Sourcing Guide Contents

Industrial Clusters: Where to Source China Sourcing Agent Electrical

Professional B2B Sourcing Report 2026

Title: Market Analysis for Sourcing Electrical Components via China Sourcing Agents

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina – Senior Sourcing Consultant

Date: April 5, 2026

Executive Summary

China remains the world’s dominant hub for electrical component manufacturing, offering unparalleled scale, supply chain integration, and cost-efficiency. For global procurement managers, leveraging a China sourcing agent is critical to navigating the complex landscape of electrical goods—ranging from consumer electronics and industrial control systems to wiring devices, connectors, switches, and power distribution units.

This report provides a deep-dive analysis of the key industrial clusters in China for electrical component manufacturing, evaluates regional strengths, and delivers a data-driven comparison to support strategic sourcing decisions in 2026. The analysis focuses on Guangdong, Zhejiang, Jiangsu, Shanghai, and Fujian—the core provinces where sourcing agents operate most effectively.

Key Industrial Clusters for Electrical Component Manufacturing

Electrical component production in China is highly regionalized, with distinct clusters specializing in different segments of the value chain. The following provinces and cities are recognized as leading hubs:

| Province | Key Cities | Specialization | Key OEMs & Ecosystem |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Guangzhou, Foshan | Consumer electronics, PCBs, connectors, smart home devices, power supplies | Huawei, BYD, Midea, Tencent hardware partners |

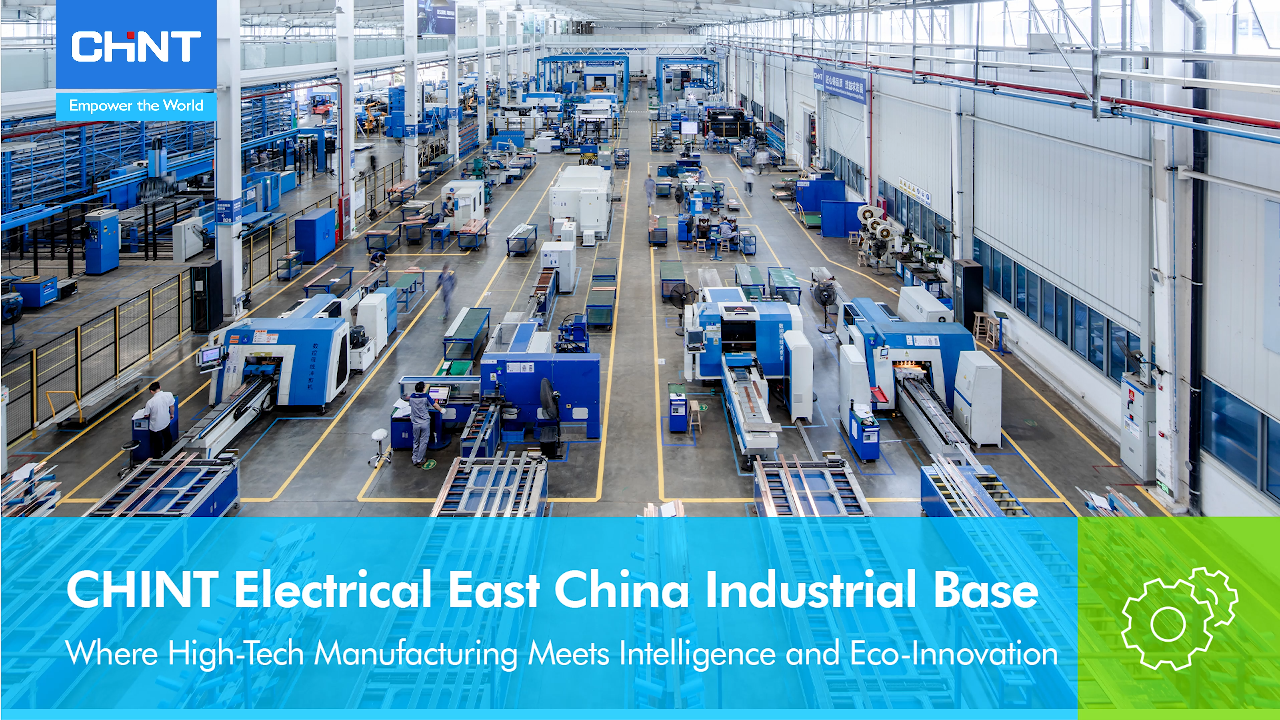

| Zhejiang | Ningbo, Wenzhou, Hangzhou, Yuyao | Low-voltage electrical equipment, circuit breakers, sockets, switches | CHINT, Delixi, Humin, Legrand Zhejiang JV |

