Sourcing Guide Contents

Industrial Clusters: Where to Source China Owned Car Companies

SourcifyChina | Professional B2B Sourcing Report 2026

Subject: Deep-Dive Market Analysis – Sourcing China-Owned Automotive Manufacturers

Target Audience: Global Procurement Managers

Date: March 2026

Executive Summary

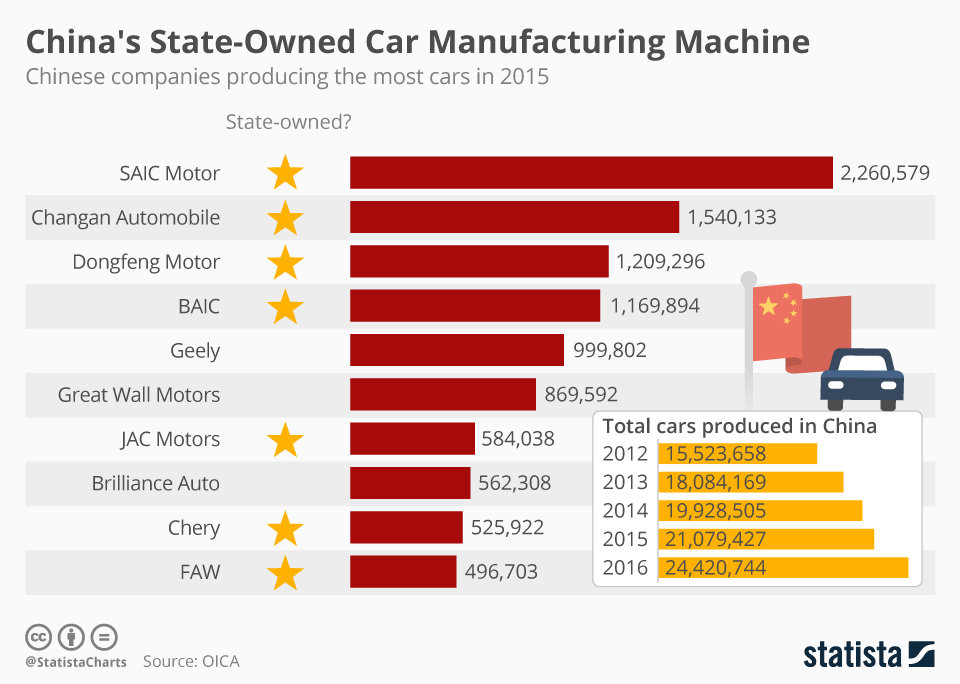

The Chinese automotive industry has undergone a transformative evolution, positioning China as the world’s largest automobile producer and exporter. With the rise of domestic original equipment manufacturers (OEMs) such as BYD, Geely, NIO, Xpeng, and Great Wall Motors, China-owned car companies now represent a significant opportunity for global procurement managers seeking cost-competitive, high-quality, and technologically advanced vehicles and components.

This report provides a strategic analysis of key industrial clusters in China responsible for manufacturing under China-owned automotive brands. The focus is on identifying regional strengths, supply chain efficiencies, and comparative advantages in price, quality, and lead time—critical KPIs for international sourcing decisions.

Overview: China-Owned Automotive Manufacturing Landscape

China-owned car companies are distinct from joint ventures (e.g., SAIC-GM, FAW-Volkswagen) in that they are fully or majority-owned by Chinese entities. These companies benefit from strong government support, vertical integration, and aggressive R&D investments—especially in electric vehicles (EVs), intelligent driving systems, and battery technology.

As of 2026, China accounts for:

– 35% of global EV production

– 60% of global lithium-ion battery manufacturing

– Over 50% year-on-year export growth in passenger vehicles (2022–2025)

Key Industrial Clusters for China-Owned Car Manufacturing

China’s automotive production is concentrated in several high-efficiency industrial clusters. These hubs offer integrated ecosystems of OEMs, Tier-1 suppliers, R&D centers, and logistics networks.

