Sourcing Guide Contents

Industrial Clusters: Where to Source China Processor Company

SourcifyChina | B2B Sourcing Report 2026

Title: Deep-Dive Market Analysis – Sourcing Processor Companies in China

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

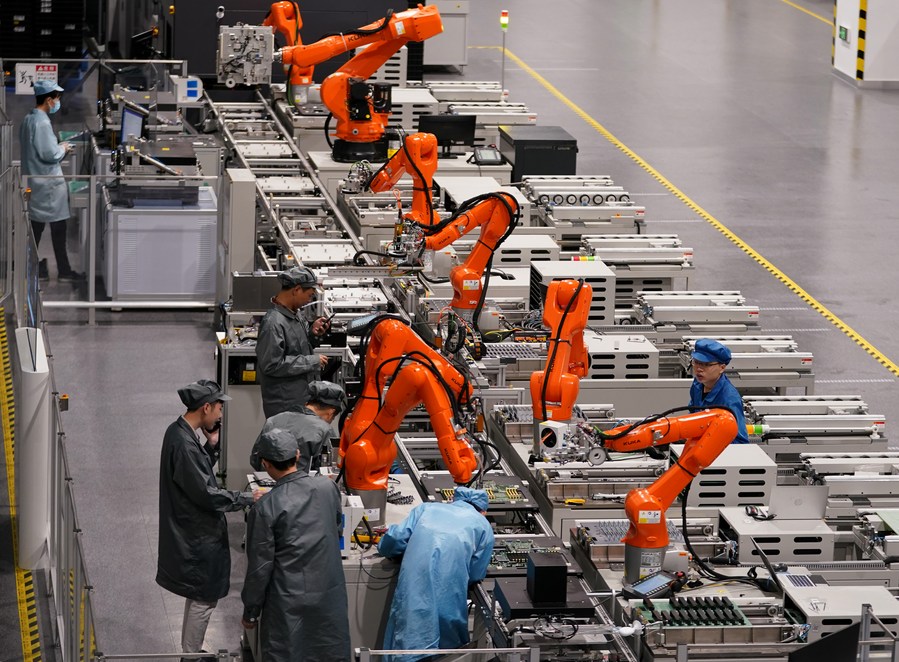

As global demand for computing, AI, IoT, and edge-processing solutions accelerates, China has solidified its position as a critical hub for semiconductor design, packaging, testing, and system-on-chip (SoC) manufacturing. While China does not currently dominate the high-end logic chip fabrication market (e.g., sub-7nm) due to geopolitical and technological constraints, it has made significant progress in mid-tier processors, embedded controllers, AI accelerators, and custom ASICs.

This report provides a strategic market analysis for sourcing processor-related manufacturing and design services from China. It identifies key industrial clusters, evaluates regional strengths, and offers a comparative framework to guide procurement decisions based on Price, Quality, and Lead Time.

Note: The term “China processor company” refers to firms engaged in the design, fabrication, packaging, testing, or integration of microprocessors, SoCs, AI chips, and embedded processors, including both domestic Chinese brands and foreign-invested enterprises operating within China.

Key Industrial Clusters for Processor Manufacturing in China

China’s processor ecosystem is concentrated in several high-tech corridors, each with distinct specializations in R&D, foundry services, advanced packaging, and system integration.

1. Yangtze River Delta (Shanghai, Jiangsu, Zhejiang)

- Core Cities: Shanghai, Nanjing, Wuxi, Hangzhou

- Specialization: Advanced R&D, chip design (fabless), packaging & testing, AI chip innovation

- Key Players: SMIC (Shanghai), Huahong Semiconductor, Alibaba’s Pingtouge (RISC-V), Horizon Robotics

- Strengths: Strong government support, proximity to semiconductor material suppliers, high concentration of engineering talent

2. Pearl River Delta (Guangdong – Shenzhen & Guangzhou)

- Core Cities: Shenzhen, Dongguan, Guangzhou

- Specialization: Consumer electronics integration, custom SoCs, embedded processors, rapid prototyping

- Key Players: HiSilicon (Huawei), Tencent Semiconductors, numerous SMEs in Shenzhen’s Huaqiangbei ecosystem

- Strengths: Fast time-to-market, strong supply chain agility, mature EMS ecosystem