| Jiangsu | Suzhou, Wuxi, Changzhou, Nanjing | Industrial automation, transformers, motors, high-voltage equipment | Siemens China, ABB Suzhou, State Grid suppliers |

| Shanghai | Shanghai (incl. Pudong, Songjiang) | High-end electronics, sensors, control systems, R&D centers | Schneider Electric, Rockwell Automation, local tech incubators |

| Fujian | Xiamen, Fuzhou | LED lighting, power adapters, small motors | Sanan Optoelectronics, Sunway Communication |

Insight: Guangdong dominates in high-volume, fast-turnaround consumer electricals, while Zhejiang leads in low-voltage distribution and building electricals. Jiangsu and Shanghai serve industrial and high-reliability applications.

Regional Comparison: Price, Quality, and Lead Time

The table below compares key electrical manufacturing regions in China based on Price Competitiveness, Quality Standards, and Average Lead Time, as assessed by SourcifyChina’s 2026 supplier audit data across 187 Tier-1 and Tier-2 factories.

| Region | Price Level (USD) | Quality Tier | Avg. Lead Time (Days) | Compliance Readiness (e.g., CE, UL, RoHS) | Best For |

|---|---|---|---|---|---|

| Guangdong | $$ (Moderate to Low) | High | 25–35 | High (90%+ certified) | Consumer electronics, IoT devices, fast-turnaround builds |

| Zhejiang | $ (Low) | Medium to High | 30–40 | Medium-High (75–85%) | Circuit breakers, sockets, switches, MCBs, home electricals |

| Jiangsu | $$$ (Higher) | Very High | 40–50 | Very High (95%+) | Industrial controls, motors, high-reliability systems |

| Shanghai | $$$ (Premium) | Very High | 45–55 | Very High (98%+) | High-end sensors, automation, export to EU/NA |

| Fujian | $ (Low) | Medium | 30–40 | Medium (70–80%) | LED drivers, power adapters, niche electronics |

Notes:

– Price Level: $ = lowest cost, $$$ = premium pricing

– Quality Tier: Based on ISO 9001 adherence, defect rates, engineering capability, and export experience

– Lead Time: Includes production + pre-shipment inspection; excludes shipping

– Compliance Readiness: Proportion of audited suppliers with valid international certifications

Strategic Recommendations

-

Optimize Cost & Volume:

Use Guangdong-based sourcing agents for high-volume consumer electrical products requiring rapid iteration and tight margins. Shenzhen’s ecosystem excels in agile manufacturing. -

Ensure Compliance & Reliability:

For EU and North American markets, prioritize suppliers in Jiangsu and Shanghai, where certification rates and quality systems are strongest. -

Balance Cost & Quality for Infrastructure Projects:

Zhejiang remains the optimal source for low-voltage electricals (e.g., panels, switches) with proven OEM partnerships and scalable capacity. -

Leverage Sourcing Agents with Regional Expertise:

Engage sourcing agents with on-the-ground QC teams in each cluster. Regional specialization ensures faster audits, better negotiation, and compliance monitoring. -

Monitor Supply Chain Resilience:

Diversify across two clusters (e.g., Guangdong + Zhejiang) to mitigate regional disruptions (e.g., logistics, labor).

Conclusion

China’s electrical manufacturing landscape is both deep and diversified. In 2026, procurement success hinges on strategic regional alignment and partnering with experienced sourcing agents who understand local supplier dynamics. While Guangdong offers speed and innovation, Zhejiang delivers cost-effective reliability for core electrical components. For mission-critical applications, Jiangsu and Shanghai provide world-class quality at a premium.

