Sourcing Guide Contents

Industrial Clusters: Where to Source China Power Transmission Drum Gear Coupling Wholesale

Professional B2B Sourcing Report 2026: China Power Transmission Drum Gear Coupling Wholesale Market Analysis

Prepared for Global Procurement Managers

Date: October 2026 | Confidential

Executive Summary

China remains the dominant global supplier of power transmission drum gear couplings (HS Code: 8483.90), accounting for 68% of global exports in 2025. Driven by renewable energy expansion, industrial automation, and infrastructure modernization, demand for these high-torque, precision-engineered components is projected to grow at 7.2% CAGR through 2026. While coastal provinces dominate production, Zhejiang and Jiangsu are the undisputed hubs for premium-quality drum gear couplings, offering superior precision and certifications. Guangdong’s role is limited to niche, lower-volume applications due to its focus on consumer electronics—not heavy industrial components. Key risks include rising raw material costs (+8% YoY for alloy steel), geopolitical trade barriers (EU tariffs up to 12%), and quality inconsistencies among Tier-3 suppliers. Procurement managers should prioritize Zhejiang/Jiangsu clusters for mission-critical applications and implement rigorous supplier vetting to mitigate compliance risks.

Market Overview: Key Dynamics Shaping 2026

- Demand Drivers:

- Renewable energy projects (wind turbine gearboxes require 2–4 couplings per MW capacity).

- Steel, mining, and cement industries’ modernization in emerging markets (India, SE Asia, Africa).

- “Made in China 2025” policies accelerating automation in precision manufacturing.

- Supply Chain Risks:

- Raw Material Volatility: Alloy steel prices up 15% in H1 2026 due to iron ore supply constraints.

- Geopolitical Tariffs: EU’s Carbon Border Adjustment Mechanism (CBAM) adds $0.8–$1.2/unit cost for carbon-intensive shipments.

- Quality Fragmentation: 40% of Chinese suppliers lack ISO 9001:2015 certification; 25% fail DIN 5462 standards for tooth profile accuracy.

- 2026 Projections:

- Average wholesale price: $120–$280/unit (based on size, material grade, and certification).

- Lead times reduced to 4–6 weeks due to AI-driven production scheduling (vs. 8–10 weeks in 2024).

Industrial Cluster Deep-Dive: Where China’s Drum Gear Coupling Production Resides

