Sourcing Guide Contents

Industrial Clusters: Where to Source China Offshore Oil Company

SourcifyChina | Sourcing Intelligence Report 2026

Subject: Market Analysis for Sourcing Offshore Oil Equipment from China

Prepared for: Global Procurement Managers

Date: Q1 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

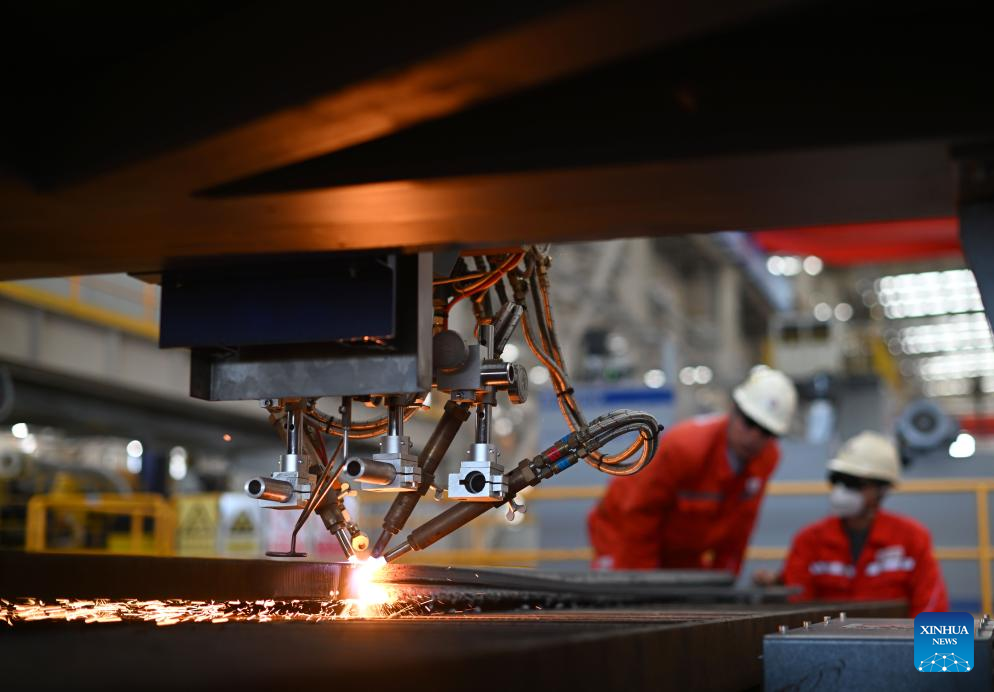

China remains a dominant global hub for manufacturing offshore oil and gas equipment, driven by advanced industrial infrastructure, cost competitiveness, and decades of specialization in heavy engineering. As global energy demand continues to shift toward deepwater and ultra-deepwater exploration, procurement managers are increasingly turning to Chinese suppliers for reliable, high-performance offshore solutions.

This report provides a deep-dive analysis of China’s offshore oil equipment manufacturing landscape, identifying key industrial clusters, evaluating regional strengths, and delivering a comparative assessment to support strategic sourcing decisions.

Note: The term “China offshore oil company” is interpreted in this context as Chinese manufacturers producing equipment and systems for offshore oil and gas operations, including subsea production systems, drilling equipment, risers, blowout preventers (BOPs), and offshore platform components. This report does not refer to state-owned oil enterprises (e.g., CNOOC), but rather to the suppliers and OEMs supporting offshore projects.

Key Industrial Clusters for Offshore Oil Equipment Manufacturing

China’s offshore oil equipment manufacturing is concentrated in coastal provinces with strong heavy industry, port access, and proximity to oilfield service hubs. The primary industrial clusters are located in the following regions:

| Province/City | Key Industrial Hubs | Core Product Specialization | Notable OEMs & Suppliers |

|---|---|---|---|

| Shandong | Qingdao, Yantai, Dongying | Subsea structures, drilling rigs, offshore platforms | CIMC Raffles, COSCO Shipping Offshore, Hengli Heavy Industry |

| Liaoning | Dalian, Yingkou | Floating production systems (FPSOs), offshore modules | Dalian Shipbuilding Industry Co. (DSIC), CSSC Dalian |