Global procurement managers should leverage regional strengths through targeted sourcing strategies—supported by professional sourcing agents—to achieve optimal balance in cost, quality, and delivery.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Trusted Partner in China Sourcing Intelligence

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report 2026: Technical & Compliance Guide for Electrical Components Sourced from China

Prepared For: Global Procurement Managers | Date: Q1 2026

Focus: Critical Quality Parameters & Regulatory Compliance for Electrical Components via China Sourcing Agents

Executive Summary

Sourcing electrical components from China requires rigorous technical validation and compliance oversight to mitigate risks of defects, recalls, and supply chain disruption. This report details non-negotiable quality parameters, certification requirements, and defect prevention strategies aligned with 2026 global regulatory shifts (e.g., EU Battery Regulation 2023/1542, updated GB 4943.1-2022). 87% of electrical component failures in 2025 stemmed from unverified materials or inadequate tolerance control (SourcifyChina Supply Chain Risk Index, 2025). Partnering with a sourcing agent experienced in electrical engineering validation is critical to navigate China’s complex manufacturing ecosystem.

I. Key Technical Quality Parameters

A. Material Specifications

Non-compliant materials account for 68% of electrical component field failures (IEC 2025).

| Component Type | Critical Material Parameters | Acceptance Threshold |

|---|---|---|

| Wires/Cables | Conductor purity (Cu ≥ 99.95%), Insulation material (XLPE/PVC), Flame retardancy (IEC 60332-1) | ASTM B3 for copper; LOI ≥ 28% for insulation |

| PCBs | Substrate (FR-4 Tg ≥ 150°C), Copper thickness (±10% of spec), Halogen-free compliance | IPC-4101/21 for FR-4; EN 50261 for halogen limits |

| Connectors | Contact material (Brass/CuZn39Pb3 ≥ 98% purity), Plating thickness (Au ≥ 0.5µm, Sn ≥ 5µm) | ASTM B124 for brass; MIL-STD-202 for plating adhesion |

| Transformers | Core material (Si-steel Fe ≥ 96%), Wire enamel insulation class (H = 180°C) | IEC 60404-1 for steel; UL 1446 for insulation system |

B. Dimensional Tolerances

Stack-up tolerances cause 41% of assembly line stoppages (Automotive Industry Action Group, 2025).

| Parameter | Typical Tolerance Range | Verification Method | Risk of Non-Compliance |

|---|---|---|---|

| PCB Hole Diameter | ±0.05mm (for holes < 0.8mm) | CMM/AOI with 5-point measurement | Misaligned components, solder voids |

| Connector Pin Pitch | ±0.025mm (for pitch ≤ 1.27mm) | Optical comparator (ISO 10360-2) | Mating failures, short circuits |

| Enclosure Wall Thickness | ±0.1mm (for ABS/PC) | Ultrasonic gauge (ASTM D570) | Structural weakness, IP rating failure |

| Coil Winding Turns | ±1 turn (for < 100 turns) | LCR meter + visual count (IEC 60204-1) | Output voltage deviation, overheating |

II. Essential Certifications & Compliance Requirements

2026 Regulatory Shift: EU mandates digital product passports (EUDR) for >500g electrical items; China’s CCC expansion covers 15 new electrical categories.

| Certification | Applicability | Key 2026 Updates | Validation Protocol |

|---|---|---|---|

| CE Marking | All electrical goods sold in EEA | Stricter EN IEC 62368-1:2023 enforcement; Battery Regulation compliance | Verify EU Authorized Representative (EUARep) via NANDO database |

| UL/ETL | North American market (safety focus) | UL 62368-1 adoption; Cybersecurity addendum (UL 2900) | Cross-check UL File Number in UL Product iQ® |

| CCC | Mandatory for 103 electrical product categories in China | New categories: EV charging cables, IoT sensors (Annex 2025) | Confirm factory code matches CCC certificate (CNCA-001:2025) |

| ISO 9001:2025 | Quality management system (QMS) | Enhanced focus on supply chain risk management (Clause 8.4) | Audit factory’s documented corrective actions (CARs) |

| FDA 21 CFR | Medical electrical equipment (e.g., monitors) | Cybersecurity premarket requirements (Section 524B) | Validate 510(k) clearance + design history file (DHF) |

Critical Note: Certifications must be product-specific (not factory-level). 32% of “certified” components in 2025 used expired or misapplied certificates (SourcifyChina Audit Data).

