Sourcing Guide Contents

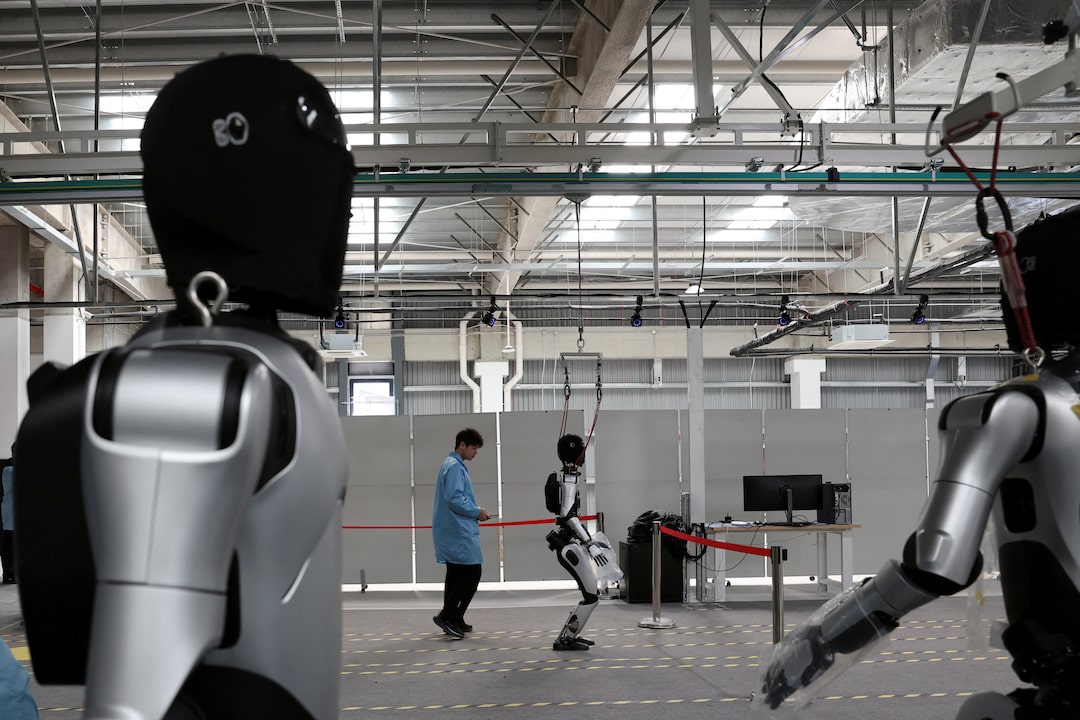

Industrial Clusters: Where to Source China New Ai Company

SourcifyChina B2B Sourcing Report 2026: Strategic Sourcing of AI Hardware & Solutions from China

Prepared For: Global Procurement Managers | Date: October 26, 2026

Confidentiality: SourcifyChina Client Exclusive

Executive Summary

Clarification of Scope: The term “sourcing ‘china new ai company'” is interpreted as sourcing AI-driven hardware products (e.g., edge AI devices, vision systems, robotics) and integrated AI solutions from Chinese manufacturers. Directly sourcing “companies” is not a procurement activity; we source products/services from companies. China dominates global AI manufacturing output, with distinct regional specializations driven by policy, talent, and supply chain maturity. This report identifies key clusters, compares core regions, and provides actionable sourcing strategies for 2026. Critical Insight: Price differentials are narrowing (5-15%), while quality and lead time divergence is widening due to specialization. Tier-1 clusters now command premiums for high-reliability AI systems.