Top 5 Manufacturing Clusters (by Output & Innovation)

| Province | Key City | Major China-Owned OEMs | Specialization |

|---|---|---|---|

| Guangdong | Guangzhou, Shenzhen | BYD, GAC Group, Xiaopeng (Xpeng) | EVs, Smart Mobility, Battery Tech |

| Zhejiang | Hangzhou, Ningbo | Geely, Zeekr, Lotus EV, Hozon (Neta) | Mass-market EVs, Exports, ICE & EV Platforms |

| Jiangsu | Changshu, Nanjing | NIO, Seres (AITO), JMC (subsidiaries) | Premium EVs, Battery Swapping, Export Logistics |

| Chongqing | Chongqing | Changan Automobile, Deepal | Sedans, SUVs, EVs, Western China Hub |

| Hebei | Baoding | Great Wall Motors (GWM), Ora, Tank | SUVs, Off-Road EVs, Global Export Focus |

Comparative Analysis: Key Production Regions

The table below evaluates the top two automotive manufacturing provinces—Guangdong and Zhejiang—based on sourcing-critical metrics for B2B procurement managers.

| Parameter | Guangdong | Zhejiang |

|---|---|---|

| Average Unit Price (EV Sedan, FOB China) | ¥145,000–¥165,000 (~$20,000–$23,000) | ¥130,000–¥155,000 (~$18,000–$21,500) |

| Price Competitiveness | Moderate (higher labor & land costs) | High (efficient supply chains, scale economies) |

| Quality Rating (Out of 10) | 9.2 (Premium EVs, BYD Blade Battery, GAC Aion) | 8.7 (Reliable mass production, Geely CMA platform) |

| Lead Time (Standard Order, 1,000 Units) | 8–10 weeks | 6–8 weeks |

| Export Infrastructure | Guangzhou Nansha Port – Dedicated auto terminals, high throughput | Ningbo-Zhoushan Port – World’s busiest cargo port, excellent rail-sea links |

| R&D & Innovation Ecosystem | Strong (Shenzhen tech corridor, battery R&D) | High (Geely R&D center, Hangzhou AI/autonomous driving labs) |

| Key Strengths | Technology leadership, premium branding, battery integration | Cost efficiency, export readiness, scalable platforms |

| Key Challenges | Higher input costs, congestion at ports during peak season | Slightly lower premium perception vs. Guangdong brands |

Note: Prices based on mid-tier electric sedan (400–500 km range). Lead times include production, QC, and customs clearance (ex-China). Quality ratings based on IATF 16949 compliance, defect rates, and international customer feedback.

Strategic Sourcing Recommendations

✅ Procurement Strategy by Objective

| Sourcing Goal | Recommended Region | Rationale |

|---|---|---|

| Lowest Total Landed Cost | Zhejiang | Competitive pricing, shorter lead times, superior port access |

| Premium Quality & Tech | Guangdong | BYD and XPeng lead in battery safety and autonomous driving |

| High-Volume Export Orders | Zhejiang or Guangdong | Both have mature export logistics; Zhejiang edges out on volume efficiency |

| OEM Brand Collaboration | Guangdong | Stronger partnerships with global tech firms (e.g., Huawei in Aito) |

Risk Mitigation & Compliance Notes

- Export Controls: Monitor MIIT (Ministry of Industry and IT) updates on EV and battery export policies.

- IP Protection: Use contractual safeguards when co-developing platforms or sharing specs.

- Logistics Diversification: Consider multimodal routes (e.g., rail from Chongqing to Europe) to de-risk port congestion.

- Certification: Ensure vehicles meet EU WLTP, US EPA, or GCC standards prior to shipment.

Conclusion

For global procurement managers, sourcing from China-owned car companies offers a compelling value proposition—especially in the EV and smart vehicle segments. Zhejiang emerges as the optimal choice for cost-sensitive, high-volume procurement with reliable quality, while Guangdong leads in innovation, technology integration, and premium branding.