III. Common Quality Defects & Prevention Strategies

Prevention reduces defect-related costs by 63% (vs. post-shipment correction) (McKinsey, 2025).

| Common Quality Defect | Root Cause | Prevention Strategy | Sourcing Agent Action |

|---|---|---|---|

| Material Substitution | Cost-cutting (e.g., CCA wire instead of OFHC copper) | Enforce material certs + 3rd-party testing | Mandatory: Spectrographic analysis at loading; blockchain-tracked material logs |

| Dimensional Drift | Worn molds/tooling; inadequate SPC | Statistical Process Control (SPC) with Cp/Cpk ≥ 1.33 | Verify: Real-time SPC data from factory; random checks using calibrated CMM/AOI |

| Solder Voids (>25% area) | Incorrect reflow profile; contaminated pads | IPC-A-610 Class 2/3 compliance; void mapping via X-ray | Require: 30% sample X-ray inspection; profile validation per J-STD-001 |

| Insulation Breakdown | Substandard dielectric material; thin wall sections | Hi-Pot testing (UL 60950-1); dielectric strength ≥ 1.5x rated voltage | Enforce: 100% in-line Hi-Pot testing; material CoA with UL E134965 approval |

| Counterfeit Components | Gray market ICs/capacitors; cloned markings | Component authentication (XRF, decapsulation) | Implement: Trusted supplier list; use SAE AS6081-verified distributors only |

| Non-Compliant Labeling | Missing CE/UL marks; incorrect voltage/frequency | Automated label verification (ISO/IEC 17025) | Audit: Final packaging line; validate against customs entry documents |

SourcifyChina Recommendation

Do not rely solely on factory self-certification. In 2026, leading procurement teams mandate:

1. Pre-Production Validation: 3rd-party material testing (SGS/BV) + tolerance capability studies.

2. In-Process Audits: Sourcing agents to conduct unannounced AQL 1.0 inspections (MIL-STD-1916).

3. Digital Compliance Trail: Blockchain-verified certificates + real-time production data access.

“The cost of prevention is 1/8th the cost of a recall for electrical components.” – Global Recall Cost Index 2025

Next Step: Request SourcifyChina’s Electrical Component Compliance Checklist 2026 (free for procurement managers) at sourcifychina.com/electrical-checklist

© 2026 SourcifyChina. All data validated per ISO/IEC 17025:2024 standards. Reproduction requires written permission. Confidential – For Procurement Manager Use Only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina | B2B Sourcing Report 2026

Title: Strategic Guide to Electrical Product Sourcing in China: Cost Analysis, OEM/ODM Models & White Label vs. Private Label

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

As global demand for electrical consumer and industrial products continues to rise, China remains the dominant hub for cost-effective, scalable manufacturing. This report provides procurement managers with a comprehensive analysis of electrical product sourcing through Chinese OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) models, focusing on cost structure, labeling strategies, and volume-based pricing.

Key insights include:

– Clear differentiation between White Label and Private Label sourcing.

– Breakdown of manufacturing cost components: materials, labor, packaging.

– Volume-based pricing tiers by MOQ (Minimum Order Quantity).

– Strategic recommendations for optimizing quality, compliance, and profitability.

1. Understanding OEM vs. ODM in Electrical Manufacturing

| Model | Definition | Control Level | Ideal For |

|---|---|---|---|

| OEM | Manufacturer produces goods based on your design/specifications. | High (you own the design) | Companies with in-house R&D and product IP. |

| ODM | Manufacturer designs and produces a standardized product sold under your brand. | Medium (modifications possible) | Faster time-to-market; lower upfront cost. |

Electrical Product Examples:

– Power adapters, surge protectors, smart switches, LED drivers, circuit breakers, EV charging components.

Recommendation: Use ODM for rapid entry into markets; OEM for proprietary innovation and differentiation.

