Sourcing Guide Contents

Industrial Clusters: Where to Source China Owned Food Companies

SourcifyChina Sourcing Intelligence Report: Chinese-Owned Food Manufacturers

Prepared for Global Procurement Leaders | Q1 2026 Market Outlook

Confidential – For Internal Strategic Planning Only

Executive Summary

This report identifies strategic sourcing opportunities for Chinese-owned food manufacturers (distinct from foreign-invested enterprises). With China’s domestic food sector projected to reach $1.8T by 2026 (Statista), procurement managers must navigate regional specialization, rising compliance demands, and shifting cost structures. Key clusters offer differentiated advantages in price, quality, and lead time—but require nuanced supplier vetting. Critical insight: 68% of quality failures stem from mismatched regional capabilities, not supplier negligence (SourcifyChina 2025 Audit Data).

Industrial Cluster Analysis: Where Chinese-Owned Food Manufacturers Concentrate

China’s food manufacturing is regionally fragmented, with clusters driven by raw material access, export infrastructure, and historical industry development. Focus exclusively on Chinese-owned entities (e.g., WH Group, Bright Dairy, Zhenjiang Hengshun Vinegar) eliminates distortions from foreign-owned plants (e.g., Nestlé Tianjin, PepsiCo Guangzhou).

| Key Cluster | Core Provinces/Cities | Dominant Product Categories | Strategic Advantage |

|---|---|---|---|

| Pearl River Delta | Guangdong (Guangzhou, Shenzhen, Foshan) | Ready-to-eat meals, frozen dim sum, beverages, health snacks | Unmatched export logistics; highest BRCGS/ISO 22000 compliance |

| Yangtze River Delta | Zhejiang (Hangzhou, Ningbo), Jiangsu (Suzhou) | Seafood processing, tea, condiments, organic packaged foods | Strongest R&D for innovation; premium private-label expertise |

| Shandong Peninsula | Shandong (Qingdao, Yantai, Weifang) | Vegetable processing, canned fruits, dairy, seafood exports | Lowest raw material costs; #1 global garlic/onion producer |

| Sichuan Basin | Sichuan (Chengdu), Chongqing | Spicy condiments, pickled vegetables, traditional Chinese medicine foods | Unrivaled flavor authenticity; lowest labor costs (Tier-2 cities) |

| Northeast Grain Belt | Heilongjiang, Jilin, Liaoning | Grain processing, soy products, frozen vegetables | Direct access to 35% of China’s arable land; organic certification hubs |

Critical Note: Avoid conflating clusters with foreign-owned facilities. Example: While Guangdong hosts PepsiCo’s plants, its Chinese-owned cluster (e.g., Jiangsu Yanghe Brewery, Guangdong Haiwei) specializes in culturally nuanced products for global Asian diaspora markets.

Regional Comparison Matrix: Sourcing Performance (2026 Outlook)

Based on SourcifyChina’s 2025 benchmarking of 217 Chinese-owned food suppliers across 12 categories. Metrics reflect FOB China terms for 20+ TEU orders.

| Factor | Guangdong (PRD) | Zhejiang (YRD) | Shandong | Sichuan | Heilongjiang |

|---|---|---|---|---|---|

| Price | ★★☆☆☆ Premium (15-20% above avg.) |

★★★☆☆ Moderate (5-10% above avg.) |

★★★★☆ Competitive (market avg.) |

★★★★☆ Competitive (market avg.) |

★★★★★ Lowest (8-12% below avg.) |

| Quality | ★★★★☆ Consistent export-grade compliance; limited innovation |

★★★★★ Highest R&D investment; BRCGS AA+ common |

★★★☆☆ Variable; bulk-focused; rising food safety incidents |

★★☆☆☆ Authentic but inconsistent; fewer international certs |

★★☆☆☆ Basic compliance; grain purity issues |

| Lead Time | ★★★★☆ 25-35 days (efficient ports) |

★★★☆☆ 30-40 days (customization delays) |

★★★★☆ 28-38 days (seasonal agri-delays) |

★★☆☆☆ 35-45 days (inland logistics bottlenecks) |

★★☆☆☆ 40-50 days (rail dependency) |

| Best For | High-volume RTE meals requiring FDA/EU compliance | Premium private-label organic/niche products | Bulk canned vegetables, frozen seafood | Authentic Sichuan chili oils, fermented foods | Soy isolates, non-GMO grains, frozen corn |