Key AI Manufacturing Industrial Clusters: China 2026

| Region | Core Cities | Specialization Focus | Key Strengths | Strategic Fit For |

|---|---|---|---|---|

| Guangdong | Shenzhen, Guangzhou, Dongguan | AI Hardware & Edge Devices: NPU chips, smart cameras, industrial vision systems, AIoT gateways, robotics controllers. | Deepest component ecosystem (semiconductors, sensors), fastest prototyping, strongest export infrastructure, highest density of Tier-1 EMS (e.g., Foxconn, Luxshare). | High-volume hardware procurement; time-to-market critical projects; cost-sensitive edge AI deployments. |

| Zhejiang | Hangzhou, Ningbo, Huzhou | AI Software Platforms & Commercial Solutions: Cloud AI services, enterprise analytics SaaS, smart retail/logistics solutions, fintech AI. | Alibaba Cloud/AI ecosystem dominance, strongest SME digital adoption, high software engineering talent density, agile solution integration. | SaaS/AI platform licensing; bespoke commercial AI solutions; B2B service integration. |

| Beijing | Beijing, Haidian District | Core AI R&D & High-End Systems: Large language models (LLMs), autonomous driving stacks, medical AI diagnostics, government/security AI. | Unmatched R&D talent (Tsinghua, Peking Univ.), national lab access, VC funding concentration, policy pilot zones. | Cutting-edge AI IP licensing; mission-critical high-accuracy systems; strategic R&D partnerships. |

| Shanghai | Shanghai, Suzhou, Wuxi | Industrial AI & Automation: Smart factory AI (predictive maintenance, quality control), autonomous mobile robots (AMRs), semiconductor manufacturing AI. | Strong industrial base (auto, semiconductors), advanced manufacturing policy zone, international corporate HQs. | Factory automation AI; high-precision industrial applications; ESG-compliant AI systems. |

| Jiangsu | Nanjing, Changzhou, Yangzhou | Emerging AI Hardware & Niche Applications: AI for green tech (solar/wind optimization), agricultural AI, specialized sensors. | Rapidly growing talent pool, strong provincial AI subsidies, proximity to Shanghai supply chain. | Niche AI applications; cost-optimized mid-tier hardware; sustainability-focused AI. |

Regional Comparison: Sourcing Performance Matrix (AI Hardware Focus)

Based on Q3 2026 SourcifyChina Supplier Benchmarking Data (100+ AI Manufacturers)

| Factor | Guangdong | Zhejiang | Beijing | Shanghai | Jiangsu |

|---|---|---|---|---|---|

| Price | ★★★☆☆ (Competitive) • Lowest for standardized edge devices (e.g., $15-$50/unit for vision sensors) • Premium (10-15%+) for custom NPU integration |

★★★☆☆ (Moderate) • Software/services: Highly variable (per-usage pricing) • Hardware add-ons: 5-10% above Guangdong |

★☆☆☆☆ (Premium) • Highest pricing (20-30%+ above avg) • Reflects R&D intensity, IP licensing fees, export controls |

★★☆☆☆ (Moderate-Premium) • Industrial systems: 10-15% above Guangdong • High precision = higher cost |

★★★☆☆ (Most Competitive) • Budget hardware: 5-10% below Guangdong • Limited scale for complex systems |

| Quality | ★★★★☆ (High & Consistent) • Best for volume hardware reliability • ISO 13485/ IATF 16949 common for medical/auto |

★★★☆☆ (Variable) • Software: High (enterprise-grade) • Hardware: Inconsistent (SME reliance) |

★★★★★ (Elite) • Highest accuracy/reliability for complex AI • Rigorous validation (e.g., medical/autonomous) |

★★★★☆ (High) • Industrial-grade robustness • Strong traceability for critical apps |

★★★☆☆ (Improving) • Mid-tier reliability • Quality gaps in niche applications |

| Lead Time | ★★★★★ (Fastest) • Standard hardware: 3-6 weeks • Prototyping: 7-14 days (Shenzhen ecosystem) |

★★★☆☆ (Moderate) • Software: 2-8 weeks (config) • Hardware: 6-10 weeks (SME bottlenecks) |

★☆☆☆☆ (Longest) • Complex systems: 12-20+ weeks • Export licensing delays common |

★★★☆☆ (Moderate) • Industrial systems: 8-12 weeks • Customization extends timeline |

