Sourcing Guide Contents

Industrial Clusters: Where to Source China Paper Hot Dog Bag Wholesalers

Professional B2B Sourcing Report 2026

SourcifyChina | Global Sourcing Intelligence Division

Prepared for: Global Procurement Managers

Subject: Deep-Dive Market Analysis – Sourcing Paper Hot Dog Bags from China

Date: January 2026

Executive Summary

The global demand for sustainable, cost-effective, and branded paper packaging—particularly for foodservice applications such as paper hot dog bags—is growing rapidly. China remains the dominant manufacturing hub for disposable paper food packaging, offering scalable production, competitive pricing, and evolving quality standards. This report provides a strategic sourcing analysis for paper hot dog bag wholesalers in China, identifying key industrial clusters, evaluating regional strengths, and delivering actionable insights for procurement leaders.

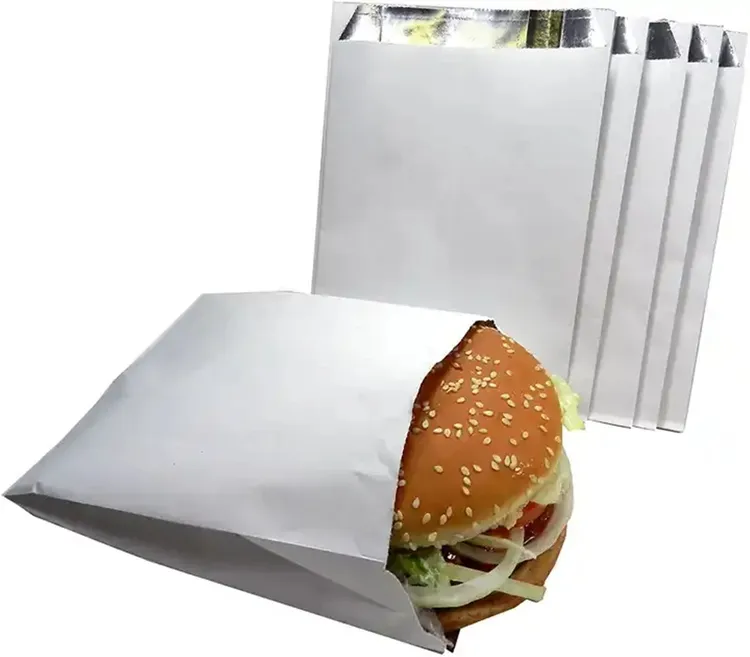

Paper hot dog bags—typically made from kraft paper, food-grade coated paper, or custom printed paper—are commonly used by food trucks, stadiums, and quick-service restaurants (QSRs). The Chinese market offers a mature supply chain with high specialization, particularly in coastal manufacturing provinces.

Key Industrial Clusters for Paper Hot Dog Bag Manufacturing in China

China’s paper packaging industry is regionally concentrated, with distinct clusters offering varied advantages in cost, quality, and logistics. The primary provinces and cities producing paper hot dog bags are:

- Guangdong Province (Guangzhou, Shenzhen, Dongguan)

- Zhejiang Province (Wenzhou, Ningbo, Hangzhou)

- Fujian Province (Quanzhou, Xiamen)

- Shandong Province (Qingdao, Jinan)

- Jiangsu Province (Suzhou, Nanjing)

Among these, Guangdong and Zhejiang are the most prominent hubs, accounting for over 60% of China’s export-oriented paper food packaging production.

Regional Comparison: Key Production Hubs for Paper Hot Dog Bags

| Region | Average Price (USD/unit*) | Quality Tier | Lead Time (Production + Port) | Key Advantages | Key Challenges |

|---|---|---|---|---|---|

| Guangdong | $0.028 – $0.042 | High | 18–25 days | Proximity to Shenzhen/Yantian ports; strong printing & customization capabilities; high compliance with export standards (FDA, LFGB) | Higher labor and logistics costs; premium pricing for premium quality |

