Sourcing Guide Contents

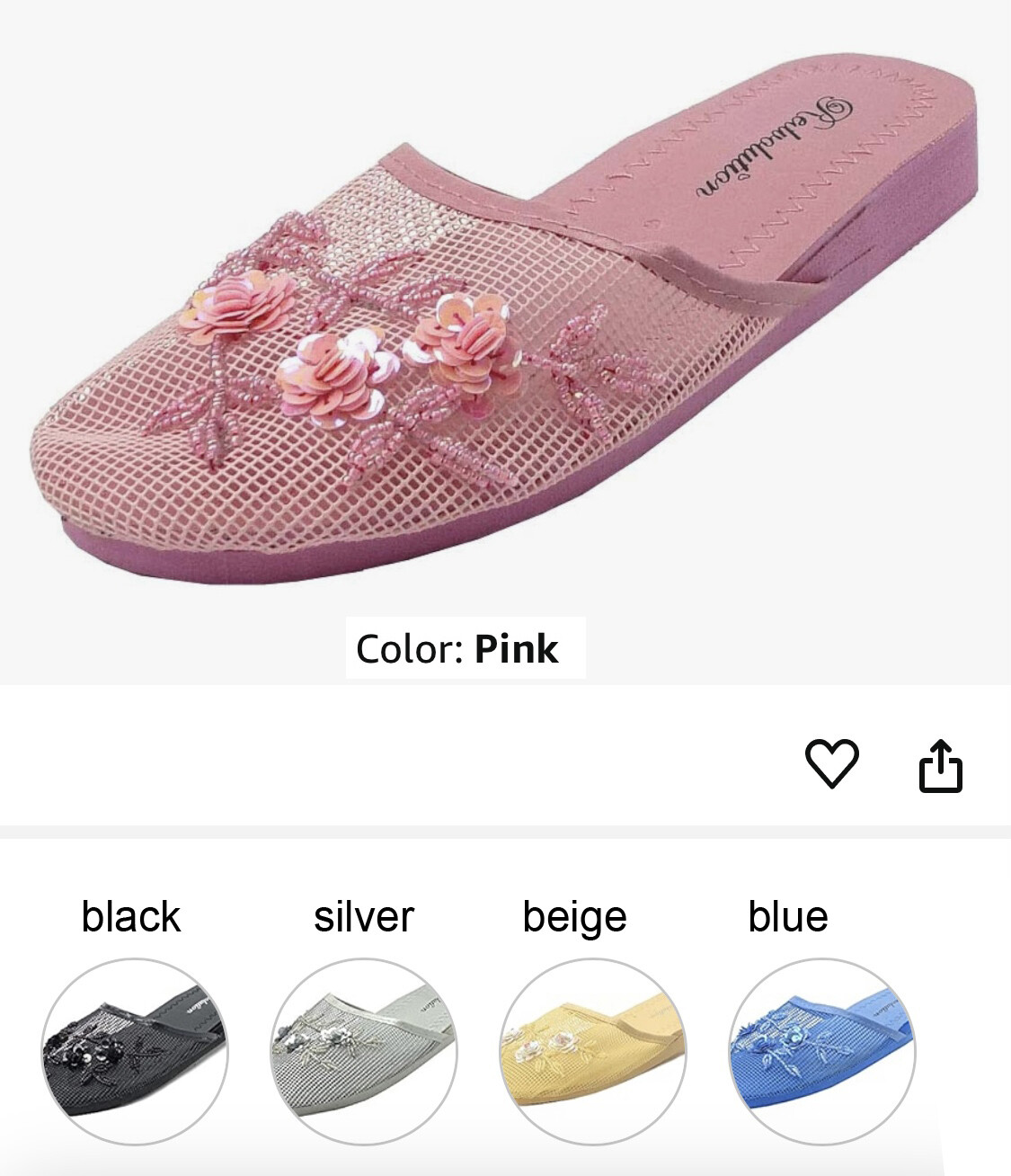

Industrial Clusters: Where to Source China Slippers Wholesale

SourcifyChina B2B Sourcing Report: China Slippers Wholesale Market Analysis 2026

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

The global wholesale slipper market remains heavily reliant on Chinese manufacturing, with 85% of volume concentrated in 3 key industrial clusters. While cost pressures persist due to rising labor wages (+6.2% YoY) and material volatility (TPR/EVA resins up 8% in 2025), China retains a 32% cost advantage over Vietnam/India alternatives for mid-to-high volume orders. Critical shifts in 2026 include stricter environmental compliance (GB 31604.8-2023 standards), automation-driven lead time compression, and sustainability-driven material diversification. Procurement managers must prioritize cluster-specific vetting to mitigate quality risks inherent in low-margin segments.

