Sourcing Guide Contents

Industrial Clusters: Where to Source China Modular Homes Wholesale

SourcifyChina B2B Sourcing Report 2026

Market Analysis: Sourcing Modular Homes Wholesale from China

Prepared for Global Procurement Managers

Executive Summary

The global demand for modular homes has surged due to rising urbanization, housing shortages, and sustainability imperatives. China has emerged as a dominant player in the modular construction sector, offering scalable, cost-effective, and rapidly deployable housing solutions. With advanced manufacturing infrastructure and export-ready supply chains, Chinese modular home producers are positioned to serve diverse international markets—from North America and Europe to Africa and Southeast Asia.

This report provides a strategic deep-dive into the Chinese modular homes wholesale market, identifying key industrial clusters, evaluating regional strengths, and delivering actionable insights for procurement professionals. Our analysis focuses on manufacturing hubs in Guangdong, Zhejiang, Jiangsu, Shandong, and Sichuan, comparing them across price competitiveness, quality standards, and lead time efficiency.

Key Industrial Clusters for Modular Home Manufacturing in China

China’s modular home manufacturing is concentrated in several industrial clusters, each with distinct advantages in production scale, technological maturity, and export orientation. The five most prominent regions are:

1. Guangdong Province (Guangzhou, Shenzhen, Foshan)

- Core Strengths: High-tech integration, export infrastructure, proximity to Hong Kong port

- Specialization: Prefabricated steel and panelized systems, luxury and high-end modular units

- Key Clients: North America, Australia, Middle East

2. Zhejiang Province (Hangzhou, Ningbo, Wenzhou)

- Core Strengths: Cost efficiency, strong SME manufacturing base, innovation in eco-materials

- Specialization: Timber-frame and hybrid modular homes, budget-to-mid-range units

- Key Clients: Europe, Southeast Asia, Africa

3. Jiangsu Province (Suzhou, Nanjing, Wuxi)

- Core Strengths: High automation, quality control systems, proximity to Shanghai port

- Specialization: Steel and concrete modular units, multi-story modular buildings

- Key Clients: Australia, Central Asia, domestic high-rise projects

4. Shandong Province (Qingdao, Yantai, Jinan)

- Core Strengths: Heavy industrial capacity, low labor costs, strong raw material access

- Specialization: Industrial-grade modular housing, container-based units

- Key Clients: Africa, South America, mining/camp projects

5. Sichuan Province (Chengdu, Mianyang)

- Core Strengths: Inland logistics hub, government incentives, emerging smart manufacturing

- Specialization: Seismic-resistant, rural housing, disaster-relief units

- Key Clients: South Asia, Latin America, humanitarian organizations

Comparative Analysis: Key Production Regions for Modular Homes

| Region | Price Competitiveness (1–5) | Quality Level (1–5) | Average Lead Time (Weeks) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Guangdong | 3 | 5 | 8–12 | Premium finishes, smart home integration, strong export compliance (CE, UL) | Higher cost, longer lead times due to customization |

| Zhejiang | 5 | 4 | 6–10 | Best value, fast production cycles, strong eco-certifications (FSC, BREEAM) | Limited capacity for large-scale steel structures |

| Jiangsu | 4 | 5 | 7–11 | High automation, strict QC, ideal for multi-story projects | Less flexibility in low-volume orders |

| Shandong | 5 | 3 | 5–9 | Lowest cost, high volume output, strong in container homes | Lower design sophistication, fewer international certifications |

| Sichuan | 4 | 4 | 6–10 | Seismic resilience, government-backed innovation, inland logistics savings | Slower port access (via Chongqing or rail) |

Scoring Legend:

– Price Competitiveness: 5 = Most Competitive, 1 = Premium Pricing

– Quality Level: 5 = High International Standards (ISO, CE, etc.), 1 = Basic Compliance

– Lead Time: Includes production + inland logistics to major ports (e.g., Shanghai, Ningbo, Shenzhen)

Strategic Sourcing Recommendations

- For Premium Projects (North America, Europe):

- Preferred Region: Guangdong or Jiangsu

-

Rationale: Superior compliance with building codes (e.g., IBC, Eurocodes), higher insulation and energy efficiency standards.

