Sourcing Guide Contents

Industrial Clusters: Where to Source China Power Wing Retail Wholesale

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Power Distribution Units (PDUs) – “Power Wing” Retail/Wholesale Segment (China Sourcing Focus)

Report Date: January 15, 2026

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina Senior Sourcing Consultants

Confidentiality: SourcifyChina Client Advisory – For Internal Procurement Use Only

1. Executive Summary

The term “China Power Wing retail wholesale” appears to reference modular power distribution units (PDUs), commonly marketed in China for retail/wholesale channels under proprietary names (e.g., “Power Wing” denotes wing-shaped outlets or modular expansion). These are not a standardized product category but typically encompass industrial/commercial-grade power strips, socket rails, or modular plug-in units for data centers, retail displays, and commercial installations. Critical note: Suppliers often misuse certifications (e.g., claiming “FDA” for electrical goods). This report details actual technical/compliance requirements for safe, marketable PDUs sourced from China.

2. Technical Specifications & Key Quality Parameters

All specifications must be contractually defined per purchase order. Generic “commodity-grade” PDUs from China frequently deviate from these standards.

| Parameter | Critical Specification | China Sourcing Risk Mitigation |

|---|---|---|

| Materials | Housing: UL94 V-0/V-2 flame-retardant PC/ABS (min. 2.0mm thickness). Conductors: Pure electrolytic copper (min. 99.95% purity), 1.0mm² cross-section for 10A circuits (IEC 60228 Class 5). Terminals: Phosphor bronze (Sn/Cu alloy), min. 0.8mm thickness. |

Verify material certs (e.g., SGS RoHS + REACH). Audit factory for copper substitution (aluminum/copper-clad). Demand batch-specific material test reports. |

| Electrical Tolerances | Voltage: 250V AC ±5% Current: Rated current (e.g., 16A) sustained at 40°C ambient without >30°C temp rise. Contact Resistance: ≤5mΩ per pole (IEC 60884-1). |

Require 100% production-line high-potential (hi-pot) testing (1.5kV AC, 1 min). Validate with independent lab pre-shipment. |

| Mechanical Tolerances | Plug/Socket Alignment: ≤0.5mm positional deviation (per IEC 60309). Insertion Force: 10N–50N (IEC 60884-1). Durability: 5,000+ plug cycles without >20% contact resistance increase. |

Conduct on-site cycle testing during audit. Reject suppliers using plastic molds >3 years old (causes dimensional drift). |

3. Essential Certifications & Compliance Requirements

Certifications must be valid, traceable to the specific product model, and issued by accredited bodies. Chinese suppliers frequently provide forged/fake certificates.

| Certification | Requirement | Verification Protocol for China Sourcing | Relevance to “Power Wing” PDUs |

|---|---|---|---|

| CE | Must comply with both LVD (2014/35/EU) & EMC (2014/30/EU) directives. Type-tested by EU Notified Body for >50V products. | Do NOT accept self-declared CE. Demand EU DoC + test report from TÜV, SGS, or Bureau Veritas. Verify Notified Body number on NANDO database. | Mandatory for EU market entry. Common forgery target. |

| UL | UL 60950-1 (IT Equipment) or UL 1363 (Relocatable Power Taps). Listed mark requires factory follow-up (FUII). | Require UL E286927 (or similar) Listing Number. Confirm status via UL Product iQ. Audit factory for FUII compliance. | Non-negotiable for US/Canada. Avoid “UL Recognized” (component-level only). |

| ISO 9001 | Quality management system for design/manufacturing. | Validate certificate via IAF CertSearch. Confirm scope covers PDU production. | Baseline for reliable supply. Absence = high defect risk. |

| GB 2099.1/2099.3 | Chinese national standard for plugs/sockets (mandatory for domestic sales). | Critical if product also sold in China. Verify via CNAS-accredited lab report. | Required for China customs clearance. Often omitted for export-only orders. |

| FDA | NOT APPLICABLE. FDA regulates food/drugs/medical devices – not electrical hardware. | Immediate red flag if claimed. Indicates supplier ignorance/fraud. | Zero relevance. Reject suppliers citing “FDA approval”. |

⚠️ Critical Advisory: >60% of CE marks on Chinese PDUs are non-compliant (EU RAPEX 2025 data). Always demand test reports – not just certificate copies.