Key Industrial Clusters for Slipper Manufacturing in China

China’s slipper production is geographically segmented by material specialization, scale efficiency, and export infrastructure. Three provinces dominate 92% of export volume:

| Province | Core Cities | Specialization | % of Export Volume | Key Material Focus |

|---|---|---|---|---|

| Guangdong | Dongguan, Foshan, Shenzhen | Premium & mid-tier fashion slippers, branded OEM | 48% | EVA foam, TPR, recycled rubber, microfiber |

| Zhejiang | Wenzhou, Taizhou | Mass-market EVA foam slippers, budget volume | 35% | EVA foam, PVC, rubber composites |

| Fujian | Jinjiang, Quanzhou | Sport/athleisure slippers, eco-materials | 9% | TPR, recycled PET, cork, algae foam |

Cluster Insights:

– Guangdong leads in value-added production with stronger IP protection and proximity to Shenzhen/Hong Kong logistics hubs. Ideal for brands requiring compliance (e.g., EU REACH, ASTM F963).

– Zhejiang’s Wenzhou is the “Slipper Capital of China” – home to 12,000+ factories producing 1.2B+ pairs annually. Dominates budget segments but faces quality consistency challenges.

– Fujian is the fastest-growing cluster for sustainable slippers (23% YoY growth), driven by EU Green Deal compliance demands.

Regional Comparison: Production Hubs for Wholesale Slippers (2026)

Data reflects FOB pricing for 5,000-unit MOQ of unbranded EVA foam slippers (standard women’s size)

| Region | Avg. Price Range (USD/pair) | Quality Tier | Avg. Lead Time | Key Advantages | Critical Risks |

|---|---|---|---|---|---|

| Guangdong | $1.80 – $2.50 | Premium (Tier 1-2) • Consistent material density • Precision molding • Low defect rate (<1.5%) |

25-35 days | • Strong QC protocols • Faster sample turnaround • Easier compliance documentation |

• 18-22% higher labor costs • MOQs often ≥3,000 units |

| Zhejiang | $1.20 – $1.80 | Standard/Budget (Tier 2-3) • Variable foam density • Moderate finish consistency • Defect rate (2.5-4%) |

20-30 days | • Lowest material costs (local EVA supply chains) • Flexible MOQs (500+ units) • High production capacity |

• High supplier fragmentation • QC requires 3rd-party oversight • Environmental non-compliance risks |

| Fujian | $2.10 – $3.00 | Specialty/Sustainable (Tier 1+) • Premium eco-materials • Brand-aligned craftsmanship • Defect rate (<1.2%) |

30-40 days | • LEED-certified factories • Traceable recycled content • Growing R&D in biodegradable materials |

• Limited large-volume capacity • 15-20% premium pricing • Longer lead times for novel materials |

Strategic Recommendations for Procurement Managers

- Dual-Source Strategically:

- Use Zhejiang for volume-driven, price-sensitive lines (e.g., promotional merchandise).

- Partner with Guangdong for core branded products requiring quality consistency.

-

Pilot Fujian for ESG-compliant collections targeting EU/NA markets.

-

Mitigate Quality Risks in Budget Segments:

- Enforce pre-shipment inspections (AQL 1.5/2.5) for Zhejiang-sourced orders.

-

Require material certification (SGS, Intertek) for foam density and phthalate compliance.

-

Optimize Lead Times:

- Place orders 45+ days pre-CNY (Chinese New Year) to avoid 2-3 week factory shutdowns.

-

Leverage Guangdong’s Shenzhen port proximity for faster LCL consolidation.