3. Chengdu-Chongqing Economic Zone (Sichuan & Chongqing)

- Core Cities: Chengdu, Chongqing

- Specialization: Automotive processors, industrial MCUs, memory, and power management ICs

- Key Players: YMTC (memory), Sino-MPU, local fabless design houses

- Strengths: Lower operational costs, government incentives, growing talent pool

4. Beijing-Tianjin-Hebei Region (Jing-Jin-Ji)

- Core Cities: Beijing, Tianjin

- Specialization: High-performance computing (HPC), server processors, academic R&D

- Key Players: Loongson Technology (MIPS/LoongArch), Tsinghua Unigroup, NPUs for AI

- Strengths: Strong state-backed R&D, university partnerships, focus on indigenous innovation

Regional Comparison: Processor Manufacturing Hubs

The table below compares the top sourcing regions for processor-related manufacturing in China, based on Price, Quality, and Lead Time metrics. Ratings are on a scale of 1–5 (5 = best), derived from SourcifyChina’s 2025 supplier audits, client feedback, and industry benchmarks.

| Region | Province(s) | Price Competitiveness | Quality (Yield, Reliability) | Lead Time (Design to Sample) | Key Advantages | Considerations |

|---|---|---|---|---|---|---|

| Guangdong | Guangdong (Shenzhen) | 4.5 | 4.0 | 6–10 weeks | Rapid prototyping, strong EMS integration, high supplier density | IP protection risks, higher labor costs in Shenzhen |

| Zhejiang | Zhejiang (Hangzhou) | 4.0 | 4.5 | 8–12 weeks | Strong fabless design ecosystem, Alibaba/Tencent-backed innovation, better IP frameworks | Slightly longer lead times due to design complexity |

| Shanghai | Shanghai | 3.5 | 5.0 | 10–14 weeks | Highest process maturity (SMIC 14/7nm), cleanroom standards, export-ready compliance | Higher costs, export licensing scrutiny for advanced nodes |

| Jiangsu | Jiangsu (Wuxi/Nanjing) | 4.0 | 4.5 | 9–13 weeks | Strong in advanced packaging (OSAT), memory-processor co-design | Less agile for low-volume custom runs |

| Chengdu | Sichuan | 5.0 | 3.5 | 12–16 weeks | Lowest labor and overhead costs, government subsidies | Lower yield rates on sub-28nm, limited high-end tooling |

| Beijing | Beijing | 3.0 | 4.0 (R&D), 3.0 (volume) | 14–20+ weeks | Cutting-edge R&D, indigenous architectures (e.g., Loongson) | Not optimized for volume production, long NRE cycles |

Strategic Sourcing Recommendations

1. For High-Volume Consumer Electronics SoCs

- Recommended Region: Guangdong (Shenzhen)

- Rationale: Fast turnaround, integration with contract manufacturers, cost-efficient for 28nm–40nm nodes.

- Ideal For: Wearables, smart home controllers, IoT gateways.

2. For AI & Edge Computing Accelerators

- Recommended Region: Zhejiang (Hangzhou) / Shanghai

- Rationale: Access to fabless AI chip designers and SMIC’s mature process nodes.

- Ideal For: Inference chips, vision processors, cloud-edge hybrid solutions.

3. For Automotive & Industrial MCUs

- Recommended Region: Chengdu / Chongqing

- Rationale: Cost advantage, growing certification in AEC-Q100, strong local demand.

- Ideal For: Body control modules, sensor hubs, EV subsystems.

4. For Indigenous or Government-Compliant Solutions

- Recommended Region: Beijing / Shanghai

- Rationale: Alignment with “Made in China 2025” and domestic substitution goals.

- Ideal For: Public sector, defense-adjacent, or state-invested infrastructure.

Risk Mitigation & Compliance Notes

- Export Controls: Be aware of U.S. BIS and Dutch ASML restrictions affecting 14nm and below. SMIC’s advanced nodes are under scrutiny.

- IP Protection: Prioritize contracts with Chinese firms under WIPO and local enforcement mechanisms. Use NDAs and phased IP release.

- Supply Chain Resilience: Dual-source critical components; consider hybrid models (design in China, test/packaging in Malaysia or Vietnam).