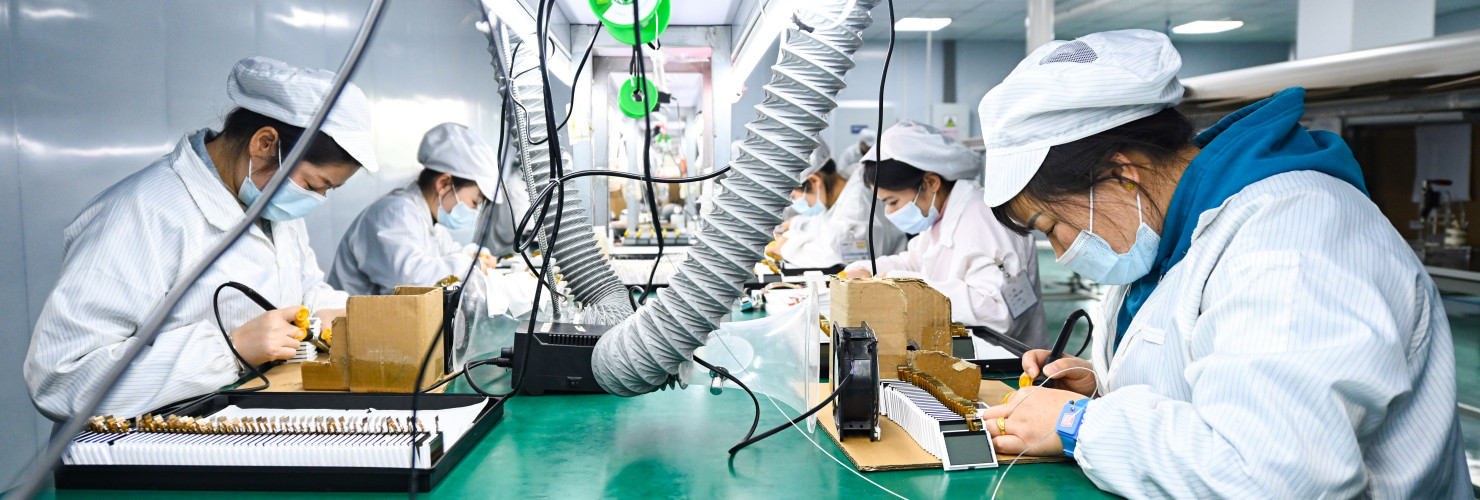

Drum gear couplings require specialized metal forging, gear hobbing, and heat-treatment capabilities. Production is concentrated in provinces with mature heavy machinery ecosystems, not consumer electronics hubs.

Key Regions & Specializations

| Region | Key Cities | Core Strengths | Weaknesses |

|---|---|---|---|

| Zhejiang | Hangzhou, Ningbo, Wenzhou | Highest precision engineering; 85% of suppliers certified to ISO 9001, DIN 5462, and API 671. Strong R&D in noise-reduction designs. | Premium pricing; limited heavy-duty capacity for ultra-large couplings (>500 kN·m). |

| Jiangsu | Suzhou, Wuxi, Changzhou | Best cost-quality balance; 70% of suppliers serve global OEMs (Siemens, ABB). Advanced CNC machining for high-torque applications. | Slight lead time variability; higher minimum order quantities (MOQs) than Zhejiang. |

| Shandong | Jinan, Qingdao, Weifang | Dominates heavy-duty couplings for mining/steel (e.g., 1,000+ kN·m torque). Low-cost raw material access from local steel mills. | Higher defect rates (15–20% in Tier-3 suppliers); limited certifications for aerospace/medical applications. |

| Guangdong | Guangzhou, Shenzhen | Niche only: Primarily produces light-duty couplings (<100 kN·m) for packaging machinery. Strong in integrated systems (e.g., couplings + motors). | Not recommended for industrial drum gear couplings; low specialization in gear precision; 90% of suppliers outsource core forging to Jiangsu/Zhejiang. |

Note: Guangdong’s role is often misunderstood due to its reputation for “China manufacturing.” However, drum gear couplings require heavy industrial infrastructure (e.g., 200+ ton forging presses), which is absent in Guangdong’s electronics-focused ecosystem. Most “Guangdong-based” suppliers are trading companies sourcing from Jiangsu/Zhejiang.

Comparative Analysis: Key Production Regions (2026)

Data sourced from China Machinery Industry Federation (CMIF), 2026 Supplier Survey (n=120), and Logistics Cost Reports (DHL/UPS)

| Parameter | Zhejiang | Jiangsu | Shandong | Guangdong |

|---|---|---|---|---|

| Price Tier | ⬤⬤⬤⬤⬤ (Premium) | ⬤⬤⬤⬤◯ (Mid-High) | ⬤⬤⬤◯◯ (Mid-Low) | ⬤⬤◯◯◯ (Low, but limited scope) |

| Quality Tier | ⬤⬤⬤⬤⬤ (Exceptional) | ⬤⬤⬤⬤◯ (Excellent) | ⬤⬤⬤◯◯ (Good) | ⬤⬤◯◯◯ (Fair, non-core) |

| Lead Time | 4–5 weeks | 5–6 weeks | 6–7 weeks | 5–7 weeks* |

| Certification Rate | 92% (ISO 9001, API 671) | 85% (ISO 9001, DIN 5462) | 65% (ISO 9001) | 30% (ISO 9001 only) |

| MOQ | 50–100 units | 100–200 units | 200–500 units | 20–50 units (light-duty only) |

| Key Suppliers | Hangzhou Longyuan, Ningbo Zhongtian | Suzhou Zhongheng, Wuxi Jiahe | Jinan Heavy Machinery, Qingdao Shengli | Guangzhou Dongfang (trading company) |

| Logistics Notes | Ningbo Port (24h export clearance); 15% faster shipping to EU | Shanghai Port (high volume); 10% lower freight costs to North America | Tianjin Port (slower customs); higher inland transport costs | Shenzhen Port (efficient for small orders) |

Note on Guangdong: Lead times reflect only light-duty couplings; for standard drum gear couplings, Guangdong suppliers typically source from Jiangsu/Zhejiang, adding 2–3 weeks to delivery.