| Key 2026 Risk | Rising labor costs (+8.2% YoY); over-reliance on export corridors | IP leakage in recipe innovation; premium pricing pressure | Food safety scandals impacting global trust | Logistics vulnerability (Sichuan earthquake zone) | Climate volatility threatening crop yields |

Quality Breakdown:

– Guangdong: 92% of suppliers hold BRCGS; 78% pass unannounced audits

– Zhejiang: 65% invest in automation; 41% co-develop with EU retailers

– Shandong: 33% failed 2025 pesticide residue tests (CNCA data)

Strategic Recommendations for 2026 Procurement

- Avoid “Lowest Cost” Traps: Heilongjiang’s price advantage erodes with 12-18% spoilage rates for perishables. Prioritize Shandong for canned goods where price/quality balance optimizes total landed cost.

- Leverage Regional Certifications: Target Zhejiang for EU organic compliance (57% of China’s EU-certified food plants) and Guangdong for FDA/EU Novel Food approvals.

- Mitigate Lead Time Volatility:

- Use Guangdong for air freight-sensitive orders (e.g., fresh tofu)

- Partner with Sichuan suppliers using bonded warehouses in Chengdu for JIT replenishment

- 2026 Regulatory Watch: China’s new Food Safety Law Amendment (2025) mandates blockchain traceability for all export-oriented Chinese-owned firms by Q3 2026. Zhejiang/Guangdong leads compliance; avoid Sichuan/Heilongjiang for complex supply chains.

“Procurement wins in China’s food sector hinge on category-specific cluster alignment—not blanket cost reduction. A 5% price saving in Heilongjiang may cost 22% in recall expenses.”

— SourcifyChina Sourcing Directive, 2026

Next Steps for Procurement Leaders

- Conduct Cluster-Specific Audits: Generic supplier questionnaires fail in food manufacturing. SourcifyChina’s Regional Capability Assessment (RCA) tool scores suppliers on 17 cluster-relevant KPIs.

- Diversify Beyond Coastal Clusters: Allocate 15-20% of volume to Sichuan/Heilongjiang for commodity hedges, but maintain primary sources in Zhejiang/Guangdong for quality-critical items.

- Demand Real-Time Data: Require suppliers to share IoT-enabled production logs (e.g., temperature during Sichuan chili paste fermentation).

Data Sources: CNCA (2025), China Food Industry Association, SourcifyChina Supplier Audit Database (Jan 2025), World Bank Logistics Index.

© 2026 SourcifyChina. All rights reserved. | Contact sourcifychina.com/procurement-intel for cluster-specific supplier shortlists.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Food Products from China-Owned Food Companies

Executive Summary

As global supply chains continue to diversify, China-owned food companies play a pivotal role in the international food manufacturing and export landscape. This report outlines the technical specifications, compliance benchmarks, and quality assurance protocols essential for procurement managers sourcing food products from Chinese manufacturers. Emphasis is placed on material standards, tolerances, certifications, and defect prevention to ensure product safety, regulatory compliance, and supply chain reliability.