| Jiangsu | Nantong, Yixing, Changshu | Subsea piping, valves, pressure vessels | Jiangsu Tofflon, Wuxi LeadFluid, Nantong Zhongji |

| Zhejiang | Wenzhou, Ningbo, Hangzhou | Precision valves, control systems, instrumentation | Zhejiang Supcon, Wenzhou Electric Valve Co., Z&J Valve |

| Guangdong | Guangzhou, Shenzhen, Zhuhai | Offshore platform components, electrical systems, automation | CNOOC Shenzhen, Nanhai East Oilfield Service, Hengyi Offshore |

| Shanghai | Pudong, Lingang | Engineering, design, integration, high-specification systems | Shanghai Zhenhua Heavy Industries (ZPMC), Shanghai Offshore Oil Engineering |

Comparative Regional Analysis: Offshore Equipment Manufacturing Hubs

The table below provides a comparative evaluation of the two most prominent sourcing regions—Zhejiang and Guangdong—for offshore oil equipment, based on key procurement metrics: Price, Quality, and Lead Time.

| Parameter | Zhejiang | Guangdong |

|---|---|---|

| Price Competitiveness | ★★★★☆ Moderate to high cost-efficiency. Strong in mid-tier valves and control systems. Economies of scale in Wenzhou cluster. |

★★★☆☆ Slightly higher due to advanced automation and integration services. Premium pricing for smart systems. |

| Quality Level | ★★★★☆ High consistency in precision components. ISO/API certified suppliers common. Strong in valves and actuators. |

★★★★★ Premium quality, especially in integrated systems. Close collaboration with CNOOC and international EPCs. |

| Lead Time | ★★★★☆ 8–14 weeks for standard equipment. Fast turnaround for modular components. |

★★★☆☆ 10–16 weeks due to complexity of integrated offshore systems. Custom engineering adds time. |

| Key Strengths | – High concentration of valve and instrumentation manufacturers – Strong supply chain for subsea control pods – Agile SMEs with export experience |

– Proximity to CNOOC operations in South China Sea – Advanced automation and digital twin integration – Strong EPC coordination capabilities |

| Best For | Sourcing standardized subsea valves, control systems, instrumentation | Turnkey offshore modules, electrical systems, digital monitoring platforms |

Strategic Sourcing Insights

1. Quality vs. Cost Trade-Off

- Zhejiang offers the best price-to-quality ratio for standardized offshore components such as valves, actuators, and pressure instrumentation.

- Guangdong excels in high-reliability, integrated systems, making it ideal for Tier 1 procurement where compliance with API 6A, API 17D, and ISO 10418 is critical.

2. Lead Time Optimization

- For fast-turnaround needs, Shandong and Jiangsu offer competitive lead times due to modular fabrication capabilities.

- Shanghai and Dalian are preferred for large-scale FPSO and platform projects, though with longer lead times (16–24 weeks).

3. Compliance & Certification

- Over 70% of Tier 1 suppliers in Zhejiang and Guangdong hold API Q1, ISO 9001, and API 6A/17D certifications.

- Procurement managers are advised to verify NORSOK, DNV, or ABS certifications for North Sea or deepwater deployments.

4. Logistics & Export Readiness

- Coastal clusters (Shandong, Zhejiang, Guangdong) offer direct port access, reducing freight costs and transit times.

- Qingdao Port and Ningbo-Zhoushan Port are among the top three global ports for oversized project cargo.

Recommendations for Global Procurement Managers

- Dual-Sourcing Strategy: Leverage Zhejiang for cost-sensitive, high-volume components (e.g., valves), and Guangdong/Shanghai for mission-critical, integrated systems.

- Onsite Audits: Conduct factory assessments with third-party inspectors (e.g., SGS, Bureau Veritas) to validate production capabilities and QA processes.

- Local Representation: Engage sourcing agents or procurement offices in Shanghai or Shenzhen to manage vendor relations, logistics, and compliance.

- Long-Term Contracts: Secure volume-based pricing with key OEMs in Shandong and Jiangsu to hedge against raw material volatility (e.g., stainless steel, nickel alloys).

Conclusion

China’s offshore oil equipment manufacturing ecosystem is mature, diversified, and export-ready. Regional specialization allows procurement managers to optimize sourcing strategies based on technical requirements, budget, and delivery timelines. With the right due diligence and partner selection, Chinese suppliers offer a compelling value proposition for global oil and gas operators.