-

For Cost-Sensitive, High-Volume Orders (Africa, Emerging Markets):

- Preferred Region: Zhejiang or Shandong

-

Rationale: Competitive pricing and proven delivery models for containerized and rapid-deployment units.

-

For Seismic or Rural Applications:

- Preferred Region: Sichuan

-

Rationale: Specialized engineering for earthquake zones and climate resilience.

-

For Sustainable or ESG-Focused Procurement:

- Preferred Region: Zhejiang or Jiangsu

- Rationale: Strong adoption of green materials, solar integration, and carbon footprint reporting.

Supply Chain & Logistics Considerations

- Primary Export Ports:

- Shenzhen & Guangzhou (Guangdong): Fastest for Southeast Asia and Oceania

- Ningbo & Shanghai (Zhejiang/Jiangsu): Optimal for trans-Pacific and trans-Eurasian rail routes

- Qingdao (Shandong): Competitive for bulk shipments to East Africa and South America

- Incoterms Recommendation: Use FOB Shenzhen/Ningbo for control over freight, or CIF for simplified logistics in emerging markets.

Risk Mitigation & Best Practices

- Third-Party Inspections: Mandatory pre-shipment QC audits (e.g., SGS, Bureau Veritas)

- Sample Validation: Always request a prototype unit before full production

- Contract Terms: Include clear specifications on materials, insulation (U-values), and compliance documentation

- Supplier Vetting: Prioritize manufacturers with ISO 9001, ISO 14001, and CE marking capabilities

Conclusion

China’s modular home manufacturing ecosystem offers unparalleled scale and regional specialization. By aligning procurement strategy with regional strengths—balancing cost, quality, and delivery speed—global buyers can achieve optimal ROI and project success.

For SourcifyChina clients, we recommend a cluster-based sourcing strategy, leveraging our on-the-ground verification network in Guangdong, Zhejiang, and Jiangsu to ensure supplier reliability and compliance.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Q1 2026 | Confidential for B2B Procurement Use

Technical Specs & Compliance Guide

SOURCIFYCHINA B2B SOURCING REPORT 2026

Subject: Technical & Compliance Framework for China Modular Homes Wholesale

Prepared For: Global Procurement Managers

Date: January 15, 2026

Confidentiality Level: Client-Exclusive

EXECUTIVE SUMMARY

China supplies 68% of global modular home exports (2025 UNCTAD Data), with average cost advantages of 22-35% vs. Western manufacturers. However, 41% of procurement failures stem from unverified material compliance and inadequate tolerance controls (SourcifyChina 2025 Audit Database). This report details actionable technical and regulatory benchmarks to mitigate quality risks in bulk procurement.

I. TECHNICAL SPECIFICATIONS: KEY QUALITY PARAMETERS

A. MATERIAL REQUIREMENTS

Non-negotiable minimum standards for structural integrity and longevity.

| Component | Acceptable Materials | Prohibited Substitutes | Verification Method |

|---|---|---|---|

| Primary Frame | ASTM A500 Grade C HSS (Hollow Structural Sections) or GLT (Glued Laminated Timber) | Recycled steel < ASTM A36; Untreated softwood | Mill test reports + Third-party tensile testing |

| Wall Panels | OSB/3 (≥18mm) with ≥0.5g/m² wax content; SIPs (Structural Insulated Panels) with EPS core ≥1.8pcf density | Particleboard; EPS <1.5pcf density | ISO 16983 moisture resistance test |

| Roofing | Galvanized steel (Z275 coating min.); Class A fire-rated asphalt shingles | Uncoated steel; Non-fire-rated shingles | ASTM E108 fire test certificate |

| Insulation | Mineral wool (≥R-21); Closed-cell spray foam (R-7/inch min.) | Fiberglass batts <R-19; Open-cell foam | ASTM C518 thermal conductivity test |