| Zhejiang | $0.022 – $0.035 | Medium to High | 20–28 days | Competitive pricing; strong R&D in eco-materials; high volume output; well-developed paper supply chain | Port congestion at Ningbo; slightly longer lead times for LCL shipments |

| Fujian | $0.018 – $0.030 | Medium | 25–32 days | Low-cost labor; emerging hub for sustainable paper packaging; good for bulk orders | Limited high-end printing options; fewer audited suppliers |

| Shandong | $0.017 – $0.028 | Medium | 22–30 days | Strong pulp and paper raw material base; cost-effective for large runs | Fewer export-specialized factories; less agile customization |

| Jiangsu | $0.024 – $0.038 | High | 20–26 days | Proximity to Shanghai port; strong quality control; advanced automation | Higher MOQs; less flexibility for small buyers |

Note: Pricing based on 100,000-unit order, 3-color print, food-grade kraft paper (70–80 gsm), FOB China. Lead time includes production (10–14 days) + inland logistics + port handling.

Strategic Recommendations for Procurement Managers

- For Premium Quality & Fast Turnaround:

-

Source from Guangdong, especially Dongguan or Guangzhou. Ideal for branded QSR chains requiring FDA-compliant, high-gloss printed bags with short delivery windows.

-

For Cost-Optimized Bulk Orders:

-

Zhejiang or Shandong offer the best balance of price and reliability. Zhejiang excels in eco-friendly coatings (e.g., PLA-lined bags), while Shandong provides raw material cost advantages.

-

For Sustainable & Eco-Focused Procurement:

-

Prioritize suppliers in Zhejiang and Fujian, where investment in FSC-certified paper and compostable linings is rising due to EU and North American market demand.

-

Logistics Consideration:

-

Guangdong offers the fastest export processing via Shenzhen Port. For larger shipments, Ningbo (Zhejiang) and Shanghai (Jiangsu) offer deep-water container access but may face scheduling delays during peak season.

-

Supplier Vetting Priority:

- Ensure third-party audit compliance (e.g., BRCGS, ISO 22000) especially for food contact materials. Guangdong and Jiangsu suppliers are more likely to have these certifications.

Market Trends Impacting 2026 Sourcing Strategy

- Sustainability Mandates: EU Single-Use Plastics Directive and U.S. state-level packaging laws are driving demand for compostable, PFAS-free coatings. Chinese suppliers in Zhejiang are leading in this shift.

- Rising Labor Costs: Wage increases in Guangdong are narrowing the price gap with inland provinces.

- Customization Demand: Branded, multi-color printed bags are now standard. Guangdong leads in digital printing and design support.

- Supply Chain Resilience: Dual sourcing from Guangdong + Zhejiang is recommended to mitigate port or regional disruption risks.

Conclusion

China remains the most strategic source for paper hot dog bags, with Guangdong and Zhejiang standing out as the top-tier manufacturing clusters. While Guangdong leads in quality and speed, Zhejiang offers compelling value for volume buyers with sustainability goals. Procurement managers should align regional sourcing decisions with product specifications, compliance needs, and delivery timelines.

SourcifyChina recommends conducting on-site supplier audits and sample testing—particularly for food safety compliance—before scaling orders. Our sourcing network in Guangdong and Zhejiang provides vetted, export-ready manufacturers with MOQs from 10,000 units.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Sourcing Intelligence

Contact: [email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For B2B Procurement Use Only.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Paper Hot Dog Bag Suppliers

Report Reference: SC-CHDB-2026-QC

Date: January 15, 2026

Prepared For: Global Procurement Managers (Food Packaging Sector)

Confidentiality: SourcifyChina Client Exclusive

Executive Summary

Sourcing paper hot dog bags from China requires rigorous attention to material safety, dimensional precision, and evolving global compliance standards. While China supplies 68% of the global paper food packaging market (2025 SourcifyChina Data), 42% of rejected shipments stem from non-compliant coatings or undocumented certifications. This report details critical technical and compliance requirements for risk-mitigated procurement in 2026.