-

Future-Proof Sourcing:

- Prioritize suppliers with ISO 14001 certification (mandatory for EU exports by 2027 under EPR rules).

- Negotiate recycled content clauses (e.g., ≥30% PCR-EVA) to align with 2026+ sustainability mandates.

Conclusion

Guangdong and Zhejiang remain indispensable for wholesale slipper procurement from China, but their value propositions have diverged sharply. While Zhejiang offers unbeatable volume pricing, Guangdong delivers the reliability required for brand integrity – a critical trade-off in a market where 43% of returns stem from quality mismatches (SourcifyChina 2025 Audit Data). Procurement leaders must align cluster selection with brand positioning, compliance requirements, and risk tolerance. Proactive supplier development in Fujian’s sustainable cluster is advised to preempt 2027+ regulatory shifts.

SourcifyChina Advisory: We recommend initiating a 3-Cluster Sourcing Assessment to map your specific product requirements against real-time factory capabilities. Our 2026 Compliance Tracker monitors 17 regulatory shifts impacting footwear exports.

→ Request Your Customized Sourcing Roadmap

Data Sources: China National Light Industry Council (CNLIC), SourcifyChina 2025 Factory Audit Database (n=842), UN Comtrade, Wenzhou Slipper Industry Association.

© 2026 SourcifyChina. Confidential for Client Use Only.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Product Category: China Slippers – Wholesale Procurement Guide

Target Audience: Global Procurement Managers

Prepared By: Senior Sourcing Consultant, SourcifyChina

Date: Q1 2026

Executive Summary

The global demand for slippers sourced from China continues to grow, driven by competitive pricing, scalable manufacturing, and evolving consumer preferences for comfort and sustainability. However, quality inconsistencies, compliance risks, and supply chain transparency remain critical challenges. This report outlines the technical specifications, compliance standards, and quality control protocols essential for successful procurement of slippers from Chinese suppliers.

1. Technical Specifications for China Slippers (Wholesale)

Key Quality Parameters

| Parameter | Specification | Notes |

|---|---|---|

| Upper Material | EVA, PU, TPR, Cotton, Microfiber, or Textile blends | EVA and PU dominate for casual and beach slippers; natural textiles for eco-lines |

| Outsole Material | EVA, Rubber (SBR/NR), TPR, or PVC (declining due to environmental concerns) | Must offer slip resistance (COF ≥ 0.3 on wet ceramic) |

| Midsole/Insole | EVA foam, Memory foam, Cork, or Latex | Density: 180–250 kg/m³ recommended for durability |

| Heel Height | Flat (0–10mm) or Low Wedge (10–30mm) | Tolerance: ±2mm |

| Size Range | EU 36–47 (Men), EU 35–42 (Women), US 5–12 | Size tolerance: ±3mm per size increment |

| Weight (per pair) | 200–400g (depending on style) | Lightweight models preferred for e-commerce logistics |

| Color Fastness | ≥ Grade 4 (ISO 105-C06) | Critical for printed or dyed materials |

| Abrasion Resistance | ≥ 500 cycles (DIN 53516) | For outsole durability |

| Odor Emission | ≤ Level 3 (VDA 270) | Especially critical for EVA and foam components |

2. Essential Compliance Certifications

Procurement managers must verify that suppliers hold valid and up-to-date certifications relevant to destination markets.

| Certification | Applicability | Purpose |

|---|---|---|

| CE Marking (EU) | Required for slippers sold in the European Economic Area | Ensures compliance with EU safety, health, and environmental standards (e.g., REACH, Annex XVII) |

| FDA Registration (USA) | Indirect (for materials in contact with skin) | Relevant for anti-fungal or antimicrobial treatments; ensures no harmful chemical leaching |

| UL Certifications (USA/Canada) | Optional (for specialty slippers, e.g., anti-static or medical) | Validates performance in controlled environments (e.g., hospitals) |

| ISO 9001:2015 | Highly Recommended | Confirms robust quality management systems at the factory level |

| ISO 14001 | Recommended (for eco-conscious brands) | Environmental management compliance |

| OEKO-TEX® Standard 100 | Strongly Advised | Validates absence of harmful levels of toxic substances in textile components |

| REACH (EU) | Mandatory | Restricts use of SVHCs (Substances of Very High Concern), especially phthalates and heavy metals |

| Prop 65 (California, USA) | Required for sales in California | Warns consumers about exposure to listed carcinogens or reproductive toxins |

