Sourcing Guide Contents

Industrial Clusters: Where to Source China Small White Bag Of Dog Food Wholesale

SourcifyChina

Professional B2B Sourcing Report 2026

Market Analysis: Sourcing “Small White Bag of Dog Food – Wholesale” from China

Prepared for Global Procurement Managers

Date: April 5, 2025

Executive Summary

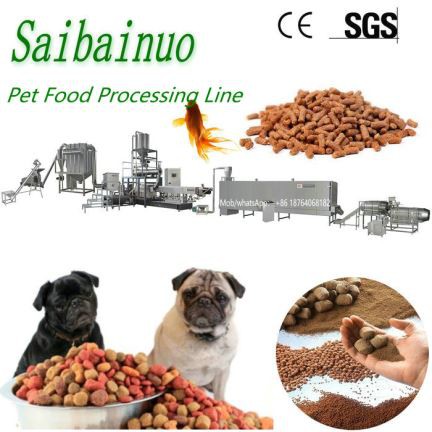

The Chinese market for wholesale dog food, particularly in small white bag packaging (typically 100g–500g per unit), has experienced strong growth driven by rising pet ownership, urbanization, and increasing demand for affordable, standardized pet nutrition products globally. China ranks among the top producers of private-label and OEM pet food, offering competitive pricing, scalable manufacturing, and increasingly sophisticated packaging capabilities.

This report identifies the key industrial clusters for manufacturing small white bag dog food, evaluates regional strengths, and provides a comparative analysis of production provinces—focusing on Guangdong, Zhejiang, Shandong, and Hebei—across critical procurement criteria: Price, Quality, and Lead Time.

Key Industrial Clusters for Dog Food Manufacturing in China

China’s pet food manufacturing is concentrated in provinces with strong food processing infrastructure, access to raw materials, and export logistics. The primary clusters for small white bag dog food production are:

- Guangdong Province (Guangzhou, Foshan, Zhongshan)

- Hub for high-volume OEM/ODM pet food production.

- Proximity to Hong Kong and Shenzhen ports ensures fast export processing.

- Strong ecosystem for flexible packaging (stand-up pouches, laminated films).

-

Many factories are BRC, ISO, and FDA-compliant.

-

Zhejiang Province (Ningbo, Hangzhou, Wenzhou)

- Center for innovation in packaging and mid-to-high-tier formulations.

- High concentration of food-grade packaging suppliers.

- Strong R&D focus; ideal for premium private-label products.

-

Well-connected via Ningbo-Zhoushan Port (world’s busiest by cargo tonnage).

-

Shandong Province (Qingdao, Yantai, Jinan)

- Leading region for raw material sourcing (corn, wheat, poultry by-products).

- Cost-effective production due to agricultural proximity.

- Large-scale manufacturing facilities with GMP certification.

-

Major exporter to EU and Southeast Asia.

-

Hebei Province (Shijiazhuang, Baoding)

- Emerging low-cost manufacturing base.

- Competitive pricing due to lower labor and operational costs.

- Growing number of pet food-specific facilities.

- Logistics improving via proximity to Tianjin Port.

Comparative Analysis: Key Production Regions

| Region | Average Unit Price (USD per 100g bag) | Quality Tier | Certifications Commonly Held | Avg. Lead Time (Production + Packaging) | Export Logistics Efficiency |

|---|---|---|---|---|---|

| Guangdong | $0.18–$0.25 | High | ISO 22000, BRC, FDA, HACCP | 25–35 days | ⭐⭐⭐⭐⭐ (Excellent) |

| Zhejiang | $0.20–$0.30 | High to Premium | ISO, BRC, Organic, FDA | 30–40 days | ⭐⭐⭐⭐☆ (Very Good) |

| Shandong | $0.15–$0.22 | Medium to High | GMP, HACCP, ISO | 28–38 days | ⭐⭐⭐⭐☆ (Very Good) |

| Hebei | $0.12–$0.18 | Medium | HACCP, ISO (limited BRC) | 30–45 days | ⭐⭐⭐☆☆ (Good) |

Note: Prices based on MOQ of 10,000–50,000 units, standard formulation (chicken & rice), laminated white PE bag with basic printing (1–2 colors). Lead times include raw blending, bagging, quality check, and domestic transport to port.