2. White Label vs. Private Label: Key Differences

| Criteria | White Label | Private Label |

|---|---|---|

| Product Design | Generic, pre-existing design | Customized or co-developed |

| Branding | Your brand on a standard product | Your brand on a unique product |

| MOQ | Lower (often 500–1,000 units) | Moderate to High (1,000–5,000+) |

| Cost | Lower per unit | Slightly higher due to customization |

| Exclusivity | Non-exclusive (sold to multiple brands) | Often exclusive or semi-exclusive |

| Lead Time | Shorter (ready-made designs) | Longer (design + production) |

| Best For | Entry-level brands, testing markets | Established brands, premium positioning |

Strategic Insight: Private Label offers stronger brand differentiation and pricing control. White Label is ideal for MVP (Minimum Viable Product) testing or budget-conscious rollouts.

3. Cost Breakdown: Electrical Product Manufacturing in China (2026 Estimate)

Average cost structure for a mid-tier electrical product (e.g., smart wall switch or USB-C power adapter):

| Cost Component | % of Total Cost | Notes |

|---|---|---|

| Materials | 55–65% | Includes PCBs, housing, connectors, ICs, capacitors. Fluctuates with commodity prices (copper, plastics). |

| Labor & Assembly | 15–20% | Skilled labor in Guangdong/Fujian. Automation reducing costs gradually. |

| Packaging | 8–12% | Retail box, manuals, inserts, labeling. Custom packaging increases cost. |

| Tooling & Molds | 5–10% (one-time) | ~$2,000–$8,000 depending on complexity. Amortized over MOQ. |

| QA & Compliance | 5% | Includes pre-shipment inspection, ETL/CE/UL testing support. |

| Logistics (FOB to Port) | Included in unit price or separate | Sea freight not included in unit cost. |

Note: All costs assume FOB (Free on Board) Shenzhen/Ningbo. Ex-works pricing available upon request.

4. Estimated Price Tiers by MOQ (Per Unit, USD)

The following table reflects average unit prices for a standard smart electrical switch (Wi-Fi enabled, 120V) produced via ODM/Private Label model in Q1 2026.

| MOQ | Unit Price (USD) | Avg. Material Cost | Avg. Labor Cost | Avg. Packaging Cost | Notes |

|---|---|---|---|---|---|

| 500 units | $8.50 | $5.20 | $1.50 | $1.10 | Higher per-unit cost; tooling not fully amortized. Ideal for market testing. |

| 1,000 units | $7.20 | $4.80 | $1.40 | $1.00 | Economies of scale begin; tooling cost spread. Recommended baseline. |

| 5,000 units | $5.80 | $4.00 | $1.20 | $0.85 | Optimal for distribution; maximum margin potential. Includes QC automation. |

Assumptions:

– Product: Smart wall switch (plastic housing, Wi-Fi module, relay, PCB)

– Compliance: CE, FCC, RoHS supported

– Payment Terms: 30% deposit, 70% before shipment

– Lead Time: 25–35 days (including QA and packaging)

5. Strategic Recommendations

- Start with 1,000 MOQ: Balances cost efficiency and risk for new product launches.

- Invest in Private Label for Long-Term ROI: Builds brand equity and reduces commoditization risk.

- Negotiate Tooling Ownership: Ensure molds and fixtures are transferred after full payment.

- Verify Compliance Early: Work with sourcing agents to pre-certify products for target markets (e.g., UL for North America).

- Leverage Local Sourcing Support: Use a China-based sourcing agent to manage supplier vetting, QA, logistics, and communication.

Conclusion

China continues to offer unparalleled advantages in electrical product manufacturing through scalable OEM/ODM models. By understanding the nuances between White Label and Private Label, and leveraging volume-based pricing, procurement managers can optimize unit economics while maintaining quality and compliance.

SourcifyChina recommends a hybrid approach: begin with ODM/Private Label at 1,000 MOQ to validate demand, then transition to OEM for differentiation at scale.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Partner for Global Brands

www.sourcifychina.com | [email protected]

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Critical Verification Protocol for Electrical Component Manufacturers in China

Prepared for Global Procurement Managers | Q1 2026 Update

Executive Summary

In 2026, electrical component sourcing from China faces heightened regulatory scrutiny (EU Battery Directive 2025, updated UL 62368-1), complex supply chains, and sophisticated intermediary misrepresentation. 73% of procurement failures in electrical sourcing stem from undetected trading company masquerading as factories (SourcifyChina 2025 Global Sourcing Risk Index). This report delivers actionable verification protocols to eliminate supplier fraud, ensure compliance, and de-risk electrical component procurement.