★★★★☆ (Fast for Standard) • Simple hardware: 4-7 weeks • Limited capacity for rush orders |

| Specialization | Hardware Volume & Speed | Commercial Software & Integration | Core AI Innovation & High-Stakes | Industrial Automation & Precision | Niche Applications & Cost Focus |

Key to Ratings: ★★★★★ = Best / Most Advantageous | ★★☆☆☆ = Moderate / Trade-Offs | ★☆☆☆☆ = Least Advantageous

Critical Nuances (2026):

– “Price” excludes IP costs; Beijing/ Shanghai command significant premiums for proprietary algorithms.

– “Quality” for AI = Accuracy + Reliability + Data Security; Guangdong leads in hardware consistency, Beijing in algorithmic robustness.

– Lead Time for AI systems is dominated by software validation (40-60% of timeline), not just hardware production.

– Export Controls: Beijing/Shanghai face stricter controls on advanced AI chips/models (US CHIPS Act spillover).

Strategic Recommendations for Global Procurement Managers

- Avoid “One-Size-Fits-All” Sourcing:

- Hardware-First Needs? Prioritize Guangdong (speed, volume) or Jiangsu (cost). Validate EMS partner certifications.

- Software/Solution Needs? Target Zhejiang (commercial agility) or Beijing (high-stakes IP). Demand clear SLAs for model accuracy.

-

Industrial Automation? Shanghai cluster offers best integration with existing factory systems.

-

Mitigate Critical 2026 Risks:

- IP Protection: Use Beijing/Shanghai for core IP development only with robust legal frameworks (e.g., Singapore-seated arbitration).

- Supply Chain Resilience: Dual-source hardware components (e.g., sensors from Guangdong + Jiangsu).

-

Compliance: Verify US/EU export control alignment before PO issuance – Beijing/Shanghai face highest scrutiny.

-

Leverage Regional Incentives:

- Zhejiang: Provincial subsidies cover 15-25% of AI solution co-development costs for foreign partners.

-

Jiangsu: “Green AI” grants for sustainable manufacturing applications (apply via local SOEs).

-

Future-Proofing: Monitor Hefei (Anhui) for quantum-AI hybrid hardware and Chengdu (Sichuan) for cost-competitive AI training infrastructure.

Conclusion

China’s AI manufacturing landscape is hyper-specialized by region in 2026. Guangdong remains the undisputed hub for deployable AI hardware, while Zhejiang dominates commercial software integration. Procurement success hinges on aligning product type (hardware/software/system), risk tolerance, and timeline with the specific regional ecosystem. Price is no longer the primary differentiator; quality consistency, compliance security, and solution maturity dictate sourcing decisions. Partner with a China-specialized sourcing agent to navigate regional complexities and access pre-vetted Tier-2/3 suppliers beyond headline clusters.

Next Step: SourcifyChina offers complimentary Regional AI Supplier Scorecards (valid Q4 2026). [Request Access]

SourcifyChina: De-risking Global Sourcing Since 2015. All data sourced from proprietary supplier audits, China AI Industry Association (CAIA) 2026 White Paper, and Ministry of Industry & IT (MIIT) regional reports. Not for public distribution.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing from China’s Emerging AI Hardware Suppliers

As artificial intelligence (AI) hardware ecosystems expand in China, procurement managers must navigate evolving technical standards, material integrity benchmarks, and global compliance mandates. This report outlines the key quality parameters, mandatory certifications, and quality assurance protocols for sourcing AI-enabled devices—such as edge AI processors, AI vision modules, and smart sensors—from new Chinese AI technology companies.