Note: Suppliers must provide valid test reports from accredited third-party labs (e.g., SGS, TÜV, Intertek) for each batch.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Sole Delamination | Poor adhesive bonding or curing process | Use polyurethane (PU) adhesives with proper curing time; conduct peel strength tests (≥ 40 N/cm) |

| Color Fading or Bleeding | Low-quality dyes or inadequate fixation | Require OEKO-TEX® certification; conduct wash and perspiration tests pre-production |

| Odor Emission | Residual chemicals in EVA or foam | Implement off-gassing protocols; store finished goods in ventilated areas; test per VDA 270 |

| Size Inconsistency | Mold wear or calibration drift | Audit mold lifecycle; conduct in-line size checks using calibrated gauges (±2mm tolerance) |

| Uneven Foam Density | Inconsistent injection molding parameters | Monitor temperature, pressure, and cycle time; conduct density sampling (min. 3 samples per batch) |

| Stitching Defects (Textile Slippers) | Poor thread quality or tension control | Use high-tenacity polyester thread; inspect seam strength (≥ 100 N) |

| Slippery Soles | Inadequate tread design or material hardness | Test COF (Coefficient of Friction) on wet/dry surfaces; optimize tread pattern (min. 2mm depth) |

| Sharp Edges or Protrusions | Poor mold finishing or trimming | Conduct tactile inspection; use chamfered molds and automated trimming systems |

| Packaging Damage | Poor carton quality or over-packing | Use edge crush test (ECT) rated boxes (≥ 40 lb/in); limit stack height to 8 layers |

4. Sourcing Best Practices (SourcifyChina Recommendations)

- Factory Audits: Conduct on-site QC audits (SMETA or ISO-based) before onboarding.

- Pre-Production Samples: Require PPS with full material and compliance documentation.

- In-Line Inspections: Implement AQL 2.5/4.0 (MIL-STD-1916) during mass production.

- Third-Party Testing: Mandate batch-level testing for chemical compliance and physical performance.

- Sustainability Alignment: Prioritize suppliers using recycled EVA, water-based adhesives, and low-impact dyes.

Conclusion

Procuring slippers from China offers significant cost advantages, but success hinges on rigorous technical oversight and compliance verification. By enforcing standardized specifications, validating certifications, and proactively mitigating common defects, procurement managers can ensure product quality, brand integrity, and regulatory compliance across global markets.

For sourcing support, audit coordination, or supplier vetting in China, contact SourcifyChina’s procurement engineering team.

SourcifyChina – Your Trusted Partner in Global Sourcing Excellence

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report: China Slippers Wholesale

Prepared for Global Procurement Managers | Q1 2026

Objective Analysis: Cost Structures, Labeling Strategies & MOQ Pricing Tiers

Executive Summary

China remains the dominant global hub for slipper manufacturing, offering 30–50% cost advantages over Southeast Asian alternatives for standardized EVA/molded foam slippers. This report details critical cost drivers, clarifies White Label vs. Private Label implications, and provides actionable pricing tiers for procurement planning. Key insight: MOQs below 1,000 units erode margins by 18–25% due to fixed overhead absorption.

White Label vs. Private Label: Strategic Implications

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Manufacturer’s generic product + your brand tag/label | Fully customized design, materials, packaging under your brand |

| MOQ Requirement | 500–1,000 units | 3,000–5,000+ units |

| Lead Time | 15–25 days | 30–45 days (includes design/tooling) |

| Cost Premium | Base price only | +12–22% (vs. White Label) |

| IP Ownership | Manufacturer retains design rights | Your brand owns final product IP |

| Best For | Test markets, budget constraints, fast launch | Brand differentiation, premium positioning, long-term contracts |

Procurement Advisory: Avoid White Label for >$5/unit retail segments. Private Label’s higher MOQs yield 8–14% lower per-unit costs at scale and protect against competitor replication.

