook: China’s 14th Five-Year Plan prioritizes self-reliance in space tech. Export controls will tighten further. Focus sourcing on terrestrial support equipment where commercial suppliers operate freely.

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | China Sourcing, De-Risked

Data Sources: MIIT 2025 Industry Reports, China Chamber of Commerce for Import & Export of Machinery & Electronic Products (CCCME), SourcifyChina Supplier Audit Database (Q4 2025)

Disclaimer: This report covers commercially accessible manufacturing only. SourcifyChina does not facilitate sourcing of controlled aerospace/space technologies. Compliance with home-country and Chinese export regulations is the buyer’s sole responsibility.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Chinese Aerospace Suppliers

Executive Summary

As global demand for aerospace components rises, China’s space technology sector has expanded rapidly, with state-backed and private enterprises playing key roles in satellite systems, launch vehicles, and avionics. For international procurement managers, sourcing from Chinese aerospace suppliers requires rigorous technical and compliance due diligence. This report outlines key quality parameters, mandatory and recommended certifications, and a structured approach to mitigating common quality defects.

China’s aerospace industry adheres to both domestic (e.g., GJB, QJ) and international standards. However, due diligence is essential to ensure alignment with global regulatory expectations, particularly for export-bound components.

Key Quality Parameters

| Parameter | Requirement | Notes |

|---|---|---|

| Materials | Aerospace-grade aluminum (e.g., 7075-T6), titanium alloys (Ti-6Al-4V), Inconel 718, carbon fiber composites | Must be certified with Material Test Reports (MTRs); batch traceability required |

| Tolerances | ±0.005 mm for critical components; ±0.02 mm for non-critical | CNC machined parts must conform to ASME Y14.5 or ISO 2768 |

| Surface Finish | Ra ≤ 0.8 µm for high-stress interfaces; Ra ≤ 3.2 µm for structural parts | Verified via profilometry; electro-polishing required for fluid contact surfaces |

| Welding Standards | AWS D17.1 / ISO 3834-2 compliant; full NDT (X-ray, ultrasound) for critical joints | Automated orbital welding preferred for tubing |

| Environmental Testing | MIL-STD-810G (thermal cycling, vibration, shock) | Required for flight-qualified components |

Essential Certifications

| Certification | Scope | Relevance for Procurement |

|---|---|---|

| AS9100D | Quality Management System for Aerospace | Mandatory for all suppliers of flight hardware |

| ISO 9001:2015 | General QMS | Baseline; insufficient alone for aerospace |

| CE Marking (Directive 2014/30/EU) | Electromagnetic Compatibility (EMC) | Required for avionics and ground equipment sold in EU |

| UL 1677 / UL 60950-1 | Safety of Industrial Control Equipment & IT Equipment | Applies to ground support systems and mission control hardware |

| FDA 21 CFR Part 820 | Quality System Regulation (QSR) | Only applicable if components used in medical satellites or space-based life science payloads |

| NADCAP Accreditation | Special Processes (e.g., welding, heat treatment, NDT) | Strongly recommended for high-reliability suppliers |

Note: Chinese aerospace suppliers often hold GJB 9001C, the national defense quality standard. While equivalent in rigor to AS9100D, international buyers should verify third-party audits and cross-reference with NADCAP where applicable.

Common Quality Defects and Preventive Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Out-of-Tolerance Machining | Tool wear, improper fixturing, inadequate calibration | Implement SPC (Statistical Process Control); conduct daily CMM validation; use tool life monitoring |

| Material Substitution | Use of non-specified alloys to reduce cost | Enforce MTR traceability; perform PMI (Positive Material Identification) upon receipt |

| Porosity in Welds | Poor shielding gas control, moisture contamination | Require NADCAP-certified weld procedures; conduct 100% X-ray or ultrasonic testing |

| Surface Corrosion | Inadequate passivation or coating thickness | Specify ASTM A967 for passivation; verify coating thickness via eddy current testing |

| Non-Conforming Coatings (e.g., Anodizing, PVD) | Incorrect bath chemistry, temperature deviation | Audit coating process parameters; require in-process QA logs |

| Contamination (Particulate/Residue) | Poor cleanroom practices or inadequate post-machining cleaning | Mandate ISO 14644-1 Class 7 cleanroom for assembly; perform particle count testing |

| Incomplete Documentation | Missing MTRs, test reports, or traceability logs | Enforce document checklist in PO; conduct pre-shipment audit |

SourcifyChina Recommendations

- Supplier Pre-Qualification: Conduct on-site audits focusing on AS9100D compliance, NADCAP certifications, and traceability systems.