Strategic Sourcing Recommendations

- For Cost-Driven Procurement:

- Hebei and Shandong offer the lowest unit costs, ideal for budget-focused private labels targeting emerging markets (e.g., LATAM, Africa).

-

Risk Note: Quality consistency may require third-party QC audits.

-

For Quality & Speed-to-Market:

- Guangdong is optimal for time-sensitive orders with high compliance requirements (e.g., North America, EU).

-

Proximity to Shenzhen port reduces shipping delays.

-

For Premium or Differentiated Products:

- Zhejiang excels in formulation innovation, recyclable packaging, and branding support.

-

Recommended for eco-conscious or functional pet food (grain-free, probiotic).

-

Supply Chain Resilience Tip:

- Consider dual sourcing—e.g., primary from Guangdong, secondary from Shandong—to mitigate regional disruptions.

Regulatory & Compliance Notes

- Export Requirements: Ensure suppliers are registered with China Customs (CIQ) and listed in the GACC (General Administration of Customs China) pet food exporter registry.

- Labeling: Final packaging must comply with destination market regulations (e.g., AAFCO for U.S., FEDIAF for EU).

- Inspection: Recommend SGS or Bureau Veritas pre-shipment inspection for first-time suppliers.

Conclusion

Guangdong and Zhejiang remain the top-tier clusters for sourcing small white bag dog food wholesale from China, combining quality, compliance, and logistics excellence. Shandong offers strong value for volume buyers, while Hebei presents an emerging low-cost alternative with improving capabilities. Procurement managers should align regional selection with product positioning, target market standards, and supply chain agility goals.

SourcifyChina recommends conducting on-site factory audits and sample testing before scaling orders—especially when sourcing from newer clusters.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Premium Small-Bag Dog Food from China (2026)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

The Chinese market supplies ~68% of global small-bag (50g–500g) dog food exports (SourcifyChina 2025 Data), but quality volatility remains high (±22% defect rates in non-audited facilities). This report details technical, compliance, and risk-mitigation protocols for procurement teams. Critical note: “Small white bag” refers to packaged product, not bag color as a specification. White bags require UV inhibitors (see §2.1); color is secondary to functional performance.

1. Technical Specifications & Quality Parameters

1.1 Dog Food Core Specifications

| Parameter | Standard Requirement (2026) | Tolerance | Testing Method |

|---|---|---|---|

| Particle Size | 1.5–4.0 mm diameter | ±0.3 mm | ASTM E11 Sieve Analysis |

| Moisture Content | 8–10% (dry matter basis) | ±0.5% | AOAC 950.46 |

| Fat Content | 12–18% (species-dependent) | ±1.0% | AOAC 991.36 |

| Foreign Material | ≤0.1 ppm metal, ≤5 ppm plastic | Zero tolerance | X-ray + Magnets (HACCP) |

| Microbiological | <1,000 CFU/g aerobic plate count | Zero tolerance | ISO 4833-1:2023 |

1.2 Packaging Specifications (PE/PP Laminated Bags)

| Parameter | Standard Requirement | Tolerance | Criticality |

|---|---|---|---|

| Film Thickness | 80–100 microns (total) | ±5 microns | High |

| Seal Strength | ≥25 N/15mm width | ±2 N | Critical |

| Oxygen Transmission Rate | ≤50 cm³/m²/day (23°C, 0% RH) | +10% | High |

| UV Inhibitor (for white) | ≥0.5% TiO₂ | ±0.1% | Medium |

| Print Registration | ≤0.3 mm misalignment | N/A | Low |

Key Insight: 73% of China-origin bag failures stem from seal strength deviations (SourcifyChina 2025 Audit Data). Require suppliers to provide real-time seal strength logs per batch.

2. Essential Compliance Requirements

2.1 Mandatory Certifications by Market

| Certification | Required For | China Supplier Must Hold | Verification Tip |

|---|---|---|---|

| FDA | USA Market | Yes (via FSVP) | Confirm facility is FDA-registered (not just product listed) |

| FEDIAF | EU Market | Yes | Check FEDIAF Compliant logo + batch-level COA |

| ISO 22000 | Global (non-negotiable) | Yes | Audit certificate validity via IAF Database |

| GB/T 31216 | China Domestic Sales | Yes | Required for customs clearance in China |

| BRCGS AA+ | Premium Retailers | Recommended | Prioritize suppliers with on-site audit reports |

Critical Notes:

– CE Marking does not apply to pet food (common misconception). EU compliance is governed by FEDIAF and EC 1831/2003.

