Sourcing Guide Contents

Industrial Clusters: Where to Source China Mobile Companies

SourcifyChina Sourcing Intelligence Report: China Mobile Device Manufacturing Landscape

Report Date: January 15, 2026

Prepared For: Global Procurement Managers (Electronics Sector)

Confidentiality Level: B2B Strategic Use Only

Executive Summary

Clarification: The term “China mobile companies” in sourcing contexts typically refers to mobile device manufacturers (smartphones, feature phones, accessories), not telecommunications operators (e.g., China Mobile Ltd.). This report analyzes China’s mobile device manufacturing ecosystem—the world’s largest, producing 85% of global smartphones. Key clusters in Guangdong, Zhejiang, and Jiangsu dominate, driven by supply chain density, skilled labor, and export infrastructure. Procurement managers must prioritize cluster selection based on product complexity, volume, and risk tolerance. Post-2025, rising labor costs and U.S. entity list restrictions necessitate strategic diversification within China.

Methodology

- Data Sources: MIIT (Ministry of Industry and IT) 2025 Production Reports, Customs Data (HS 8517), SourcifyChina Supplier Database (1,200+ verified factories), On-Ground Audits (Q4 2025).

- Scope: OEM/ODM manufacturers of smartphones, IoT mobile devices, and value-added accessories (cases, chargers). Excludes telecom operators and pure-component suppliers.

- Key Metrics Tracked: Unit price (USD), defect rates (PPM), lead time (order-to-shipment), compliance certifications (ISO 13485, IATF 16949), export capacity.

Key Industrial Clusters: Mobile Device Manufacturing

1. Guangdong Province (Pearl River Delta)

- Core Cities: Shenzhen (HQs of Huawei, OPPO, vivo), Dongguan (Foxconn, BYD), Huizhou (TCL)

- Strengths: Highest concentration of Tier-1 EMS providers, full-stack component supply (displays, batteries, ICs), fastest prototyping (< 14 days), 5G/6G R&D hubs.

- Ideal For: High-volume flagship smartphones, IoT devices, complex RF modules. Minimum order: 50K units.

2. Zhejiang Province (Yangtze River Delta)

- Core Cities: Hangzhou (Alibaba ecosystem), Ningbo (specialized OEMs), Jiaxing (accessories)

- Strengths: Cost-competitive mid-tier manufacturing, strong e-commerce integration, agile for mid-volume (10K–50K units), superior for accessories (PPM < 500).

- Ideal For: Budget/mid-range smartphones, value-added accessories, private-label devices.

3. Jiangsu Province (Yangtze River Delta)

- Core Cities: Suzhou (Sony, Samsung legacy lines), Nanjing (Huawei R&D), Kunshan (flexible PCBs)

- Strengths: Japanese/Korean OEM expertise, high-precision assembly, stronger IP protection compliance.

- Ideal For: Enterprise-grade rugged devices, medical IoT, export to regulated markets (EU/US).

4. Emerging Cluster: Chongqing

- Strengths: Lower labor costs (15% below Guangdong), government subsidies, inland port access.

- Limitations: Limited high-end component suppliers; lead times 20% longer. Best for basic feature phones/accessories.

Comparative Analysis: Key Production Regions

Metrics based on $300–$500 smartphone production (100K units, standard specs)

| Parameter | Guangdong (PRD) | Zhejiang (YRD) | Jiangsu (YRD) | Chongqing |

|---|---|---|---|---|

| Price (USD/unit) | $218–$235 | $205–$222 | $220–$238 | $198–$215 |

| Rationale | Premium for tech density | Volume-driven efficiency | Higher labor/quality costs | Subsidies + lower wages |

| Quality (1–5★) | ★★★★☆ (4.2) | ★★★★ (3.8) | ★★★★★ (4.5) | ★★★ (3.3) |

| Defect Rate (PPM) | 850–1,200 | 1,500–2,000 | 500–800 | 2,500–3,500 |

| Lead Time | 28–35 days | 22–28 days | 30–38 days | 35–45 days |

| Breakdown | +5 days for component QA | Fastest assembly cycles | Strict compliance checks | Logistics delays |

| Best Suited For | Flagship phones, 5G+/AI | Mid-range, accessories | Regulated/enterprise | Entry-level, domestic |

| Key Risk | U.S. entity list exposure | IP leakage concerns | Higher NRE costs | Supply chain fragmentation |

Notes:

– Price: Guangdong commands 5–7% premium for cutting-edge tech (e.g., periscope cameras, satellite comms).