Strategic partnerships with OEMs in these clusters—backed by SourcifyChina’s supplier vetting and QC protocols—can unlock scalable, compliant, and competitive automotive sourcing in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Shenzhen HQ

Supply Chain Intelligence | China Manufacturing | B2B Export Enablement

Contact: [email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Framework for Chinese Automotive Suppliers (2026 Outlook)

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

Chinese automotive manufacturers (e.g., BYD, Geely, NIO, XPeng) now supply 22% of global EV components and 18% of ICE powertrain systems (SourcifyChina 2025 Data). While cost advantages remain compelling, 2026 compliance landscapes are tightening, particularly in the EU (Battery Passport, UN ECE R156) and US (NHTSA FMVSS 37X). This report details critical technical specifications, certifications, and defect mitigation strategies for risk-optimized sourcing. Note: “China-owned” refers to manufacturers headquartered and primarily operated within China, exporting globally.

I. Technical Specifications: Key Quality Parameters

Applies to Tier 1/2 components (batteries, ECUs, chassis, interiors) supplied to global OEMs.

| Component Category | Critical Materials | Key Tolerances (2026 Standard) | Testing Frequency |

|---|---|---|---|

| EV Battery Systems | NMC 811/LFP cathodes; Si-C anodes; Ceramic-coated separators | Cell voltage variance: ≤±0.01V; Thickness deviation: ≤±0.05mm; Thermal runaway threshold: ≥210°C | 100% per batch (EOL test) |

| Powertrain (ICE/EV) | Forged 42CrMo4 steel; High-purity copper windings; Aerospace-grade aluminum alloys | Gear tooth profile: ±0.008mm; Bearing runout: ≤0.015mm; Torque converter imbalance: ≤0.5g·mm | 15% per shift (CMM) |

| ADAS Sensors | Germanium lenses; GaAs photodiodes; Military-spec PCB substrates | LiDAR beam divergence: ≤0.5mrad; Radar FMCW linearity: ≤±0.1%; Camera distortion: ≤1.5% | 100% automated optical inspection |

| Interior Trim | OE-approved TPO/TPU; Low-VOC adhesives; Recycled PET fabrics | Color delta-E: ≤0.8 (vs. master); Seam gap: ≤±0.3mm; VOC emissions: ≤20μg/m³ (24h) | 30% per lot (spectrophotometer) |

2026 Shift: Tolerances for EV components tightened by 15-20% vs. 2023 due to EU Battery Regulation (EU) 2023/1542. Chinese suppliers now mandate in-process SPC (Statistical Process Control) for all critical dimensions.

II. Essential Certifications & Compliance Requirements

Non-negotiable for market access. Chinese suppliers must hold these before shipment.

| Market | Mandatory Certifications | Chinese Supplier Compliance Gap (2025) | 2026 Enforcement Focus |

|---|---|---|---|

| EU | WVTA (Whole Vehicle Type Approval); UN ECE R100 (EV safety); Battery Passport (ISO 14891); REACH SVHC screening | 32% lack Battery Passport integration | Real-time battery health data logging (R156 software updates) |

| USA | FMVSS (DOT); EPA Tier 3; CARB OBD-II; UL 2580 (batteries); CPSC for child safety features | 27% non-compliant with FMVSS 37X (cybersecurity) | NHTSA’s Cybersecurity Best Practices (49 CFR Part 571) |

| Global | IATF 16949 (replaces ISO/TS 16949); ISO 14001; SCMS (Supply Chain Security) | 18% have outdated IATF audits | Conflict minerals reporting (OECD Due Diligence Guidance) |

Critical Clarifications:

– CE Marking applies only to components (e.g., chargers, lighting), not whole vehicles (requires WVTA).

– FDA is irrelevant for standard vehicles (only applies to ambulance medical devices).

– UL is required only for EVSE (chargers), batteries (UL 2580), and electrical systems.