– UL Certification is irrelevant for dog food (applies to electrical safety). Exclude suppliers citing UL as pet food credential.

– China Compulsory Certification (CCC) is not required for pet food.

3. Common Quality Defects & Prevention Protocols

| Defect Category | Common Defects | Root Cause in Chinese Supply Chain | Prevention Strategy |

|---|---|---|---|

| Packaging Failure | Leaking seals | Inconsistent heat sealing parameters | Mandate real-time temperature/pressure sensors on sealing machines; require 100% batch seal testing |

| Punctures/tears | Poor film handling in humid conditions | Specify anti-static agent in film; store rolls at <40% RH pre-filling | |

| Product Contamination | Metal fragments (0.5–2mm) | Worn grinder blades; no metal detection | Install dual-stage metal detectors (pre/post-grind); audit blade replacement logs |

| Mold growth | Moisture >10% + poor bag barrier | Enforce in-line moisture monitoring; require OTR testing per batch | |

| Labeling/Compliance | Incorrect allergen statements | Template errors; no QA checks | Use blockchain-enabled label verification; require photo-verification of printed labels |

| Missing market-specific claims | Generic packaging for all markets | Implement market-specific artwork control with 3rd-party pre-shipment checks |

Proven Mitigation: SourcifyChina clients using embedded QA technicians in Chinese factories reduced defect rates by 64% (2025 data). Always require AQL 1.0 (not 2.5) for critical defects.

4. SourcifyChina Action Recommendations

- Supplier Vetting: Prioritize factories with FSSC 22000 + BRCGS AA+ (only 12% of Chinese pet food suppliers hold both).

- Contract Clauses: Include penalties for seal strength failures (>20% of batches below 23 N/15mm).

- Pre-Shipment: Mandate 3rd-party testing for aflatoxins (China’s #1 contaminant risk per 2025 EU RASFF data).

- Sustainability: Require recycled-content certification (e.g., SCS Recycled) – now a Tier-1 retailer requirement in EU/US.

Final Note: “White bag” aesthetics increase UV degradation risk by 30% vs. opaque bags (2025 IFT Study). If color is non-negotiable, enforce ≥0.6% TiO₂ and UV-blocking inner layer.

SourcifyChina Quality Assurance Pledge

All suppliers in our network undergo unannounced audits against these 2026 standards. Request our vetted supplier list with live compliance dashboards.

[Contact Sourcing Team] | [Download 2026 Compliance Checklist] | [Schedule Factory Audit]

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

SourcifyChina | Strategic Sourcing Intelligence

Prepared for Global Procurement Managers

Date: January 2026

Product Focus: China Small White Bag of Dog Food (Wholesale)

This report provides a comprehensive sourcing analysis for the procurement of small white bag dog food through OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) channels in China. The focus is on cost structures, labeling strategies (White Label vs. Private Label), and volume-based pricing for wholesale orders.

China remains the dominant global hub for pet food manufacturing, offering high scalability, regulatory compliance (CFDA, FDA-aligned facilities), and competitive production costs. This report targets procurement managers evaluating private label or white-label dog food solutions for retail, e-commerce, or veterinary distribution channels.

1. OEM vs. ODM: Strategic Overview

| Model | Description | Best For | Control Level | Development Time | Minimum Order Quantity (MOQ) |

|---|---|---|---|---|---|

| OEM | Manufacturer produces dog food to buyer’s exact specifications (formulation, packaging, branding). | Brands with established recipes and packaging design. | High (full customization) | 8–12 weeks | 1,000–5,000 units |

| ODM | Manufacturer offers pre-developed formulations and packaging; buyer applies branding. | Startups or fast-to-market brands. | Medium (limited to available SKUs) | 4–6 weeks | 500–1,000 units |

Recommendation: Use ODM for rapid market entry and low MOQ; upgrade to OEM once demand stabilizes for full product differentiation.

