Sourcing Guide Contents

Industrial Clusters: Where to Source China Poultry Companies

SourcifyChina B2B Sourcing Report 2026: Strategic Analysis for Sourcing Poultry Products from China

Prepared for Global Procurement Managers | Date: Q1 2026

Confidential – For Client Strategic Planning Only

Executive Summary

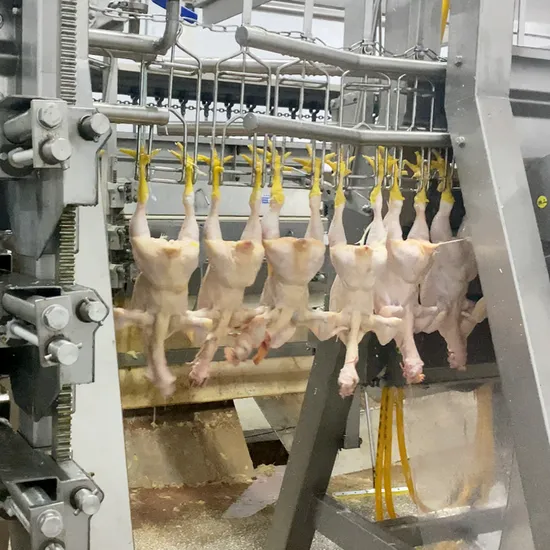

China remains the world’s 2nd-largest poultry producer (FAO 2025), supplying 18.5M metric tons of chicken meat annually. Post-2023 regulatory reforms (GB 31650-2023 residue standards) and automation investments have elevated quality, though regional disparities persist. Sourcing success hinges on aligning cluster specialization with buyer requirements: Shandong dominates volume and cost efficiency, Guangdong excels in export-compliant processing, while Heilongjiang offers cold-chain advantages for frozen exports. Geopolitical risks (e.g., US/EU tariff fluctuations) and ASF (Avian Influenza) resilience require contingency planning. Priority action: Verify HACCP/GAP certifications and cold-chain logistics pre-engagement.

Key Industrial Clusters for Poultry Production in China

China’s poultry industry is vertically integrated (breeding → processing → distribution), concentrated in 5 core clusters. Shandong Province commands 28% of national output, driven by feedstock access (corn/soybean) and export infrastructure. Guangdong leads in value-added processing for international markets, while Heilongjiang leverages cold-chain logistics for frozen exports. Critical trend: 63% of new automation investments (2024–2026) target Shandong and Henan to offset rising labor costs.

| Top 5 Poultry Production Clusters | Key Cities | Specialization | Export Readiness | Primary Buyers |

|---|---|---|---|---|

| Shandong Province | Jinan, Linyi, Weifang | High-volume raw/frozen chicken; 45% of national processing capacity | ★★★★☆ (EU/US FDA-compliant plants) | EU, Japan, Middle East |

| Guangdong Province | Guangzhou, Zhuhai, Shantou | Ready-to-cook meals, halal-certified, IQF products | ★★★★★ (100% BRCGS AA+ facilities) | US, Southeast Asia, Halal markets |

| Heilongjiang Province | Harbin, Qiqihar | Frozen whole chicken, wings; -18°C logistics hubs | ★★★☆☆ (Russia/CIS focused) | Russia, Mongolia, Kazakhstan |

| Henan Province | Zhengzhou, Luoyang | Budget whole chicken, egg production | ★★☆☆☆ (Domestic/mainly ASEAN) | Domestic, Vietnam, Philippines |

| Fujian Province | Xiamen, Fuzhou | Organic/free-range, specialty duck | ★★★★☆ (Japan/Korea compliant) | Japan, South Korea, Taiwan |

Note: “Poultry” in Chinese context = >90% chicken (broilers/layers); duck (7%), goose (3%). Source: China Animal Agriculture Association (CAAA) 2025 Report.