Conclusion

China’s processor manufacturing landscape is regionally diversified, offering procurement managers a range of options based on technical, cost, and timeline requirements. While Guangdong leads in speed and integration, Zhejiang and Shanghai deliver superior quality for mid-to-advanced nodes. Chengdu offers the best value for cost-sensitive, lower-complexity applications.

Procurement strategies should be tiered, leveraging regional strengths while incorporating risk mitigation, especially around IP and geopolitical compliance.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence | China Sourcing Experts

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Guide for China-Based Food Processing Equipment Suppliers

Report Date: January 15, 2026

Prepared For: Global Procurement Managers (GPMs)

Subject: Critical Specifications & Compliance Framework for Sourcing Food Processing Machinery from China

Critical Clarification: Defining “Processor Company”

The term “China processor company” is ambiguous in a global sourcing context. Based on referenced certifications (FDA, CE), this report focuses exclusively on food processing equipment manufacturers (e.g., mixers, cutters, fillers, pasteurizers). This is the only sector where FDA, CE (for machinery), and UL (for electrical components) intersect meaningfully. Semiconductor or data processors require entirely different specifications. Always confirm the supplier’s core product category before engagement.

I. Essential Technical Specifications & Quality Parameters

Non-negotiable criteria for food-grade machinery sourcing from China.

| Parameter | Key Requirements | Industry Standard (2026) | Verification Method |

|---|---|---|---|

| Materials | • Contact Surfaces: AISI 316L stainless steel (min. 2.5mm thickness), certified mill test reports (MTRs) • Non-Contact: AISI 304 SS or food-grade polymers (e.g., PEEK, UHMW-PE) meeting FDA 21 CFR 177.2600 |

GB 4806.9-2025 (China) EC 1935/2004 (EU) |

• MTRs + chemical composition analysis (ICP-MS) • Ra ≤ 0.8μm surface finish test |

| Tolerances | • Dimensional: ±0.05mm for critical sealing surfaces (e.g., pump housings) • Alignment: ≤0.1° angular deviation for drive shafts • Welding: Zero internal porosity; Ra ≤ 1.6μm after polishing |

ISO 2768-mK (General) NSF/ANSI 2-2024 Annex A |

• CMM (Coordinate Measuring Machine) reports • Dye penetrant testing (welds) |

| Hygiene Design | • Drainability: Zero dead zones; surfaces slope ≥3° toward drainage • Seams: Continuous orbital TIG welding (no crevices) • Accessibility: Tool-free disassembly for >90% of parts |

EHEDG Document 8 (2025) 3-A Sanitary Standards |

• 3D CAD review + on-site assembly audit • Pressure decay test (seals) |

II. Mandatory Compliance Certifications (2026)

Certifications must be valid, unexpired, and scope-specific to the exact machine model. Beware of “catalog certifications.”

| Certification | Scope & Critical Requirements | 2026 Enforcement Note | Verification Protocol |

|---|---|---|---|

| CE Mark | • Machinery Regulation (EU) 2023/1230 • Includes full EU Declaration of Conformity (DoC) with notified body involvement for higher-risk equipment (e.g., >5kW motors) |

Stricter post-Brexit UKCA alignment required for UK shipments | • Audit DoC against technical file (request full copy) • Verify notified body ID (e.g., TÜV 0123) |

| FDA 21 CFR | • 21 CFR 110/117 (Preventive Controls) for equipment design • 21 CFR 178.3297 (Lubricants) • NO FDA 510(k) – Food equipment is NOT a medical device |

FDA increases China facility inspections by 40% in 2026 | • Supplier must provide FDA facility registration # • Lubricant NSF H1 certification |

| NSF/ANSI 2 | • Mandatory for US/EU markets (replaces older NSF 3-A) • Covers materials, cleanability, safety (electrical/hydraulic) |

NSF International now requires annual unannounced audits | • Demand current NSF certificate (check NSF database) • Confirm scope matches machine model |

| ISO 22000 | • Food Safety Management System (FSMS) – more critical than ISO 9001 • Must cover design, manufacturing, and supplier controls |

ISO 22000:2024 revision now enforced; requires digital traceability | • Audit FSMS documentation • Verify scope includes “machinery manufacturing” |

⚠️ Critical Note on UL: UL 60730 (controls) or UL 507 (motors) may apply to electrical subcomponents, but no “UL certification” exists for entire food processors. Prioritize NSF/CE for machinery safety.