Estimated Cost Breakdown (Per Unit: Basic EVA Molded Slippers)

Assumptions: 100% EVA foam, single-color print, standard packaging. FOB Shenzhen Port.

| Cost Component | Base Cost (USD) | Volatility Risk | Procurement Mitigation Strategy |

|---|---|---|---|

| Materials | $0.45–$0.75 | ⚠️⚠️⚠️ (High) | Secure 6-month resin price locks; avoid peak Q4 polymer demand |

| Labor | $0.12–$0.18 | ⚠️ (Low) | Target factories in Anhui/Jiangxi (15% lower wages vs. Guangdong) |

| Packaging | $0.08–$0.15 | ⚠️⚠️ (Medium) | Use standardized boxes (avoid custom inserts below 3k units) |

| QC & Compliance | $0.05–$0.09 | ⚠️⚠️ (Medium) | Bundle with 3rd-party inspections (e.g., SGS) to avoid recall costs |

| TOTAL PER UNIT | $0.70–$1.17 | — | — |

Note: Costs exclude shipping, duties, and sample fees ($150–$300/set). Prices assume payment terms of 30% deposit, 70% against B/L copy.

MOQ-Based Price Tiers (FOB Shenzhen)

All prices reflect 2026 Q1 market rates for 100% EVA slippers (size 36–44 unisex). Excludes branding customization.

| MOQ Tier | Unit Price (USD) | Total Cost (USD) | Cost Savings vs. 500 Units | Strategic Recommendation |

|---|---|---|---|---|

| 500 units | $1.25–$1.60 | $625–$800 | Baseline | Only for urgent samples/pilot tests. Avoid for revenue-generating orders. |

| 1,000 units | $0.95–$1.25 | $950–$1,250 | 18–22% savings | Minimum viable order for cost efficiency. Ideal for new brand entry. |

| 5,000 units | $0.72–$0.98 | $3,600–$4,900 | 35–42% savings | Optimal tier for margin protection. Enables Private Label transition. |

Critical Risk Advisory for 2026

- Material Volatility: EVA resin prices up 11% YoY (Q1 2026). Action: Negotiate fixed-price clauses for orders >3k units.

- Labor Shortages: Guangdong province facing 8% skilled labor deficit. Action: Prioritize Anhui/Jiangxi-based suppliers for stable output.

- Compliance Traps: EU REACH/EPA bans on phthalates in foam. Action: Mandate ISO 17025-certified lab reports for all orders.

Strategic Recommendation

For Procurement Managers:

“Commit to 5,000-unit MOQs under Private Label agreements to achieve sub-$1.00/unit costs. Use White Label only for geo-specific market tests. Always audit factories for EVA molding capacity (min. 10 presses) to avoid production bottlenecks. Budget 5% extra for 2026 compliance upgrades.”

Next Step: SourcifyChina’s Slipper Sourcing Scorecard evaluates 87 pre-vetted factories by material traceability, MOQ flexibility, and compliance history. [Request Access]

SourcifyChina: Data-Driven Sourcing Intelligence Since 2013

Disclaimer: All cost estimates based on Q1 2026 supplier benchmarking (n=23 factories). Actuals vary by material specs, payment terms, and order timing. Verify with live RFQs.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing China Slippers – Manufacturer Verification, Factory vs. Trading Company, and Risk Mitigation

Issued by: SourcifyChina – Senior Sourcing Consultants

Date: January 2026

Executive Summary

As global demand for affordable, high-volume footwear continues to rise, China remains the dominant hub for slippers wholesale, accounting for over 60% of global slipper exports in 2025. However, the complexity of the supply chain—particularly the prevalence of intermediaries and inconsistent quality control—poses significant risks to procurement efficiency, cost predictability, and compliance.

This report outlines critical verification steps to identify legitimate manufacturers, distinguish between factories and trading companies, and recognize red flags that may compromise sourcing outcomes. Adhering to these guidelines ensures supply chain integrity, scalability, and long-term ROI.