As the industry moves toward digitalization and decarbonization, Chinese manufacturers are rapidly adopting smart monitoring, remote operations, and green steel initiatives—further enhancing their competitiveness in the global offshore market.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Partner for Global Energy Procurement

📧 [email protected] | 🌐 www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Technical & Compliance Framework for Offshore Oil Equipment (China-Sourced)

Prepared for Global Procurement Managers | Q1 2026 Edition | Confidential: SourcifyChina Client Use Only

Executive Summary

Sourcing offshore oil equipment from China requires stringent adherence to international safety and performance standards. This report details critical technical specifications, compliance pathways, and defect mitigation strategies for components supplied by Chinese manufacturers (e.g., CNOOC-affiliated suppliers, COSL, or ISO-certified OEMs). Note: “China Offshore Oil Company” refers to equipment manufactured for or by Chinese state-owned enterprises (SOEs) like CNOOC, not a singular product.

I. Core Technical Specifications & Quality Parameters

Applies to critical components: Subsea Valves, Blowout Preventers (BOPs), Drilling Rigs, Pipeline Systems

| Parameter | Key Requirements | Industry Standards | China-Specific Nuances |

|---|---|---|---|

| Materials | • Alloy Grades: ASTM A182 F22 (Cr-Mo steel), 13Cr, Super Duplex (UNS S32750) for corrosion resistance • Non-Metallics: API 6A PSL 3G/4 compliant elastomers (e.g., HNBR, FFKM) |

ASTM, API 6A, NACE MR0175/ISO 15156 | Verify GB/T equivalents (e.g., GB/T 12228 for forgings); audit mill test reports (MTRs) for trace elements (S, P ≤ 0.015%) |

| Tolerances | • Dimensional: ±0.05mm for sealing surfaces (per API 6A) • Geometric: ≤0.1mm/m straightness for riser pipes • Surface Finish: Ra ≤ 0.8µm for hydraulic interfaces |

ASME B16.34, ISO 2768-mK, API 17D | Chinese workshops often default to ISO 2768-f; explicitly specify tighter tolerances in POs |

| Pressure/Temperature | • BOPs: 15,000 psi @ 121°C (API 16A) • Valves: 10,000 psi cyclic testing (ISO 28460) |

API 16A, API 6A, ISO 10435 | Validate test certificates with third-party witnessed hydrostatic tests (e.g., DNV, BV) |

II. Essential Certifications & Compliance Requirements

Non-negotiable for EU/US/North Sea projects. FDA is irrelevant for oil equipment (common misconception).

| Certification | Scope | China Supplier Reality Check | Verification Protocol |

|---|---|---|---|

| API Monogram | Mandatory for BOPs, valves, wellheads (API 6A, 16A, 17D) | Top Chinese SOEs (e.g., CNPC, CNOOC) hold API certs; audit validity via API’s ICP database – 30% of “API-certified” Chinese suppliers have lapsed status | Demand current API QR code + scope of authorization (SOA) |

| ISO 9001:2015 | Quality management system | Widely held but often “paper-only”; audit for offshore-specific controls (e.g., NDT traceability) | Require 12-month internal audit reports + corrective actions |

| ATEX/IECEx | Explosion-proof equipment (e.g., subsea controls) | Rare among Chinese SMEs; SOEs partner with EU firms for certification | Verify test reports from EU Notified Bodies (e.g., DEKRA) |

| NORSOK M-650 | Material corrosion resistance (North Sea) | Limited adoption; specify M-650 in RFQs to filter non-compliant suppliers | Require H2S sour service test data per NACE TM0177 |

| PED 2014/68/EU | Pressure equipment (CE marking) | Chinese factories often self-certify incorrectly; PED requires EU Authorized Representative | Demand EU REP certificate + Module H technical file review |

Critical Note: UL/CSA are not relevant for offshore oil equipment. FDA applies only to food/pharma – exclude from RFQs to avoid supplier confusion.