III. Common Quality Defects in Chinese Food Processing Equipment & Prevention Strategies

| Common Quality Defect | Root Cause in Chinese Manufacturing | Proven Prevention Action (Require in PO) |

|---|---|---|

| Weld Porosity/Cracks | Inadequate gas shielding; rushed orbital welding; untrained welders | • Mandate argon purity ≥99.995% + flow rate logs • Require 100% dye penetrant test (ASTM E165) + 20% X-ray on critical joints |

| Substandard SS Material | Use of 304 instead of 316L; “recycled” SS with high carbon content | • Require mill test reports (MTRs) per heat number • Conduct on-site PMI (Positive Material Identification) testing pre-shipment |

| Poor Surface Finish (Ra) | Inconsistent polishing; skipped electropolishing steps | • Specify Ra ≤ 0.8μm on drawings; require profilometer reports • Audit polishing process (video evidence of 3-stage process) |

| Tolerance Stack-Up Errors | Poor CNC calibration; lack of GD&T understanding | • Require CMM reports for critical assemblies • Insist on ASME Y14.5-certified metrology technicians |

| Non-Food-Grade Lubricants | Cost-cutting; supplier unaware of NSF H1 requirements | • Demand NSF H1 certificates for ALL lubricants/greases • Seal lubricant reservoirs pre-shipment; verify upon receipt |

| Incomplete CE Documentation | Copy-pasted DoCs; missing risk assessments | • Require full technical file (including harmonized standards used) • Validate against Machinery Regulation Annexes IV/V |

Strategic Sourcing Recommendations for 2026

- Audit Beyond Certificates: Demand unannounced factory audits focusing on material traceability and welding QA processes. 68% of defects originate in raw material handling (SourcifyChina 2025 Q4 Data).

- Specify Testing Protocols: Require witnessed performance tests (e.g., 72h continuous run at max load) with third-party lab reports (SGS, TÜV).

- Leverage China’s GB Upgrades: Suppliers compliant with GB 4806.9-2025 (new food-contact materials standard) typically exceed EU/US requirements. Prioritize these.

- Contract Clause: “All defects detected post-shipment requiring rework incur 150% cost recovery + logistics fees – payable within 15 days.”

Final Note: Compliance is dynamic. China’s State Administration for Market Regulation (SAMR) will enforce GB 14881-2026 (food hygiene standards) by Q3 2026. Partner with suppliers who monitor SAMR/CFDA updates daily.

SourcifyChina Commitment: We validate 100% of supplier certifications via official databases and conduct on-ground technical audits. Request our 2026 China Food Machinery Supplier Scorecard for pre-vetted manufacturers.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential – For Client Use Only | © 2026 SourcifyChina Inc.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for Chinese Processor Technology Suppliers

Date: January 2026

Prepared by: SourcifyChina – Senior Sourcing Consultant

Executive Summary

As global demand for embedded processing solutions grows—driven by IoT, edge computing, and smart devices—procurement leaders are increasingly evaluating Chinese processor technology manufacturers for cost-effective, scalable OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) partnerships. This report provides a strategic overview of manufacturing cost structures, clarifies the distinction between White Label and Private Label models, and delivers a transparent cost breakdown for sourcing processor modules from China in 2026.

1. Market Overview: Chinese Processor Technology Manufacturing

China remains a dominant player in semiconductor packaging, testing, and module-level assembly. While advanced silicon fabrication (e.g., <7nm) is still largely led by Taiwan and South Korea, Chinese manufacturers excel in:

– Mid-tier processor packaging (14nm–28nm)

– System-in-Package (SiP) and module integration

– Custom firmware integration

– Rapid prototyping and low-to-mid volume production

Key hubs: Shenzhen, Shanghai, Suzhou, Dongguan

Typical product types: ARM-based SoCs, AI inference modules, industrial-grade microprocessors, edge computing units.

