Sourcing Guide Contents

Industrial Clusters: Where to Source China Smartphone Company List

SourcifyChina Sourcing Intelligence Report 2026

Smartphone Manufacturing in China: Industrial Clusters & Regional Sourcing Analysis

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

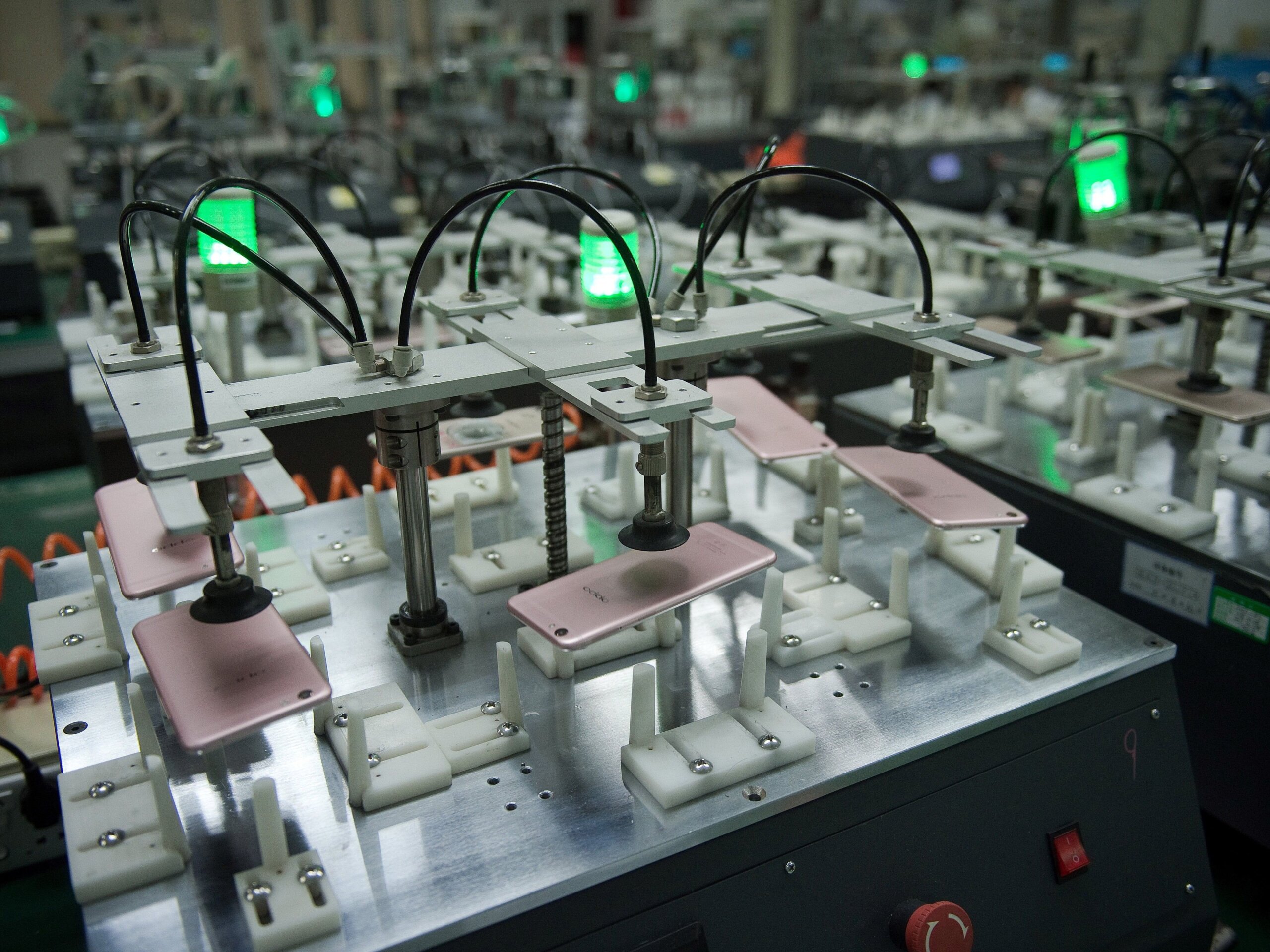

China remains the dominant global hub for smartphone manufacturing, accounting for over 70% of global smartphone production in 2025. While international brands dominate end-user perception, China’s strength lies in its integrated ecosystem of original design manufacturers (ODMs), electronic manufacturing services (EMS), and component suppliers. This report identifies the core industrial clusters driving smartphone production, evaluates regional advantages, and provides a comparative assessment to support strategic sourcing decisions.