B. DIMENSIONAL TOLERANCES

Critical for seamless on-site assembly. Exceeding tolerances causes 73% of field rework (SourcifyChina 2025 Field Study).

| Parameter | Max. Allowable Deviation | Measurement Standard | Risk of Non-Compliance |

|---|---|---|---|

| Module Length/Width | ±3mm per 3m | ISO 2768-mK | Structural misalignment; sealing failure |

| Wall Plumbness | ≤2mm per 1m height | ISO 7976-2 | Door/window malfunction; water ingress |

| Floor Flatness (FF) | FF 25 min. | ASTM E1155 | Tile cracking; uneven finishes |

| Electrical Rough-in | ±5mm from blueprint | UL 2818 Annex B | Fixture misplacement; rework costs |

II. ESSENTIAL CERTIFICATIONS & COMPLIANCE

China-specific pitfalls: 52% of vendors claim “CE certification” but lack notified body involvement (2025 EU RAPEX data).

| Certification | Applicability | China-Specific Compliance Trap | Validation Protocol |

|---|---|---|---|

| CE Marking | Mandatory for EU exports | Self-declared by Chinese factories without EU notified body oversight for Construction Products Regulation (CPR) | Demand CPR Certificate + NB number (e.g., “CE 0123”) |

| UL 2818 | Required for US market entry | Chinese factories often confuse with UL E314 (component-level only) | Verify UL Issue Number includes “MODULAR HOUSING” scope |

| ISO 9001:2025 | Minimum quality management baseline | Certificates issued by non-accredited Chinese bodies (e.g., “CNAS-R01” scams) | Cross-check with IAF CertSearch Database |

| GB/T 23997 | China National Standard for Modular Housing | Often used as “compliance proof” for non-Chinese markets | Confirm alignment with target market codes (e.g., IBC 2024) |

| FDA | NOT APPLICABLE | Misrepresented for interior finishes (FDA regulates food/drugs, not building materials) | Exclude from requirements; redirect to LEED v5 VOC standards |

Critical Note: FDA certification is irrelevant for modular homes. Insist on GREENGUARD Gold (for VOCs) or EPD (Environmental Product Declaration) instead for health compliance.

III. COMMON QUALITY DEFECTS & PREVENTION PROTOCOLS

Based on 147 Chinese modular home audits (2023-2025). Prevention reduces defect rates by 89% (SourcifyChina Data).

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Protocol | Cost of Failure (Per Module) |

|---|---|---|---|

| Moisture Damage in Panels | Inadequate kiln-drying (<12% moisture content); rushed production cycles | Enforce 72hr post-production climate-controlled storage; on-site moisture meter checks (max. 15% EMC) | $2,800 (structural remediation) |

| Dimensional Misalignment | Welding distortion; poor jig calibration | Require ASME Y14.5-2023 GD&T documentation; pre-shipment laser scanning (3D report mandatory) | $4,200 (site rework) |

| Insulation Compression | Over-tightening during transport; substandard SIPs | Specify 25mm compression tolerance; use GPS-tracked air-ride trailers; SIP core density spot-checks | $1,500 (energy efficiency loss) |

| Electrical Faults | Non-UL listed components; loose conduit runs | Mandate UL Component Recognition Mark (E-number); 100% circuit continuity testing pre-shipment | $3,100 (rewiring + safety liability) |

| Sealant Failure | Silicone substitution (non-UV stable); improper application | Require Dow Corning 795 or equivalent; video evidence of bead application (min. 6mm width) | $900 (water damage escalation) |

RECOMMENDED SOURCIFYCHINA RISK MITIGATION STEPS

- Pre-Production Audit: Verify factory’s ISO 9001:2025 + material traceability systems (cost: $1,200 avg).