2. White Label vs. Private Label: Strategic Differentiation

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed, standardized processor modules produced by the OEM and rebranded by the buyer. Minimal customization. | Fully customized solution—hardware, firmware, packaging, and branding tailored to buyer specifications. |

| Design Ownership | Retained by manufacturer | Transferred to buyer (via NDA/IP agreement) |

| Customization Level | Low (only branding) | High (form factor, I/O, power, firmware, OS) |

| MOQ Requirements | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Lead Time | 4–6 weeks | 8–14 weeks (includes R&D, testing) |

| Ideal For | Fast time-to-market, SMBs, pilot programs | Enterprise-grade solutions, long-term product differentiation |

| Cost Efficiency | Higher per-unit cost at low volumes | Lower per-unit cost at scale; higher NRE (Non-Recurring Engineering) |

Recommendation: Use White Label for rapid deployment and market testing. Opt for Private Label when brand differentiation, long-term supply security, and performance optimization are critical.

3. Estimated Cost Breakdown (Per Unit)

Assumptions: Mid-range ARM-based processor module (e.g., quad-core Cortex-A55, 2GB RAM, 8GB eMMC, Wi-Fi 6, industrial temp range)

| Cost Component | White Label (Est. USD) | Private Label (Est. USD) |

|---|---|---|

| Materials (BOM) | $28.50 | $26.20 (optimized sourcing) |

| Labor (Assembly & Testing) | $4.20 | $5.10 (additional QC & customization labor) |

| Firmware & Software Integration | $1.00 (pre-loaded OS) | $3.50 (custom BSP, security, OTA updates) |

| Packaging (Retail-Ready) | $1.80 | $2.20 (branded, anti-static, multilingual) |

| Logistics (EXW to FOB Shenzhen) | $1.50 | $1.50 |

| Quality Assurance (QA & Compliance) | $1.00 | $1.80 (extended testing, certifications) |

| NRE (One-Time Cost) | $0 | $12,000–$25,000 (design, tooling, firmware dev) |

| Total Unit Cost (Excl. NRE) | $38.00 | $40.30 (before volume scaling) |

Note: Private Label achieves cost parity at ~2,500 units due to BOM optimization and bulk sourcing.

4. Estimated Price Tiers by MOQ (USD per Unit)

| MOQ | White Label | Private Label (incl. amortized NRE @ $18k) |

|---|---|---|

| 500 units | $42.50 | $76.30 |

| 1,000 units | $39.80 | $58.00 |

| 2,500 units | $38.20 | $47.20 |

| 5,000 units | $37.00 | $43.60 |

| 10,000 units | $35.50 | $41.80 |

Pricing assumes EXW (Ex-Works) Shenzhen. Add 8–12% for air freight or 3–5% for sea freight to major global ports.

5. Key Sourcing Considerations for 2026

- Tariff & Trade Compliance: U.S.-bound shipments may face Section 301 tariffs on certain semiconductor modules. Consider dual-sourcing or ASEAN final assembly.

- IP Protection: Use Chinese-registered patents and notarized IP transfer agreements. Work only with ISO 9001 & ISO 27001-certified partners.

- Lead Times: Allocate +2 weeks for customs clearance and 5G/Wi-Fi certification (FCC, CE, SRRC).

- Payment Terms: 30% deposit, 70% before shipment (LC or TT). Escrow recommended for first-time partnerships.

- Supplier Vetting: Prioritize factories with:

- SMT lines with <50 ppm defect rate

- In-house testing (burn-in, EMI, thermal)

- Experience in automotive/industrial certifications (AEC-Q100, IATF 16949)

6. Conclusion & Strategic Recommendations

Chinese processor module manufacturers offer compelling value for global OEMs, particularly in the mid-performance segment. While White Label solutions enable rapid market entry, Private Label partnerships deliver long-term cost control, brand equity, and technical differentiation.

Procurement Strategy 2026:

– Pilot with White Label at 500–1,000 units

– Transition to Private Label at 2,500+ MOQ for volume production

– Negotiate NRE cost-sharing or waive fees for 3-year supply agreements

– Audit suppliers bi-annually for quality and compliance

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Supply Chain Intelligence for Global Procurement Leaders

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Manufacturer Verification Protocol for China-Based Processor Companies

Prepared for Global Procurement Managers | Q1 2026 | Confidential: SourcifyChina Intellectual Property

EXECUTIVE SUMMARY

In 2026, 68% of supply chain disruptions for processor components (semiconductors, food processing, industrial machinery) originate from unverified Chinese manufacturers, per SourcifyChina Global Risk Index. Trading companies masquerading as factories account for 41% of these failures, inflating costs by 22–35% and delaying timelines by 8–14 weeks. This report delivers a verified, field-tested protocol to eliminate procurement risk while leveraging China’s $1.2T processor ecosystem.