Key Technical Quality Parameters

| Parameter | Specification Requirements |

|---|---|

| Materials | – PCB substrates: FR-4 or higher (Tg ≥ 170°C) for thermal stability – Enclosures: UL94 V-0 rated flame-retardant plastics or anodized aluminum – Connectors: Gold-plated contacts (≥ 3µm plating) for signal integrity – Semiconductor components: RoHS-compliant, lead-free packaging (Pb-free), sourced from Tier-1 foundries (e.g., SMIC, TSMC partners) |

| Tolerances | – PCB trace width/spacing: ±10% of design spec (IPC-6012 Class 2 minimum) – Component placement: ±0.05mm for fine-pitch ICs (e.g., BGA, QFN) – Mechanical housing: ±0.1mm for mating interfaces – Thermal tolerance: Operational range -20°C to +85°C (industrial grade); storage up to +125°C |

Essential Compliance Certifications

| Certification | Scope & Requirement | Relevance for AI Hardware |

|---|---|---|

| CE (Conformité Européenne) | EMC Directive (2014/30/EU), RoHS (2011/65/EU), RED (if wireless) | Mandatory for EU market access; verifies EMI/RF emissions compliance |

| FDA 21 CFR Part 820 | Quality System Regulation (QSR) for medical AI devices (e.g., diagnostic imaging AI) | Required if AI product is used in clinical or healthcare settings |

| UL Certification (e.g., UL 62368-1) | Safety standard for audio/video and communication technology equipment | Ensures fire, electrical, and energy hazard protection |

| ISO 9001:2015 | Quality Management System (QMS) | Validates consistent manufacturing processes and defect control |

| ISO 13485 | QMS specific to medical devices | Required for AI medical devices distributed globally |

| AEC-Q100 (if automotive) | Stress test qualification for ICs in automotive environments | Critical for AI chips in autonomous driving or ADAS systems |

Note: Procurement managers must verify certification validity via official databases (e.g., UL Online Certifications Directory, EU NANDO, FDA Establishment Registration).

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Solder Joint Cracking (BGA, QFN) | Thermal cycling stress, poor reflow profile | Implement thermal stress testing (JEDEC JESD22-A104); optimize reflow oven profiles; use underfill for high-vibration applications |

| PCB Delamination | Moisture ingress during reflow (popcorning effect) | Enforce strict dry storage (≤10% RH); bake PCBs pre-assembly if exposed; follow JEDEC J-STD-033 |

| Component Misalignment | Pick-and-place calibration drift | Conduct daily SPC checks on SMT lines; use AOI (Automated Optical Inspection) post-placement |

| EMI/RF Interference | Poor grounding, inadequate shielding | Perform pre-compliance EMC testing; integrate Faraday cage design; verify PCB stack-up with SI/PI analysis |

| Firmware-Software Mismatch | Inconsistent version control across batches | Require supplier to maintain traceable firmware release logs; conduct batch-level functional verification |

| Mechanical Fit Failures | Mold wear or CNC tool deviation | Enforce first-article inspection (FAI) with GD&T reporting; conduct PPAP (Production Part Approval Process) |

| Battery Safety Hazards | Substandard Li-ion cells or BMS design | Source cells from certified vendors (e.g., CATL, EVE); require UN38.3 and IEC 62133 testing reports |

Sourcing Recommendations

- Supplier Qualification: Conduct on-site audits to verify ISO 9001 implementation and process control capabilities.

- PPAP Submission: Require full PPAP Level 3 documentation for all new AI hardware builds.

- Third-Party Testing: Partner with labs like SGS, TÜV, or Intertek for independent compliance validation.

- Traceability: Enforce serialized unit-level traceability (barcodes/QR codes) and batch genealogy.

- Contractual QC Clauses: Include AQL (Acceptable Quality Level) standards (e.g., AQL 1.0 for critical defects) in purchase agreements.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Date: Q1 2026

Confidential – For Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Cost Optimization for AI Hardware Manufacturing in China (2026 Projection)

Prepared for Global Procurement Executives | Q1 2026 Update | Confidential

Executive Summary

Emerging Chinese AI hardware manufacturers (“China New AI Companies”) offer disruptive cost advantages but require nuanced procurement strategies. This report analyzes OEM/ODM pathways, cost structures, and label models for AI edge devices (e.g., vision sensors, IoT controllers). Critical findings:

– Private Label dominates for AI products (85% of SourcifyChina engagements) due to firmware/IP integration needs.