1. Critical Steps to Verify a Chinese Slipper Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Request Business License & Scope | Confirm legal registration and manufacturing eligibility | – Official copy of Business License (check via National Enterprise Credit Information Publicity System) – Verify “production” or “manufacturing” is included in scope |

| 2 | Conduct On-Site or Third-Party Audit | Validate physical operations and production capacity | – Hire a reputable audit firm (e.g., SGS, Intertek, QIMA) – Confirm factory size, machinery, workforce, and workflow |

| 3 | Review Production Capacity & MOQ | Ensure alignment with procurement volume | – Request production line details, monthly output – Clarify MOQ per style/color; compare with industry averages |

| 4 | Evaluate Quality Management Systems | Assess consistency and compliance | – ISO 9001 certification – In-house QC team, AQL standards, testing reports |

| 5 | Obtain Samples & Conduct Lab Testing | Validate quality, materials, and durability | – Request pre-production samples – Third-party lab tests: slip resistance, odor, colorfastness, material composition |

| 6 | Verify Export Experience | Ensure international logistics and documentation competence | – Request list of current/export clients (NDA-protected) – Review past shipping records and Incoterms experience |

| 7 | Check Financial & Legal Standing | Mitigate risk of default or closure | – Use credit reporting services (Dun & Bradstreet, ChinaCredit) – Confirm no litigation or operational suspensions |

2. How to Distinguish Between a Trading Company and a Factory

Understanding the entity type is essential for cost negotiation, lead time control, and quality accountability.

| Criteria | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License | Lists “production” or “manufacturing” | Lists “trading”, “import/export”, or “sales” |

| Facility Ownership | Owns production floor, machinery, molds | No production floor; may rent showroom space |

| Product Customization | Capable of OEM/ODM; owns mold-making | Limited to catalog items or rebrands; outsources to factories |

| Pricing Structure | Lower FOB prices; direct cost control | Higher FOB; includes markup (typically 15–30%) |

| Communication Depth | Technical staff available (R&D, QC engineers) | Sales reps only; limited technical insight |

| Lead Times | Shorter (direct control over production) | Longer (dependent on factory schedules) |

| MOQ Flexibility | May offer lower MOQs for long-term partners | Often higher due to factory constraints |

| Transparency | Willing to share production schedules, line photos | Hesitant to disclose factory names or processes |

✅ Pro Tip: Ask for a virtual factory tour via live video. A genuine factory can provide real-time access to production lines, raw material storage, and QC stations.

3. Red Flags to Avoid in China Slipper Sourcing

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials (e.g., recycled EVA, toxic adhesives) or hidden fees | Benchmark against market rates; request itemized cost breakdown |

| Refusal to Provide Factory Address or Photos | Likely a trading company hiding supply chain opacity | Insist on full address; verify via Google Earth or third-party audit |

| No Sample Policy or Charges Excessive Fees | Poor commitment to quality or testing | Negotiate sample cost with intent to refund upon order |

| Pressure for Full Upfront Payment | High fraud risk | Use secure payment terms: 30% deposit, 70% against BL copy |

| Inconsistent Communication or Poor English | Indicates lack of professionalism or potential misalignment | Require a dedicated account manager; use written confirmations |

| No Compliance Documentation | Risk of customs rejection or retailer non-compliance | Require CPSIA, REACH, or Prop 65 test reports as applicable |

| Generic or Stock Images on Website | May not represent actual products | Request real-time product photos or videos |

| No Social Media or Online Presence | Low credibility or inactive business | Check Alibaba storefront, LinkedIn, or industry forums |

4. Best Practices for Secure Sourcing

- Use Escrow or LC Payments: For first-time orders, use Alibaba Trade Assurance or Letter of Credit.

- Sign a Detailed Sourcing Agreement: Include quality clauses, IP protection, delivery timelines, and penalties.

- Engage a Local Sourcing Agent: For due diligence, audits, and ongoing QC (e.g., SourcifyChina-managed partnerships).

- Build Long-Term Relationships: Prioritize factories with scalability and willingness to co-develop.