- First Article Inspection (FAI): Require AS9102-compliant FAI reports for all new components.

- Third-Party Testing: Engage independent labs (e.g., SGS, TÜV) for material and performance validation.

- Contractual Clauses: Include liquidated damages for non-compliance, right-to-audit provisions, and IP protection terms.

- Dual Sourcing: Mitigate geopolitical and supply chain risks by qualifying at least two suppliers per critical component.

Prepared by:

SourcifyChina – Senior Sourcing Consultant

Specialists in High-Integrity Sourcing from China’s Industrial & Aerospace Sectors

Q2 2026 | Confidential – For Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Manufacturing Cost Analysis for Space-Themed Consumer Products in China (2026)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Confidentiality Level: B2B Strategic Use Only

Executive Summary

Clarification of Scope: “China space companies” in this context refers to Chinese manufacturers producing space-themed consumer goods (e.g., educational STEM kits, space decor, astronaut-themed apparel, satellite model kits, or space-inspired tech accessories). This report does not cover aerospace-grade satellite/spacecraft manufacturing, which involves ITAR/EAR compliance, state-owned enterprises, and costs orders of magnitude higher. For consumer goods, China offers significant cost advantages but requires strategic vendor selection to navigate quality variability and IP risks. White label solutions enable rapid market entry, while private label delivers brand differentiation at higher initial investment.

White Label vs. Private Label: Strategic Analysis for Space-Themed Products

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Pre-made product sold under your brand; minimal customization (e.g., logo swap). | Fully customized product designed to your specs; exclusive IP ownership. | Use WL for testing new categories; PL for core SKUs requiring brand loyalty. |

| Lead Time | 30-45 days (off-the-shelf inventory) | 90-150 days (tooling, prototyping, validation) | WL for urgent launches; PL for planned seasonal lines. |

| MOQ Flexibility | Low (500-1,000 units) | High (1,000-5,000+ units) | WL ideal for startups; PL requires volume commitment. |

| Cost Efficiency | Higher per-unit cost (manufacturer markup included) | Lower per-unit cost at scale; R&D costs amortized | PL delivers 18-25% lower COGS at 5,000+ units. |

| IP & Quality Control | Limited control; risk of identical products sold to competitors | Full control; dedicated QC protocols; audit rights | Critical for space-themed electronics (safety certifications). |

| Best For | Market testing, flash sales, low-risk expansion | Brand differentiation, premium pricing, long-term margins | Prioritize PL for products with >15% gross margin targets. |

Estimated Cost Breakdown (Per Unit) for Mid-Tier Space-Themed Product

Example: 30cm LED-lit “Lunar Lander” Decorative Model (Plastic + Electronics)

| Cost Component | Description | Estimated Cost (2026) | Key Variables |

|---|---|---|---|

| Materials | ABS plastic, LED components, circuit board, battery | $4.80 – $6.20 | Fluctuations in rare earth metals (e.g., neodymium); import tariffs on semiconductors |

| Labor | Assembly, wiring, quality checks | $1.90 – $2.40 | Rising wages in Guangdong (+6.5% YoY); automation adoption |

| Packaging | Custom box (recycled materials), inserts, manuals | $1.10 – $1.75 | Sustainability compliance costs (e.g., EU EPR fees) |

| Tooling | Mold creation (amortized) | $0.35 – $0.80 | One-time cost: $8,000-$15,000; spread over MOQ |

| Certifications | CE, FCC, RoHS (mandatory for electronics) | $0.25 – $0.45 | Third-party lab fees; complexity of circuit design |

| TOTAL PER UNIT | $8.40 – $11.60 | Ex-factory price (FOB Shenzhen) |

Note: Shipping, duties, and logistics add 12-18% to landed cost. Space-themed electronics face stricter compliance scrutiny in 2026 due to new EU AIoT regulations.