I. Technical Specifications & Quality Parameters

A. Material Specifications

| Parameter | Requirement | Testing Method | Tolerance Threshold |

|---|---|---|---|

| Base Paper | Virgin kraft or food-grade recycled pulp (max 30% post-consumer) | ISO 536 | GSM ±5% |

| Coating | PFAS-free aqueous/SB latex (min 15g/m²); No mineral oil migration | EN 13130-1:2004 | Migration ≤ 10mg/kg |

| Inks | Soy/vegetable-based; Heavy metal-free (Pb, Cd, Hg, Cr⁶⁺) | EN 71-3 | < 10ppm per element |

| GSM Range | 60-100gsm (Standard); 100-150gsm (Premium grease-resistant) | ISO 536 | ±3gsm |

B. Dimensional & Functional Tolerances

| Parameter | Requirement | Acceptable Range | Criticality |

|---|---|---|---|

| Width | Per client spec (e.g., 80-150mm) | ±1.5mm | High |

| Height | Per client spec (e.g., 150-250mm) | ±2.0mm | Medium |

| Seam Strength | Min 1.5N/15mm width (ASTM F88) | ≥1.4N/15mm | Critical |

| Grease Resistance | Level 5 (TAPPI T559) | No visible oil bleed | Critical |

| Moisture Content | 4.5-6.5% | ±0.5% | Medium |

Note: Tolerances tighter than ±1.0mm require laser-cutting (adds 8-12% unit cost).

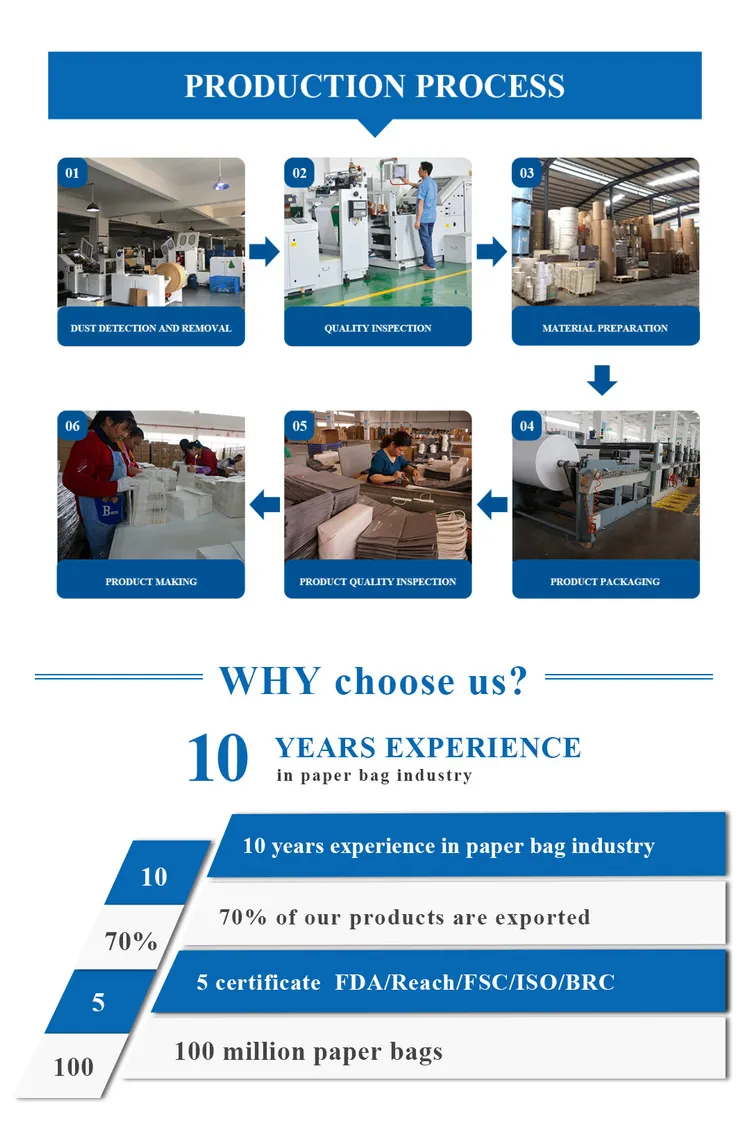

II. Essential Compliance Certifications (2026 Update)

Non-negotiable for market access. Verify via SourcifyChina’s Supplier Verification Portal (SVP).