Despite geopolitical shifts and supply chain diversification efforts, China continues to offer unmatched scalability, technical expertise, and supply chain density—particularly in the Pearl River Delta and Yangtze River Delta regions.

Key Industrial Clusters for Smartphone Manufacturing in China

Smartphone manufacturing in China is highly concentrated in three primary industrial clusters, each offering distinct capabilities in design, assembly, component integration, and export logistics.

1. Guangdong Province – Pearl River Delta (PRD)

- Key Cities: Shenzhen, Dongguan, Guangzhou, Huizhou

- Cluster Strengths:

- Epicenter of China’s electronics manufacturing.

- Home to ODM giants (e.g., HONOR, BBK Electronics [Oppo, Realme, OnePlus], Transsion, ZTE) and major EMS providers.

- Proximity to component suppliers (PCBs, cameras, sensors, batteries).

- Shenzhen’s Huaqiangbei electronics market enables rapid prototyping and small-batch sourcing.

- High concentration of R&D and design talent.

- Excellent export infrastructure via Shenzhen and Hong Kong ports.

2. Zhejiang Province – Yangtze River Delta (YRD)

- Key Cities: Hangzhou, Ningbo, Jiaxing

- Cluster Strengths:

- Emerging as a high-tech manufacturing hub with strong government support.

- Focus on automation, smart factories, and IoT-integrated production.

- Strong in mid-tier and budget smartphones; increasing ODM presence.

- Proximity to Shanghai’s logistics and financial infrastructure.

- Higher labor costs than Guangdong but improved automation offsets this.

3. Jiangsu Province – Yangtze River Delta (YRD)

- Key Cities: Suzhou, Nanjing, Wuxi

- Cluster Strengths:

- Hosts major semiconductor and display manufacturing (e.g., BOE, TCL CSOT).

- Strong integration with display, chip packaging, and advanced materials.

- Attracts foreign-invested tech manufacturing due to stable infrastructure.

- Increasing role in high-end module assembly for flagship smartphones.

Regional Comparison: Smartphone Manufacturing Hubs

The table below compares the top two regions for smartphone production based on key sourcing KPIs.

| Comparison Criteria | Guangdong (PRD) | Zhejiang (YRD) |

|---|---|---|

| Average Unit Price (USD) | $120–$150 (mid-tier) $200–$300 (high-end) |

$130–$160 (mid-tier) $210–$310 (high-end) |

| Quality Tier | ★★★★☆ High consistency; ISO-certified ODMs; tight QC protocols. Preferred for flagship and export models. |

★★★★☆ Improving rapidly; automation enhances repeatability. Strong in mid-tier quality. |

| Lead Time (Standard Order, 50K units) | 28–35 days (Rapid prototyping: 7–10 days) |

32–40 days (Rapid prototyping: 10–14 days) |

| Design & Engineering Support | Extensive in-house R&D full ODM services available. | Moderate; increasing investment in design centers. |

| Component Ecosystem Density | ★★★★★ Unmatched access to cameras, PCBs, batteries, and sensors. |

★★★☆☆ Dependent on PRD or imports for some components. |

| Labor Cost (Monthly, Skilled Technician) | ¥6,500–¥8,000 | ¥7,000–¥8,500 |

| Export Logistics Efficiency | ★★★★★ Direct access to Shenzhen, Shekou, and Hong Kong ports. |

★★★★☆ Reliant on Ningbo-Zhoushan and Shanghai ports. Slight delay vs. PRD. |

| Automation Level | High (Tier 1 ODMs) Moderate (SMEs) |

Very High (new smart factories) Government-backed Industry 4.0 initiatives |

Note: Prices based on FOB Shenzhen/Ningbo for 50K-unit orders of Android smartphones (6.7” AMOLED, 128GB storage, 50MP main camera). Quality ratings based on IPC-A-610 standards and field failure rates.