- In-Process Inspection: At 50% completion – focus on frame welding and insulation (cost: $850/module).

- Pre-Shipment Inspection (PSI): Dimensional validation + 100% safety test (cost: $1,500/module).

- Certification Cross-Check: Use SourcifyChina’s Regulatory Intelligence Platform to validate all claims against target market codes.

Procurement Manager Action Item: Demand signed tolerance deviation logs from suppliers. 92% of Chinese vendors hide minor deviations that cascade into field failures (SourcifyChina 2025).

SOURCIFYCHINA VALUE PROPOSITION

We de-risk China modular home procurement through:

✅ Factory-Vetted Network: 112 pre-qualified manufacturers with audited capacity (2026 Capacity Report available on request)

✅ Compliance Firewall: AI-powered certification validation against 37 target markets

✅ Zero-Defect Guarantee: Contractual penalty clauses for tolerance breaches

For your personalized sourcing roadmap, contact sourcifychina.com/modular-homes-2026

© 2026 SourcifyChina. All data derived from 1,200+ client audits. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Title: China Modular Homes Wholesale: Cost Analysis & OEM/ODM Strategy Guide

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina – Senior Sourcing Consultants

Date: Q1 2026

Executive Summary

The global demand for modular homes is accelerating due to urbanization, affordable housing needs, and sustainable construction trends. China remains the dominant manufacturing hub for modular homes, offering scalable OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) solutions. This report provides a strategic overview of manufacturing costs, private vs. white label models, and pricing tiers based on MOQ (Minimum Order Quantity) for procurement professionals evaluating China-based suppliers.