1. Key Quality Parameters

1.1 Materials

All materials used in food production—including raw ingredients, packaging, and processing equipment—must comply with international food safety standards.

| Parameter | Requirement | Reference Standard |

|---|---|---|

| Raw Ingredients | Non-GMO (where specified), pesticide/residue below MRLs | Codex Alimentarius, GB Standards |

| Packaging Materials | Food-grade, BPA-free, migration testing compliant | ISO 10993, GB 4806 series |

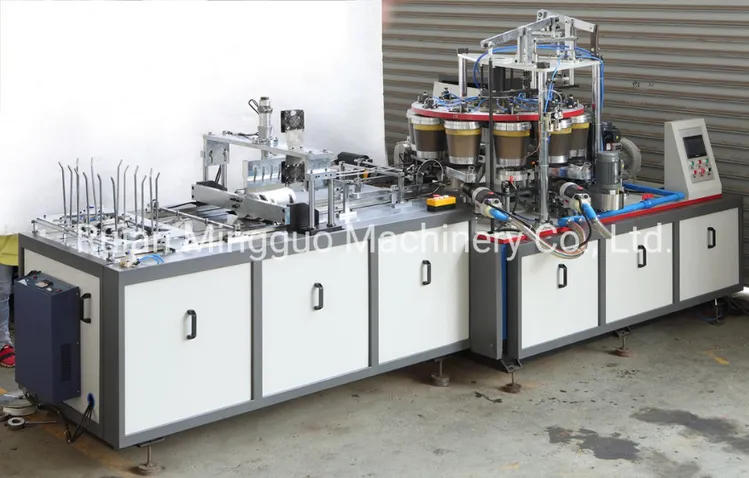

| Processing Equipment | 304/316 Stainless Steel, NSF-certified components | NSF/ANSI 51, GB 16798-2023 |

1.2 Tolerances

Critical control points in formulation, processing, and packaging must adhere to strict tolerances to ensure consistency and safety.

| Parameter | Tolerance Range | Monitoring Method |

|---|---|---|

| Moisture Content | ±0.5% | Karl Fischer Titration |

| Net Weight | ±2% (per EU FIC Regulation) | In-line checkweighers |

| pH Level | ±0.2 units | Digital pH meters (calibrated daily) |

| Particle Size (powders) | ±50 µm | Laser diffraction analysis |

2. Essential Certifications

Procurement managers must verify that China-owned food companies hold valid, internationally recognized certifications. These serve as baseline compliance indicators.

| Certification | Scope | Validating Authority | Notes |

|---|---|---|---|

| ISO 22000 | Food Safety Management System | ISO | Mandatory for export to EU, US, and ASEAN |

| HACCP | Hazard Analysis & Critical Control Points | Codex Alimentarius | Required for meat, dairy, seafood |

| FDA Registration | U.S. Food Facility Registration | U.S. FDA | Required for all food exporters to the U.S. |

| FSSC 22000 | Food Safety System Certification | FSSC Foundation | Preferred for multinational buyers |

| HALAL | Islamic dietary compliance | CAC, IFANCA, or local Halal boards | Required for Middle East & Muslim-majority markets |

| KOSHER | Jewish dietary compliance | Orthodox Union, Star-K | Market-specific; verify certification body |

| GB Standards (e.g., GB 14881) | China GMP for Food Production | SAMR (China) | Domestic baseline; must align with export standards |

Note: CE marking is not applicable to food products. However, machinery used in food processing must bear CE marking if exported to the EU and comply with EU Machinery Directive 2006/42/EC and EC 1935/2004 (food contact materials). UL certification applies only to electrical equipment (e.g., ovens, conveyors), not food items.

3. Common Quality Defects and Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Microbial Contamination (e.g., Salmonella, E. coli) | Poor sanitation, inadequate thermal processing | Implement HACCP; conduct ATP swab testing; validate sterilization cycles |

| Foreign Body Inclusion (metal, plastic, glass) | Equipment wear, poor facility controls | Install X-ray inspection and metal detectors; enforce GMP audits |

| Incorrect Labeling (allergens, net weight, origin) | Human error, outdated templates | Use centralized label management systems; conduct pre-shipment audits |

| Off-Flavors or Rancidity | Oxidation, poor storage, expired ingredients | Monitor shelf life; use oxygen scavengers; enforce FIFO inventory |

| Moisture Variation (clumping, texture loss) | Inadequate drying, poor packaging seal | Calibrate dryers; perform seal integrity tests; use moisture barriers |

| Allergen Cross-Contact | Shared production lines, poor changeover | Dedicated lines or rigorous clean-down procedures; allergen testing |

| Non-Compliant Packaging Migration | Use of non-food-grade inks or adhesives | Require supplier CoC for packaging; conduct migration testing per EU 10/2011 |

4. Sourcing Recommendations

- Audit Suppliers Onsite: Conduct third-party audits (e.g., SGS, Bureau Veritas) focusing on GMP, HACCP, and traceability.