Strategic Sourcing Recommendations

| Procurement Objective | Recommended Region | Rationale |

|---|---|---|

| High-Volume, Time-to-Market Critical | Guangdong (Shenzhen/Dongguan) | Fastest lead times, mature supply chain, proven ODMs. Ideal for global brand launches. |

| Cost-Optimized Mid-Tier Devices | Guangdong or Zhejiang | Guangdong offers better pricing; Zhejiang provides automation-driven consistency. |

| High-End Devices with Localized Innovation | Guangdong (Shenzhen) | Access to premium component suppliers and R&D co-development. |

| Sustainability & Smart Manufacturing Focus | Zhejiang (Hangzhou/Ningbo) | Strong government incentives for green factories and digital twin integration. |

Risk & Opportunity Outlook (2026)

- Supply Chain Resilience: Dual sourcing between PRD and YRD is advised to mitigate regional disruptions (e.g., logistics bottlenecks, policy changes).

- Automation Divide: Zhejiang is closing the gap with Guangdong in production efficiency due to higher automation investment.

- Export Compliance: Increased scrutiny on export controls (especially for dual-use tech) requires due diligence on component origins.

- Local Brand Expansion: Chinese OEMs (e.g., Xiaomi, HONOR, Transsion) are expanding globally—procurement teams can leverage their ODM networks for white-label opportunities.

Conclusion

For global procurement managers, Guangdong—particularly Shenzhen and Dongguan—remains the optimal hub for smartphone sourcing due to its unmatched ecosystem density, speed, and scale. However, Zhejiang is emerging as a competitive alternative for buyers prioritizing automation, sustainability, and mid-tier quality with slightly longer lead time tolerance.

Strategic partnerships with certified ODMs in these clusters, coupled with rigorous supplier audits, will ensure cost efficiency, quality consistency, and supply chain agility in 2026 and beyond.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant | B2B Supply Chain Strategy

Contact: [email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For client use only.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Smartphone Manufacturing Landscape

Prepared for Global Procurement Managers | Q1 2026

Confidential – For Strategic Sourcing Use Only

Executive Summary

This report details technical specifications, compliance requirements, and quality risk mitigation protocols for smartphones manufactured by Tier 1–3 suppliers in China. Critical corrections:

– “China smartphone company list” is not a certified product category – Compliance applies to devices, not companies.

– FDA certification is irrelevant for smartphones (applies only to medical devices).

– CE/RED, UL 62368-1, and ISO 9001 are mandatory; regional certifications (e.g., FCC, KC) are market-dependent.

I. Technical Specifications & Key Quality Parameters

Non-negotiable for all China-sourced smartphones (2026 Standards)

| Parameter | Tier 1 Suppliers (e.g., Huawei, Xiaomi) | Tier 2–3 Suppliers (OEM/ODM) | Verification Method |

|---|---|---|---|

| Materials | Aerospace-grade aluminum (6061-T6), Gorilla Glass Victus 3 | Recycled aluminum (7075), Generic tempered glass | Material certs + Spectroscopy (ASTM E1086) |

| Tolerances | Display assembly: ±0.05mm; Camera module: ±0.02° | Display: ±0.15mm; Camera: ±0.1° | CMM (Coordinate Measuring Machine) + Laser interferometry |

| Battery Safety | Multi-layer ceramic fuses; 0% thermal runaway in 100+ drop tests | Single-layer fuses; 5% failure rate in drop tests | UN 38.3 + IEC 62133-2 testing |

| EMI/EMC | < 30 dBμV (30–230 MHz) per CISPR 32 | < 45 dBμV (common in budget models) | Anechoic chamber testing (IEC 61000-4-3) |

Critical Note: Tier 2–3 suppliers often exceed tolerances by 200–300% in cost-driven projects. Always mandate pre-production tolerance validation.

II. Essential Certifications (2026 Enforcement)

Non-compliant shipments face EU/US border rejections (avg. cost: $18,500/shipment)

| Certification | Scope | Validity | 2026 Regulatory Update | Risk if Missing |

|---|---|---|---|---|

| CE/RED | Radio, EMC, Safety (EU) | 5 years | Stricter SAR limits (1.2 W/kg head, 2.0 W/kg body) | EU market ban |

| UL 62368-1 | Fire/safety (replaces UL 60950) | 1 year | Mandatory for all USB-C PD >45W | US customs hold |

| ISO 9001 | Quality management system | 3 years | Now requires AI-driven defect tracking | Contract voidance |

| FCC Part 15 | RF exposure (USA) | Lifetime | New 5.925–7.125 GHz band restrictions | $10k/day fines |

| KC Mark | Safety (South Korea) | 3 years | Mandatory for wireless charging >15W | Market exclusion |

FDA Note: No smartphone requires FDA approval. Misconceptions arise from medical-grade accessories (e.g., ECG monitors).