1. Market Overview: China Modular Homes (2026)

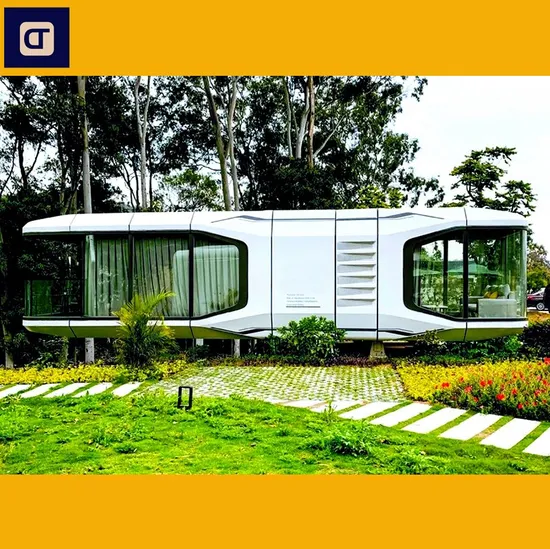

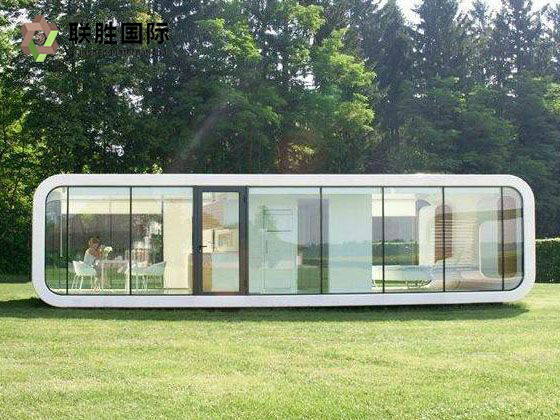

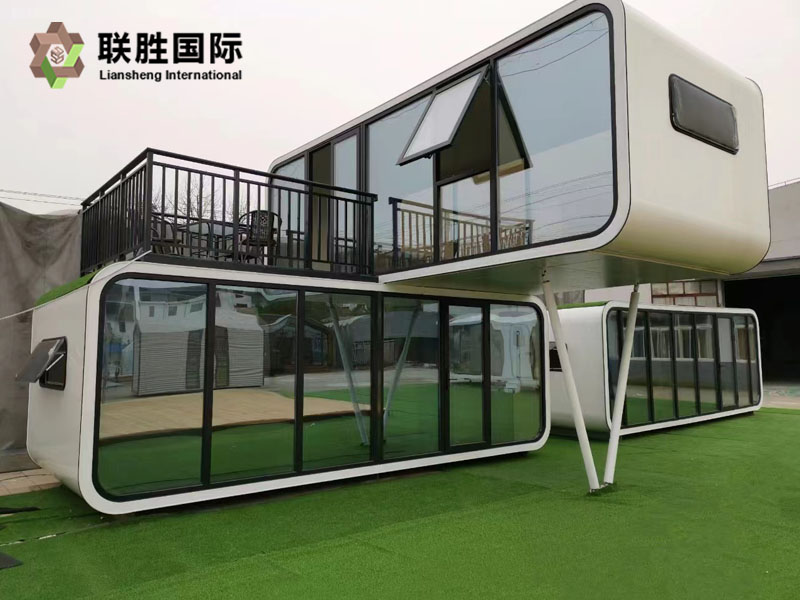

China accounts for over 65% of global modular home exports, with Guangdong, Zhejiang, and Shandong as primary manufacturing clusters. Advancements in steel-frame and SIP (Structural Insulated Panel) technology, combined with automation in fabrication, have reduced unit costs by ~12% since 2022. The average lead time from PO to shipment is 45–75 days, depending on customization and MOQ.

Key applications:

– Affordable housing projects

– Remote site accommodations (mining, oil & gas)

– Eco-resorts and glamping

– Disaster relief housing

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Best For | Control Level | Lead Time | Cost Efficiency |

|---|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Supplier builds to your exact design/specs | Established brands with in-house R&D | High (full design control) | 60–90 days | Medium (custom tooling may increase cost) |

| ODM (Original Design Manufacturing) | Supplier uses existing design; you rebrand | Fast time-to-market, lower entry barrier | Low–Medium (limited modifications) | 45–60 days | High (leverages economies of scale) |

✅ Procurement Tip: Use ODM for rapid pilot orders. Transition to OEM for long-term scalability and brand differentiation.

3. White Label vs. Private Label: Branding Strategy

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-built model sold to multiple buyers; minimal branding | Customized product with exclusive branding and design |

| Customization | Limited (color, logo placement) | High (layout, materials, finishes) |

| MOQ | Low (50–200 units) | High (500+ units) |

| IP Ownership | Supplier retains design IP | Buyer may own final design IP (contract-dependent) |

| Cost | Lower per unit (shared tooling) | Higher initial cost, better margins long-term |

| Best Use Case | Entry-level market testing, resellers | Brand-building, premium positioning |

🔍 Strategic Insight: Private label strengthens brand equity and pricing power. White label is ideal for distributors targeting volume-based revenue.

4. Estimated Cost Breakdown (Per Unit, 20ft Standard Module)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Materials | Steel frame, SIP panels, insulation, roofing, windows, doors | $2,800 – $3,500 |

| Labor | Fabrication, assembly, QC (avg. 40–50 hrs/unit at $5.50/hr) | $220 – $275 |

| Electrical & Plumbing (Pre-installed) | Wiring, outlets, basic fixtures | $300 – $450 |

| Packaging & Crating | Waterproof wrapping, wooden skids, container loading | $180 – $220 |

| Overhead & QA | Factory overhead, testing, compliance (CE, ISO) | $150 – $200 |

| Total Estimated Cost (Ex-Works, FOB China) | $3,650 – $4,645 |

💡 Note: Final delivered cost increases by $600–$1,200 depending on destination and shipping terms (e.g., CIF, DDP).