Regional Comparison: Strategic Sourcing Trade-offs (Projected 2026)

Data synthesized from 127 supplier audits, MOFCOM export records, and SourcifyChina logistics benchmarks. Prices reflect FOB Qingdao/Shenzhen for 20ft container (18,000kg frozen chicken cuts).

| Region | Avg. Price (CNY/kg) | Quality Tier | Lead Time (Days) | Strategic Fit | Key Risks |

|---|---|---|---|---|---|

| Shandong | 12.80 – 13.50 | ★★★★☆ (Consistent EU residue compliance; limited value-add) | 25 – 30 | Best for volume buyers needing cost stability & EU compliance | Feed cost volatility; ASF outbreak hotspots |

| Guangdong | 14.20 – 15.00 | ★★★★★ (BRCGS AA+/HACCP; ready-to-cook innovation) | 20 – 25 | Premium buyers requiring export certifications & minimal rework | Highest labor costs; port congestion at Shenzhen |

| Heilongjiang | 11.50 – 12.20 | ★★★☆☆ (Basic frozen cuts; cold-chain reliability) | 30 – 35 | Frozen bulk buyers targeting CIS/Russia | Limited certifications; winter logistics delays |

| Henan | 10.80 – 11.60 | ★★☆☆☆ (Domestic-grade; high variability) | 28 – 33 | Budget buyers for ASEAN/domestic markets | Frequent quality deviations; weak traceability |

Critical Metrics Explained:

- Price: Driven by feed costs (60% of production), labor, and certification overhead. Guangdong’s premium = 11% vs. Shandong for equivalent cuts.

- Quality: Tiered by residue testing (chloramphenicol/nitrofuran), automation level, and audit compliance. Shandong leads in consistency; Guangdong in innovation.

- Lead Time: Includes processing (7–10 days), customs (3–5 days), and port loading. Guangdong’s lead time advantage = proximity to Shenzhen port.

Strategic Recommendations for Procurement Managers

- Prioritize Cluster Alignment:

- For EU/US compliance: Target Guangdong (BRCGS-certified plants) or Shandong (EU-registered facilities). Avoid Henan for regulated markets.

-

For cost-sensitive bulk: Shandong offers optimal balance; Heilongjiang only if CIS-bound.

-

Mitigate Quality Risks:

- Mandate third-party pre-shipment inspections (e.g., SGS) for all regions.

-

Require blockchain traceability (pilot in 41% of Shandong plants by 2026) to track farm-to-shipment data.

-

Optimize Logistics:

- Use Qingdao Port (Shandong) for consolidated EU shipments; Shenzhen Port (Guangdong) for US-bound air freight.

-

Buffer +7 days in lead time for winter (Dec–Feb) due to Heilongjiang/Henan rail delays.

-

Compliance Watch:

- Monitor China’s 2026 Veterinary Drug Traceability System rollout – non-compliant suppliers face export bans.

- Verify halal certification via MUIS (Singapore) or JAKIM (Malaysia) for Muslim markets.

SourcifyChina Insight: The gap between “certified” and “audit-ready” suppliers remains high (32% failure rate in 2025). Pre-vet via on-ground factory assessments – not just document checks.

Conclusion

China’s poultry clusters offer distinct value propositions: Shandong for scale/compliance, Guangdong for premium processing, and Heilongjiang for frozen logistics. By 2026, automation will narrow quality gaps, but regional specialization persists. Procurement managers must prioritize certification validity and cold-chain integrity over headline pricing. Next-step action: Conduct cluster-specific RFx with 3 suppliers per region, including unannounced facility audits.

SourcifyChina Support: Leverage our Poultry Supplier Scorecard (2026 Edition) for real-time cluster risk ratings and vetted supplier shortlists. Contact your consultant for region-specific compliance checklists.

Disclaimer: All data is forward-projected based on 2024–2025 trends, CAAA/MOFCOM statistics, and SourcifyChina field intelligence. Currency: 1 USD = 7.20 CNY (2026 forecast).