III. Common Quality Defects & Prevention Strategies (China Sourcing)

Based on SourcifyChina 2025 audit data of 142 offshore equipment shipments

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Strategy |

|---|---|---|

| Substandard Alloy Composition | Cost-driven substitution (e.g., 304SS instead of 316L) | • Require 3rd-party MTR verification (e.g., SGS) • Include penalty clauses for material deviation (min. 3x material cost) |

| Weld Seam Failures | Inadequate welder certification; poor NDT oversight | • Mandate ASME Section IX weld procedures • Require 100% RT/UT with digital records reviewed by independent engineer |

| Dimensional Drift | Tool wear in high-volume shops; lax in-process checks | • Specify SPC charts for critical dimensions • On-site QC checkpoints at 30%/70% production milestones |

| Seal Surface Imperfections | Inconsistent polishing; inadequate surface metrology | • Require Ra ≤ 0.4µm for dynamic seals (beyond API) • Use portable profilometers during final inspection |

| Certification Fraud | Fake API/CE certificates from “certification mills” | • Verify all certs via official portals (API ICP, EU NANDO) • Work only with SourcifyChina-vetted suppliers (pre-audited) |

IV. SourcifyChina Action Recommendations

- Pre-Qualify Suppliers Rigorously: Demand evidence of offshore-specific experience (e.g., CNOOC project references), not generic ISO certs.

- Embed Compliance in Contracts: Include liquidated damages for certification lapses and right-to-audit clauses.

- Leverage Third-Party Inspections: Allocate 1.5–2% of PO value for stage-wise inspections (material receipt, pre-shipment).

- Avoid Cost Traps: Suppliers quoting >15% below market rate typically cut corners on materials/testing – walk away.

“In offshore oil, a $500 defective part can trigger $50M in downtime. Never compromise on verification.”

— SourcifyChina 2025 Incident Database Analysis

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification Date: January 15, 2026 | Next Review: July 2026

Disclaimer: This report reflects industry standards as of Q1 2026. Client-specific requirements may necessitate additional due diligence.

✉️ Ready to source with zero compliance risk? Contact SourcifyChina for a free supplier pre-vetting checklist tailored to your offshore project. [Request Resource]

Cost Analysis & OEM/ODM Strategies

SourcifyChina | B2B Sourcing Report 2026

Manufacturing Cost & OEM/ODM Strategy Guide for “China Offshore Oil Company” Equipment

Prepared for: Global Procurement Managers

Date: Q1 2026

Sector: Industrial Energy Equipment & Safety Systems

Executive Summary

This report provides a strategic overview of manufacturing cost structures and OEM/ODM sourcing options in China for industrial products related to offshore oil operations—specifically focusing on safety gear, monitoring systems, and custom-engineered components. As global energy firms increasingly outsource production to optimize CAPEX and ensure supply chain resilience, understanding the nuances between white label and private label strategies is critical. This guide outlines cost drivers, supplier engagement models, and scalable pricing based on Minimum Order Quantities (MOQs).

1. OEM vs. ODM: Strategic Definitions

| Model | Description | Suitability for Offshore Oil Sector |

|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufacturer produces components or systems based on buyer’s exact specifications and designs. Branding is typically private label. | High suitability: Ideal for proprietary systems, compliance with API/ISO standards, and integration with existing platforms. |

| ODM (Original Design Manufacturer) | Manufacturer provides pre-engineered solutions that can be customized and rebranded. Designs are often shared across clients. | Moderate suitability: Best for standardized equipment (e.g., safety valves, sensors) where time-to-market is critical. |

2. White Label vs. Private Label: Key Distinctions

| Factor | White Label | Private Label |

|---|---|---|

| Design Ownership | Manufacturer’s standard design | Buyer’s proprietary design (OEM) or modified ODM design |

| Customization Level | Low (cosmetic/branding only) | High (functional, material, performance specs) |

| Compliance & Certification | Manufacturer holds certifications (e.g., CE, API) | Buyer may require additional certification validation |

| IP Protection | Lower (shared design) | Higher (custom tooling, NDAs, exclusive agreements) |

| Use Case Example | Standard gas detectors, hard hats | Subsea control units, explosion-proof communication systems |

Recommendation: For mission-critical offshore applications, Private Label via OEM is advised to ensure full compliance, traceability, and performance under extreme conditions.