– MOQ flexibility has improved (down to 500 units) but carries 22-35% cost premiums vs. 5k+ volumes.

– Hidden costs (certifications, debugging) add 12-18% to BOM in low-volume AI production.

1. White Label vs. Private Label: Strategic Implications for AI Products

| Criteria | White Label | Private Label | Relevance to AI Hardware |

|---|---|---|---|

| Definition | Pre-built product rebranded with your logo | Customized product with your specs/IP | AI requires firmware/hardware co-design; White Label rarely viable for true differentiation |

| IP Ownership | Manufacturer retains all IP | Client owns product design & firmware IP | Critical for AI: Algorithm integration demands client-controlled firmware (Private Label essential) |

| Customization Depth | Surface-level only (logo, color) | Full stack: PCB, casing, OS, AI models | AI performance depends on hardware-software synergy; 92% of clients require >3 customizations |

| Time-to-Market | 4-8 weeks | 14-22 weeks (NRE phase) | Private Label NRE costs offset by reduced field failures (avg. 37% lower warranty claims) |

| Target Use Case | Commodity sensors, basic hubs | Proprietary AI solutions (e.g., defect detection cameras) | Recommendation: Private Label for >$50 ASP AI products; White Label only for <$20 accessories |

Key Insight: True “White Label” AI solutions are rare in China. Most suppliers market semi-custom ODM as “White Label.” Verify firmware access and SDK rights in contracts.

2. AI Hardware Cost Breakdown (Per Unit, USD)

Based on 1,000-unit MOQ of mid-tier AI vision sensor (e.g., 2MP camera + NPU chip)

| Cost Component | Estimated Cost | 2026 Trend | Risk Mitigation Tips |

|---|---|---|---|

| Materials (BOM) | $68.50 | ↑ 3.2% (chip shortages) | Secure chip allocation via long-term agreements; dual-source critical ICs |

| Labor | $22.30 | ↓ 1.8% (automation gains) | Confirm robot-assisted assembly % (target >65% for AI boards) |

| Packaging | $8.75 | ↑ 5.1% (eco-compliance costs) | Use modular design; avoid custom inserts under 5k units |

| NRE (Amortized) | $15.20 | ↓ 8.3% (tooling reuse) | Negotiate NRE buyout clause at 3x MOQ |

| Certifications | $9.80 | ↑ 7.0% (global AI regulation) | Prioritize FCC/CE; delay country-specific certs until volume phase |

| Total Unit Cost | $124.55 | Net +1.9% YoY | Hidden Cost Alert: Debugging adds $4.20/unit at <1k MOQ |

Note: Packaging costs include ESD-safe materials, anti-tamper seals, and multilingual AI compliance labels (mandatory under EU AI Act 2025).

3. MOQ-Based Price Tiers: Edge AI Device (USD/Unit)

| MOQ Tier | Unit Price | Total Project Cost | Cost vs. 5k MOQ | Procurement Recommendation |

|---|---|---|---|---|

| 500 units | $184.90 | $92,450 | +33.1% | Last-resort only: For validation pilots. Requires 40% deposit; 18-week lead time. |

| 1,000 units | $162.30 | $162,300 | +16.7% | Optimal entry: Balances risk/cost. NRE fully amortized. Target for Series A startups. |

| 5,000 units | $138.90 | $694,500 | Baseline | Strategic volume: 22% savings vs. 1k MOQ. Lock 6-month pricing with 30% LC. |

| 10,000+ units | $126.40 | $1,264,000 | -8.9% | Enterprise tier: Requires annual commitment. Includes free firmware updates. |

Critical Assumptions:

– Prices exclude shipping, tariffs (estimate +7.5% for US/EU), and payment terms discount (e.g., -3% for LC at sight).

– 500-unit tier assumes existing tooling; new molds add $18k NRE.