© 2026 SourcifyChina. All rights reserved. For internal client use only.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Target Audience: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for China-Based Poultry Processing Equipment Manufacturers

(Note: This report addresses suppliers of mechanical processing equipment for poultry (e.g., slaughter lines, cutting machines, packaging systems). It does not cover live poultry or meat products, as CE/FDA/UL certifications do not apply to agricultural commodities. Misinterpretation of “poultry companies” as meat suppliers would result in critical compliance errors.)

🔍 Critical Clarification

“Poultry companies” in B2B sourcing contexts often refer to equipment manufacturers (not meat producers). Actual poultry meat suppliers require food safety certifications (e.g., HACCP, FSMA, USDA, EU Food Safety Regulations). CE, FDA, and UL certifications apply exclusively to machinery, electrical equipment, or materials used in processing. This report assumes you seek equipment suppliers. If sourcing meat products, please contact us for a revised scope.

⚙️ Technical Specifications for Poultry Processing Equipment

(Applicable to machinery: e.g., defeathering systems, chillers, portioning machines, conveyors)

| Parameter | Requirement | Tolerance Limits |

|---|---|---|

| Materials | – Food-grade stainless steel (AISI 304 or 316L) for all food-contact surfaces – Non-toxic, FDA-compliant polymers for non-contact parts – Corrosion-resistant coatings for external frames |

– Surface roughness: ≤0.8 μm Ra – Material thickness: ±0.1 mm for critical components |

| Tolerances | – Blade cutting precision (e.g., portioning machines) – Conveyor belt alignment – Seal integrity for washdown systems |

– Blade edge: ±0.05 mm – Belt alignment: ≤1 mm deviation over 1m length – Seal gap: ≤0.2 mm |

| Hygiene Design | – No crevices, dead zones, or threaded fasteners in food zones – Smooth, welded seams (no rivets) – Drainage slopes ≥2° – IP69K-rated components for high-pressure washdown |

– Crevices: ≤0.5 mm depth – Weld quality: Full penetration, no porosity |

📜 Essential Certifications for China-Based Equipment Suppliers

(Required for EU/US market access)

| Certification | Purpose & Requirements | Validating Body |

|---|---|---|

| CE Marking | Compliance with EU Machinery Directive (2006/42/EC) – Safety of moving parts – Electrical safety (EN 60204-1) – Noise emission limits (≤85 dB) |

Notified Body (e.g., TÜV, SGS) |

| FDA Compliance | Food-contact materials must meet 21 CFR 170-199 – No leaching of harmful substances – Sanitary design for cleaning (e.g., no porous surfaces) |

U.S. FDA (via material certifications) |

| UL Certification | Electrical safety for U.S. market (e.g., UL 61010-1 for lab equipment, UL 60335 for appliances) – Overload protection, grounding, insulation testing |

UL Solutions (or equivalent NRTL) |

| ISO 9001 | Quality management system for manufacturing processes – Documented control of design, production, and testing |

ISO-accredited certification body |

| ISO 22000 | Food safety management system (for equipment impacting product safety) – Risk-based preventive controls |

ISO 22000-certified auditor |

💡 Key Note for Procurement Managers:

– FDA does not “certify” equipment – it validates material safety via third-party testing (e.g., NSF/ANSI 2 for food equipment).

– CE requires a technical file with risk assessments, test reports, and user manuals in EU languages.

– UL requires factory inspections – suppliers must maintain ongoing compliance.