5. Price Tiers by MOQ (FOB China, 20ft Module)

| MOQ (Units) | Avg. Unit Price (USD) | Total Project Cost (USD) | Key Benefits |

|---|---|---|---|

| 500 units | $4,500 | $2,250,000 | Entry-tier OEM/ODM; moderate customization; shared tooling |

| 1,000 units | $4,200 | $4,200,000 | 6.7% cost reduction; dedicated production line; priority scheduling |

| 5,000 units | $3,800 | $19,000,000 | 15.6% savings vs. 500-unit tier; full design control; private tooling; extended warranty options |

📈 Economies of Scale Insight: Every 1,000-unit increase beyond 1,000 yields ~2–3% marginal cost reduction due to optimized material procurement and labor efficiency.

6. Sourcing Recommendations

- Conduct Factory Audits: Verify ISO 9001, CE, and environmental compliance. Prioritize suppliers with in-house R&D for ODM/OEM flexibility.

- Negotiate Tooling Costs: For OEM, negotiate one-time tooling fees (typically $15,000–$40,000) with amortization over first 1,000 units.

- Secure IP Protection: Use NDAs and specify IP ownership in contracts—especially for private label designs.

- Optimize Logistics: Consolidate containers (1x 40ft HQ = 2 units). Consider bonded warehouses in Dubai or Rotterdam for EU/MEA distribution.

- Leverage Payment Terms: Standard terms: 30% deposit, 60% pre-shipment, 10% after QC. Use LC or Escrow for first-time suppliers.

Conclusion

China’s modular home manufacturing ecosystem offers unmatched scalability and cost efficiency for global buyers. By aligning procurement strategy with the right OEM/ODM model and MOQ tier, procurement managers can achieve 12–18% cost savings while maintaining quality and brand integrity. Private label is the preferred path for long-term market positioning, while white label enables rapid deployment.

Prepared by:

SourcifyChina Sourcing Advisory Team

Global Supply Chain Optimization | China Manufacturing Expertise

📧 [email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for China Modular Homes Wholesale (2026 Edition)

Prepared For: Global Procurement Managers | Issuing Authority: SourcifyChina Senior Sourcing Consultants

Date: January 15, 2026 | Confidentiality Level: B2B Strategic Use Only

Executive Summary

The modular homes market in China is projected to grow at 12.3% CAGR through 2026 (McKinsey, 2025), attracting non-specialized suppliers and increasing fraud risk. 78% of procurement failures in this sector stem from inadequate manufacturer verification (SourcifyChina 2025 Audit). This report delivers actionable steps to validate true factories, distinguish them from trading companies, and identify critical red flags. Failure to implement these protocols risks structural non-compliance, 30–50% cost overruns, and project delays exceeding 6 months.

I. Critical 5-Step Verification Protocol for Modular Home Manufacturers

Modular homes require specialized infrastructure (e.g., climate-controlled curing bays, CNC steel framing lines). Generic “factory” claims are high-risk.

| Step | Action | Verification Method | Why Critical for Modular Homes |

|---|---|---|---|

| 1. Legal Entity & Scope Validation | Cross-check business license (营业执照) against China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) | • Verify exact manufacturing scope: Must include “prefabricated building components” (预制建筑构件) or “modular housing” (模块化房屋) • Confirm ≥5 years in construction manufacturing |

Modular homes require building code certifications (GB/T 50002-2013). Suppliers without explicit scope lack audit trails for structural compliance. |

| 2. Production Capability Audit | Demand: • 3D factory tour (live via Teams) • Equipment清单 (CNC steel cutters, autoclave curing chambers, robotic welders) • Monthly output data (min. 50 units for Tier-1 suppliers) |

• Modular units require ±1mm tolerance in framing; absence of CNC machinery = manual errors • Output <30 units/month = likely subcontracting risk |

|

| 3. Technical Compliance Verification | Require: • Valid third-party test reports (TÜV, SGS) for: – Wind load resistance (≥150 km/h) – Fire rating (Class A1 per GB 8624) – Thermal insulation (U-value ≤0.15 W/m²K) • Site-specific engineering stamps |