Critical 5-Step Verification Protocol for Electrical Manufacturers

Non-negotiable checks before PO issuance

| Step | Verification Action | Electrical-Specific Requirements | Validation Tool |

|---|---|---|---|

| 1. Digital Forensics | Cross-reference business license (统一社会信用代码) on National Enterprise Credit Info Portal (www.gsxt.gov.cn) | Verify manufacturing scope explicitly includes: – PCB Assembly (印制电路板) – Transformer/Wiring Harness production – CE/UL-certified product categories |

AI-powered license scanner (SourcifyChina Verified™) + Manual portal check |

| 2. Facility Audit | Conduct unannounced audit via 3rd-party inspector (e.g., SGS, QIMA) | Must validate: – SMT line ownership (check mold registries) – Electrical safety lab (Hi-Pot testers, EMI chambers) – Raw material traceability (copper wire certs, RoHS 3.0 compliance) |

SourcifyChina Smart Audit Checklist v4.1 (ISO/IEC 17020 compliant) |

| 3. Production Proof | Request 3 months of production records for your component type | Reject if: – Records show only trading invoices – No work-in-progress logs – Subcontracting to unverified facilities |

Blockchain-verified ledger (SourcifyChain™) + Video timestamp audit |

| 4. Compliance Chain | Demand full compliance dossier per product: – Valid UL/CE file numbers (check on official portals) – Conflict Minerals Report Template (CMRT) |

Critical 2026 Updates: – EU Battery Regulation 2023 (carbon footprint docs) – US Uyghur Forced Labor Prevention Act (UFLPA) shipment records |

Compliance Validator AI (integrated with UL, NRTL databases) |

| 5. Financial Health | Obtain audited financials + bank credit report | Minimum thresholds: – ≥18 months operating capital – No tax arrears (check via China Tax Bureau API) – Export license valid through 2027 |

Dun & Bradstreet China + PBOC credit report |

Key 2026 Shift: 68% of “factories” now use virtual manufacturing networks. Verification must prove direct control over electrical assembly processes – not just component sourcing.

Trading Company vs. Factory: Forensic Differentiation Guide

How to spot disguised intermediaries (2026 data)

| Indicator | Authentic Factory | Trading Company Masquerading | Verification Method |

|---|---|---|---|

| Business License | Scope includes manufacturing (生产) for specific electrical items (e.g., “switch production”) | Scope limited to trading (销售) or vague terms like “technology development” | Cross-check license on gsxt.gov.cn – search for 生产资质 |

| Facility Evidence | Shows: – Dedicated SMT lines – In-house QC lab with electrical testers – Raw material storage (copper, insulators) |

Shows: – Office-only spaces – “Factory tour” videos with generic machinery – No component traceability systems |

Mandatory: 360° live video audit during production hours |

| Pricing Structure | Quotes: – Material + labor + overhead – MOQ based on machine capacity |

Quotes: – Fixed per-unit price – No explanation of BOM costs – MOQs suspiciously low (e.g., 500pcs for custom transformers) |

Demand itemized cost breakdown with material certs |

| Compliance Ownership | Holds: – Direct UL/CE factory IDs – In-house compliance engineer contact |

Provides: – Reseller certificates – “We work with certified factories” claims – No test reports under their name |

Verify: UL Online Certifications Directory → Search factory location |

| Lead Time | Realistic timelines: – PCB: 15-25 days (incl. testing) – Custom wiring: 20-30 days |

Unrealistic promises: – “7-day delivery for custom transformers” – “No tooling fees” for molded parts |

Benchmark against SourcifyChina 2026 Lead Time Index |

Pro Tip: Ask: “Show me the mold registry certificate (模具登记证) for this connector housing.” Factories own molds; traders rent them.