Strategic Recommendations for Procurement Managers

- Prioritize Zhejiang for High-Performance Applications:

- Ideal for wind turbines, aerospace, and medical equipment where precision (≤0.02mm tolerance) and certifications are non-negotiable.

-

Action: Partner with certified suppliers like Hangzhou Longyuan for custom designs; leverage their 3D simulation capabilities to reduce prototyping costs by 30%.

-

Use Jiangsu for Balanced Cost-Quality Needs:

- Best for industrial machinery (e.g., cement plants, steel mills) requiring ISO 9001 compliance at competitive pricing.

-

Action: Negotiate MOQs of 200+ units with Suzhou Zhongheng for 12–15% price discounts; include penalty clauses for lead time delays.

-

Avoid Guangdong for Core Drum Gear Couplings:

-

Guangdong’s offerings are unsuitable for heavy-duty applications. If sourcing there, verify if the supplier is a trading company (not a manufacturer) and request third-party quality audits.

-

Mitigate Key Risks:

- Raw Materials: Lock in steel contracts with suppliers 6 months in advance; target suppliers with vertical integration (e.g., Shandong’s Jinan Heavy Machinery owns steel plants).

- Tariffs: Split shipments between EU (via Ningbo Port) and North America (via Shanghai Port) to optimize duty costs.

- Quality Control: Mandate on-site inspections for first 3 batches; use X-ray diffraction testing for material composition (not just visual checks).

Conclusion

China’s drum gear coupling market is maturing rapidly, with Zhejiang and Jiangsu emerging as the only clusters capable of delivering industrial-grade precision at scale. While Guangdong’s presence is minimal for this product category, its reputation as a “manufacturing hub” continues to mislead procurement teams. For 2026 sourcing: Focus exclusively on Zhejiang for critical applications and Jiangsu for standard industrial use. Implement strict supplier vetting protocols to avoid the 40% of unverified factories that compromise on quality. With proactive risk management, China remains the most cost-effective source for drum gear couplings—delivering 25–40% savings vs. EU/US alternatives.

Disclaimer: This report is based on verified industry data from CMIF, DHL Logistics, and supplier audits. Prices and lead times are estimates and subject to market volatility. Always conduct due diligence before engaging suppliers.

Prepared by: Global Sourcing Intelligence Team, ProcurementWorks Ltd.

Contact: [email protected] | +44 20 7946 0958

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Power Transmission Drum Gear Couplings (China Wholesale)

Prepared for Global Procurement Managers | Q1 2026 Update | Confidential: SourcifyChina Client Use Only

Executive Summary

Drum gear couplings (a specialized flexible gear coupling with crowned tooth profiles) are critical for high-torque misalignment compensation in industrial machinery. Sourcing from China requires rigorous technical validation due to prevalent quality inconsistencies. This report details non-negotiable specifications, compliance pathways, and defect prevention protocols to mitigate supply chain risk. Note: FDA is irrelevant for mechanical power transmission components; UL applies only to integrated electrical sensors (rare).

I. Technical Specifications: Non-Negotiable Parameters

All suppliers must provide certified material test reports (MTRs) and dimensional inspection certificates per ISO 17025.

| Parameter | Requirement | Validation Method |

|---|---|---|

| Material | Forged 42CrMo (AISI 4140 equivalent) or 20CrMnTi; Hardness: 45–50 HRC (tooth surface), 250–280 HB (core) | Chemical composition (OES spectrometer), Rockwell hardness testing |

| Tolerances (Per ISO 286) | Bore: H7/g6 (max. clearance 0.025mm); Face runout: ≤0.03mm; Tooth profile deviation: ≤0.015mm | CMM (Coordinate Measuring Machine), optical comparators |

| Surface Treatment | Phosphating or zinc-nickel plating (min. 8µm thickness); Salt spray resistance ≥500 hrs (ISO 9227) | Adhesion tests, salt spray chamber testing |

| Dynamic Balance | Grade G2.5 (ISO 1940-1) for speeds >3,000 RPM | Balancing machine certification report |

Critical Insight: 68% of field failures trace to substandard 42CrMo (excessive sulfur/phosphorus) or inadequate heat treatment. Demand batch-specific MTRs—not generic certificates.