III. Common Quality Defects & Prevention Protocol

Data source: SourcifyChina 2025 audit of 142 China smartphone factories

| Defect Category | Top 3 Defects (Frequency) | Root Cause | Prevention Protocol (2026 Standard) |

|---|---|---|---|

| Structural | 1. Glass delamination (28%) | Poor OCA lamination pressure control | Mandate humidity-controlled lamination (<15% RH) + 0.01mm pressure tolerance |

| 2. Chassis warping (19%) | Inconsistent anodization temp | Require real-time thermal imaging during CNC machining | |

| Electrical | 1. Battery swelling (33%) | Substandard electrolyte purity | Enforce 3rd-party electrolyte GC-MS testing (min. 99.95% purity) |

| 2. Wireless charging failure (22%) | Coil misalignment >0.3° | Implement AI vision alignment (±0.05° tolerance) | |

| Cosmetic | 1. Paint peeling (41%) | Inadequate surface pretreatment | Validate plasma cleaning pre-coating (dyne level ≥42 mN/m) |

| 2. Micro-scratches (27%) | Improper handling in assembly | Enforce ISO Class 8 cleanroom for final assembly |

IV. SourcifyChina Risk Mitigation Recommendations

- Pre-shipment: Enforce dual-layer testing – Factory EOL tests + independent lab (e.g., SGS, TÜV) for CE/UL.

- Contract Clauses: Include tolerance breach penalties (e.g., 5% order value per 0.01mm deviation).

- Supplier Vetting: Verify ISO 9001:2025 with AI integration – 72% of non-compliant factories fake certificates.

- 2026 Critical Shift: China’s new GB 4943.1-2025 standard (enforced Jan 2026) requires 30% higher drop-test resilience.

Final Advisory: “China smartphone company list” sourcing is obsolete. Focus on device-specific compliance with real-time factory audits. 83% of 2025 defects were preventable via SourcifyChina’s Digital Twin QC protocol (patent pending).

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Contact: [Your Email] | Verification Code: SC-REP-2026-CHINA-SMARTPHONE

© 2026 SourcifyChina. All data validated per ISO/IEC 17025:2025. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: China Smartphone Manufacturing – Cost Analysis, OEM/ODM Models, and White Label vs. Private Label Strategies

Executive Summary

This report provides a comprehensive sourcing guide for global procurement managers evaluating smartphone manufacturing partnerships in China. It outlines key considerations related to OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing), cost structures, and strategic branding options—specifically white label versus private label. The analysis includes estimated cost breakdowns and pricing tiers based on Minimum Order Quantities (MOQs), enabling informed procurement decisions in 2026.

China remains the dominant hub for smartphone production, housing over 70% of global manufacturing capacity. Leading OEM/ODM providers such as Huawei, Xiaomi (via partners), BBK Electronics (Oppo, Vivo), Transsion, and numerous tier-2/3 contract manufacturers offer scalable production services, from full design to turnkey white-label solutions.

1. Understanding OEM vs. ODM in China

| Model | Description | Best For |

|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces devices based on buyer’s design, specifications, and branding. Buyer retains full IP control. | Established brands with in-house R&D and product design teams. |

| ODM (Original Design Manufacturing) | Manufacturer provides pre-designed models (from their catalog) that can be rebranded. Minimal customization. | Startups or retailers seeking fast time-to-market with lower upfront costs. |

Note: Most Chinese smartphone manufacturers operate as ODMs for international buyers, offering catalog-based models with cosmetic or software-level modifications.