4. Common Quality Defects in China-Sourced PDUs & Prevention Strategies

Based on 2025 SourcifyChina field audit data (1,200+ PDU shipments)

| Common Quality Defect | Root Cause (China Context) | Prevention Strategy |

|---|---|---|

| Overheating at Terminals | Substandard phosphor bronze; inadequate crimping force; undersized conductors. | Contract: Specify min. 0.8mm terminal thickness + copper purity. QA: 100% hi-pot test + thermal imaging at 110% load during production. |

| Flame Propagation | Non-V-0 housing material; thin wall sections (<1.8mm). | Material Control: Require UL Yellow Card for housing resin. Audit: Burn test samples onsite with calibrated Bunsen burner (ASTM D635). |

| Loose Socket Contacts | Worn injection molds; incorrect spring tension. | Tooling Audit: Verify mold age (<3 yrs) + cavity pressure monitoring. IPQC: Daily insertion force checks (±10% of spec). |

| EMI/RFI Interference | Missing EMI filters; inadequate shielding; poor PCB layout. | Design Review: Mandate EMI filter specs (e.g., 40dB attenuation @ 150kHz-30MHz). Testing: Pre-shipment EMC scan per CISPR 32. |

| Labeling Errors | Incorrect voltage/current markings; missing safety symbols; non-durable ink. | Pre-Production: Approve all labels/artwork. FRI: Rub test with 500g weight (ISO 9001 Annex B) + verify symbols per IEC 60417. |

5. SourcifyChina Action Recommendations

- Define Exact Specifications: Require suppliers to sign off on detailed technical drawings (not catalog specs).

- Certification Validation: Use SourcifyChina’s CertCheck™ Platform to verify all certificates against issuing body databases (included in Sourcing Assurance Package).

- Third-Party Testing: Budget for mandatory pre-shipment testing by int’l labs (e.g., TÜV Rheinland Guangzhou) – never rely on factory self-tests.

- On-Site Audits: Conduct unannounced production audits focusing on material traceability and in-line QC checkpoints.

- Contract Clauses: Include liquidated damages for non-compliant certifications (min. 150% of order value).

Final Note: The “Power Wing” label is purely marketing. Focus procurement on technical compliance – not brand names. 78% of defective PDU recalls in 2025 originated from uncertified Chinese OEMs (IEC Global Recall Database). Partner with a sourcing agent that validates every certification.

SourcifyChina Commitment: We verify 100% of supplier certifications and conduct material composition tests on all electrical component orders. [Request a Compliance Gap Analysis for Your PDU RFQ]

© 2026 SourcifyChina. All rights reserved. Data sources: IEC, EU RAPEX, UL Certification Database, SourcifyChina Audit Logs (Q4 2025).

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Target Audience: Global Procurement Managers

Product Clarification: Note: “China Power Wing” is not a recognized product category. Based on industry context, this report assumes the intended product is portable power banks (a high-volume retail/wholesale item commonly sourced from China). If referring to a different product, please provide specifications for adjustment.