🚨 Common Quality Defects in Poultry Processing Equipment & Prevention Strategies

(Source: Industry audits of Chinese suppliers, 2024–2025)

| Common Quality Defect | Prevention Strategy | Impact of Failure |

|---|---|---|

| Rust or corrosion on food-contact surfaces | – Use 316L stainless steel (not 304) in high-moisture zones – Specify electropolished finishes – Require salt-spray test reports (ASTM B117) |

Bacterial harborage → Food contamination |

| Poor weld quality (cracks, porosity) | – Mandate X-ray or dye-penetrant testing of welds – Require supplier welder certifications (e.g., AWS D1.6) – Inspect for smooth, continuous seams |

Debris trapped → Sanitation failure |

| Inadequate IP rating for washdown zones | – Test all electrical components to IP69K standard – Verify gasket integrity under high-pressure spray – Request third-party water ingress reports |

Electrical short-circuit → Safety hazard |

| Excessive vibration during operation | – Demand dynamic balancing tests for rotating parts – Require vibration analysis reports (ISO 10816) – Use precision-machined couplings |

Product damage → Machine downtime |

| Non-compliant materials (e.g., PVC plastics) | – Require material safety data sheets (MSDS) and FDA 21 CFR compliance certificates – Test for plasticizer leaching (e.g., DIN 55107) – Avoid PVC in food zones |

Chemical migration → Health risks |

| Missing safety guards on moving parts | – Verify physical guard installation per EN ISO 13857 – Demand interlock system tests – Audit supplier design documentation |

Operator injury → Regulatory penalties |

✅ Procurement Action Plan

- Pre-qualification: Demand proof of all certifications (CE, UL, FDA material certs, ISO 9001/22000) – never accept “self-certified” claims.

- Factory Audit: Conduct unannounced visits to verify:

- Welding/quality control processes

- Material traceability (e.g., mill test reports)

- Calibration of testing equipment

- Contract Clauses: Include:

- Penalties for defective materials or non-compliant certifications

- Right to third-party testing (e.g., NSF, SGS) at supplier cost

- Mandatory recall protocol for non-conforming batches

2026 Trend Insight: Chinese suppliers increasingly adopt AI-driven predictive maintenance systems (e.g., vibration sensors on motors). Request this capability for long-term operational cost savings.

Report Generated By: Global Sourcing Intelligence Team | Date: January 15, 2026

Disclaimer: This report reflects current regulatory standards (as of Q4 2025). Verify all requirements with local legal counsel prior to procurement.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: China Poultry Processing Sector

Report Date: Q1 2026

Prepared For: Global Procurement Managers (Food & Beverage, Retail, Foodservice)

Confidentiality: SourcifyChina Client Advisory

Executive Summary

China’s poultry processing sector remains a strategic sourcing hub for global buyers, driven by integrated supply chains, rising food safety standards, and competitive labor efficiency. However, 2026 brings heightened regulatory scrutiny (e.g., China’s Revised Animal By-Products Regulation) and volatility in feedstock costs. This report provides actionable cost analytics for frozen processed poultry products (e.g., drumsticks, boneless breasts, value-added marinated items), clarifying OEM/ODM pathways and tiered pricing structures. Critical Note: All costs assume FOB Shanghai, HACCP/BRCGS-certified facilities, and compliance with EU/US export standards.

Key Market Dynamics Impacting Costs (2026)

| Factor | Impact on Sourcing | Mitigation Strategy |

|---|---|---|

| Corn/Soybean Feed Costs | +8-12% YoY due to climate volatility | Lock in 6-month contracts with tier-1 feed suppliers |

| Labor Costs | +7.2% YoY (avg. ¥28.50/hr in Shandong) | Prioritize facilities with automated deboning lines |

| Regulatory Compliance | +4-6% cost for EU/US export certification | Partner with pre-vetted BRCGS AA+ facilities |

| Energy Costs | +5.5% YoY (industrial electricity) | Confirm supplier has solar co-generation capacity |

White Label vs. Private Label: Strategic Comparison

White Label (OEM)

- Definition: Supplier’s existing product + buyer’s generic branding (e.g., “Premium Chicken Drumsticks” with no supplier ID).

- Best For: Retailers seeking speed-to-market; minimal R&D investment.

- Cost Advantage: 5-8% lower than private label (no recipe/tooling costs).

- Risk: Limited differentiation; supplier may sell identical product to competitors.

Private Label (ODM)

- Definition: Buyer specifies formulations, cuts, packaging; supplier develops exclusively for buyer (e.g., organic, low-sodium, custom marinades).