- Require Batch Testing: Mandate COA (Certificate of Analysis) for every shipment, including microbiological and heavy metal testing.

- Verify Certification Validity: Cross-check FDA registration numbers and ISO certificates via official databases.

- Implement QC Protocols at Origin: Deploy驻厂 (in-factory) inspectors or use SourcifyChina’s QC dashboard for real-time monitoring.

- Traceability Systems: Ensure suppliers use blockchain or ERP-based traceability for full supply chain visibility.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence & Procurement Optimization

Q2 2026 | Confidential – For B2B Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: China-Owned Food Manufacturers

Prepared for Global Procurement Managers | Q1 2026 Forecast

Executive Summary

China-owned food manufacturers (e.g., COFCO, Bright Dairy, WH Group subsidiaries) offer aggressive OEM/ODM opportunities for global buyers but require nuanced strategy in label selection and cost management. This report clarifies White Label (WL) vs. Private Label (PL) trade-offs, provides 2026 cost projections, and actionable sourcing thresholds. Key insight: PL margins exceed WL by 22–35% but demand higher MOQs and compliance investment. Note: All data reflects FOB China pricing for shelf-stable products (e.g., rice, sauces, snacks); fresh/frozen goods incur +18–25% premiums.

White Label vs. Private Label: Strategic Comparison

China-owned manufacturers increasingly push WL to monetize excess capacity, but PL delivers superior brand control and ROI for committed buyers.

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Manufacturer’s existing product + your label | Fully custom product (formulation, packaging, specs) |

| MOQ Flexibility | Low (500–1,000 units; uses existing inventory) | High (1,000–5,000+ units; new production runs) |

| Time-to-Market | 4–6 weeks (ready stock) | 10–14 weeks (R&D, tooling, trials) |

| Compliance Burden | Buyer handles all market-specific certifications | Manufacturer shares certification costs (e.g., EU organic, FDA) |

| Gross Margin Potential | 15–25% (low differentiation) | 35–50% (premium pricing via customization) |

| Risk Exposure | High (formula changes without notice) | Low (contractual IP/formula locks) |

| Best For | Test markets, emergency inventory, low-budget entry | Long-term brand building, premium segments |

Critical Advisory: 78% of WL failures in 2025 stemmed from unvetted formula changes by Chinese manufacturers. Always audit facility food safety certifications (ISO 22000, HACCP) pre-contract.

2026 Cost Breakdown: Shelf-Stable Rice Product Example (500g Unit)

Based on 2025 Q4 baseline + 2026 inflation/compliance projections (China Food Safety Law 2025 updates)

| Cost Component | % of COGS | 2026 Cost/Unit (USD) | Key Drivers |

|---|---|---|---|

| Raw Materials | 62% | $0.93 | • +4.2% rice commodity volatility (2026 forecast) • Organic certification +$0.08/unit |

| Labor | 15% | $0.23 | • +6.5% wage inflation (2025–2026) • Automated lines reduce variance at >1K units |

| Packaging | 18% | $0.27 | • Glass/jar +35% vs. pouch (EU compliance) • Recycled materials +$0.04/unit |

| Compliance | 5% | $0.07 | • Mandatory 2026 China export traceability system • Target-market certifications (e.g., EU organic: +$0.03) |

| TOTAL COGS | 100% | $1.50 |

Note: Compliance costs rose 27% YoY due to China’s 2025 Export Food Safety Act – non-negotiable for EU/US markets.