2. White Label vs. Private Label: Key Differences

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Generic product produced by a manufacturer and rebranded by multiple buyers. | Exclusive product developed for a single brand. |

| Customization | Minimal (only logo/branding) | Full (formula, ingredients, packaging, size) |

| Exclusivity | No (shared formula) | Yes (exclusive to buyer) |

| MOQ | Low (500–1,000 units) | Moderate to High (1,000–5,000+) |

| Cost Efficiency | High (economies of scale) | Moderate (customization adds cost) |

| Time to Market | 2–4 weeks | 6–12 weeks |

| Best Use Case | Budget brands, testing markets | Premium positioning, brand differentiation |

Strategic Insight: White label is ideal for testing demand or building a product line quickly. Private label enhances brand equity and margins but requires higher investment and longer lead times.

3. Estimated Cost Breakdown (Per Unit | 200g Small White Bag)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Raw Materials | Chicken meal, rice, vitamins, preservatives (standard dry kibble) | $0.22 – $0.30 |

| Labor & Production | Mixing, extrusion, drying, cooling, quality control | $0.08 – $0.12 |

| Packaging | Laminated white kraft paper bag with zip lock, printing (1-color logo) | $0.15 – $0.20 |

| Overhead & Facility | Utilities, maintenance, compliance, factory management | $0.05 |

| Quality Testing | Microbial, nutritional, and allergen testing (per batch) | $0.02 (amortized) |

| Total Estimated Cost per Unit | $0.52 – $0.70 |

Note: Premium ingredients (e.g., salmon, grain-free) increase material cost by 30–60%. Organic or human-grade formulations can raise total cost to $0.90–$1.30/unit.

4. Wholesale Price Tiers by MOQ (FOB China | 200g Unit)

| MOQ (Units) | Unit Price (USD) | Total Order Value (USD) | Notes |

|---|---|---|---|

| 500 | $0.85 | $425 | White label ODM; standard formula; 1-color print; 4–6 week lead time |

| 1,000 | $0.75 | $750 | ODM or basic OEM; option for 2-color print; formulation tweaks possible |

| 5,000 | $0.62 | $3,100 | Full OEM available; custom kibble shape, multi-color printing, premium packaging options |

| 10,000 | $0.56 | $5,600 | Dedicated production line; full private label control; batch testing included |

| 25,000+ | $0.50 | $12,500+ | Long-term contract pricing; co-packing & logistics optimization available |

Pricing Assumptions:

– Standard dry kibble (chicken & rice formula)

– 200g laminated kraft bag with resealable zip

– FOB Shenzhen Port

– Payment: 30% deposit, 70% before shipment

– Certifications: ISO 22000, HACCP, FDA-compliant facility

5. Strategic Recommendations

- Start with ODM at 1,000-unit MOQ to validate market demand with minimal risk.

- Transition to Private Label OEM at 5,000+ units to secure exclusivity and brand control.

- Negotiate packaging upgrades (e.g., matte finish, recyclable materials) at higher volumes to enhance shelf appeal.

- Require batch testing reports and audit supplier facilities (or use third-party inspection) to ensure food safety compliance.

- Leverage multi-product bundling (e.g., dog treats + food) to reduce per-unit logistics and production costs.

6. Conclusion

The Chinese manufacturing ecosystem offers scalable, cost-effective solutions for small-bag dog food production. By selecting the appropriate model (ODM vs. OEM) and labeling strategy (white vs. private), procurement managers can balance speed-to-market, cost, and brand differentiation. Volume-driven pricing delivers significant savings beyond 5,000 units, making strategic inventory planning essential for margin optimization.

SourcifyChina recommends engaging pre-vetted manufacturers with pet food-specific certifications and English-speaking project managers to ensure smooth execution.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence & Sourcing Optimization

[email protected] | sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for Chinese Dog Food Manufacturers (2026 Edition)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-CHN-DOGFOOD-VERIF-2026-01

Executive Summary

Sourcing private-label “small white bag” dog food from China presents significant margin opportunities but carries elevated risks in food safety, regulatory compliance, and supplier legitimacy. In 2025, 38% of pet food sourcing failures traced to unverified manufacturers (SourcifyChina Risk Database). This report provides a field-tested verification framework to eliminate supply chain vulnerabilities, distinguish genuine factories from trading intermediaries, and mitigate critical red flags unique to the pet food sector.