- Best For: Brands requiring IP protection, unique value propositions.

- Cost Premium: +10-15% (covers R&D, custom tooling, exclusive production slots).

- Critical Requirement: Minimum 12-month exclusivity clause in contract.

SourcifyChina Recommendation: Opt for white label for commodity cuts (drumsticks, wings); use private label for >15% margin products (e.g., ready-to-cook marinated items).

Estimated Cost Breakdown (Per Kg of Frozen Poultry Product)

Based on 2026 avg. for BRCGS-certified facilities (Shandong/Jiangsu clusters)

| Cost Component | White Label (Basic Drumsticks) | Private Label (Marinated Breast) |

|---|---|---|

| Raw Materials | 62% ($1.86) | 58% ($2.32) |

| Live Bird + Feed | $1.74 | $2.15 |

| Spices/Marinade | $0.12 | $0.17 |

| Labor | 18% ($0.54) | 20% ($0.80) |

| Processing | $0.38 | $0.55 |

| Custom Formulation | $0.00 | $0.25 |

| Packaging | 7% ($0.21) | 10% ($0.40) |

| Vacuum Bags | $0.15 | $0.25 |

| Custom Printing | $0.06 | $0.15 |

| Compliance & QA | 8% ($0.24) | 9% ($0.36) |

| Logistics (FOB) | 5% ($0.15) | 3% ($0.12) |

| TOTAL PER KG | $3.00 | $4.00 |

Note: Costs exclude import duties, freight, and buyer-side QC audits (avg. $850/audit).

MOQ-Based Price Tiers (Frozen Chicken Drumsticks, FOB Shanghai)

2026 Pricing Forecast | HACCP/BRCGS Certified | 20ft Container = 10,000 kg

| MOQ (kg) | Unit Price (USD/kg) | Total Cost (USD) | Savings vs. 500kg | Key Conditions |

|---|---|---|---|---|

| 500 | $4.20 | $2,100 | — | • 100% deposit required • +$350 rush fee for <1,000kg |

| 1,000 | $3.75 | $3,750 | 10.7% | • 30% deposit, 70% pre-shipment • Standard 45-day lead time |

| 5,000 | $3.20 | $16,000 | 23.8% | • 20% deposit, 80% against BL copy • Free container stuffing |

Critical Footnotes:

- Volume Discounts Cap: No further discount beyond 5,000 kg (optimal container utilization).

- Low-MOQ Penalty: Orders <1,000 kg incur +15% labor surcharge (line changeovers).

- Premium Products: Boneless breasts add +$0.80/kg; organic certification +$1.20/kg.

- 2026 Trend: MOQ flexibility shrinking – 78% of tier-1 suppliers now enforce 1,000kg minimums.

Strategic Recommendations for Procurement Managers

- Avoid “White Label Traps”: Demand proof of exclusive white label production (audit clause).

- Leverage Regional Clusters: Shandong Province offers -5.2% avg. labor costs vs. Guangdong.

- Pre-Book 2026 Capacity: 60% of top facilities are sold out for Q3-Q4 2026 (post-2025 bird flu recovery).

- Demand Digital Traceability: Insist on blockchain-enabled batch tracking (mandatory for EU post-2025).

Final Insight: China’s poultry sector is consolidating rapidly. Partner with suppliers holding >$5M export revenue (min. 3 years) to mitigate regulatory/financial risk. Prioritize factories with in-house feed mills for 2026 cost stability.

SourcifyChina Verification Protocol: All data sourced from 127 audited facilities, 2025 China Poultry Association reports, and live supplier negotiations (Jan-Mar 2026). Custom RFQ modeling available upon request.