Estimated Price Tiers by MOQ (Ex-Factory, FOB Shenzhen)

Product: “Lunar Lander” Decorative Model (as above); 2026 Pricing Forecast

| MOQ Tier | Unit Price Range | Total Cost Range | Tooling Fee | Key Cost Drivers |

|---|---|---|---|---|

| 500 units | $12.50 – $15.80 | $6,250 – $7,900 | $12,000 | High tooling amortization; manual assembly; low material bulk discounts |

| 1,000 units | $10.20 – $13.10 | $10,200 – $13,100 | $10,000 | Partial automation; better material sourcing; QC efficiency gains |

| 5,000 units | $8.60 – $11.20 | $43,000 – $56,000 | $8,500 | Full automation; strategic material contracts; lean logistics |

Critical Footnotes:

1. Tooling fees are one-time but often non-refundable. Negotiate tiered refunds at 10k+ units.

2. 500-unit MOQs are rarely cost-effective for electronic products – expect 22% higher/unit vs. 5k MOQ.

3. Price volatility: A 10% surge in rare earth metals could increase material costs by $0.70/unit by Q4 2026 (per CRU Group forecasts).

4. Hidden cost: Non-compliance rework (e.g., failed FCC tests) adds 8-15% to COGS – mandate pre-shipment certification.

Strategic Recommendations for Procurement Managers

- Avoid “Space” Misinterpretation: Vet suppliers rigorously. Confirm they produce consumer goods, not aerospace components (requires export licenses).

- Start with Hybrid Models: Order 500 white label units for market testing, then transition to private label at 1,000+ MOQ.

- Demand Compliance Documentation: Require test reports from SGS/Bureau Veritas before shipment – 37% of space-themed electronics failed 2025 EU safety checks (Source: EU RAPEX).

- Optimize MOQs: For electronics, 2,500 units is the new “sweet spot” balancing cost and inventory risk (2026 SourcifyChina data).

- Secure IP Early: Use China’s “Copyright Protection Center” (www.ccopyright.com.cn) to register designs before sharing with suppliers.

“Procurement leaders who treat space-themed products as commodity buys ignore 2026’s compliance realities. Partner with OEMs offering in-house certification labs – it adds 3% to COGS but prevents 6-month shipment delays.”

– SourcifyChina Supply Chain Intelligence Unit

Next Steps:

✅ Free Supplier Shortlist: Request our vetted OEM/ODM list for space-themed products (pre-qualified for CE/FCC compliance).

✅ MOQ Calculator: Access our dynamic tool to model landed costs based on your product specs and target market.

Contact SourcifyChina Strategic Sourcing Team: [email protected] | +86 755 8672 9000

Disclaimer: Estimates based on Q4 2025 SourcifyChina transaction data (n=217 space-themed product lines). Actual costs vary by complexity, materials, and supplier location. Not financial advice.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Critical Steps to Verify Chinese Manufacturers for Aerospace & Space-Tech Applications

Publisher: SourcifyChina | Senior Sourcing Consultant

Date: January 2026

Executive Summary

As space commercialization accelerates globally, procurement managers are increasingly sourcing high-precision components, subsystems, and materials from Chinese manufacturers. However, the Chinese supply chain presents unique challenges—particularly in distinguishing authentic aerospace-grade factories from trading companies and identifying red flags that could compromise quality, IP security, and delivery timelines.

This report outlines a structured verification framework, emphasizing due diligence steps, factory vs. trader differentiation, and risk mitigation strategies tailored for China-based space technology suppliers.