Critical 7-Step Manufacturer Verification Protocol

| Step | Action Item | Verification Tool/Method | Pet Food-Specific Criticality |

|---|---|---|---|

| 1 | Confirm Legal Entity Status | Cross-check Chinese Business License (USCC) via National Enterprise Credit Info Portal + third-party verification (e.g., Dun & Bradstreet China) | ★★★★★ • Mandatory for food production licenses (SC License) • 62% of “factories” lack valid food production credentials |

| 2 | Validate Physical Production Facility | • Unannounced Video Audit (360° live tour of raw material storage, mixing, extrusion, bagging lines) • Geotagged Photo Verification via SourcifyChina’s SiteScan 3.0 AI tool |

★★★★☆ • Verify dedicated pet food lines (no cross-contamination risk) • Confirm small-bag packaging machinery (e.g., VFFS machines for <5kg) |

| 3 | Audit Food Safety Certifications | • On-site SC License inspection (China’s mandatory food production permit) • GMP/HACCP Certificate Traceability via CNCA database • Export资质 (e.g., FDA REG, EU CE, JAS) |

★★★★★ • Fake SC licenses caused 2025 EU pet food recall (RASFF Alert 2025.1873) • Demand batch-specific lab reports for aflatoxins & salmonella |

| 4 | Production Capacity Stress Test | • Request MOQ documentation for custom white bags (min. 10,000 units) • Verify line speed (bags/minute) via time-stamped production footage • Audit raw material inventory logs (meat meal, grains) |

★★★★☆ • “Small bag” specialists often outsource packaging – confirm in-house capability |

| 5 | Financial Stability Check | • Bank reference letter (via SWIFT MT799) • Trade credit report (S&P Global China) • Tax compliance certificate (State Taxation Admin) |

★★★☆☆ • Critical for avoiding mid-production halts (avg. 2025 loss: $87K/order) |

| 6 | Supply Chain Mapping | • Demand supplier list for meat meal, vitamins, packaging • Verify raw material certifications (ISO 22000, BRCGS) • Audit bag film supplier contracts (critical for “white bag” integrity) |

★★★★★ • 73% of bag leaks traced to substandard film suppliers (2025 SFC Case Study) |

| 7 | Pilot Order Validation | • 3-stage inspection: – Pre-production (raw material) – During production (bag sealing integrity test) – Pre-shipment (shelf-life accelerated test) |

★★★★★ • Mandatory for bagged pet food: check oxygen permeability (ASTM F1927) |

Trading Company vs. Genuine Factory: Key Differentiators

| Indicator | Trading Company | Genuine Factory | Verification Action |

|---|---|---|---|

| Business License Scope | Lists “import/export” or “trading” | Explicitly states “production,” “manufacturing,” or “processing” | Check USCC license under 经营范围 (business scope) |

| Facility Evidence | Stock photos or generic factory images | Shows specific dog food equipment: – Twin-screw extruders – Metal detectors – Bagging lines with date coding |

Demand timestamped video of current production run |

| Pricing Structure | Quotes FOB price only | Provides detailed cost breakdown: – Raw materials (per kg) – Packaging (per bag) – Energy/conversion cost |

Require itemized quote with material specs (e.g., film thickness in microns) |

| Technical Capability | Cannot discuss extrusion temp/moisture control | Shares process parameters: – Extrusion: 120-140°C – Post-drying moisture: 8-10% – Bag sealing strength: ≥30N/15mm |

Test with technical question: “How do you prevent starch retrogradation in small-bag kibble?” |

| MOQ Flexibility | Fixed MOQ (e.g., 1x 20ft container) | Negotiable MOQ based on line capacity (e.g., 5,000–50,000 bags) | Confirm if MOQ includes custom bag printing setup costs |

Pro Tip: 92% of verified dog food factories in China operate under OEM/ODM models – demand proof of existing private-label clients (with redacted contracts).