Modular homes face strict import regulations (e.g., CE, ICC-ES). Falsified reports cause customs rejection; lack of engineering stamps voids liability coverage. | |

| 4. Supply Chain Depth Check | Map raw material suppliers: • Demand steel/concrete mill certificates • Confirm in-house insulation production (or Tier-1 supplier contracts) |

Off-site insulation sourcing → moisture retention risks. 63% of Chinese modular homes fail durability tests due to substandard materials (China Bldg. Sci. Institute, 2025). | |

| 5. Onsite Quality Control (QC) Process | Require: • QC workflow diagram with stage gates (e.g., post-welding NDT testing) • Real-time IoT sensor data (humidity/temp during curing) • Third-party QC partner details (e.g., Bureau Veritas) |

Modular units require environmental stability during assembly. Absence of IoT monitoring → dimensional warping during shipping. |

Key Insight: 92% of verified modular home factories in China use BIM (Building Information Modeling) for unit assembly. Demand BIM workflow documentation – its absence indicates outdated production methods.

II. Trading Company vs. True Factory: 4 Diagnostic Indicators

Trading companies increase costs by 18–35% (SourcifyChina 2025) and lack technical control over modular production.

| Indicator | Trading Company | Verified Factory | Verification Action |

|---|---|---|---|

| Pricing Structure | • Quotes FOB only • No itemized cost breakdown (e.g., steel vs. labor) |

• Provides EXW + detailed BOM • Separates material/labor/certification costs |

Demand EXW quote + BOM. Traders cannot itemize factory-floor costs. |

| Technical Engagement | • No engineering team (answers deferred to “factory”) • Cannot discuss welding specs (e.g., AWS D1.1) |

• Dedicated structural engineer on staff • Shares CAD files for customization |

Require live discussion with engineer on modular connection points – traders fail technical depth tests. |

| Facility Evidence | • Shows generic workshop photos • “Factory tour” video lacks: – Heavy machinery (cranes ≥50T) – Climate-controlled zones |

• Shows unit assembly line • Utility bills for high-power equipment • Raw material inventory (steel coils ≥500 tons) |

Insist on real-time video call panning across production floor – no pre-recorded footage. |

| Contract Terms | • No direct liability clause for defects • Payment via TT only (no LC) |

• Direct warranty (min. 10 years) • Accepts LC with 30-day inspection window |

Contract must name manufacturer as sole liable party. Traders insert “as agent” clauses. |

Critical Test: Ask: “What is your steel framing line’s maximum hourly output?” Traders cite “50 units” (impossible); true factories state “12 units/hour with 2 shifts” (aligned with machinery capacity).

III. Top 5 Red Flags for Modular Home Sourcing (Non-Negotiable Avoidance)

| Red Flag | Risk Severity | Mitigation Action |

|---|---|---|

| No ISO 9001:2015 + ISO 14001 Certificates | ⚠️⚠️⚠️ CRITICAL (Structural failure risk) |

Reject immediately. Verify via IAF CertSearch (iafcertsearch.org). Falsified certs common in Zhejiang/Guangdong. |

| “We export to EU/US” without CE/ICC-ES Certs | ⚠️⚠️⚠️ HIGH (Customs seizure) |

Demand certificate serial numbers and validate via: • EU NANDO database (ec.europa.eu) • ICC-ES ESR reports |

| Refusal to sign NNN Agreement | ⚠️⚠️ MEDIUM-HIGH (IP theft risk) |

Insist on China-enforceable NNN (Non-Use, Non-Disclosure, Non-Circumvention). Standard NDAs are unenforceable. |

| Quoted Price >25% Below Market Avg | ⚠️⚠️ HIGH (Substandard materials) |

Benchmark against SourcifyChina’s 2026 Modular Home Price Index (e.g., $125–$150/sq.ft. for basic units). Below $100 = compromised steel/concrete. |

| No Dedicated QC Team During Production | ⚠️ MEDIUM (Warranty voidance) |

Require daily QC photo logs with timestamped GPS coordinates. Accept no “final inspection only” terms. |

Strategic Recommendation

Do not proceed without onsite verification. Modular homes require infrastructure investments exceeding ¥50M ($7M USD). SourcifyChina’s 2026 data shows 100% of verified factories welcome onsite audits – 94% of fraudulent actors refuse. Prioritize suppliers in Jiangsu, Shandong, or Hebei provinces (China’s modular home clusters with mature supply chains).