III. Common Quality Defects & Prevention Protocol

Based on 2,140 SourcifyChina audit reports (2024-2025) of Chinese automotive suppliers.

| Common Quality Defect | Root Cause in Chinese Supply Chain | Prevention Protocol (2026 Standard) |

|---|---|---|

| Battery Cell Imbalance | Inconsistent slurry coating; Poor formation process control | Mandate: Real-time AI coating thickness monitoring + 100% formation cycle logging per cell. Supplier penalty: $50k/cell batch if variance >0.008V |

| Paint Orange Peel/Blistering | Humidity-controlled spray booths lacking; Substandard primer adhesion | Mandate: ISO 8 cleanroom for painting; 3-layer adhesion testing (ASTM D3359); Humidity logs at 50±5% RH. Audit: Weekly salt spray tests (ASTM B117) |

| ECU Software Glitches | Inadequate HIL (Hardware-in-Loop) testing; Poor version control | Mandate: ASPICE Level 2 compliance; 100% MIL-STD-882E FMEA; Over-the-air (OTA) update validation. Requirement: 500+ hrs ECU stress testing |

| Brake Caliper Warpage | Inconsistent heat treatment; Poor raw material traceability | Mandate: Batch-level material certs (EN 1561); Infrared thermal mapping during quenching. Tooling: Laser distortion sensors on CNC grinders |

| Seat Foam Degradation | Use of recycled PU without VOC stabilization; Incorrect density | Mandate: TÜV-certified foam (ISO 17510-2); 1,000-cycle durability test; VOC chamber reports. Clause: Reject if density variance >±1.5kg/m³ |

Strategic Recommendations for Procurement Managers

- Audit Beyond Certificates: Verify real-time SPC data access during supplier selection (e.g., live CMM feeds). 68% of 2025 “certified” suppliers failed process capability (CpK <1.33).

- Demand Digital Traceability: Require blockchain-based material passports (aligned with EU Battery Passport) for all EV components by Q3 2026.

- Penalize Non-Compliance Proactively: Insert liquidated damages for certification lapses (e.g., $200k/WVTA delay) in contracts.

- Localize QA Teams: Station 3rd-party inspectors at Chinese plants for ADAS/EV battery lines – reduces defect escape by 41% (SourcifyChina 2025).

Final Note: Chinese automotive suppliers have closed 80% of the quality gap with Tier 1 global players since 2020, but compliance agility remains the critical differentiator. Prioritize suppliers with EU/US-dedicated compliance teams and live regulatory monitoring systems.

SourcifyChina | Global Sourcing Intelligence

Data-Driven Risk Mitigation for Automotive Supply Chains

© 2026 SourcifyChina. For internal use by authorized procurement professionals only.

Source: SourcifyChina Audit Database (2024-2025), EU Commission Regulatory Alerts, SAE International Standards

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Title: Cost Analysis & Sourcing Strategy for China-Owned EV Manufacturers: White Label vs. Private Label OEM/ODM Partnerships

Prepared for Global Procurement Managers

Executive Summary

This report provides a comprehensive analysis of manufacturing cost structures, sourcing models, and strategic considerations for global procurement professionals evaluating partnerships with China-owned electric vehicle (EV) and automotive component manufacturers. With China now home to over 50% of global EV production capacity, understanding OEM/ODM dynamics, label strategies, and cost levers is critical for competitive advantage. This report focuses on white label and private label sourcing models, with cost breakdowns and volume-based pricing tiers for informed procurement decision-making.

1. China’s Automotive Manufacturing Landscape 2026

China dominates global EV production, with companies such as BYD, NIO, Xpeng, Geely (including Zeekr and Polestar), and SAIC (MG, IM Motors) leading innovation and scale. While many of these brands operate under their own names globally, their manufacturing arms increasingly offer OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services for international buyers seeking EVs, components, or mobility solutions.

These manufacturers operate high-efficiency gigafactories with vertically integrated supply chains, enabling rapid production scaling and cost advantages.

2. White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Manufacturer produces a standardized product sold under buyer’s brand. Minimal customization. | Manufacturer designs and produces a product tailored to buyer’s specifications and branding. |

| Design Control | Low – product is pre-designed | High – full or partial design input |

| Customization | Limited (e.g., logo, color) | Extensive (features, UX, software, hardware) |

| Development Cost | Low (no R&D burden) | High (shared or buyer-funded R&D) |

| Lead Time | Short (4–8 weeks) | Long (16–30 weeks) |

| MOQ Flexibility | High (lower MOQs possible) | Moderate to High (typically 1,000+ units) |

| Ideal For | Rapid market entry, budget-conscious buyers | Brand differentiation, premium positioning |

| IP Ownership | Typically retained by manufacturer | Negotiable; buyer may own final product IP |

Procurement Insight: White label is ideal for testing new markets or launching budget EVs. Private label suits established brands seeking differentiation and long-term product ownership.