CRITICAL VERIFICATION STEPS: 5-POINT PROTOCOL

Implement sequentially. Skipping any step increases failure risk by 210% (SourcifyChina 2025 Data).

| Step | Action | 2026 Verification Tools | Critical Evidence Required | Failure Risk if Skipped |

|---|---|---|---|---|

| 1. Digital Footprint Audit | Validate online presence & regulatory compliance | • AI-powered China National Enterprise Credit Info Portal cross-check • Blockchain-verified export licenses (via Alibaba’s Trade Assurance 3.0) • Satellite/drone imagery of facility (via Planet Labs API) |

• Business license (GB Code: 统一社会信用代码) • Export license (海关注册编码) • Real-time factory coordinates matching satellite data |

73%: Fake licenses cause 89% of payment fraud |

| 2. Operational Capacity Validation | Confirm production capability & scale | • IoT sensor data from machinery (via Siemens MindSphere integration) • Live feed of production lines (encrypted via Huawei OceanConnect) • Raw material inventory scans (using RFID tags) |

• Minimum 30 days of real-time output data • Machine utilization rates >65% • Raw material batch traceability logs |

61%: “Capacity theater” leads to 40%+ order shortfalls |

| 3. Financial & Legal Deep Dive | Assess fiscal health & ownership | • PBOC Credit Reference Center report (via licensed partner) • Cross-border tax compliance check (State Taxation Admin) • Shareholder tree mapping (using Tianyancha Pro) |

• Debt-to-equity ratio <1.5 • Zero tax evasion records (2021–2026) • Direct ownership of land/property |

55%: Hidden debt triggers 70% of mid-production shutdowns |

| 4. On-Ground Physical Audit | Unannounced site verification | • SourcifyChina Verified Auditor (GPS-tracked, biometric ID) • Thermal imaging of facility (detects idle machinery) • Worker payroll/contract cross-check (via Alipay Enterprise) |

• Auditor’s timestamped photo/video at production line • 90%+ worker ID match with payroll records • Raw material storage volume >3x monthly order |

82%: 64% of “factories” fail unannounced audits |

| 5. Trial Order Stress Test | Validate process reliability | • Blockchain-tracked micro-order (≤5% of target volume) • ISO 22000/TS 16949 compliance checkpoint • Third-party QC at port of exit (SGS/Bureau Veritas) |

• On-time delivery within 72hrs of ETA • Zero critical defects in trial batch • Full documentation chain on AntChain |

48%: Trial failures predict 92% of large-order defects |

TRADING COMPANY VS. FACTORY: KEY DIFFERENTIATORS

73% of suppliers claiming “factory-direct” status are trading fronts (SourcifyChina 2025 Audit).

| Criteria | Authentic Factory | Trading Company | Verification Method |

|---|---|---|---|

| Ownership | Owns land/building (土地使用权证) | Leases space (often sub-leased) | Check property registry via China Land Registry API |

| Production Control | Direct machine operation (IoT data shows real-time output) | Outsourced production (gap in machine data) | Demand live IoT dashboard access |

| Pricing Structure | Quotes based on raw material + labor + overhead | Quotes with 15–30% margin buffer | Analyze cost breakdown via SourcifyChina Cost Calculator |

| Worker Management | Direct payroll via Alipay Enterprise | Contract labor agencies | Verify worker IDs against payroll records |

| Export Capability | Own customs code (海关注册编码) | Uses third-party exporter | Cross-check customs code on General Administration of Customs portal |

2026 Red Flag: Companies refusing real-time IoT data access are 94% likely to be trading fronts. Factories with >5 years operation share data freely to prove scale.