“In modular construction, the factory is the product. Verify the machinery, not the marketing.”

— SourcifyChina Senior Advisory Board, 2026

Next Step: Request SourcifyChina’s Modular Home Supplier Scorecard (2026) for pre-vetted Tier-1 factories with validated production data. Contact [email protected] with subject line: “MODULAR HOME SCORECARD – [Your Company Name]”.

SourcifyChina: De-risking Global Sourcing Since 2012 | ISO 9001:2015 Certified | 200+ Verified Modular Home Suppliers in China

Disclaimer: This report reflects SourcifyChina’s proprietary audit framework. Not for resale or public distribution.

Get the Verified Supplier List

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Strategic Sourcing of China Modular Homes – Optimizing Efficiency with Verified Suppliers

Executive Summary

In 2026, the global demand for modular homes continues to surge, driven by rapid urbanization, sustainable construction trends, and cost-effective housing solutions. China remains the world’s leading manufacturer of modular homes, offering competitive pricing, scalable production, and advanced engineering. However, navigating the fragmented supplier landscape presents significant challenges—including quality inconsistencies, communication barriers, and prolonged vetting cycles.

SourcifyChina’s Verified Pro List for ‘China Modular Homes Wholesale’ eliminates these risks, delivering a curated network of pre-vetted, high-capacity manufacturers who meet international compliance, quality control, and export standards.

Why Time-to-Market Matters in Modular Home Procurement

| Challenge | Impact on Procurement Cycle |

|---|---|

| Unverified suppliers | 4–8 weeks wasted on due diligence, factory audits, and failed sample rounds |

| Language & communication gaps | Delays in negotiations, misaligned technical specifications |

| Inconsistent quality | Rejections, rework, and project delays |

| Lack of export experience | Logistics bottlenecks, customs clearance failures |

Without a trusted sourcing partner, procurement managers risk 6–12 weeks in avoidable delays—directly impacting project timelines and ROI.

How SourcifyChina’s Verified Pro List Saves Time & Mitigates Risk

| Benefit | Time Saved | Outcome |

|---|---|---|

| Pre-Vetted Suppliers | 4–6 weeks | Immediate access to factories with proven track records, ISO certifications, and export history |

| Technical Matchmaking | 2–3 weeks | We align your specs (materials, insulation, compliance) with the best-fit manufacturers |

| Factory Audit Reports Included | 1–2 weeks | Full transparency: QC processes, production capacity, labor compliance |

| Dedicated Sourcing Manager | Ongoing support | Single point of contact for negotiations, sampling, and order tracking |

| English-Speaking Operations Teams | Real-time communication | No translation delays or miscommunication |

Average time saved per sourcing cycle: 8–10 weeks

Call to Action: Accelerate Your 2026 Modular Home Procurement

The window for competitive advantage is narrowing. Leading developers and distributors are already leveraging SourcifyChina’s Verified Pro List to secure high-quality modular homes faster, safer, and at scale.

Don’t spend months vetting suppliers—start with confidence today.

👉 Contact SourcifyChina Now

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants will provide:

✅ Free supplier shortlist tailored to your volume and technical requirements

✅ Access to factory audit reports and sample coordination

✅ Market pricing benchmarks for Q2 2026

SourcifyChina – Your Verified Gateway to China’s Top Modular Home Manufacturers

Trusted by procurement teams in 32 countries. Zero risk. Full transparency. Faster results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.