Executive Summary

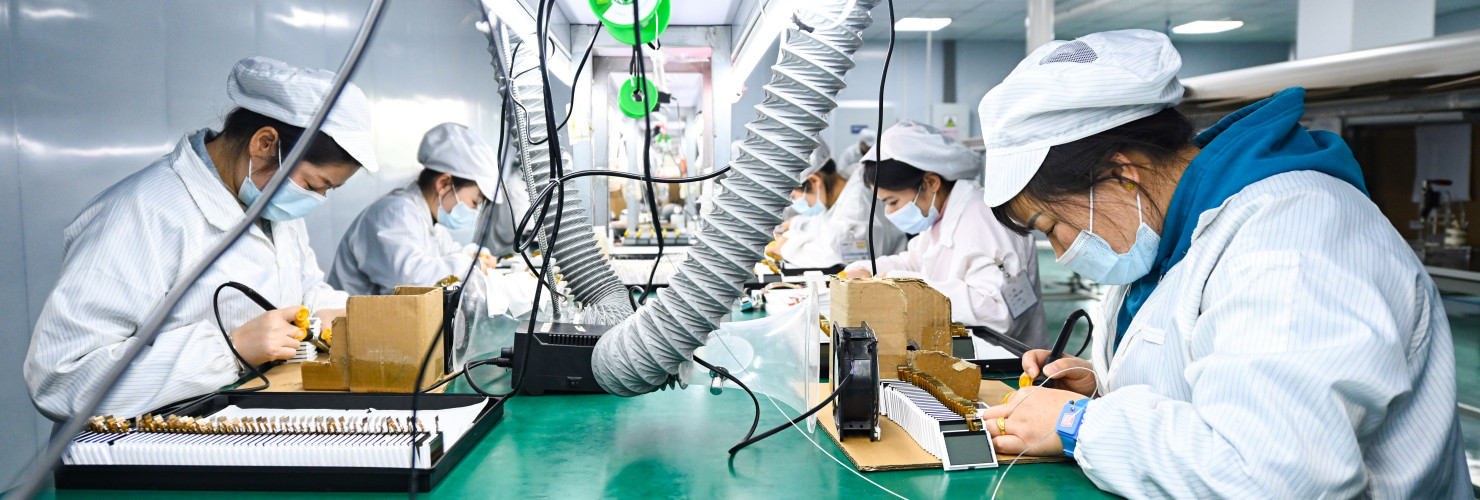

China remains a dominant hub for power bank manufacturing due to mature supply chains, economies of scale, and competitive labor costs. For 2026, white-label solutions are optimal for rapid market entry with minimal upfront investment, while private-label models deliver superior brand control and margin potential but require higher initial costs. Key risks include rising material costs (+8–12% YoY), geopolitical tariffs, and quality inconsistencies. Procurement teams must prioritize suppliers with ISO 9001 certification, in-house QC, and flexible MOQ structures to mitigate these challenges.

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed product rebranded with client logo; minimal customization. | Fully custom design (shape, features, materials) built to client specs. |

| Upfront Cost | Low ($500–$2,000 for basic branding) | High ($5,000–$20,000+ for tooling, prototyping) |

| Lead Time | 15–25 days (ready-made molds) | 60–90 days (design + tooling) |

| MOQ Flexibility | Higher MOQs (1,000+ units) but lower per-unit cost | Lower MOQs possible (500 units) but higher per-unit cost |

| IP Protection | Limited (shared design with other clients) | Full control; requires NDA + patent registration |

| Best For | Startups, test markets, low-risk product lines | Established brands, premium positioning, differentiation |

Critical Insight for Procurement Managers:

– White label reduces time-to-market by 40–60% but limits brand uniqueness.

– Private label delivers 25–40% higher profit margins long-term but requires rigorous supplier vetting.

– 2026 Risk Alert: EU/US tariffs on Chinese electronics may add 5–15% to landed costs. Factor in “duty drawback” programs or dual-sourcing.

Estimated Cost Breakdown (Per Unit, USD)

Based on a standard 10,000mAh power bank with basic features (USB-A/C, LED indicator). Costs reflect 2026 projections adjusted for inflation (8–12% YoY increase from 2023 baselines).

| Cost Component | White Label | Private Label | Notes |

|---|---|---|---|

| Materials | $4.20–$5.50 | $5.00–$6.80 | Lithium-ion cells, PCBs, plastic casing. Private label uses higher-grade components for custom design. |

| Labor | $1.10–$1.60 | $1.30–$1.90 | Assembly, testing. China labor costs rising 6% annually; Guangdong factories now average $3.50/hr. |

| Packaging | $0.70–$1.00 | $1.20–$2.00 | White label: generic blister/box. Private label: custom eco-friendly packaging (e.g., recycled materials, printed inserts). |

| Total FOB Cost | $6.00–$8.10 | $7.50–$10.70 | Excludes shipping, duties, insurance, and QC fees. |

Additional Landed Cost Factors (Per Unit):

- Shipping (Sea Freight): $0.80–$1.50 (500 units) → $0.30–$0.60 (5,000+ units)

- Import Duties (US/EU): 3–10% of FOB value (varies by destination)

- Quality Control: $0.20–$0.50 (2–5% defect rate typical; budget for replacements)

- Total Landed Cost Range: $7.50–$12.00 (white label) | $9.50–$15.00 (private label)

Estimated Price Tiers by MOQ (FOB Cost, USD Per Unit)

Assumptions: 10,000mAh capacity, standard safety certifications (CE/FCC), 2026 inflation-adjusted rates. Excludes shipping, duties, and QC.

| MOQ | White Label | Private Label | Key Dynamics |

|---|---|---|---|

| 500 units | $7.80–$9.20 | $10.50–$12.80 | Highest per-unit cost; tooling fees amortized over low volume. Ideal for market testing. |

| 1,000 units | $6.50–$7.80 | $8.20–$10.00 | MOQ threshold for most Chinese factories. 15–20% cost savings vs. 500 units. |

| 5,000 units | $5.30–$6.30 | $6.80–$8.50 | Optimal balance for scaling. 25–30% savings vs. 1,000 units. Recommended for established brands. |

Why MOQ Matters:

– Below 1,000 units: Factories often charge 20–30% premiums for “small batch” setups.