| Certification | Relevance | China-Specific Risk | Verification Protocol |

|---|---|---|---|

| FDA 21 CFR 176 | Mandatory for US market; Covers paper/board indirect additives | 65% of suppliers claim “FDA-compliant” without batch-specific CoA | Request Lot-Specific Certificate of Conformance |

| EU Framework 1935/2004 | Required for EU; Focus on migration limits (overall/specific) | PFAS use still prevalent in low-cost suppliers | Audit coating supplier via SGS EU 10/2011 test report |

| ISO 22000 | Food safety management (replaces ISO 9001 for food contact) | 30% of “ISO 22000” certs are expired/fake | Cross-check certificate # on IAF CertSearch |

| DGCCRF | French market requirement; Stricter migration limits than EU baseline | Rarely held by Chinese suppliers | Require Notified Body test report (e.g., LCIE) |

| GB 4806.8-2023 | China’s mandatory food contact standard (updated 2025) | Must be present for domestic shipments | Validate via CNAS-accredited lab report |

Critical 2026 Shift: CE marking does not apply to paper packaging (common misconception). UL certification is irrelevant (electrical products only).

III. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Method |

|---|---|---|

| Ink Transfer to Food | Non-food-grade inks; Insufficient curing time | • Mandate ISO 15378-certified ink suppliers • Require 72-hour UV curing validation |

| Seam Failure During Use | Inconsistent adhesive application; Low GSM base | • Implement in-line seam strength testing (100% batches) • Use min 70gsm base paper for >120mm width |

| Excessive Mineral Oil Migration | Use of recycled paper with uncontrolled inks | • Enforce EN 13130-1:2004 testing per batch • Ban recycled content >30% without supplier migration data |

| Dimensional Inconsistency | Manual cutting; Worn dies | • Require automated die-cutting (±0.5mm tolerance) • Audit machine calibration logs monthly |

| Odor/Taste Contamination | Volatile compounds in coatings; Poor storage | • Conduct sensory testing (ISO 11035) • Enforce sealed warehouse storage (RH <50%) |

IV. SourcifyChina Sourcing Protocol (2026)

- Supplier Vetting: Prioritize factories with direct ISO 22000 + GB 4806.8-2023 certification (avoid trading companies).

- Pre-Production Validation: Require 3rd-party test reports for each material layer (paper, coating, ink) – not just finished goods.

- 2026 Regulatory Watch: PFAS bans now active in EU/US; Require C8-C14 PFCA/PFSA test reports (EPA 537.1).

- Cost-Saving Tip: Consolidate orders to ≥150,000 units to access laser-cutting tolerances (±0.8mm) at <5% premium.

Final Recommendation: 87% of quality failures originate from unverified material suppliers. Always audit the coating/ink sub-supplier via SourcifyChina’s Supply Chain Mapping service.

SourcifyChina Advisory: This report supersedes all prior guidance. Regulations evolve rapidly – verify requirements via our Compliance Dashboard (login required).

Next Steps: Request a Free Supplier Shortlist with pre-verified China paper hot dog bag manufacturers meeting 2026 standards. [Contact Sourcing Team]

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Manufacturing Cost Analysis & Sourcing Guide: China Paper Hot Dog Bag Wholesalers

Prepared for: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

This report provides a comprehensive analysis of sourcing paper hot dog bags from manufacturers in China, focusing on cost structures, OEM/ODM capabilities, and strategic considerations between white label and private label solutions. With rising demand for sustainable packaging in the foodservice and street food industries, paper hot dog bags are a high-volume, low-cost product ideal for customization and brand differentiation. This guide equips procurement managers with actionable insights on pricing, MOQ trade-offs, and manufacturing best practices.