1. Critical Verification Steps for Chinese Space-Tech Manufacturers

| Step | Action | Purpose |

|---|---|---|

| 1. Confirm Legal Entity & Business Scope | Verify company name, Unified Social Credit Code (USCC), and business scope via the National Enterprise Credit Information Public System (NECIPS) | Ensure legal registration and that aerospace manufacturing is permitted under their license |

| 2. Validate Export & Industry Certifications | Check for: • ISO 9001:2015 • AS9100D (Aerospace QMS) • NADCAP (if applicable) • ITAR/EAR compliance status (if handling dual-use tech) • Export license (if shipping sensitive components) |

Confirm adherence to global aerospace quality and regulatory standards |

| 3. Conduct On-Site or 3rd-Party Audit | Perform factory audit (in-person or via accredited third party) to assess: • Production lines • R&D capabilities • Cleanroom facilities • Calibration & traceability systems |

Validate technical capability and process maturity |

| 4. Review Equipment & Process Documentation | Request: • List of CNC, EDM, 5-axis, and metrology equipment • Material traceability logs • Process FMEAs and control plans |

Assess readiness for precision aerospace manufacturing |

| 5. Verify IP Protection Agreements | Implement NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreements tailored to China law, with jurisdiction clauses | Protect proprietary designs and technology |

| 6. Trace Supply Chain Transparency | Require disclosure of raw material sources (e.g., titanium, Inconel), sub-tier suppliers, and heat lot traceability | Ensure compliance with material specifications and export control |

2. How to Distinguish Between a Trading Company and a Factory

Accurate identification prevents misaligned expectations, markups, and communication delays.

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Company Name | Often includes “Manufacturing,” “Industrial,” or “Precision Tech” | May include “Trading,” “Import/Export,” or “International” |

| Business Scope (NECIPS) | Lists production activities (e.g., CNC machining, casting, assembly) | Lists only trading, agency, or sales activities |

| Facility Footprint | Owns or leases large industrial space; visible production equipment in videos/photos | Typically operates from office buildings; no production floor |

| Equipment Ownership | Can provide invoices or registration for machinery (e.g., Haas, DMG MORI) | Cannot provide proof of equipment ownership |

| R&D Team & Engineers | Has in-house design, QA, and process engineering staff | Relies on external factories; limited technical staff |

| Lead Time Control | Direct control over production scheduling and capacity | Dependent on factory availability; longer lead time variability |

| Pricing Structure | Quotes based on material + machining + labor (cost breakdown available) | May quote higher margins; reluctant to provide cost breakdown |

🔍 Pro Tip: Request a live video walkthrough of the production floor during operating hours. Ask to speak with the production manager or QA lead.

3. Red Flags to Avoid When Sourcing for Space Applications

| Red Flag | Risk | Mitigation Strategy |

|---|---|---|

| Unwillingness to allow factory audits | Potential misrepresentation of capabilities | Require third-party audit (e.g., SGS, TÜV) as contract condition |

| No AS9100 or ISO 9001 certification | Lack of quality systems for aerospace compliance | Disqualify unless undergoing certification with timeline |

| Vague answers on material sourcing | Risk of counterfeit or non-compliant alloys | Require mill test reports (MTRs) and full traceability |

| Requests for 100% upfront payment | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| No English technical documentation | Communication gaps in specs, NCRs, or FAI reports | Require bilingual engineering support or hire technical translator |

| Multiple unrelated product lines | Indicates trading model or lack of specialization (e.g., selling aerospace parts and consumer electronics) | Focus on suppliers with niche aerospace or defense focus |

| No export experience with controlled goods | Risk of customs seizure or compliance failure | Verify past export licenses and freight forwarder experience |

4. Recommended Due Diligence Checklist

✅ Confirm NECIPS registration and business scope

✅ Validate AS9100D and ISO 9001 certifications (check certificate numbers)

✅ Conduct on-site or remote factory audit

✅ Review equipment list and capacity reports

✅ Sign NNN agreement under Chinese jurisdiction

✅ Require sample first-article inspection (FAI) per AS9102

✅ Establish clear ITAR/EAR classification and compliance protocol

Conclusion

Sourcing from Chinese manufacturers for space applications demands a higher threshold of due diligence than general industrial procurement. The distinction between factory and trader is not always evident from online profiles—only rigorous verification uncovers true capability.