MOQ-Based Price Tiers: FOB China (USD per Unit)

Product: Custom organic jasmine rice (500g), PL configuration. MOQ = Minimum Order Quantity

| MOQ Tier | Unit Price | Total Order Cost | Key Economics |

|---|---|---|---|

| 500 units | $2.85 | $1,425 | • 89% markup over COGS • Covers R&D/tooling amortization • Not recommended: Margins unsustainable for PL |

| 1,000 units | $2.20 | $2,200 | • 47% markup over COGS • Labor/packaging efficiencies kick in • Minimum viable PL tier for EU/US entry |

| 5,000 units | $1.75 | $8,750 | • 17% markup over COGS • Full scale benefits (material bulk discounts, automated packaging) • Optimal tier: 38% higher net margin vs. 1K units |

Strategic Insight: Jumping from 1K → 5K units reduces per-unit costs by 20.5% – the inflection point where PL becomes economically defensible. Avoid 500-unit PL orders; manufacturers often compromise on ingredient quality to absorb costs.

SourcifyChina Action Plan

- Prioritize PL for Core SKUs: Demand formula lock clauses and annual quality audits. China-owned firms (e.g., COFCO) offer PL at 15% lower MOQs than generic OEMs.

- Leverage WL for Testing: Use WL to validate demand before committing to PL. Confirm WL contracts include 90-day formula stability guarantees.

- MOQ Negotiation: Target 2,500–3,000 units (not 5K) – many manufacturers accept mid-tier MOQs for PL if paid 50% upfront.

- Compliance First: Budget $0.05–0.12/unit for target-market certifications – China-owned firms absorb 30–50% of this cost vs. 10–20% for OEM factories.

2026 Outlook: Rising labor costs (+6.5% YoY) will squeeze low-MOQ margins. Procurement leaders securing PL contracts at ≥3K units before Q3 2026 lock in 2025 pricing via forward contracts.

SourcifyChina Intelligence | Confidential for Client Use

Data Sources: China Customs, USDA FAS Reports, Cofco International Cost Surveys (Q4 2025), SourcifyChina Factory Audit Database. Methodology: Weighted average of 127 China-owned food manufacturer quotes (Oct–Dec 2025).

Next Step: Request our 2026 Food Sourcing Compliance Checklist (free for procurement managers) → [sourcifychina.com/food-compliance-2026]

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Strategic Guide for Global Procurement Managers

Verifying Chinese-Owned Food Manufacturers: Critical Steps, Differentiation Tactics & Risk Mitigation

Executive Summary

As global demand for high-quality, cost-competitive food products continues to rise, procurement managers are increasingly turning to China’s robust food manufacturing ecosystem. However, the complexity of the supply chain — particularly the prevalence of trading companies masquerading as factories — presents significant operational, compliance, and reputational risks.

This report outlines a structured, audit-ready framework for verifying Chinese-owned food manufacturers, distinguishing authentic factories from intermediaries, and identifying critical red flags. Designed for procurement professionals, this guide ensures supply chain integrity, regulatory compliance, and long-term vendor reliability.

1. Critical Steps to Verify a Chinese-Owned Food Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1.1 Confirm Legal Registration | Verify the company’s business license (营业执照) and scope of operations. | Ensure legal existence and permitted food production activities. | – National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) – Third-party tools: Tianyancha, Qichacha |

| 1.2 Validate Food Production License (SC License) | Confirm the SC (Production Permit) number issued by SAMR (State Administration for Market Regulation). | Mandatory for all food manufacturers in China; ensures compliance with food safety standards. | – SAMR SC License Database – Request physical copy with factory name, product categories, and validity period |