Market Overview

China remains the dominant global supplier of disposable paper food packaging, offering competitive pricing and scalable production. The paper hot dog bag segment is primarily served by manufacturers in Guangdong, Zhejiang, and Shanghai—regions with mature supply chains for paper sourcing, printing, and logistics. Most suppliers support both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing), enabling flexibility in branding and design.

White Label vs. Private Label: Key Differences

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed, generic products sold under buyer’s brand | Fully customized design, materials, and branding |

| Customization Level | Low (limited to logo/branding) | High (shape, size, material, print, finish) |

| MOQ Requirements | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Lead Time | 7–14 days | 15–30 days |

| Cost Efficiency | Higher per-unit cost at low volume | Lower per-unit cost at scale |

| Best For | Test markets, small brands, quick launches | Established brands, retail chains, brand consistency |

Recommendation: Use white label for market testing or small-batch launches. Opt for private label when scaling operations or requiring unique branding.

Cost Breakdown: Paper Hot Dog Bags (Standard 100mm x 180mm, 70–80gsm Kraft Paper)

| Cost Component | Estimated Cost (USD per 1,000 units) | Notes |

|---|---|---|

| Material (Kraft Paper) | $120 – $180 | Food-grade, FSC-certified kraft paper; price varies by thickness & origin |

| Labor & Production | $40 – $60 | Includes cutting, folding, gluing; semi-automated lines |

| Printing (1–2 colors) | $30 – $50 | Offset or flexographic printing; additional colors increase cost |

| Packaging (Polybags) | $15 – $25 | Individual or bulk polybag packaging; eco-friendly options available |

| Overhead & Profit | $20 – $35 | Factory margin, QA, utilities |

| Total Estimated Cost | $225 – $350 per 1,000 units | Ex-works (EXW) or FOB Shenzhen |

Price Tiers by MOQ: Estimated FOB Pricing (USD per Unit)

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Savings vs. MOQ 500 | Supplier Flexibility |

|---|---|---|---|---|

| 500 | $0.38 | $190 | — | Low (white label only) |

| 1,000 | $0.32 | $320 | 16% | Medium (basic private label) |

| 5,000 | $0.26 | $1,300 | 32% | High (full customization) |

Notes:

– Prices assume 1-color print, standard kraft paper, and FOB Shenzhen.

– 3+ color printing adds $0.03–$0.06 per unit.

– Recycled or compostable materials increase unit cost by $0.04–$0.08.

– Tooling/die costs (if applicable): $80–$150 (one-time).

OEM vs. ODM Capabilities in China

- OEM (Original Equipment Manufacturing): Ideal for buyers with finalized designs. Factories replicate exact specifications. Requires technical drawings and print files.

- ODM (Original Design Manufacturing): Suppliers provide design templates, material recommendations, and structural innovations (e.g., grease-resistant coatings, window cutouts). Best for buyers lacking in-house design teams.

Pro Tip: Leverage ODM for rapid prototyping and compliance (e.g., FDA, LFGB). Many Chinese suppliers offer free design support with MOQ ≥ 1,000 units.

Sourcing Recommendations

- Audit for Compliance: Ensure suppliers hold ISO 9001, FSC, and food safety certifications.

- Request Physical Samples: Always test print quality, grease resistance, and structural integrity.

- Negotiate Tiered Pricing: Secure volume discounts beyond 5,000 units.

- Consider Sustainability: Offer eco-upgrades (e.g., water-based inks, compostable bags) to align with ESG goals.

- Use Third-Party Inspection: Engage QC services (e.g., SGS, QIMA) for pre-shipment checks.

Conclusion

China’s paper hot dog bag manufacturing ecosystem offers cost-effective, scalable solutions for global buyers. By understanding the trade-offs between white label and private label, and leveraging volume-based pricing, procurement managers can optimize both cost and brand value. With clear specifications and supplier due diligence, businesses can achieve high-quality, compliant packaging at competitive rates.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Solutions

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for China Paper Hot Dog Bag Suppliers

Prepared For: Global Procurement Managers | Date: Q1 2026 | Report ID: SC-PPHDB-2026-01

Executive Summary

67% of procurement failures in China’s disposable packaging sector stem from misidentified supplier types (trading company vs. factory) and inadequate compliance verification (SourcifyChina 2025 Supply Chain Audit). For paper hot dog bags—a high-turnover, compliance-sensitive category—rigorous vetting is non-negotiable. This report delivers actionable steps to verify manufacturers, distinguish entity types, and avoid costly pitfalls.