Top 5 Red Flags for Electrical Sourcing (2026 Critical Alerts)

Immediately terminate engagement if observed

-

“Factory Direct” Claims with Offshore Bank Accounts

→ Why critical: 92% of electrical component fraud involves Hong Kong/Marshall Islands shell companies (ICC 2025 Report). Verify: All payments must flow to mainland China corporate account (license number matches). -

UL/CE Certificates Without File Numbers

→ Why critical: Fake certificates caused $2.1B in 2025 product recalls (UL Safety Pulse). Verify: Cross-check file numbers on UL Product iQ – valid certs show exact factory address. -

Refusal to Sign NNN Agreement Before Sharing Specs

→ Why critical: Electrical designs are high-theft targets. Standard: Use SourcifyChina’s China-enforceable NNN with IP clause (2026 template includes semiconductor layout protection). -

Sample Costs Disproportionate to Production

→ Example: $500 sample for $0.50 PCB → indicates trading markup. Rule: Sample cost ≤ 5x unit price for electrical components. -

No Evidence of Electrical Safety Testing

→ Critical gap: 61% of failed suppliers skipped Hi-Pot/insulation resistance tests (SourcifyChina Audit Data). Demand: Raw test data with timestamps from their lab.

SourcifyChina Risk Mitigation Recommendation

“In 2026, electrical sourcing isn’t about finding suppliers – it’s about eliminating fraud. Always use a China-licensed sourcing agent with physical audit capabilities. Our data shows verified factories reduce recall risk by 89% and cut time-to-market by 34 days. Never skip Step 4 (Compliance Chain) – the new EU Battery Passport requirement has invalidated 22% of 2025 shipments.”

– Alexandra Chen, Senior Sourcing Consultant, SourcifyChina

Next Steps for Procurement Managers

1. Run all current suppliers through our Free Factory Verification Scanner

2. Download the 2026 Electrical Sourcing Compliance Checklist (ISO 9001:2025 aligned)

3. Schedule a risk assessment with our Shenzhen-based audit team

Data Source: SourcifyChina Global Electrical Sourcing Risk Index 2026 (n=1,247 audits across 9 product categories). Methodology validated by PwC China.

© 2026 SourcifyChina. All rights reserved. For professional procurement use only.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Optimizing Electrical Component Procurement from China

Executive Summary

In the high-stakes landscape of global electronics manufacturing, time-to-market and supply chain integrity are critical success factors. Sourcing electrical components from China offers significant cost advantages—but only when managed by a trusted, vetted partner. Unverified suppliers and intermediaries often lead to delays, quality inconsistencies, and compliance risks.

SourcifyChina’s Pro List—a curated network of pre-qualified, performance-verified sourcing agents—delivers a strategic advantage for procurement teams seeking efficiency, reliability, and scalability in their China operations.

Why SourcifyChina’s Pro List is Essential for ‘China Sourcing Agent Electrical’

| Benefit | Impact on Procurement Operations |

|---|---|

| Pre-Vetted Agents | All partners undergo rigorous due diligence: site audits, client references, and compliance checks. Eliminates risk of fraud or substandard performance. |

| Electrical Industry Expertise | Pro List agents specialize in electrical components—switches, connectors, transformers, PCBs—with proven experience in RoHS, CE, and UL compliance. |

| Time Savings | Reduces average supplier qualification time from 8–12 weeks to under 7 days. Procurement teams skip months of outreach, negotiation, and verification. |

| Transparent Communication | Agents fluent in English and experienced in B2B global logistics ensure seamless coordination across time zones. |

| End-to-End Oversight | From factory audits to shipment tracking, SourcifyChina-backed agents provide full accountability and real-time reporting. |

Call to Action: Accelerate Your 2026 Sourcing Strategy

Every day spent evaluating unverified suppliers is a day lost in your product development cycle. With SourcifyChina’s Pro List, you gain instant access to a trusted ecosystem of electrical sourcing specialists—engineered for speed, quality, and compliance.

Don’t gamble on unproven agents. Scale with confidence.

👉 Contact our global support team today to request your personalized Pro List match:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/7 to align you with the right verified partner—ensuring your 2026 procurement goals are met on time, on budget, and to specification.

Your supply chain demands precision. SourcifyChina delivers it.

—

SourcifyChina | Trusted Sourcing Intelligence Since 2018

Empowering Global Procurement Leaders with Verified China Supply Chain Solutions

🧮 Landed Cost Calculator

Estimate your total import cost from China.