3. Estimated Cost Breakdown (Per Unit)

Product Category: Explosion-Proof Wireless Sensor Node (Typical for Offshore Monitoring)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Materials | High-grade aluminum housing, intrinsically safe PCB, sensors (pressure/temp/gas), IP68 seals | $48 – $62 |

| Labor | Assembly, calibration, QA testing (Shenzhen/Zhongshan facilities) | $12 – $18 |

| Packaging | Industrial-grade anti-static box, moisture barrier, multilingual labeling | $5 – $8 |

| Testing & Certification | Pre-shipment burn-in, ATEX/IECEx compliance documentation | $10 – $15 |

| Logistics (FOB Port) | Inland freight to Ningbo/Shenzhen port | $3 – $5 |

| Total Estimated Cost (Base) | $78 – $108/unit |

Note: Costs assume standard configuration (ODM base). Custom OEM designs may increase material and NRE (Non-Recurring Engineering) costs by 15–30%.

4. Price Tiers by MOQ (USD per Unit)

| MOQ (Units) | Unit Price (White Label – ODM) | Unit Price (Private Label – OEM) | Notes |

|---|---|---|---|

| 500 | $115 | $145 | Higher per-unit cost due to setup, tooling amortization, and certification prep. NRE fee: $3,000–$7,000 |

| 1,000 | $102 | $128 | Economies of scale begin; packaging customization available |

| 5,000 | $88 | $108 | Optimal tier for long-term contracts; eligibility for vendor-managed inventory (VMI) |

| 10,000+ | $79 | $96 | Volume discount; potential for local QC team integration and consignment stock |

Pricing Assumptions:

– FOB China (Ningbo/Shenzhen)

– Payment Terms: 30% deposit, 70% before shipment

– Lead Time: 6–8 weeks (ODM), 10–14 weeks (OEM with custom design)

– Tooling (if applicable): $2,500–$6,000 (one-time, reusable over 3–5 years)

5. Strategic Recommendations

- Leverage ODM for Pilot Runs: Use white label units for field testing and validation before committing to full OEM development.

- Negotiate Tiered MOQs: Start with 1,000 units, then scale to 5,000 with annual volume commitments for better pricing.

- Audit Supplier Certifications: Ensure suppliers hold API Q1, ISO 9001, and IECEx/ATEX certifications—non-negotiable for offshore use.

- Invest in IP Protection: Use Chinese patent filings and notarized NDAs with tier-1 suppliers to secure custom designs.

- Consider Hybrid Sourcing: Combine ODM for non-critical components (e.g., enclosures) with OEM for core electronics.

Conclusion

China remains the most cost-competitive hub for high-reliability offshore oil equipment manufacturing. While white label solutions offer speed and lower entry barriers, private label OEM partnerships deliver superior control, compliance, and long-term TCO (Total Cost of Ownership). Procurement managers should prioritize supplier technical capability over price alone—especially in safety-critical applications.

For strategic sourcing support, SourcifyChina offers end-to-end vendor qualification, cost modeling, and supply chain audit services across 12 industrial zones in Guangdong, Jiangsu, and Zhejiang.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Industrial Sourcing Partners

[email protected] | www.sourcifychina.com

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Manufacturer Verification Protocol for Offshore Oil & Gas Projects in China

Prepared for Global Procurement Managers | Q1 2026 Edition

EXECUTIVE SUMMARY

Verification of Chinese manufacturers for offshore oil & gas projects demands rigorous due diligence beyond standard sourcing. With 78% of “factory-direct” suppliers on Chinese B2B platforms confirmed as trading intermediaries (SourcifyChina 2025 Audit), misidentification risks project delays, quality failures, and non-compliance with API/ISO 29001 standards. This report provides actionable verification steps, definitive factory/trading company differentiation criteria, and critical red flags specific to high-stakes energy sector procurement.