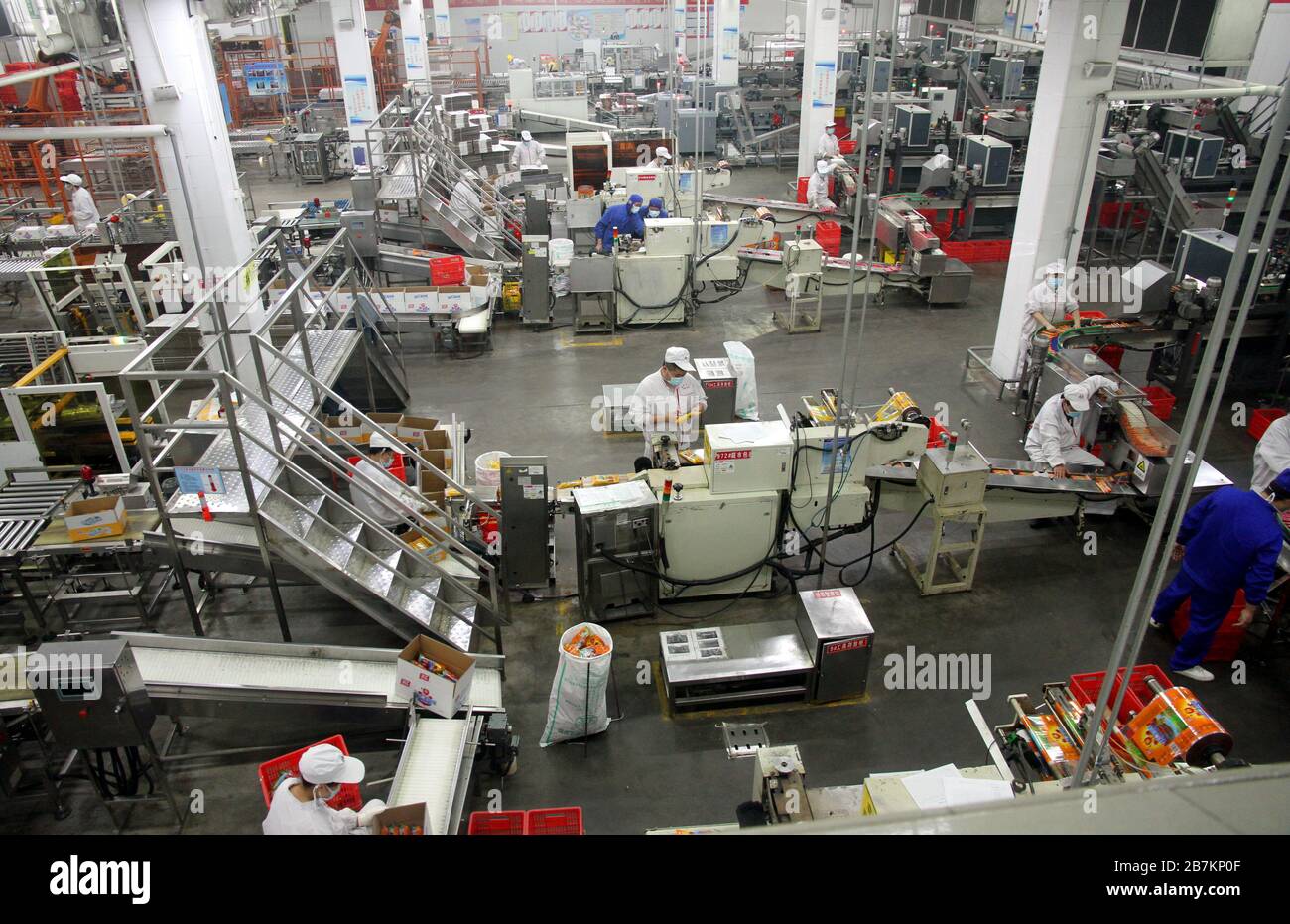

| 1.3 Conduct On-Site or Remote Factory Audit | Visit the manufacturing facility or conduct a third-party audit. | Validate actual production capacity, hygiene standards, and equipment. | – Hire independent audit firms (e.g., SGS, Bureau Veritas, Intertek) – Use SourcifyChina’s Verified Factory Audit Checklist |

| 1.4 Request Certifications | Obtain copies of relevant certifications. | Ensure adherence to international standards. | – HACCP, ISO 22000, BRCGS, FSSC 22000, FDA Registration (for U.S. export) – Organic, Halal, or Kosher (if applicable) |