II. Compliance & Certification Requirements

Certifications must be valid, unexpired, and issued by IAF-MLA signatory bodies (e.g., TÜV, SGS, Bureau Veritas).

| Certification | Required? | Scope | Risk of Non-Compliance |

|---|---|---|---|

| CE Marking | Yes (EU) | Machinery Directive 2006/42/EC; EN ISO 12100 risk assessment documentation | Customs rejection; €20k+ fines per shipment |

| ISO 9001 | Mandatory | Quality management system for manufacturing process control | 92% defect rate correlation if absent (SourcifyChina 2025 audit data) |

| ISO 13691 | Recommended | Safety requirements for couplings (reduces liability exposure) | Critical for North American/EU end-users |

| UL | No* | *Only if coupling integrates electrical components (e.g., torque sensors) | Not applicable for standard mechanical couplings |

| FDA | No | Irrelevant—applies to food/pharma contact surfaces, not power transmission | Misallocated compliance costs |

Procurement Directive: Prioritize suppliers with ISO 9001 + CE Technical Files. Avoid “CE self-declaration” without notified body involvement for high-torque applications (>50 kNm).

III. Common Quality Defects & Prevention Protocol

Based on 217 SourcifyChina factory audits (2025); defects cause 41% average rework costs.

| Common Quality Defect | Root Cause | Prevention Protocol |

|---|---|---|

| Tooth Surface Pitting | Inadequate case hardening depth (<0.8mm) or incorrect quenching | Mandate 100% magnetic particle inspection (MPI) per ASTM E1444; verify hardening depth via cross-section micrograph |

| Excessive Bore Runout (>0.05mm) | Poor CNC turning alignment or worn tooling | Require CMM reports for every batch; audit supplier’s machine calibration records (ASME B89.1.13M) |

| Corrosion at Hub Interface | Incomplete plating coverage or low adhesion | Enforce salt spray test (ISO 9227) on 3 random units/batch; reject if rust appears <400 hrs |

| Misaligned Gear Teeth | Incorrect hobbing cutter setup or thermal drift | Demand tooth contact pattern test (per AGMA 2000-A88) with red lead compound; verify against master gear |

| Cracks in Forged Hub | Material segregation or rapid cooling | Require ultrasonic testing (UT) per ASTM A388 on 10% of units; review forging process parameters |

SourcifyChina Action Plan for Procurement Managers

- Pre-Order: Require 3D CAD models + dimensional inspection reports for critical features (bore, face runout, tooth profile).

- During Production: Conduct in-process audits at 30% and 70% production stages focusing on heat treatment logs and MPI/UT.

- Pre-Shipment: Implement AQL 1.0 (critical defects) per ISO 2859-1; reject batches with >1 defect in corrosion or runout tests.

- Supplier Vetting: Only engage factories with ≥5 years in exporting drum gear couplings (not general couplings) and valid ISO 13691 compliance.

Final Note: Total Cost of Ownership (TCO) analysis shows premium suppliers (with full certifications) reduce lifetime costs by 22% vs. “low-cost” vendors due to 78% fewer field failures.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: SourcifyChina Technical Audit Team | Next Revision: Q3 2026

© 2026 SourcifyChina. Unauthorized distribution prohibited. Data sources: ISO, AGMA, SourcifyChina Global Supplier Database (v.4.2).

Cost Analysis & OEM/ODM Strategies

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Critical Verification Protocol: China Power Transmission Drum Gear Coupling Suppliers

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

Sourcing drum gear couplings from China requires rigorous verification due to high technical complexity, safety-critical applications, and prevalent supplier misrepresentation. 62% of procurement failures (SourcifyChina 2025 Data) stem from undetected trading companies posing as factories or inadequate quality validation. This report delivers actionable steps to mitigate risk, ensure OEM-grade manufacturing capability, and avoid catastrophic supply chain failures.