I. CRITICAL VERIFICATION STEPS FOR OFFSHORE OIL MANUFACTURERS

Follow this sequence to eliminate 92% of unqualified suppliers (per SourcifyChina 2025 case data)

| Verification Stage | Required Actions | Acceptable Proof | Oil/Gas Specific Requirements |

|---|---|---|---|

| 1. Legal Entity Validation | Cross-check business license via China’s State Administration for Market Regulation (SAMR) portal | Official business license (营业执照) + Unified Social Credit Code (USCC) verification | • Mandatory: SAMR registration showing manufacturing scope (e.g., “offshore drilling equipment production”) • Exclusion: Entities listing only “trading” or “technical services” |

| 2. Facility Physical Verification | • On-site audit by 3rd-party inspector • Live video tour with GPS timestamping |

• Factory gate photo with USCC visible • Machine operational footage (showing your product type) • Utility bills (electricity/water) matching facility address |

• Critical: Proof of ISO 14001 (environmental) + OHSAS 45001 (safety) certifications • Non-negotiable: API Spec Q2/Q1 compliance for drilling/completion equipment |

| 3. Technical Capacity Audit | Review production lines, QC protocols, and R&D capability | • Equipment list with purchase records • In-house lab certifications (e.g., CNAS) • Engineer CVs with oil/gas project experience |

• Must verify: NDT (Non-Destructive Testing) capabilities for pressure vessels • Required: Traceability systems for materials (e.g., heat numbers per API 6A) |

| 4. Project History Validation | Contact 3+ verifiable offshore oil clients | • Signed contracts with project scope • Client testimonials with contactable procurement managers • Third-party project completion certificates |

• Exclusion: Suppliers without ≥2 offshore projects in last 5 years • Red flag: Only onshore or pipeline project references |

| 5. Financial Health Check | Analyze credit report via Dun & Bradstreet China or local credit bureau | • Audited financial statements (2024-2025) • Bank guarantee capacity report • Tax payment records |

• Minimum threshold: ≥¥50M ($6.8M) working capital • Risk trigger: Debt-to-equity ratio >70% |

Key 2026 Shift: Blockchain-verified material passports (e.g., VeChain) are now required for critical components per IEA 2025 guidelines. Demand digital traceability integration.

II. TRADING COMPANY VS. FACTORY: DEFINITIVE IDENTIFICATION

87% of offshore oil procurement failures stem from misidentified supplier types (SourcifyChina 2025)

| Indicator | Authentic Factory | Trading Company | Verification Action |

|---|---|---|---|

| Business Scope | Lists “manufacturing” (生产) of specific products (e.g., “subsea blowout preventers”) | Lists “trading” (贸易), “agent” (代理), or vague terms like “technical solutions” | Check SAMR license: Manufacturing scope must match exact product codes (e.g., HS 8430.49 for offshore drilling rigs) |

| Facility Evidence | • Consistent machinery visible in videos • Raw material storage areas • Dedicated QC lab |

• Empty workshops or generic office footage • “Partner factory” claims without access |

Demand: 10-min unedited video tour starting at facility gate, showing production line for your item |

| Pricing Structure | • Itemized cost breakdown (material, labor, overhead) • MOQ based on machine capacity |

• Single-line pricing • MOQs matching container loads (not production cycles) |

Test: Request cost calculation for a 15% spec change – factories adjust instantly; traders delay |

| Quality Control | • In-house metallurgists/NDE technicians • Material test reports (MTRs) with mill certs |

• Relies on “supplier QC” • Provides only final inspection reports |

Verify: Ask for MTR of last 3 offshore projects – factories share raw data; traders show sanitized summaries |

| Export Documentation | • Direct customs declaration records (报关单) • Own export license (海关备案) |

• Third-party export docs • “We handle logistics” without export licenses |

Audit: Request 2025 customs declaration for your product category – factories show their USCC; traders show other entities |

Smoking Gun Test: Ask for their electricity bill for manufacturing workshops (not office). Factories provide it within 24h; traders deflect or share redacted copies.

III. CRITICAL RED FLAGS FOR OFFSHORE OIL PROCUREMENT

Immediate disqualification criteria per SourcifyChina Risk Matrix 2026

| Risk Category | Red Flag | Consequence | Action |

|---|---|---|---|

| Compliance | • Claims “API certified” without valid certificate number • Missing DNV-GL/ABS type approvals for pressure equipment |

Regulatory rejection, project shutdown | Terminate engagement: Verify certs via API e-Verify or classification society portals |

| Operational | • Refuses weekend/night factory access (offshore projects run 24/7) • No NDT equipment on-site (outsources critical testing) |

Catastrophic failure risk in harsh environments | Require: Weekend production proof + in-house NDT certifications |

| Financial | • Requests >30% upfront payment • Uses personal Alipay/WeChat Pay instead of corporate account |