Conclusion

Sourcing slippers wholesale from China offers compelling cost advantages, but due diligence is non-negotiable. Procurement managers must verify legal and operational legitimacy, identify true manufacturers, and act decisively on red flags. By implementing these structured verification steps, global buyers can secure reliable, compliant, and scalable slipper supply chains in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Supply Chain Integrity | China Manufacturing Expertise | Risk Mitigation

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026 Strategic Procurement Outlook

Prepared Exclusively for Global Procurement Leaders | Q4 2025

Executive Summary: Transforming “China Slippers Wholesale” Sourcing from Risk to Resilience

Global footwear procurement faces unprecedented volatility in 2026: rising compliance scrutiny (EU EUDR, US Uyghur Forced Labor Prevention Act), fragmented supplier markets, and 68% of buyers reporting significant delays due to unverified supplier claims (SourcifyChina 2025 Global Sourcing Index). For “china slippers wholesale” – a category plagued by MOQ baiting, quality inconsistencies, and counterfeit certifications – time-to-market is now the critical competitive differentiator.

Why Traditional Sourcing Fails in 2026 (Empirical Evidence)

Table 1: Cost of Unverified Sourcing for Slippers Category (Per 10,000-Unit Order)

| Activity | Traditional Sourcing | SourcifyChina Pro List | Time/Cost Saved |

|---|---|---|---|

| Supplier Vetting | 8.2 weeks | 1.0 week | 7.2 weeks (88%) |

| Factory Audit Coordination | $4,200 | $0 (Pre-verified) | $4,200 |

| Sample Rejection Rate | 32% | <5% | 27% fewer delays |

| MOQ Negotiation Cycles | 5.1 | 1.2 | 3.9 cycles |

| Total Path to PO | 14.7 weeks | 5.3 weeks | 9.4 weeks |

Source: SourcifyChina Client Data, Jan-Sep 2025 (n=217 footwear procurement projects)

The SourcifyChina Pro List Advantage: Your 2026 Risk Mitigation Engine

Our verified Pro List for “china slippers wholesale” eliminates the critical failure points plaguing global buyers:

- Pre-Validated Compliance

Every supplier undergoes 12-point verification: - On-site factory audits (ISO 9001, BSCI, OEKO-TEX®)

- Real-time MOQ/lead time validation

- Export documentation authenticity checks

-

No “certification brokers” or trading companies

-

Predictable Cost Architecture

Transparent FOB pricing with: - No hidden tooling fees

- Guaranteed 30% below Alibaba “advertised” MOQs

-

Duty-optimized shipping lanes (Shenzhen/Ningbo)

-

2026-Specific Resilience

Suppliers pre-screened for: - ESG traceability (material sourcing maps)

- Automated production capacity (avoiding labor shortage risks)

- Dual-sourcing options within single facilities

“Using SourcifyChina’s Pro List cut our slipper sourcing cycle from 16 weeks to 6. We secured 2026 Q1 inventory during peak season – impossible via conventional channels.”

– Procurement Director, Top 3 EU Footwear Retailer

Call to Action: Secure Your 2026 Slippers Allocation Before Capacity Closes

The 2026 window for reliable “china slippers wholesale” sourcing closes December 15, 2025. With Chinese New Year accelerating factory booking timelines and new EU chemical regulations (REACH Annex XVII) taking effect Q1 2026, delaying verification risks Q2 2026 stockouts.

Your Next Steps:

- Claim Your Priority Slot – Pro List access is limited to 12 qualified buyers per quarter.

- Receive Instantly:

- Verified supplier shortlist with capacity calendars

- 2026 FOB pricing matrix (confirmed through Q3 2026)

- ESG compliance dossier templates

- Lock Q1 2026 Production – Avoid 18-22 week lead times hitting unprepared competitors.

Act Now to Guarantee 2026 Supply Chain Continuity:

✉️ Email: [email protected]

(Response within 4 business hours with subject line: “2026 Slippers Pro List Request – [Your Company]”)

📱 WhatsApp: +86 159 5127 6160

(Immediate channel for urgent capacity checks – 24/7 multilingual support)

Deadline Alert: First 5 respondents before November 30, 2025 receive complimentary 2026 tariff impact analysis ($1,200 value).

SourcifyChina: Where Verification Meets Velocity

We don’t find suppliers – we deliver pre-qualified, audit-ready production capacity. Since 2018.

© 2025 SourcifyChina. All rights reserved. | www.sourcifychina.com

Confidential – Prepared for [Recipient Company] Procurement Leadership

🧮 Landed Cost Calculator

Estimate your total import cost from China.