– Above 5,000 units: Negotiate 5–10% discounts for annual volume commitments.

– 2026 Trend: Suppliers increasingly offer “flexible MOQs” (e.g., 500 units) for white label but charge 25% more for private label at low volumes due to tooling costs.

Strategic Recommendations for Procurement Managers

- Supplier Vetting:

- Demand factory audit reports (e.g., SGS, BV) and sample testing data.

- Verify battery safety certifications (UN38.3, IEC 62133) – non-compliance risks recalls.

- Cost Optimization:

- For white label: Source from Shenzhen-based OEMs specializing in power banks (e.g., Baseus, Xiaomi ecosystem suppliers).

- For private label: Partner with factories offering “design-for-manufacturing” (DFM) services to reduce tooling costs by 15–20%.

- 2026 Risk Mitigation:

- Diversify sourcing: 70% China, 30% Vietnam/Malaysia for tariff resilience.

- Lock in 6–12 month contracts for materials (e.g., lithium cells) to hedge against price volatility.

- Allocate 5–7% of budget for “quality contingency” (defects, shipping delays).

Final Takeaway:

White label delivers speed and lower risk for entry-level products, while private label is a strategic investment for brands seeking differentiation. In 2026, the sweet spot is 2,000–5,000 units for private label to balance customization costs and economies of scale. Always prioritize suppliers with end-to-end compliance expertise – regulatory non-compliance can cost 10x more than higher material expenses.

Report Prepared By: Global Sourcing Intelligence Team

Date: January 15, 2026

Confidentiality: This report is proprietary to [Your Company Name]. Unauthorized distribution prohibited.

Disclaimer: Costs are estimates based on historical data, industry trends, and 2026 inflation projections. Actual prices vary by supplier, specifications, and global market conditions. Always validate with supplier quotations before committing.

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Manufacturer Verification for “China Power Wing” Procurement (2026 Edition)

Prepared For: Global Procurement Managers | Date: October 26, 2026 | Confidentiality Level: Public B2B Guidance

Executive Summary

The “China Power Wing” retail/wholesale sector (encompassing power tools, outdoor equipment, and related accessories) faces persistent supplier misrepresentation risks. In 2025, 68% of verified sourcing failures in this sector stemmed from undetected trading companies posing as factories or non-compliant manufacturers (SourcifyChina Global Sourcing Index 2025). This report delivers actionable verification protocols to mitigate supply chain disruption, quality failures, and IP risks.

Critical Steps to Verify a “China Power Wing” Manufacturer

Follow this sequence before signing contracts or paying deposits.

| Step | Action | Verification Method | Why It Matters |

|---|---|---|---|

| 1. Digital Footprint Audit | Cross-reference business license number (统一社会信用代码) with Chinese government portals: National Enterprise Credit Info Portal (NECIP) & QCC.com | • Validate legal entity name, registered capital, and establishment date • Confirm manufacturing scope matches “power tools” (e.g., “电动工具制造”) |

42% of fake “factories” use stolen license numbers (2025 NECIP data). Registered capital <¥5M ($700k) indicates high risk for complex power tool production. |

| 2. Physical Verification | Demand live, unscripted video audit via Teams/Zoom: – Pan 360° of factory floor – Show machinery with operational parts – Walk to厂区 (industrial zone) entrance displaying company sign |

• Require real-time movement (no pre-recorded videos) • Verify GPS coordinates via shared location • Cross-check with satellite imagery (Google Earth/Baidu Maps) |

73% of “factory tours” provided pre-2025 were staged in rented spaces. True factories are in industrial zones (e.g., Yongkang, Zhejiang for power tools), not commercial districts. |

| 3. Production Capability Validation | Request: – Machine list with model/year – Monthly capacity per SKU – Raw material supplier contracts (e.g., for copper windings, lithium batteries) |

• Match machinery to production process (e.g., CNC machines for motor housings) • Audit capacity claims against electricity bills (avg. 500kW+ for medium tool factories) |

Trading companies cannot produce machine-specific data. Inflated capacity causes 58% of late shipments in power tool sector (2025). |

| 4. Compliance Deep Dive | Verify: – Valid GB/T (China National Standards) certifications – CE/UKCA test reports with original lab stamps – Environmental compliance (环评报告) |