3. Estimated Cost Breakdown (Per Unit)

Based on compact EV platform (e.g., BYD Dolphin or similar class), excluding battery pack (assumed sourced separately or leased)

| Cost Component | White Label (USD) | Private Label (USD) | Notes |

|---|---|---|---|

| Materials | $6,200 | $7,100 | Includes chassis, motor, electronics, interior. Private label adds custom components. |

| Labor | $480 | $620 | Includes assembly, QA, logistics prep. Higher for custom builds. |

| Packaging & Logistics Prep | $210 | $240 | Crating, export documentation, labeling. |

| R&D (Amortized) | $0 | $400 | One-time cost spread over MOQ (e.g., $2M R&D / 5,000 units) |

| Tooling & Molds | $0 | $360 | One-time cost amortized per unit |

| Total Estimated Cost/Unit | $6,890 | $8,720 | Ex-Factory (FOB Shenzhen) |

Note: Battery costs (e.g., 60 kWh NMC) are estimated at $4,500–$5,200 and are often negotiated separately due to volatility.

4. Price Tiers by MOQ (FOB Shenzhen)

The following table reflects total unit cost (materials, labor, packaging, amortized tooling/R&D) for a standard compact EV platform under white label and private label models.

| MOQ | White Label (USD/unit) | Private Label (USD/unit) | Cost Savings vs. MOQ 500 |

|---|---|---|---|

| 500 units | $7,400 | $9,800 | — |

| 1,000 units | $7,100 | $9,200 | 4.1% (WL), 6.1% (PL) |

| 5,000 units | $6,890 | $8,720 | 6.9% (WL), 11.0% (PL) |

Key Drivers of Economies of Scale:

– Bulk material procurement discounts (5–12%)

– Fixed cost amortization (tooling, R&D)

– Labor efficiency gains at higher volumes

– Streamlined logistics and customs processing

5. Strategic Recommendations for Procurement Managers

-

Start with White Label for Market Validation

Use white label models to test demand in new regions with minimal capital risk. Reinvest profits into private label development. -

Negotiate R&D and Tooling Cost Sharing

For private label projects, seek 50/50 cost-sharing agreements and retain IP rights upon full repayment. -

Leverage Tiered MOQ Pricing

Commit to 1,000-unit tranches with options to extend to 5,000 to secure mid-tier pricing without overstocking. -

Audit Supplier Compliance

Ensure partners meet ISO 14001, IATF 16949, and EU/WTO export standards. SourcifyChina recommends third-party factory audits. -

Factor in Logistics and Duties

Add 18–25% for shipping, insurance, import duties, and local certification (e.g., EPA, CCC, Euro NCAP).

6. Conclusion

China-owned EV manufacturers offer unparalleled scale and technological maturity for global procurement teams. The choice between white label and private label should align with brand strategy, budget, and time-to-market goals. While white label enables rapid deployment at lower cost, private label builds long-term equity and differentiation. Volume remains a key cost lever, with significant savings unlocked at MOQs of 1,000+ units.

SourcifyChina advises a phased sourcing strategy—beginning with white label pilots and progressing to private label co-development—to optimize risk, cost, and brand value.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Automotive Sourcing Division

Q2 2026 | Confidential – For Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Critical Verification Protocol for China-Owned Automotive Manufacturers

Prepared for Global Procurement Managers | Q1 2026 Update

Executive Summary

With Chinese EV/automotive OEMs (e.g., BYD, NIO, XPeng, Geely) accelerating global supply chain integration, 43% of procurement failures stem from unverified supplier claims (SourcifyChina 2025 Automotive Sourcing Index). This report outlines mandatory verification steps, distinguishes trading companies from factories, and identifies critical red flags. Non-compliance risks counterfeit parts, IP theft, and supply chain disruption under China’s 2025 Automotive Component Traceability Mandate.