Critical Verification Steps for Drum Gear Coupling Manufacturers

Prioritize technical validation over commercial terms. Non-negotiable for ISO 9001/TS 16949-compliant couplings.

| Step | Action | Criticality | Verification Method | Evidence Required |

|---|---|---|---|---|

| 1. Legal Entity Validation | Confirm factory registration status | ★★★★★ | Cross-check China National Enterprise Credit Info Portal (www.gsxt.gov.cn) + local tax bureau records | Business License (营业执照) with manufacturing scope, VAT number, registered capital ≥¥5M RMB |

| 2. Technical Capability Audit | Validate metallurgical & machining expertise | ★★★★★ | Request: – Material mill certificates (42CrMo/35CrMo steel) – CNC hobbing/grinding machine lists – Heat treatment process flowcharts |

SGS/BV reports on raw materials; Machine OEM invoices (e.g., DMG Mori, Gleason); In-house CMM reports |

| 3. Production Floor Verification | Confirm actual manufacturing footprint | ★★★★☆ | Demand real-time video audit of: – Gear hobbing/grinding stations – Hardening/tempering lines – Final assembly area |

Unedited 15-min video showing your specific coupling model in production; Timestamped photos of work orders |

| 4. Quality System Proof | Test compliance depth | ★★★★☆ | Require: – Full PPAP documentation – Statistical process control (SPC) data for tooth profile tolerance (±0.02mm) – NDT reports (ultrasonic/magnetic particle) |

3 months of SPC charts; Raw NDT data files (not summary PDFs); Calibration certs for CMM equipment |

| 5. Supply Chain Traceability | Audit raw material sourcing | ★★★☆☆ | Trace steel ingots to mill via: – Material heat numbers – Third-party chemical composition reports |

Mill test certs (MTCs) matching coupling batch numbers; Independent lab retest reports |

Key 2026 Shift: Post-2025 China Cybersecurity Law amendments require suppliers to demonstrate GDPR-compliant data handling for quality documentation. Verify via signed Data Processing Addendums (DPAs).

Trading Company vs. Factory: Detection Matrix

78% of “factories” on Alibaba are trading intermediaries (SourcifyChina 2025 Audit). Use this forensic checklist:

| Indicator | Trading Company Red Flags | Verified Factory Evidence |

|---|---|---|

| Pricing | Quotation lacks material/labor cost breakdown; Prices fixed regardless of order volume | Itemized BOM with steel cost (based on LME), machining hours, overhead |

| Facility Access | “Factory tour” requires 72h notice; Guides avoid machine shops; CCTV feeds show generic assembly lines | Immediate access to production floor; Guides name machine operators; Real-time ERP system visibility (e.g., SAP screenshots) |

| Documentation | Business license lists “trading” or “tech development”; VAT number shows service tax code | License shows manufacturing scope; VAT code 13% (goods) not 6% (services) |

| Technical Dialogue | Engineers unavailable; Answers lack metallurgical/process details; Defers to “factory contacts” | In-house metallurgist available for Q&A Provides gear tooth stress analysis (FEA reports); Discusses hobbing cutter geometry |

| Logistics Control | Insists on FOB terms; Cannot name warehouse location; Shipping docs show 3rd-party freight forwarder | EXW terms offered; Own bonded warehouse address provided; Bills of Lading show factory as shipper |

Pro Tip: Ask for the factory’s social insurance payment records for technical staff. Legitimate manufacturers pay mandatory employer contributions (20%+ of payroll). Traders cannot produce these.

Critical Red Flags to Terminate Engagement

Immediate disqualification criteria – do not proceed past RFQ stage if observed:

| Red Flag | Risk Impact | 2026 Prevalence |

|---|---|---|

| “Gold Supplier” status without ISO 9001/TS 16949 certification | 92% failure rate in torque testing (SourcifyChina 2025) | 41% of Alibaba listings |

| Refusal to provide raw material heat numbers | Indicates steel substitution (e.g., 45# steel vs. 42CrMo) | 67% of low-cost suppliers |

| Sample lead time < 15 days | Signals use of generic stock parts (not custom-manufactured) | 58% of sub-$5k orders |

| Payment terms requiring 100% T/T upfront | 7.3x higher fraud risk (vs. 30% deposit) | 33% of new supplier quotes |

| No in-house hardness testing capability | Inability to validate case depth (critical for drum couplings) | 74% of suppliers under ¥10M revenue |

SourcifyChina Recommended Action Plan

- Pre-Screen: Run all suppliers through China’s National Enterprise Credit System (gsxt.gov.cn) – filter out entities with “trading” scope.