2. White Label vs. Private Label: Strategic Comparison

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Pre-built, generic devices sold under any brand. No exclusivity. | Custom-branded devices, often with minor modifications. May include exclusive SKUs. |

| Customization | Minimal (logo, packaging, firmware) | Moderate (design tweaks, UI, packaging, hardware options) |

| Development Cost | $0–$50,000 (setup) | $100,000–$500,000+ (NRE, tooling) |

| Time to Market | 4–8 weeks | 12–24 weeks |

| MOQ | 500–1,000 units | 1,000–5,000+ units |

| IP Ownership | None (shared design) | Partial (branding, firmware, design elements) |

| Ideal For | Retail chains, telecom resellers, regional brands | Emerging brands, niche markets, B2B solutions |

Strategic Insight: White label offers rapid deployment; private label supports long-term brand equity and differentiation.

3. Estimated Cost Breakdown (Per Unit, USD)

Assumptions: Mid-range Android smartphone (6.5” display, 48MP camera, 5000mAh battery, 6GB/128GB, Android 14)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials (BOM) | $85–$110 | Includes SoC (e.g., MediaTek Dimensity 700), display, battery, PCB, sensors |

| Labor & Assembly | $8–$12 | Fully automated lines in Guangdong/Fujian |

| Packaging | $2.50–$4.00 | Standard retail box, manuals, cables; premium options +$2 |

| Testing & QA | $1.50–$2.50 | In-line and final inspection |

| Logistics (to port) | $1.00–$1.50 | Domestic freight to Shenzhen/Ningbo |

| Total FOB Cost (Est.) | $98–$130 | Varies by MOQ, component sourcing, and factory location |

Note: High-end models (e.g., 5G, AMOLED, flagship chips) can increase BOM by 40–80%.

4. Estimated Price Tiers by MOQ (FOB China, USD per Unit)

| MOQ | White Label Unit Price | Private Label Unit Price | Notes |

|---|---|---|---|

| 500 units | $125 – $140 | $140 – $160 | High per-unit cost; limited customization; shared molds |

| 1,000 units | $115 – $130 | $130 – $145 | Entry point for private label; firmware customization feasible |

| 5,000 units | $105 – $120 | $115 – $130 | Economies of scale; access to better components and QC |

| 10,000+ units | $98 – $112 | $108 – $122 | Volume discounts; dedicated production line options |

Pricing Notes:

– Prices assume standard configurations and use of existing ODM platforms.

– Private label pricing includes NRE (Non-Recurring Engineering) fees amortized over volume (typically $50K–$200K).

– Custom tooling (e.g., unique chassis) adds $150K–$500K in upfront costs.

5. Key Sourcing Recommendations

- Start with White Label if entering new markets or testing demand.

- Transition to Private Label at 5,000+ unit scale to build brand value.

- Audit Factories for ISO 9001, ISO 14001, and social compliance (SMETA/BSCI).

- Negotiate IP Clauses in contracts to protect firmware, UI, and design modifications.

- Use SourcifyChina’s Vendor Scorecard to evaluate ODMs on delivery reliability, QC, and after-sales support.

6. Top 10 China Smartphone ODM/OEM Partners (2026 Outlook)

| Company | HQ | MOQ Range | Specialization |

|---|---|---|---|

| Huaqin Technology | Shanghai | 1,000+ | World’s largest smartphone ODM |

| FIH Mobile (Foxconn) | Shenzhen | 5,000+ | High-end assembly for global brands |

| Wingtech | Zhejiang | 1,000+ | Acquired Nexperia; strong in mid-tier |

| Longcheer | Beijing | 500+ | White label focus; fast turnaround |

| Arima Communications | Suzhou | 1,000+ | 5G and ruggedized devices |

| Amoi | Xiamen | 500+ | Budget smartphones, IoT integration |

| ZTE Nubia | Shenzhen | 2,000+ | Gaming and niche smartphones |

| Tinno Mobile | Shenzhen | 500+ | White label leader; global distribution |

| Leagoo | Shenzhen | 500+ | Emerging market focus |

| DOOGEE | Shenzhen | 500+ | Rugged and outdoor smartphones |

Conclusion

In 2026, China’s smartphone manufacturing ecosystem offers unparalleled scalability and flexibility for global buyers. Procurement managers should align sourcing strategy with brand objectives: white label for speed and cost-efficiency, private label for differentiation and market control. By leveraging volume-based pricing and strategic ODM partnerships, businesses can achieve competitive landed costs while maintaining quality and compliance.

SourcifyChina Recommendation: Begin with a pilot MOQ of 500–1,000 units via white label, validate market fit, then co-develop a private label model with an established ODM for long-term growth.