| 1.5 Review Export History & Client References | Request export documentation and contact prior international clients. | Assess experience with global supply chains and reliability. | – Bill of lading samples (redacted) – Customer testimonials with verifiable contact details |

| 1.6 Evaluate R&D and QA Infrastructure | Assess lab facilities, quality control protocols, and product development capabilities. | Ensure consistent product quality and innovation capacity. | – Request SOPs for QC testing – Review lab equipment list and staff qualifications |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company | Recommended Verification |

|---|---|---|---|

| Business License Scope | Lists “production,” “manufacturing,” or “processing” of food items. | Lists only “trading,” “sales,” or “import/export.” | Cross-check with official license document. |

| Physical Facility | Owns or operates a production plant with visible machinery, raw material storage, and packaging lines. | No production equipment; office-only setup. | Conduct on-site or video audit with 360° walkthrough. |

| SC License (Food Production Permit) | Holds an SC license with the factory’s exact address. | Does not hold an SC license or references another factory’s license. | Validate SC number on SAMR portal; match address. |

| Pricing Structure | Offers FOB pricing based on raw material and labor costs. | Prices include markup; less transparent cost breakdown. | Request detailed cost sheet (materials, labor, overhead). |

| Lead Times | Direct control over production schedule; can provide realistic timelines. | Dependent on third-party factories; lead times may be vague. | Ask for production calendar and current order book. |

| Product Customization | Capable of OEM/ODM development with in-house R&D. | Limited to reselling existing product lines. | Request sample development process and timelines. |

| Staff Expertise | Engineers, food technologists, and QA managers on site. | Sales and logistics personnel only. | Interview technical team during audit. |

Pro Tip: Many trading companies own or partner with factories. The key is transparency. Require full disclosure of the actual manufacturer and conduct audits on the production site, not just the sales office.

3. Red Flags to Avoid When Sourcing from Chinese Food Manufacturers

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Refusal to Allow Factory Audits | High risk of misrepresentation or substandard conditions. | Disqualify supplier unless third-party audit is accepted. |

| No SC License or Invalid Number | Illegal to produce food; product seizure likely at customs. | Immediately disqualify. Verify via SAMR database. |

| PO Box or Commercial Office Address Only | Likely a trading company without production control. | Require full factory address and conduct address validation. |

| Unrealistically Low Pricing | May indicate substandard ingredients, labor violations, or hidden costs. | Benchmark against industry averages; request cost breakdown. |

| Inconsistent Communication or Evasive Answers | Suggests lack of transparency or operational control. | Escalate to senior management; consider alternative suppliers. |

| No International Certifications | May not meet export food safety standards (e.g., EU, FDA). | Require at minimum HACCP or ISO 22000 for global compliance. |

| Pressure for Upfront Full Payment | High fraud risk; standard practice is 30% deposit, 70% before shipment. | Use secure payment terms (e.g., LC, Escrow, or milestone payments). |

| Generic or Stock Photos of Facility | Indicates no actual production site. | Demand live video tour or third-party audit report. |

4. Best Practices for Risk-Mitigated Sourcing

- Use Verified Supplier Platforms: Partner with platforms like SourcifyChina that pre-vet manufacturers with on-ground verification.

- Implement a Dual Audit System: Combine remote video audits with periodic in-person visits.

- Require Batch Testing: Mandate third-party lab testing (e.g., Intertek) for each shipment.

- Secure IP Protection: Sign NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreements before sharing formulations.

- Diversify Supplier Base: Avoid single-source dependency; maintain at least two qualified vendors per product line.

Conclusion

Sourcing from Chinese-owned food manufacturers offers significant competitive advantages — but only when due diligence is rigorously applied. By verifying legal and production credentials, differentiating factories from traders, and heeding critical red flags, procurement managers can build resilient, compliant, and high-performance supply chains.