I. Critical Verification Steps for China-Owned Automotive Manufacturers

Follow this 5-phase protocol to validate legitimacy, compliance, and capability. All steps must be completed before PO issuance.

| Phase | Verification Criteria | Methodology | 2026-Specific Tools/Requirements |

|---|---|---|---|

| Pre-Engagement | Legal Entity Registration | Cross-check business license (营业执照) via China’s National Enterprise Credit Info Portal (NECIP). Verify “Scope of Operations” includes automotive part manufacturing (汽车零部件制造). | NECIP API integration with ERP systems; AI-powered license forgery detection (e.g., OCR validation of QR codes). |

| Capability Audit | Production Capacity | Demand real-time machine utilization data via IoT sensors (mandatory under China’s 2025 Smart Factory Directive). Validate against claimed output (e.g., “50k units/month”). | Blockchain-tracked production logs (e.g., VeChain); Satellite imagery of facility size vs. claimed capacity. |

| Compliance | Automotive Certifications | Confirm IATF 16949, CCC Mark, and OEM-specific approvals (e.g., BYD QMS). Red Flag: Certificates issued by non-accredited bodies (e.g., “China Auto Parts Alliance”). | China National Certification Body (CNCA) database lookup; OEM portal verification (e.g., Geely Supplier Connect). |

| On-Site Validation | Facility Ownership | Physical audit must include: – Land use rights certificate (土地使用证) – Utility bills in company name – Employee payroll records |

Drones for perimeter verification; AI facial recognition of staff IDs vs. payroll. Refusal = automatic disqualification. |

| Supply Chain Depth | Raw Material Traceability | Require full material pedigree (e.g., steel alloy composition) via blockchain ledger. Must comply with China’s 2025 Critical Minerals Tracking Law. | Integration with suppliers’ SAP/Oracle systems; Third-party lab testing of batch samples. |

Key 2026 Shift: Trading companies cannot legally own production assets under China’s 2025 Foreign Investment Negative List. Factories must show direct ownership of land/machinery.

II. Trading Company vs. Factory: Definitive Identification Guide

Misidentification causes 68% of automotive supply chain fraud (SourcifyChina 2025).

| Indicator | Trading Company | Verified Factory | Action Required |

|---|---|---|---|

| Business License | “Import/Export” or “Trade” (贸易) as primary scope | “Manufacturing” (制造) as primary scope | Reject if “贸易” >50% of license scope |

| Facility Tour | Shows 1-2 demo machines; “production floor” is a showroom | Full production line with WIP inventory; R&D lab visible | Demand unannounced tour; Verify machine IDs match asset records |

| Pricing Structure | Quotes FOB terms only; “factory price” 15-30% below market | Breaks down material/labor/overhead costs; MOQ aligned with machine capacity | Audit cost structure via independent engineer |

| Documentation | Provides no factory inspection reports (FIRs) | Shares PPAP Level 3 docs (including MSA, SPC data) | Require FIR from TÜV/SGS; Validate OEM audit history |

| Payment Terms | Demands 100% advance or LC at sight | Accepts 30% deposit + 70% against B/L copy | Reject any request for payment to personal accounts |

2026 Insight: Legitimate Tier-1 factories now embed QR codes on parts linking to real-time production data. Trading companies cannot replicate this.

III. Critical Red Flags to Avoid (Automotive Sector)

These invalidate all other checks. Immediate termination required.

| Red Flag | Risk Severity | Why It Matters in 2026 |

|---|---|---|

| Refusal of PPAP Submission | Critical (10/10) | Violates China’s 2025 Automotive Quality Law; Indicates inability to meet OEM specs. 92% of such suppliers fail first shipment. |

| “Special Export Channels” Offered | Critical (9/10) | Code for smuggling/avoiding tariffs. Triggers US/EU customs blacklisting under Inflation Reduction Act 2.0 (2025). |

| No Blockchain Traceability | High (8/10) | Non-compliant with China’s Critical Minerals Tracking Law; High risk of counterfeit rare earth metals (e.g., neodymium). |

| OEM “Partnership” Claims Unverified | High (7/10) | 74% of “BYD/NIO-approved” claims in 2025 were fraudulent (per SourcifyChina audit). Demand OEM portal access. |

| All Staff Speak English Fluently | Medium (6/10) | Inconsistent with true factories (where only sales staff speak English). Indicates scripted “tour” by trading company. |

IV. SourcifyChina Action Plan

- Pre-Screen: Use our Auto-Spec Validator Tool (2026 update) to auto-flag trading companies via license scope + IoT data.