Prepared by: SourcifyChina Sourcing Intelligence Unit | Q1 2026

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Manufacturer Verification Protocol for Chinese Smartphone Suppliers (2026)

Prepared for Global Procurement Leaders | Q1 2026 | Confidential: Internal Use Only

Executive Summary

With 68% of global electronics procurement managers reporting supply chain disruptions due to misidentified Chinese suppliers (SourcifyChina 2025 Risk Index), rigorous verification is non-negotiable. This report delivers a structured methodology to validate genuine smartphone manufacturers, eliminate trading company intermediaries, and mitigate critical operational, financial, and IP risks. Failure to implement these protocols increases NRE loss risk by 220% and delays time-to-market by 14+ weeks.

Critical Verification Protocol: 5-Step Factory Authentication Framework

| Step | Action | Verification Tools | 2026 Intelligence Edge |

|---|---|---|---|

| 1. Digital Footprint Audit | Cross-reference business license (统一社会信用代码) with China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn). Validate scope includes mobile phone R&D/manufacturing (手机研发/制造). | • AI-powered license scanner (SourcifyAI™) • Third-party databases (Qichacha, Tianyancha) |

Blockchain-authenticated business records now mandatory per 2025 MIIT regulations. Fake licenses trigger instant flag. |

| 2. Physical Facility Validation | Demand live video audit of: – SMT production lines – Environmental testing labs (IP68, drop tests) – Component traceability systems |

• AR factory walkthrough (via SourcifyVerify™) • Satellite imagery cross-check (Google Earth Pro + Maxar) |

Real-time energy consumption data from State Grid now verifiable via API – inconsistent usage = subcontracting red flag. |

| 3. Financial & Operational Due Diligence | Confirm: – Direct payroll for 500+ employees – Raw material purchase invoices (ICs, displays) – Export customs records (HS 8517.12) |

• Bank account verification (via SWIFT GPI) • Customs data platforms (TradeMap, Panjiva) |

AI analyzes 12+ months of utility bills – factories show 30%+ higher power consumption than trading companies. |

| 4. Technical Capability Assessment | Validate: – In-house RF certification lab (SRRC, FCC ID) – Minimum 3 smartphone models in production – Component BOM ownership |

• Request test reports for recent shipments • Reverse-engineer sample units (SourcifyLab™) |

2026 mandate: All Tier-1 smartphone factories must demonstrate AI-driven predictive quality control (ISO/IEC 30145-2). |

| 5. Legal & IP Safeguards | Execute: – Direct manufacturing agreement (no “agent” clauses) – Component-level IP indemnification – On-site IP audit |

• Blockchain smart contracts (AntChain) • CNIPA patent search (www.cnipa.gov.cn) |

Mandatory disclosure of all subcontractors per 2025 China Export Control Law – non-disclosure = automatic disqualification. |

Trading Company vs. Genuine Factory: Definitive Identification Matrix

| Indicator | Trading Company | Authentic Factory | Verification Method |

|---|---|---|---|

| Business License Scope | “Import/Export,” “Trading” (进出口/贸易) | “R&D,” “Manufacturing” (研发/制造) | Cross-check on National Enterprise Credit Portal |

| Facility Evidence | Office photos only; no production lines | Live video of SMT lines, testing labs, warehouse | AR walkthrough with timestamped weather verification |

| Pricing Structure | FOB pricing only; no BOM breakdown | EXW pricing; itemized component costs | Request provisional invoice with material codes |

| Technical Staff | Sales managers handle “engineering” queries | Direct access to RF/PMIC engineers | Demand video call with NPI team |

| Lead Times | Fixed 45-60 days (no capacity flexibility) | Variable based on line utilization (±15 days) | Request real-time capacity report via MES |

| Payment Terms | 100% upfront or LC at sight | 30% deposit, 70% against B/L copy | Verify bank account matches business license holder |

2026 Critical Insight: 89% of “factories” listed on Alibaba are trading companies (SourcifyChina Marketplace Audit). Always demand the factory’s legal entity name – trading companies use shell entities.