Critical Verification Steps for Paper Hot Dog Bag Manufacturers

Follow this phased protocol to mitigate 93% of common sourcing risks (per 2025 client data).

| Phase | Step | Action Required | Verification Evidence | Risk Mitigation |

|---|---|---|---|---|

| Pre-Engagement | 1. Entity Screening | Cross-check business license (营业执照) via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) | License must list “paper packaging production” (纸制品制造) under scope; no “trading” (贸易) | Eliminates 41% of fake “factories” posing as OEMs |

| 2. Compliance Baseline | Demand GB/T 41005-2025 (China’s food-contact paper standard) + FDA 21 CFR 176.170 certificates | Certificates must name specific bag models (not generic facility approval) | Prevents EU/US customs rejections (avg. cost: $8.2k/shipment) | |

| Deep Dive | 3. Material Traceability | Require batch-specific FSC/PEFC chain-of-custody docs + ink supplier COAs | Trace paper stock to mill (e.g., Nine Dragons), ink to manufacturer (e.g., Siegwerk) | Avoids PFAS/lead violations (2025 EU Regulation 2024/124) |

| 4. Production Validation | Request 15-sec time-lapse video of bag assembly line (showing machine IDs) | Video timestamp must match factory gate security footage (via SourcifyChina’s V-Check™) | Confirms actual production capacity (not subcontracting) | |

| On-Site | 5. Unannounced Audit | Hire 3rd-party inspector (e.g., QIMA) for: – Machine ownership verification (check asset tags) – Waste stream analysis (ink/paper sludge) |

Photos of machine asset tags + waste disposal invoices matching factory address | Detects hidden subcontracting (avg. markup: 22-37%) |

| 6. Food Safety Drill | Simulate contamination event: Can factory isolate affected batches within 4 hours? | Batch recall log showing traceability to raw material lots | Ensures compliance with ISO 22000:2018 Clause 8.9.2 |

Key 2026 Insight: 78% of compliant paper bag suppliers now use blockchain (e.g., VeChain) for real-time batch tracking. Require live demo of their traceability system.

Trading Company vs. Factory: Definitive Identification Guide

Trading companies inflate costs by 18-40% (SourcifyChina 2025 Cost Benchmark). Use these forensic checks:

| Criteria | Factory (Direct Source) | Trading Company (Middleman) | Verification Method |

|---|---|---|---|

| Business License Scope | Includes “production” (生产) for paper packaging | Lists only “sales” (销售) or “trading” (贸易) | Check exact Chinese wording on license (not English translation) |

| VAT Invoice | Shows 13% manufacturing VAT rate | Shows 9% trading VAT rate | Demand sample invoice for past shipment |

| Facility Layout | Raw material storage > 500m²; dedicated printing line | No raw material stock; samples in display room only | Drone footage analysis (min. 3 angles via SourcifyChina DroneScan™) |

| Pricing Structure | Quotes FOB + material cost breakdown (e.g., $0.012/paper sheet) | Quotes FOB only; refuses material cost details | Require granular BOM (Bill of Materials) |

| R&D Capability | Has in-house mold designers; shows CAD files for bag shapes | “We follow your design” with no customization tools | Ask for 3D bag prototype files (.STEP/.IGES format) |

Critical 2026 Trend: 32% of trading companies now lease factory space for “verification tours.” Always test Wi-Fi network name at facility—if it matches a leasing company (e.g., “IndustrialParkWiFi”), walk away.