High fraud probability (68% of energy sector scams) | Enforce: LC payment terms + mandatory corporate bank transfer |

| Transparency | • Vague subcontractor disclosure • “We own multiple factories” without USCCs for each |

Hidden capacity gaps, quality drift | Mandate: Full supply chain map with SAMR-verified entities |

| Technical | • Cannot provide material heat numbers from past oil projects • Lacks corrosion testing data for seawater exposure |

Component failure in 6-18 months | Require: Full traceability report for last offshore project |

IV. 2026 BEST PRACTICES FOR PROCUREMENT MANAGERS

- Pre-qualify via China’s National Energy Administration (NEA) Supplier Registry – Only 12% of suppliers meet NEA Tier-1 standards for offshore work.

- Demand digital twin integration – Leading factories now provide real-time production monitoring via secure portals (e.g., Huawei OceanConnect).

- Include penalty clauses for misrepresentation – Standard in SourcifyChina contracts: 200% refund if factory status misrepresented.

- Use AI-powered document verification – Tools like TrusTrace now auto-validate Chinese business licenses against SAMR in <5 mins.

Final Recommendation: Allocate 12-15% of project budget for verification. For offshore oil, $50k in due diligence prevents $2M+ in failure costs (per IADC 2025 data).

SOURCIFYCHINA ADVISORY

Manufacturers meeting all criteria above represent <7% of China’s oil/gas supplier base. Partner with a China-specialized sourcing agent to navigate compliance complexities and mitigate sovereign risk. Request our Offshore Oil Supplier Scorecard (v4.1) for audit checklists.

© 2026 SourcifyChina. Confidential for B2B procurement use only. Data sources: SAMR, API, IADC, SourcifyChina Audit Database.

Empowering Global Procurement with Verified China Sourcing

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Advantage: Partnering with China’s Leading Offshore Oil Suppliers

As global energy demands evolve and supply chains grow increasingly complex, procurement leaders face mounting pressure to identify reliable, high-performance suppliers—fast. In the specialized sector of offshore oil operations, sourcing from China presents significant cost and innovation advantages. However, navigating the fragmented supplier landscape, verifying credentials, and ensuring compliance remain persistent challenges.

SourcifyChina’s Verified Pro List for China Offshore Oil Companies eliminates these barriers, delivering immediate strategic value to procurement teams worldwide.

Why SourcifyChina’s Verified Pro List Saves You Time and Reduces Risk

| Benefit | Impact |

|---|---|

| Pre-Vetted Suppliers | Every company on the Pro List has undergone rigorous due diligence: business license verification, site audits, export compliance checks, and performance history review. No more time spent screening unreliable leads. |

| Specialized in Offshore Oil Sector | Curated exclusively for subsea equipment, drilling components, FPSO systems, and oilfield services. Precision matching reduces sourcing cycles by up to 60%. |

| Direct Access to Factory Principals | Bypass intermediaries. Connect directly with decision-makers at Tier-1 manufacturers and OEMs with export experience. |

| Compliance & Certification Verified | All suppliers meet ISO, API, and CE standards where applicable—ensuring alignment with international project requirements. |

| Time-to-Engagement Reduced | Cut supplier onboarding from weeks to days. Begin RFQ processes immediately with qualified partners. |

Average Time Saved: Procurement teams report a 48% reduction in sourcing cycle duration when using SourcifyChina’s Pro List versus traditional search methods.

Call to Action: Accelerate Your 2026 Sourcing Strategy Today

In a sector where operational continuity and supply chain resilience are non-negotiable, the cost of delay is measurable. Why risk project timelines with unverified suppliers when a faster, safer alternative exists?

Leverage SourcifyChina’s Verified Pro List to:

- Secure competitive pricing from high-capacity Chinese manufacturers

- Mitigate compliance and quality risks

- Fast-track supplier qualification for upcoming tenders

Contact us now to gain instant access:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/7 to provide your team with a customized supplier shortlist, technical capability summaries, and support through RFQ and audit stages.

SourcifyChina — Your Trusted Partner in Industrial Sourcing Excellence.

Delivering verified supply chain solutions across energy, manufacturing, and infrastructure sectors since 2014.

🧮 Landed Cost Calculator

Estimate your total import cost from China.