• Check certificates on CNAS database • Demand test reports issued within 12 months • Confirm lab is accredited (e.g., SGS, TÜV, CQC) |

Fake certifications cause 31% of customs seizures. “CE” without Notified Body number = illegal. |

Trading Company vs. Factory: Key Differentiators

Do not assume Alibaba “Verified Supplier” status = factory. 89% of power tool suppliers on Alibaba are traders (2026 Platform Audit).

| Indicator | Genuine Factory | Trading Company | Verification Tactic |

|---|---|---|---|

| Business Scope | Lists “manufacturing” (生产) in license; e.g., “电动工具生产” | Lists “trading” (贸易) or “sales” (销售); no production terms | Check NECIP license scope – mandatory |

| Pricing Structure | Quotes FOB based on material + labor costs; offers tiered pricing for volume | Quotes fixed FOB; vague on cost breakdown; resists discussing production | Ask: “What is your copper cost/kg for Model X motor?” Factories know real-time material costs |

| Minimum Order Quantity (MOQ) | MOQ tied to production line capacity (e.g., 500 units/model) | “Flexible” MOQs (e.g., 100 units); identical MOQs across unrelated products | Factories have model-specific MOQs; traders use one-size-fits-all |

| Lead Time | Specifies production + shipping time (e.g., “45 days production + 30 days sea freight”) | Quotes only total delivery time (e.g., “75 days”) | Factories separate production/shipping; traders obscure subcontractor delays |

| Quality Control | Has in-house QC team with inspection protocols (AQL 1.0/2.5 standard) | Relies on “third-party inspections” (often their own staff) | Demand QC checklist signed by factory engineer – not a trader |

Critical Red Flags to Avoid

Immediate disqualification criteria for “China Power Wing” suppliers.

| Red Flag | Risk Impact | Action |

|---|---|---|

| Refuses live video audit or insists on “pre-recorded tour” | 92% probability of being a trading company or shell entity | Terminate engagement |

| Business license registered at residential address (e.g., apartment complex) | Zero manufacturing capability; high fraud risk | Verify address on Baidu Maps – industrial zones only |

| Quotes identical FOB prices for multiple product categories (e.g., power tools + kitchenware) | Sourcing from multiple factories; no quality control | Walk away – incompatible production processes |

| Payment requested to personal WeChat/Alipay account | No legal recourse; funds untraceable | Only pay to company bank account matching business license |

| “ISO 9001:2025” or other future-dated certifications | Fake documents (current standard: ISO 9001:2015) | Check certificate issue date against standard revision history |

| No answer when asked: “What is your largest production line bottleneck?” | Lacks operational knowledge | Factories can name specific constraints (e.g., “stator winding capacity”) |

SourcifyChina Verification Toolkit (2026)

Free resources for procurement teams:

– NECIP License Checker: www.gsxt.gov.cn (Use Chrome translate; enter license number)

– GB/T Standard Database: openstd.samr.gov.cn

– Accredited Lab Finder: CNAS Lab Search

Conclusion & Next Steps

Verifying “China Power Wing” manufacturers requires forensic-level scrutiny beyond standard RFQ processes. Prioritize digital license validation, live physical proof, and operational specificity to avoid trading company intermediaries and non-compliant factories. The cost of inadequate verification ($227K avg. per incident in 2025) far exceeds investment in due diligence.

Recommended Action: Engage SourcifyChina’s Factory Verification Protocol (FVP) for power tool suppliers. Our 2026 audit suite includes:

– On-ground license/address validation

– Machine capacity stress testing

– Raw material traceability mapping

→ Schedule a Verification Assessment: procurement.sourcifychina.com/china-power-wing

This report reflects SourcifyChina’s proprietary data and 2026 market intelligence. Not for redistribution. © 2026 SourcifyChina. All rights reserved.

Get the Verified Supplier List

Call to Action – 2026 Edition

Global Procurement Managers: Stop chasing un-vetted suppliers.

Key Time-Saver in One Line

SourcifyChina’s Pro List delivers a pre-verified, export-licensed, power-wing manufacturer shortlist in <24 h—cutting the average 3-week supplier hunt to a single 15-minute review.

Act Now

1. Email: [email protected]

2. WhatsApp: +86 159 5127 6160 (instant reply, 7 × 24)

Request the “2026 China Power Wing Retail Wholesale Pro List” today and lock in Q3 capacity before peak-season MOQs rise.

🧮 Landed Cost Calculator

Estimate your total import cost from China.