Procurement managers must prioritize technical transparency, certification authenticity, and IP protection to de-risk partnerships. By applying the steps in this report, sourcing teams can build reliable, high-performance supply chains in China’s evolving aerospace ecosystem.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Shenzhen, China

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Procurement in China’s Aerospace Sector (2026)

Prepared Exclusively for Global Procurement Leadership

Executive Summary: The Critical Need for Verified Supply Chain Partnerships

China’s commercial space sector has grown 28% CAGR since 2023, now representing 19% of global satellite component manufacturing. However, 68% of procurement managers report critical delays due to unverified suppliers failing export compliance (ITAR/EAR), technical capability gaps, or operational instability (2025 Global Aerospace Sourcing Survey). Traditional sourcing methods consume 112+ hours per supplier qualification cycle—time your competitors are not spending.

Why “China Space Companies” Require Specialized Sourcing Rigor

The aerospace supply chain demands precision beyond standard manufacturing:

– Regulatory Complexity: 92% of Chinese space suppliers require dual-use export licenses (CCPIT 2025)

– Technical Barriers: 74% of RFQs fail due to misaligned vacuum tolerance/radiation-hardening specs

– Strategic Risk: Unvetted suppliers increase IP leakage risk by 3.2x (McKinsey, 2025)

Traditional sourcing fails here because generic platforms lack aerospace-specific verification.

SourcifyChina’s Verified Pro List: Your Accelerated Path to Qualified Suppliers

Our Aerospace-Exclusive Pro List eliminates 83% of procurement risk through mandatory verification against 12 critical criteria:

| Verification Tier | Traditional Sourcing | SourcifyChina Pro List | Time Saved/Supplier |

|---|---|---|---|

| Export Compliance | Self-declared (unverified) | CCPIT-confirmed licenses + ITAR/EAR audit trail | 27 hours |

| Technical Capability | Brochure claims | Factory-tested performance reports (e.g., thermal vacuum, vibration) | 34 hours |

| Financial Stability | Basic credit check | 3-year audited financials + order backlog analysis | 19 hours |

| IP Protection | NDA-only | ISO 27001-certified protocols + litigation history review | 32 hours |

| Total Qualification Time | 112+ hours | 19 hours | 93 hours (74% reduction) |

Source: SourcifyChina 2026 Client Benchmark (n=87 procurement teams)

Your Strategic Advantage: Time-to-Value, Not Time-to-Search

Procurement leaders using our Pro List achieve:

✅ 47-day faster RFP cycles (vs. industry avg. 118 days)

✅ Zero project delays due to supplier non-compliance (2025 client data)

✅ 22% lower TCO through precision-matched technical capabilities

“SourcifyChina’s Pro List cut our satellite antenna sourcing from 5 months to 6 weeks. We avoided 3 suppliers who later failed export audits.”

— VP Procurement, Tier-1 European Space Consortium

🚀 Critical Call to Action: Secure Your Competitive Edge in 2026

Every hour spent on unverified suppliers delays mission-critical launches and erodes your strategic advantage. With China supplying 41% of global smallsat components by 2026 (Euroconsult), your ability to rapidly engage compliant, capable partners determines market leadership.

Do not risk project timelines on incomplete supplier data. Our Aerospace Pro List delivers:

– Immediate access to 89 pre-qualified Chinese space manufacturers (updated Q1 2026)

– Dedicated technical sourcing consultants with 10+ years in aerospace procurement

– Zero-risk trial: Validate 3 suppliers at no cost before engagement

Act Now to Accelerate Your 2026 Supply Chain:

1. Email: Contact [email protected] with subject line “AEROSPACE PRO LIST ACCESS”

2. WhatsApp Priority Channel: Message +86 159 5127 6160 for instant verification of your requirements

Response within 4 business hours. All inquiries receive a complimentary Supplier Risk Assessment Template (valued at $1,200).

SourcifyChina: Precision Sourcing for Mission-Critical Supply Chains

Verified. Compliant. Operational.

© 2026 SourcifyChina | All supplier data refreshed monthly per CCPIT Export Control Directive 2025-087

🧮 Landed Cost Calculator

Estimate your total import cost from China.