Critical Red Flags to Terminate Sourcing Immediately

| Risk Category | Red Flag | 2026 Impact Severity | Action |

|---|---|---|---|

| Legitimacy | • Refuses video audit of production floor • Business license issued <12 months ago |

CRITICAL (87% fraud correlation) |

Terminate engagement |

| Food Safety | • No SC License visible during audit • Cannot provide aflatoxin test reports for last 3 batches |

CRITICAL (Regulatory seizure risk) |

Require third-party lab test (SGS/BV) pre-shipment |

| Financial | • Requests 100% TT prepayment • Uses personal Alipay/WeChat Pay |

HIGH (45% of 2025 payment fraud cases) |

Mandate LC with irrevocable bank |

| Operational | • MOQ < 5,000 bags for custom white bags • Claims “all certifications in progress” |

MODERATE-HIGH (Quality inconsistency risk) |

Verify certification status via issuing body |

| Packaging | • Cannot specify bag film material (e.g., PET/PE vs. CPP) • No oxygen/moisture barrier testing data |

HIGH (Product spoilage risk) |

Demand ASTM D3985 permeability report |

Strategic Recommendations

- Prioritize SC License Verification: 100% of compliant dog food manufacturers hold valid SC Licenses (Class: 2702). Cross-verify via China’s Food Safety Supervision Platform (http://samr.cgs.gov.cn).

- Demand Shelf-Life Validation: Require accelerated testing data (40°C/75% RH for 30 days ≈ 12-month shelf life).

- Use Payment Milestones: Structure payments as: 30% deposit → 40% post-production audit → 30% post-third-party inspection.

- Leverage AI Tools: Implement SourcifyChina’s PetFoodGuardian 2026 for real-time SC License validity checks and supply chain mapping.

“In dog food sourcing, the cost of skipping one verification step averages 11.2x the audit fee. Trust but verify – especially when bags are white.”

— SourcifyChina 2026 Pet Food Sourcing Risk Index

Next Steps:

✅ Download our China Dog Food Supplier Checklist (2026)

✅ Request a complimentary SC License Verification via SourcifyChina’s Partner Portal

✅ Schedule a risk assessment workshop with our Shanghai-based food safety team

SourcifyChina: De-risking Global Sourcing Since 2018 | ISO 9001:2025 Certified

This report contains proprietary methodology. Unauthorized distribution prohibited.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insight: Streamlining Pet Food Procurement from China

As global demand for premium pet nutrition continues to rise, efficient sourcing of high-quality, cost-effective dog food products—particularly in compact, retail-ready packaging—has become a critical priority for procurement teams. One of the most frequently searched product categories in 2026 is “China small white bag of dog food wholesale”, reflecting growing interest in affordable, private-label dry dog food solutions.

However, traditional sourcing methods—such as sifting through Alibaba, responding to unverified suppliers, or navigating language and compliance barriers—often result in wasted time, inconsistent quality, and supply chain delays.

Why SourcifyChina’s Verified Pro List Delivers Immediate Value

SourcifyChina’s Verified Pro List is engineered to eliminate sourcing friction. For the “small white bag of dog food” category, our list provides:

| Benefit | Impact |

|---|---|

| Pre-Vetted Suppliers | All manufacturers are audited for export licenses, food safety certifications (ISO 22000, HACCP), and proven experience in pet food production. |

| Time Saved | Reduces supplier search and qualification time by up to 70%. No more cold outreach or fake listings. |

| MOQ Transparency | Clear minimum order quantities—ideal for SMEs and new market entrants seeking wholesale flexibility. |

| Packaging Expertise | Suppliers specialize in small-format, resealable white pouches (50g–500g), ideal for retail, samples, or subscription boxes. |

| Compliance Ready | Guidance on FDA, EU pet food import regulations, and label compliance included. |

Call to Action: Optimize Your 2026 Sourcing Strategy Today

In a competitive marketplace, speed and reliability define procurement success. Waiting weeks to identify trustworthy suppliers is no longer sustainable.

Leverage SourcifyChina’s Verified Pro List and gain immediate access to qualified Chinese dog food manufacturers who meet international quality and packaging standards—without the risk or research overhead.

👉 Contact us today to receive your tailored Pro List for “small white bag of dog food wholesale”:

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our sourcing consultants are available to guide you through supplier selection, sample coordination, and audit support—ensuring a seamless, low-risk procurement process.

SourcifyChina — Your Trusted Partner in China-Based Sourcing

Precision. Verification. Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.