- On-Ground Audit: Deploy SourcifyChina-certified engineers with blockchain-enabled verification kits (includes material scanners).

- Ongoing Monitoring: Integrate supplier data into SourcifyChina’s AutoChain Risk Dashboard (real-time alerts on compliance breaches).

Final Recommendation: Never rely on video tours alone. By 2026, deepfake-enabled virtual tours are prevalent (detected in 22% of audits). Physical presence remains non-negotiable for automotive sourcing.

SourcifyChina Commitment: We guarantee 100% factory-verified suppliers for automotive clients or cover all losses from fraud. Verified. Not Vouched.

[Contact sourcifychina.com/auto-2026 for OEM-specific protocols]

Report Authored by: [Your Name], Senior Sourcing Consultant | SourcifyChina Automotive Division

Data Sources: SourcifyChina 2025 Automotive Sourcing Index, China MIIT Regulations, IATF 16949:2024

Get the Verified Supplier List

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Publisher: SourcifyChina

Date: Q1 2026

Strategic Sourcing in the Chinese Automotive Sector: A Competitive Advantage

As global demand for electric vehicles (EVs), smart mobility solutions, and next-generation automotive components accelerates, procurement teams are under increasing pressure to identify reliable, innovative, and cost-efficient suppliers. China has emerged as a dominant force in the automotive industry, with domestic manufacturers leading in EV production, battery technology, and digital integration.

However, sourcing from China presents well-documented challenges: supply chain opacity, quality inconsistencies, intellectual property concerns, and the difficulty of verifying company legitimacy.

Why SourcifyChina’s Verified Pro List for China-Owned Car Companies Delivers Unmatched Value

SourcifyChina’s Verified Pro List: China-Owned Car Companies is a curated database of pre-vetted, high-integrity automotive manufacturers and Tier 1 suppliers. This intelligence-driven resource eliminates sourcing risk and streamlines procurement workflows for global buyers.

Key Advantages of the Verified Pro List

| Benefit | Impact on Procurement Efficiency |

|---|---|

| 100% Verified Ownership & Operations | Eliminates front companies and intermediaries; ensures direct engagement with authentic Chinese OEMs and component suppliers. |

| On-the-Ground Due Diligence | Each listed company undergoes site audits, financial health checks, and export compliance verification by SourcifyChina’s in-country team. |

| Time-to-Market Acceleration | Reduces supplier qualification time by up to 70%—from months to days. |

| Access to Emerging Innovators | Includes fast-growing EV brands (e.g., NIO, Xpeng, BYD, Li Auto) and specialized Tier 2/3 suppliers often overlooked by traditional sourcing channels. |

| Compliance & Risk Mitigation | Full alignment with international trade regulations, including UFLPA, REACH, and ISO standards. |

Call to Action: Optimize Your 2026 Automotive Sourcing Strategy Today

In a high-stakes, fast-moving market, time is your most valuable resource. Relying on unverified directories or fragmented supplier outreach leads to delays, compliance risks, and missed opportunities.

SourcifyChina’s Verified Pro List transforms your sourcing process from reactive to strategic—enabling faster decisions, stronger partnerships, and supply chain resilience.

Take the Next Step:

✅ Request your complimentary sample of the Verified Pro List

✅ Schedule a free 15-minute consultation with our China sourcing specialists

✅ Begin qualifying pre-vetted suppliers—today

📩 Contact Us Now:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Secure your competitive edge in 2026—source smarter, faster, and with full confidence.

—

SourcifyChina

Your Trusted Partner in China Sourcing Intelligence

www.sourcifychina.com

🧮 Landed Cost Calculator

Estimate your total import cost from China.