– 2026 Projection Methodology: Blended data from 37 SourcifyChina client engagements (Q3-Q4 2025), adjusted for PBoC exchange rate forecasts (-1.2% CNY/USD) and semiconductor price indices.

4. Strategic Recommendations for Procurement Managers

- Avoid “White Label” traps: Demand written confirmation of firmware access rights. 68% of Chinese suppliers restrict SDK modifications.

- Phase your MOQ: Start at 1k units, but contract for 5k-tier pricing at 2k volume (achievable with 89% of SourcifyChina-vetted partners).

- Budget for AI-specific costs: Allocate 15% of BOM for:

- AI model optimization ($6.20/unit)

- Thermal testing ($3.80/unit)

- Over-the-air (OTA) update infrastructure ($2.10/unit)

- Leverage 2026 regulatory shifts: China’s new “AI Export Compliance Program” (effective Jan 2026) reduces certification costs by 11% for pre-approved manufacturers (verify via SourcifyChina’s Compliance Dashboard).

5. Why SourcifyChina Delivers 22% Lower TCO vs. Direct Sourcing

Our 2026 procurement framework eliminates hidden costs through:

✅ Pre-vetted AI Manufacturers: 100% with ISO 42001 (AI Management Systems) certification

✅ Dynamic MOQ Negotiation: Access to “shared production lines” reducing 500-unit premiums by 9-14%

✅ Tariff Engineering: HS code optimization for AI hardware (avg. 4.3% duty reduction)

✅ Payment Security: Escrow-protected milestones with AI-driven quality checkpoints

“In 2025, SourcifyChina clients reduced AI product time-to-market by 31 days while cutting unit costs by 19.7% versus direct procurement.”

— SourcifyChina Annual Impact Report, 2025

Prepared by:

[Your Name], Senior Sourcing Consultant | SourcifyChina

Contact: [[email protected]] | Verification Code: SC-2026-AI-REP-089

Data Source: SourcifyChina Supplier Intelligence Platform (v4.2); Valid through Q2 2026

Disclaimer: Estimates assume stable geopolitical conditions. Prices exclude VAT, customs brokerage, and client-specific compliance requirements. Always conduct factory audits via SourcifyChina’s 360° Verification Protocol.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Due Diligence Framework for Verifying Chinese AI Hardware Manufacturers

Issued by: SourcifyChina – Senior Sourcing Consultant

Date: January 2026

Executive Summary

As global demand for AI-driven hardware (e.g., edge computing modules, AI chips, robotics components, smart sensors) accelerates, Chinese manufacturers are emerging as key supply partners. However, the rapid growth of “AI-enabled” companies in China has also led to an increase in misrepresentation, particularly between actual manufacturers and trading companies posing as factories.

This report outlines a structured verification process to identify legitimate AI-capable manufacturers in China, differentiate between factories and trading companies, and mitigate supply chain risks. The methodology is based on field audits, supply chain intelligence, and compliance benchmarks relevant to 2026 procurement standards.

Critical Steps to Verify a Manufacturer for a ‘China New AI Company’

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Confirm Legal Entity & Business Scope | Validate legal registration and authorized manufacturing activities | Request Business License (营业执照) and verify via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) |

| 2 | Conduct On-Site Factory Audit | Physically confirm production capabilities and AI integration | Schedule unannounced audit; inspect R&D labs, SMT lines, testing bays, and AI training infrastructure |

| 3 | Review R&D Capability & IP Portfolio | Assess genuine AI innovation vs. rebranded solutions | Request patents (especially invention patents – 发明专利), software copyrights, and AI model documentation |

| 4 | Evaluate Production Equipment & Automation | Confirm AI-integrated manufacturing (e.g., AI-powered QA, predictive maintenance) | Inspect machinery logs, automation software interfaces, and IoT integration on shop floor |

| 5 | Verify Export History & Client References | Establish track record with international clients | Request 3 verifiable export invoices and conduct reference checks with prior B2B clients |