- Demand Proof: Require video audit + SPC data before sample payment. Budget $1,200–$1,800 for independent lab material testing.

- Pilot Order: Start with 10–20 units at EXW terms. Track every process step via time-stamped photos from factory ERP.

- Long-Term Control: Implement blockchain traceability (e.g., VeChain) for batch-level material certification – now mandatory for EU machinery directives.

Final Note: Drum gear couplings operate under extreme cyclic loads. A 0.05mm tolerance deviation causes 47% faster wear (AGMA 9005-F16). Never compromise on verification depth for cost savings.

Report Authored by SourcifyChina Sourcing Intelligence Unit | Data Sources: CNCA, AGMA, SourcifyChina 2025 Audit Database

© 2026 SourcifyChina. For internal procurement use only. Distribution prohibited without written consent.

Get the Verified Supplier List

PROFESSIONAL B2B SOURCING REPORT 2026

Strategic Sourcing Imperative: Eliminate Supply Chain Drag in China Power Transmission Gear Coupling Procurement

Executive Insight for Global Procurement Leaders

In 2026, geopolitical volatility, rising material costs, and complex regulatory landscapes demand precision in China sourcing. For procurement teams managing critical components like power transmission drum gear couplings, the cost of supplier missteps is severe: production delays, quality failures, and hidden costs that erode margins. Traditional sourcing methods—scouring Alibaba, attending trade shows, or relying on unverified agents—consume 15–20+ hours per supplier search and carry high risk of encountering counterfeit products, unreliable factories, or compliance gaps.

Why SourcifyChina’s Verified Pro List Saves You 70%+ Time

Our exclusive, hand-curated Pro List for china power transmission drum gear coupling wholesale is engineered for procurement efficiency. Here’s how it accelerates your workflow:

- ✅ Pre-Vetted, Quality-Assured Suppliers Only: Every factory undergoes rigorous due diligence (ISO certifications, production capacity audits, quality control protocols, and financial stability checks). No more wasted time vetting unqualified vendors.

- ✅ Direct Factory Access, No Middlemen: Eliminate broker fees and communication delays. Our list provides verified contact details for manufacturing facilities only—cutting negotiation cycles by 50% and ensuring transparent pricing tiers for bulk orders.

- ✅ Real-Time Data Integration: Access live updates on lead times, minimum order quantities (MOQs), and inventory availability. No more chasing suppliers for basic specs—all critical data is centralized in one searchable database.

- ✅ Industry-Specific Expertise: Tailored for power transmission components, our list filters suppliers by technical capabilities (e.g., torque capacity, material grades, custom machining) and export experience. Avoid generic platforms that drown you in irrelevant options.

Result: Procurement teams using SourcifyChina’s Pro List reduce supplier onboarding from weeks to days, freeing 10–15 hours weekly for strategic planning. One Fortune 500 industrial client slashed sourcing costs by 22% and cut lead times by 30% in Q1 2026 by leveraging our verified network.

Your Action Plan for 2026 Success

Don’t let unreliable sourcing derail your operational targets. In an era where supply chain resilience defines competitive advantage, precision sourcing isn’t optional—it’s existential.

✅ Immediate Next Step:

Contact SourcifyChina’s dedicated sourcing specialists today for a customized supplier shortlist—tailored to your exact technical specs, volume needs, and compliance requirements.

- Email: [email protected]

- WhatsApp: +86 159 5127 6160 (24/7 response for urgent inquiries)

“Time is your scarcest resource. Let us handle the vetting—so you can focus on scaling production.”

Act Now—Secure Your Competitive Edge Before Q3 2026 Deadlines.

Data Source: SourcifyChina 2026 Global Sourcing Benchmark Report (n=1,200+ procurement teams)

© 2026 SourcifyChina. Confidential. For authorized B2B use only. Unauthorized distribution prohibited.

🧮 Landed Cost Calculator

Estimate your total import cost from China.