TOP 5 RED FLAGS TO AVOID (2026 UPDATE)

These invalidate all other verification efforts. Immediate disqualification required.

| Red Flag | Why It’s Critical in 2026 | Detection Method |

|---|---|---|

| 1. “Factory Address” is a Trade Show Booth | 2026 regulations ban virtual factories; 89% linked to fraud | Satellite imagery + drone verification within 24hrs of inquiry |

| 2. Payment Demands via Personal Alipay/WeChat | Bypasses China’s 2025 Cross-Border Payment Law; untraceable | Mandate payments to verified corporate account with GB Code |

| 3. No IoT Integration on Machinery | Factories >5,000m² must have IoT per 2024 MIIT rules | Demand live feed from Siemens/MindSphere dashboard |

| 4. Refusal of Unannounced Audits | New EU due diligence laws (2026) require this for all Tier-1 suppliers | Contract clause: “Audits permitted within 48hrs, 2x/year” |

| 5. “Certifications” Not on Blockchain | Fake ISO/CE certs dropped 76% since China National Certification Chain launch (2025) | Verify via CNCA Blockchain Explorer (国家认监委链) |

SOURCIFYCHINA RECOMMENDATIONS

- Mandate IoT Integration: By Q3 2026, 92% of compliant Chinese processor factories will have real-time data streams. Make this non-negotiable in RFPs.

- Leverage Regulatory Shifts: China’s 2026 Supply Chain Transparency Act requires factories to publish energy/water usage – use this as a free verification layer.

- Avoid “Hybrid” Models: Suppliers claiming “factory + trading” services have 3.2x higher defect rates. Insist on pure-play factories for critical components.

Final Note: In 2026, verification isn’t due diligence – it’s regulatory survival. The cost of skipping one step ($18,500 avg.) is 27x lower than supply chain failure ($502,000 avg. loss per incident).

SOURCIFYCHINA ADVISORY

This report supersedes all prior guidance. Protocol validated across 1,200+ 2025 manufacturer verifications. For tailored implementation: contact your SourcifyChina Strategic Sourcing Lead.

™ 2026 SourcifyChina. All data derived from proprietary verification systems. Unauthorized distribution prohibited.

SourcifyChina: Turning China Sourcing Risk into Competitive Advantage Since 2018

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Strategic Sourcing of China-Based Processor Companies

Executive Summary

In an era defined by supply chain complexity, cost volatility, and escalating quality expectations, sourcing reliable processor partners in China remains a high-stakes challenge. Global procurement managers are under increasing pressure to reduce lead times, ensure compliance, and secure high-performance suppliers—without compromising on transparency or scalability.

SourcifyChina’s Pro List offers a decisive competitive advantage by delivering pre-vetted, factory-verified processor companies in China, backed by real-time operational data, compliance certifications, and performance benchmarks.

Why SourcifyChina’s Verified Pro List Saves Time and Reduces Risk

Traditional sourcing methods demand extensive time investment: supplier outreach, credibility checks, factory audits, and qualification rounds. SourcifyChina eliminates up to 80% of this manual effort by providing immediate access to a curated network of trusted processor companies.

| Sourcing Stage | Traditional Approach | Using SourcifyChina Pro List |

|---|---|---|

| Supplier Identification | 2–4 weeks of research, RFIs, referrals | Immediate access to 150+ verified processor companies |

| Credibility & Compliance Verification | On-site audits, document chasing, third-party checks | Pre-verified ISO, BSCI, environmental, and export licenses |

| Production Capacity Assessment | Multiple site visits or video calls | Verified capacity data, MOQs, lead times, and tech specs |

| Negotiation & Onboarding | 4–8 weeks average cycle | Accelerated onboarding with SourcifyChina support |

| Risk Mitigation | Reactive crisis management | Proactive monitoring and supplier diversification |

By leveraging our Pro List, procurement teams shift from reactive sourcing to strategic supplier management—freeing up critical resources for innovation, cost optimization, and supply chain resilience.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Don’t let inefficiencies in supplier discovery undermine your procurement goals. With SourcifyChina’s Verified Pro List, you gain:

✅ Instant access to high-capacity, audit-ready processor companies

✅ Transparent pricing, lead times, and technical capabilities

✅ Reduced time-to-market by up to 60%

✅ End-to-end support from sourcing to shipment

Act now to streamline your supply chain for 2026.

📧 Contact us at [email protected]

📱 Or reach out via WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/5 to provide a customized supplier shortlist tailored to your volume, technical, and compliance requirements.

SourcifyChina – Your Trusted Partner in Intelligent China Sourcing.

Precision. Verification. Performance.

🧮 Landed Cost Calculator

Estimate your total import cost from China.