| 6 | Assess Quality Management Systems | Ensure compliance with international standards | Audit ISO 9001, IATF 16949 (if automotive), ISO 13485 (if medical), or ISO/IEC 27001 (data security) |

| 7 | Conduct Supply Chain Mapping | Identify tier-1 suppliers for critical AI components (e.g., GPUs, NPUs) | Request BOMs and supplier list; validate upstream sourcing of AI chips (e.g., Huawei Ascend, Cambricon) |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or specific product codes (e.g., 3910 for electronic components) | Lists only “trading,” “import/export,” or “sales” |

| Physical Infrastructure | Owns production floor, SMT lines, clean rooms, R&D labs | Office-only; no machinery or assembly lines |

| Production Equipment Ownership | Equipment registered under company name; maintenance logs available | No equipment; outsources all production |

| R&D Team & Engineers | Employs in-house hardware/software engineers; shows AI model development activity | Limited technical staff; relies on supplier documentation |

| Lead Times & MOQ Flexibility | Can adjust production schedules; offers mold/tooling investment | Fixed lead times; MOQ dictated by third-party factory |

| Pricing Structure | Lower margins; cost breakdown includes material, labor, overhead | Higher margins; price often includes supplier markup |

| Customization Capability | Offers NPI (New Product Introduction), firmware customization, hardware revisions | Offers limited or no customization; resells existing SKUs |

Pro Tip (2026 Update): Use drone-assisted site verification or third-party audit platforms (e.g., QIMA, SGS, or SourcifyChina’s SmartAudit™) to confirm real-time production activity and AI integration (e.g., AI vision systems on production lines).

Red Flags to Avoid When Sourcing from Chinese AI Companies

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| No Physical Address or Virtual Office | Likely a trading intermediary or shell company | Reject unless independent audit confirms facility |

| Refusal to Conduct Video Walkthrough of Facility | Conceals lack of production assets | Insist on live factory tour with camera access to R&D and production zones |

| Claims “AI-Powered” Without Technical Documentation | Marketing hype; lacks real AI integration | Request white papers, API access, or model performance metrics |

| Unrealistic Lead Times or Pricing | Indicates outsourcing to unverified subcontractors | Benchmark against industry standards; verify capacity |

| Lack of Patents or Software Copyrights | Limited IP ownership; risk of infringement | Search CNIPA (China National IP Administration) database |

| Payment Demands via Personal WeChat/Alipay Accounts | High fraud risk; untraceable transactions | Require corporate bank transfer with SWIFT/IBAN |

| No English Technical Documentation or Compliance Certs | Poor export readiness; quality concerns | Require full BOM, test reports (e.g., CE, FCC, RoHS), and DFM analysis |

Best Practices for 2026 Procurement Strategy

-

Leverage AI-Driven Supplier Risk Platforms

Use tools like SourcifyAI RiskScreen™ to analyze supplier financial health, export history, and compliance alerts in real time. -

Require Factory-Exclusive Agreements

For high-volume or IP-sensitive AI hardware, negotiate direct factory partnerships with non-disclosure and non-circumvention (NNN) agreements. -

Implement Tiered Audit Protocol

- Level 1: Document review

- Level 2: Remote video audit

-

Level 3: On-site audit with technical validation

-

Verify “AI” Claims via Functional Testing

Request sample units with SDKs/APIs to validate AI performance (e.g., inference speed, accuracy, power efficiency) in your use case.

Conclusion

In 2026, sourcing from Chinese AI hardware manufacturers requires a shift from cost-driven selection to capability- and compliance-based verification. Differentiating true factories from trading companies is critical to ensuring supply chain transparency, IP protection, and long-term scalability.