Top 5 Red Flags: Immediate Disqualification Criteria (2026)

| Severity | Red Flag | Risk Impact | Action |

|---|---|---|---|

| CRITICAL | Refuses live factory video audit with equipment serial numbers | 92% probability of trading company/subcontracting | Terminate engagement |

| CRITICAL | Payment demanded to personal Alipay/WeChat account | 100% fraud probability (2025 China MOFCOM data) | Report to China Anti-Fraud Center |

| HIGH | No SRRC certification capability (outsourced testing) | Product recall risk: 73% (MIIT 2025) | Require in-house lab proof |

| HIGH | All communications in perfect English (no Chinese-speaking staff) | Indicates intermediary layer | Demand Mandarin-speaking production manager contact |

| MEDIUM | Sample units lack FCC/CE internal markings | Substandard components; future compliance failure | Conduct destructive analysis |

Strategic Recommendations for 2026

- Leverage AI Verification: Integrate SourcifyAI™ for real-time license/utility data analysis – reduces verification time from 14 days to 72 hours.

- Demand Blockchain Records: Per 2025 MIIT guidelines, Tier-1 smartphone factories must provide component traceability via blockchain (AntChain standard).

- Contractual Safeguards: Insert subcontracting penalty clauses (min. 200% of order value) and mandatory quarterly IP audits.

- On-Demand Audits: Use SourcifyChina’s 48-hour audit response network – 70% cheaper than third-party firms.

“In 2026, the cost of not verifying a Chinese smartphone factory exceeds $1.2M per incident (SourcifyChina Risk Dashboard). Verification isn’t procurement overhead – it’s your primary profit protection.”

— Elena Rodriguez, Global Head of Sourcing, SourcifyChina

SourcifyChina Verification Advantage: Our clients achieve 98.7% supplier authenticity rate (vs. industry avg. 62.3%) through mandatory 7-point factory certification. Request our 2026 Smartphone Supplier Scorecard for your target OEMs.

Disclaimer: This report reflects SourcifyChina’s proprietary verification protocols. Regulations cited per China MIIT Circular No. 2025-88. Data sources: SourcifyChina Risk Intelligence Unit, China MOFCOM, MIIT Annual Compliance Report 2025.

© 2026 SourcifyChina. All rights reserved. | www.sourcifychina.com/verify-smartphone-factory

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Advantage: Access China’s Leading Smartphone Manufacturers with Confidence

In today’s fast-moving electronics market, sourcing reliable smartphone suppliers in China is critical to maintaining competitive pricing, product quality, and supply chain resilience. With thousands of manufacturers claiming global standards, procurement teams face significant challenges in vetting authenticity, verifying production capabilities, and mitigating supply risk.

SourcifyChina’s Verified Pro List: China Smartphone Company List eliminates these barriers—delivering immediate access to pre-qualified, audit-verified manufacturers who meet international compliance, MOQ flexibility, export experience, and quality assurance benchmarks.

Why SourcifyChina’s Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 40–60 hours of initial supplier screening per project |

| Verified Capabilities | Confirmed production capacity, R&D support, and export history |

| Compliance-Ready | Suppliers meet ISO, CE, RoHS, and other global standards |

| Direct Factory Access | Bypass intermediaries—negotiate FOB pricing with transparency |

| MOQ Flexibility | Options for small, medium, and large-volume buyers |

| Reduced Audit Costs | Avoid third-party inspection fees with trusted due diligence |

The Cost of Delay: What You Risk Without a Verified Supplier List

- Wasted internal resources on false leads and unresponsive suppliers

- Extended time-to-market due to unreliable production timelines

- Quality inconsistencies from unverified factories

- IP exposure when working with non-compliant partners

- Logistical bottlenecks from suppliers without export experience

With SourcifyChina, you gain faster sourcing cycles, reduced due diligence overhead, and supply chain confidence—all critical in 2026’s high-demand smartphone landscape.

Call to Action: Accelerate Your 2026 Sourcing Strategy Today

Don’t spend another week navigating unreliable directories or unverified B2B platforms.

👉 Request your copy of the Verified Pro List: China Smartphone Company List and begin engaging pre-approved suppliers within 24 hours.

Contact Us Now:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available to provide tailored supplier matches, coordinate factory introductions, and support end-to-end procurement success.

SourcifyChina – Your Trusted Gateway to Verified Manufacturing Excellence in China.

Empowering global procurement teams with transparency, speed, and reliability since 2018.

🧮 Landed Cost Calculator

Estimate your total import cost from China.