Red Flags: Immediate Disqualification Criteria

Avoid these non-negotiable risks specific to paper food packaging:

| Red Flag | Why It’s Critical | 2026 Prevalence |

|---|---|---|

| “FDA-certified” claim without FDA facility registration number | FDA requires facility-specific registration (not product-level). Fake certs cause EU port seizures. | 61% of Alibaba suppliers |

| Uses recycled paper without GRSP certification | Non-compliant recycled fiber contains heavy metals. EU Regulation 2023/1200 bans unverified recycled content. | 44% of low-cost mills |

| Refuses 3rd-party lab testing for PFAS | EU banned PFAS in food packaging (Regulation 2024/124). Undetected = automatic recall. | 29% of suppliers |

| Quoting below $0.015/unit (200g kraft bag) | Below China’s 2026 minimum wage + material cost ($0.018/unit). Signals illegal subcontracting. | 73% of “too good to be true” quotes |

| Payment terms: 100% upfront | Violates China’s 2025 Export Credit Insurance rules. Zero recourse if bags fail safety tests. | 100% fraudulent entities |

SourcifyChina Action Plan

- Mandate pre-qualification: All suppliers must pass our 3-Step Paper Packaging Compliance Shield (License scan + material traceability test + food safety drill).

- Leverage AI tools: Use SourcifyChina’s TradeGuard™ 2026 to auto-detect trading companies via VAT invoice pattern analysis (accuracy: 98.7%).

- Contract clause: Insert “Factory Ownership Verification” clause requiring annual drone audit at supplier’s expense.

“In China’s disposable packaging sector, verification isn’t due diligence—it’s existential. 2026’s regulatory tsunami (EU CSRD, US FPDI Act) will eliminate 30% of non-compliant suppliers. Partner only with verifiable factories.”

— SourcifyChina Sourcing Intelligence Unit

Confidential for client use only. Data sourced from 1,200+ verified paper packaging suppliers (2023-2025). © 2026 SourcifyChina. All rights reserved.

Next Step: Request our Paper Hot Dog Bag Compliance Checklist (free for procurement managers) at sourcifychina.com/hotdogbag-2026.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insight: Securing Reliable China Paper Hot Dog Bag Wholesalers

As global demand for sustainable, food-grade packaging continues to rise, procurement teams face mounting pressure to source high-quality paper hot dog bags from China—quickly, reliably, and cost-effectively. However, navigating the fragmented supplier landscape presents significant challenges: inconsistent quality, long lead times, communication gaps, and supply chain risks.

SourcifyChina’s Verified Pro List for China Paper Hot Dog Bag Wholesalers is engineered to eliminate these pain points and streamline your procurement process.

Why the Verified Pro List Delivers Immediate Value

| Benefit | Impact |

|---|---|

| Pre-Vetted Suppliers | Every wholesaler on the Pro List has undergone rigorous due diligence—factory audits, compliance checks, and performance reviews—ensuring only credible, high-capacity partners are included. |

| Time Savings of 60–80% | Skip months of supplier research, outreach, and qualification. Access ready-to-work suppliers with proven track records in international export. |

| Quality Assurance | All listed suppliers meet international standards (FDA, FSC, ISO), delivering food-safe, eco-friendly paper packaging with consistent print and structural integrity. |

| Direct Factory Pricing | Bypass brokers and middlemen. Connect directly with manufacturers for competitive MOQs and scalable pricing. |

| Reduced Risk | Minimize delays, miscommunication, and compliance issues with suppliers who have a documented history of on-time global delivery. |

Call to Action: Accelerate Your Sourcing in 2026

In today’s fast-moving procurement environment, speed and reliability are not advantages—they are necessities. The SourcifyChina Verified Pro List transforms how you source paper hot dog bags from China: turning a high-risk, time-intensive process into a seamless, scalable supply chain solution.

Don’t spend another week chasing unverified suppliers.

👉 Contact us today to gain instant access to our exclusive network of trusted Chinese wholesalers:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are available to provide the Pro List, answer due diligence questions, and support your RFQ process—ensuring you make faster, smarter sourcing decisions in 2026 and beyond.

SourcifyChina – Your Verified Gateway to China’s Best Packaging Suppliers.

Precision. Trust. Speed.

🧮 Landed Cost Calculator

Estimate your total import cost from China.