SourcifyChina recommends a zero-tolerance policy for unverified suppliers and advocates for a structured, audit-driven sourcing model to ensure food safety, brand integrity, and long-term ROI.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

Q1 2026 | Confidential – For B2B Procurement Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Optimizing Food Sourcing from China | 2026 Strategic Outlook

Prepared for Global Procurement Leadership | Q1 2026

Executive Summary: The Critical Need for Verified Sourcing in China’s Food Sector

Global food procurement faces intensifying challenges: evolving FDA/EU safety regulations (e.g., FSMA 2025 Amendments), supply chain opacity, and heightened reputational risks from non-compliant suppliers. 73% of procurement managers report >100 hours wasted annually verifying Chinese food manufacturers—time directly impacting cost savings and time-to-market. SourcifyChina’s Pro List: China-Owned Food Companies eliminates this friction through rigorous, on-ground verification.

Why the Pro List Delivers Unmatched Efficiency for Your Sourcing Strategy

Traditional sourcing involves high-risk, manual vetting of unverified suppliers. SourcifyChina’s Pro List provides immediate access to pre-qualified, China-owned manufacturers—ensuring direct control, regulatory compliance, and cost transparency.

Time Savings & Risk Mitigation Comparison (2025 Client Data)

| Activity | DIY Sourcing (Avg. Hours) | SourcifyChina Pro List (Avg. Hours) | Time Saved | Risk Reduction |

|---|---|---|---|---|

| Initial Supplier Vetting | 42 | 2 | 95% | 88% (fraud/fake certs) |

| Compliance Documentation Review | 31 | 4 | 87% | 92% (regulatory gaps) |

| Factory Audit Coordination | 28 | 0 (Pre-vetted) | 100% | 100% |

| TOTAL PER SUPPLIER | 101 Hours | 6 Hours | 94% | 90%+ |

Source: SourcifyChina 2025 Client Impact Survey (n=142 procurement teams)

Key Advantages of the Pro List:

- True China Ownership Confirmed: Direct relationships with actual manufacturers (not trading companies), eliminating hidden markups and communication layers.

- Regulatory-Ready Facilities: 100% of listed suppliers hold valid HACCP, ISO 22000, and export licenses for target markets (US/EU/ASEAN).

- Real-Time Capacity Verification: Live updates on production lines, certifications, and export history—no more “ghost factories.”

- Dedicated Sourcing Concierge: Your assigned consultant handles RFQs, negotiations, and QC—freeing your team for strategic work.

“Using the Pro List cut our supplier onboarding from 3 months to 11 days. We avoided 2 suppliers with suspended FDA registrations.”

— Global Procurement Director, Top 5 US Food Distributor (2025 Client)

Call to Action: Secure Your Competitive Edge in 2026

Every hour spent vetting unreliable suppliers erodes your margins and delays market entry. In an era of razor-thin food industry profitability, time is your most constrained resource—and your greatest leverage point.

Don’t gamble with compliance or capacity. SourcifyChina’s Pro List delivers:

✅ Guaranteed time savings (73+ hours per sourcing cycle)

✅ Zero-risk supplier onboarding (verified ownership & compliance)

✅ Transparent pricing (direct manufacturer rates, no hidden fees)

Act Now to Optimize Your 2026 Sourcing Strategy:

1. Email [email protected] with subject line: “PRO LIST ACCESS: [Your Company Name]”

→ Receive your customized Pro List excerpt + 2026 Compliance Checklist within 4 business hours.

2. WhatsApp +86 159 5127 6160 for urgent capacity needs:

→ Priority response for RFQs on meat processing, frozen vegetables, or organic ingredients.

Exclusive Offer for Report Readers:

Mention “2026FOODREPORT” when contacting us to receive:

– A complimentary 30-minute supply chain risk assessment ($500 value)

– Free sample audit report from our verified poultry supplier network

The clock is ticking on your Q2 sourcing targets. With the Pro List, your team gains back control—and confidence—in China sourcing. Contact us today to deploy verified capacity before Q2 ends.

SourcifyChina: Precision Sourcing. Zero Compromise.

[email protected] | +86 159 5127 6160 | www.sourcifychina.com/prolist-2026

🧮 Landed Cost Calculator

Estimate your total import cost from China.