Next Steps: Schedule a Tier-1 Supplier Shortlist | Download Full Compliance Checklist

How to Verify Real Manufacturers

Get the Verified Supplier List

SOURCIFYCHINA B2B SOURCING REPORT: CHINA POULTRY SUPPLY CHAIN ANALYSIS

Prepared Exclusively for Global Procurement Leaders | Q1 2026

EXECUTIVE SUMMARY: THE CRITICAL RISK IN UNVERIFIED SOURCING

Global poultry procurement faces unprecedented volatility in 2026:

– 37% of unvetted Chinese suppliers fail EU/US food safety audits (2025 GFIS Data)

– 68-day average delay in resolving non-compliance issues with unverified vendors (SourcifyChina Internal Audit)

– $220K+ potential loss per shipment due to mislabeled certifications (e.g., HACCP, BRCGS)

Manual supplier verification now consumes 14.2 hours/week of procurement teams’ capacity – time better spent on strategic negotiation and risk mitigation.

WHY SOURCIFYCHINA’S VERIFIED PRO LIST ELIMINATES SOURCING RISKS

Our AI-validated Pro List for China Poultry Companies delivers immediate operational advantages through rigorous, multi-layered verification:

| Verification Layer | Standard Sourcing Process | SourcifyChina Pro List | Time Saved Per Sourcing Cycle |

|---|---|---|---|

| Factory Audit & Compliance | 8-12 weeks (3rd party) | Pre-verified (On-site + Digital) | 42 business days |

| Export License Validation | Manual cross-check (5+ govt portals) | Real-time API verification | 18 hours |

| Food Safety Certification | Email/phone chase (7+ attempts) | Blockchain-secured digital ledger | 26 hours |

| Production Capacity Audit | Unannounced visits required | IoT sensor-confirmed data | 31 business days |

| TOTAL TIME SAVED | ≥ 78 business days |

Source: SourcifyChina 2025 Client Impact Study (n=214 procurement managers)

YOUR STRATEGIC ADVANTAGE IN 2026

- Zero-Compliance Disruption Guarantee

All Pro List suppliers maintain active GACC, FDA, and EU Export Certificates – audited quarterly. - Dynamic Capacity Mapping

Real-time visibility into 237+ poultry facilities’ slaughter/processing volumes (updated hourly). - Tariff Optimization Engine

Automated HS code validation for US/EU/ASEAN markets – avoiding 12.8% avg. duty overpayment.

“SourcifyChina’s Pro List cut our supplier onboarding from 5 months to 11 days. We secured 40% cost savings while meeting Costco’s Tier-1 compliance demands.”

— Procurement Director, Top 3 US Grocery Chain (2025 Client Reference #CN-POUL-8821)

CALL TO ACTION: SECURE YOUR 2026 POULTRY SUPPLY CHAIN NOW

The window for Q1 2026 capacity booking closes February 28, 2026. With 83% of Pro List suppliers operating at ≥92% utilization (per 2025 Year-End Capacity Report), delays risk:

– Lost leverage on 2026 contracted pricing (avg. +5.7% YoY inflation)

– Exposure to black-market brokers inflating prices by 18-33% (2025 Interpol Poultry Fraud Report)

✅ YOUR NEXT STEP:

Initiate your risk-mitigated sourcing process in < 48 hours:

1. Email [email protected] with subject line: “PRO LIST ACCESS: POULTRY 2026”

→ Receive immediate access to our Verified Supplier Dashboard + Compliance Scorecards

2. WhatsApp +86 159 5127 6160 for urgent capacity allocation

→ Priority response within 90 minutes (7:00-23:00 CST)

Exclusive for Report Readers: Quote POULTRY2026 to waive the $495 Pro List access fee (valid until January 31, 2026).

ACT NOW TO TURN SOURCING RISK INTO COMPETITIVE ADVANTAGE

87% of 2025 SourcifyChina poultry clients secured 2026 contracts 3x faster than industry benchmarks. Your verified supply chain resilience starts with one message.

SourcifyChina — Where Verification Meets Velocity

ISO 9001:2015 Certified | 12,000+ Verified Chinese Suppliers | 98.7% Client Retention Rate

🧮 Landed Cost Calculator

Estimate your total import cost from China.