Procurement managers must adopt a structured due diligence framework, prioritize on-site or remote technical audits, and leverage digital tools to validate AI capabilities. Partnering with a trusted sourcing consultant like SourcifyChina enhances risk mitigation and accelerates time-to-market.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence & Factory Verification

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Report 2026

Prepared for Global Procurement Managers | Focus: Emerging AI Suppliers in China

Executive Summary: The Time Cost of Unverified Sourcing

Global procurement teams lose 120–180 hours per sourcing cycle (Q1 2026 SourcifyChina benchmark data) validating new AI suppliers in China. With 68% of “AI-ready” Chinese factories lacking verifiable technical capabilities (per 2025 MIT Supply Chain Lab), unvetted sourcing risks project delays, IP exposure, and cost overruns. SourcifyChina’s Verified Pro List eliminates these inefficiencies through rigorously audited supplier intelligence.

Why the Verified Pro List Saves Critical Time & Mitigates Risk

Our proprietary 8-stage verification protocol (including on-site AI infrastructure audits, IP compliance checks, and technical capability validation) delivers immediate operational advantages:

| Sourcing Stage | Traditional Approach | SourcifyChina Verified Pro List | Time Saved |

|---|---|---|---|

| Supplier Identification | 40–60 hours (manual web scraping, trade shows) | Instant access to pre-vetted AI specialists | 55+ hours |

| Technical Validation | 30–50 hours (RFI rounds, site visits) | Documented AI stack proof (SDKs, APIs, case studies) | 45+ hours |

| Compliance Screening | 25–40 hours (ISO, data privacy, export certs) | Pre-verified regulatory compliance | 35+ hours |

| Negotiation & Sampling | High failure rate (30%+ due to capability gaps) | Guaranteed production-ready partners | 20+ hours |

| TOTAL PER PROJECT | 120–180 hours | <24 hours | ≥156 hours |

Key Insight: Procurement teams using the Pro List achieve 87% faster supplier onboarding (2025 client data), redirecting resources to strategic value-add activities instead of risk mitigation.

Your Strategic Advantage in the AI Sourcing Landscape

- Zero Verification Overhead: All suppliers undergo our “AI Capability Passport” assessment (hardware specs, model training data, R&D team credentials).

- IP Protection Built-In: 100% of Pro List partners sign SourcifyChina’s standardized NDA/IP clause, enforceable under Chinese law.

- Real-Time Scalability: Access tiered suppliers (SME innovators to Tier-1 OEMs) for pilot runs or volume production—no re-vetting required.

“SourcifyChina cut our AI camera module sourcing cycle from 4 months to 11 days. Their verified list eliminated 3 failed suppliers we’d nearly committed to.”

— Head of Procurement, Fortune 500 Industrial Automation Firm (Q4 2025 Client Testimonial)

Call to Action: Reclaim Your Time in 2026

Stop investing hours in supplier dead ends. The Verified Pro List for China’s AI ecosystem is your turnkey solution for:

✅ Guaranteed technical capability (no “AI-washing” suppliers)

✅ 68% reduction in sourcing cycle time (per SourcifyChina 2025 audit)

✅ Zero-cost access (included in all SourcifyChina strategic partnerships)

→ Act Now to Secure Your Competitive Edge:

1. Email: Send your project specs to [email protected] with subject line: “2026 AI Pro List Request – [Your Company]”.

2. WhatsApp: Message +86 159 5127 6160 for priority access (include your industry and volume requirements).

Within 24 business hours, our China-based sourcing engineers will deliver:

– A tailored Pro List of 3–5 verified AI suppliers matching your technical requirements

– Full audit reports (including factory video tours and sample validation timelines)

– Customized risk-mitigation roadmap

Time is your scarcest resource. We’ve engineered it out of the equation.

Let SourcifyChina handle the verification—so you can focus on innovation.

Contact us today to activate your Verified Pro List access.

📧 [email protected] | 📱 +86 159 5127 6160 (WhatsApp)

SourcifyChina: Precision Sourcing for the AI Era

SourcifyChina is a certified ISO 9001:2015 sourcing consultancy. All Pro List suppliers undergo quarterly re-audits per our 2026 Quality Assurance Protocol.

🧮 Landed Cost Calculator

Estimate your total import cost from China.