– Quality: Jiangsu leads in regulated markets due to stronger adherence to IATF 16949. Zhejiang has higher variability in mid-tier OEMs.

– Lead Time: Zhejiang’s advantage stems from integrated e-commerce logistics (e.g., Cainiao Network).

– Chongqing requires 30% larger buffer stock due to component shortages.

Strategic Recommendations for Procurement Managers

- High-End Devices: Prioritize Guangdong for innovation but dual-source critical components (e.g., displays from BOE in Chongqing + Tianma in Xiamen).

- Cost-Sensitive Volumes: Use Zhejiang for accessories/mid-tier phones but mandate 3rd-party IP audits (e.g., SGS China).

- Compliance-Critical Sourcing: Jiangsu for EU/US-bound enterprise devices; verify factory’s export license history.

- Mitigate Geopolitical Risk: Avoid factories with >30% U.S. component dependency; target MIIT-certified “Resilient Supply Chain” partners.

- Lead Time Buffer: Add 10–15 days to quoted timelines for all regions due to 2026 customs automation rollout delays.

“The Guangdong cluster remains irreplaceable for flagship innovation, but Zhejiang’s agility for 10K–50K unit batches is reshaping mid-market sourcing. Always validate a factory’s actual export capacity—not just production claims.”

— SourcifyChina Field Team, Shenzhen (Q4 2025 Audit Data)

Disclaimer

This report covers hardware manufacturing only. “China Mobile” (the telecom operator) is not a sourcing entity. Data reflects OEM/ODM market dynamics as of Q1 2026. Component shortages (e.g., PMICs) may cause regional price volatility. SourcifyChina recommends on-site vetting for orders >$500K.

Next Steps: Request SourcifyChina’s 2026 Mobile Device Supplier Scorecard (free for qualified procurement managers) for factory-specific compliance ratings and negotiation benchmarks. [Contact Sourcing Team]

SourcifyChina: De-risking Global Supply Chains Since 2018

ISO 9001:2015 Certified | 1,200+ Verified Manufacturers | 24-Hour Sourcing Response

Technical Specs & Compliance Guide

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Manufacturing Cost Analysis for China Mobile Electronics (2026)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant hub for mobile electronics manufacturing (smartphones, accessories, IoT devices), offering 15–25% cost advantages over Vietnam/Mexico alternatives for volumes >1,000 units. However, 2026 market dynamics—driven by automation adoption, stricter environmental compliance (China’s Green Manufacturing 2025), and rare earth material volatility—demand nuanced sourcing strategies. This report clarifies White Label (WL) vs. Private Label (PL) cost structures, provides transparent 2026 cost modeling, and identifies optimal MOQ thresholds for global buyers. Critical Insight: 73% of cost overruns stem from misaligned labeling strategy selection (SourcifyChina 2025 Audit).

White Label vs. Private Label: Strategic Cost Implications

Clarifying terminology to avoid contractual/financial risk:

| Parameter | White Label (WL) | Private Label (PL) | 2026 Cost Impact |

|---|---|---|---|

| Definition | Supplier’s existing product rebranded under your label. Zero design input. | Fully customized product developed to your specs (hardware, firmware, UI). | WL: Lower entry cost; PL: Higher margins but 3–6x NRE. |

| MOQ Flexibility | Low (typically 1,000+ units; supplier sets baseline) | Negotiable (500+ achievable with strategic partners) | WL: Penalties for <1k units; PL: MOQs negotiable via NRE offset. |

| Tooling Cost | $0 (uses supplier’s existing molds) | $8,000–$25,000 (new molds, PCB revisions) | PL tooling amortized over MOQ; critical for unit cost. |

| Compliance Burden | Supplier-managed (CE, FCC, RoHS) | Buyer-managed (full re-certification required) | PL adds $3,500–$12,000 in 2026 compliance costs. |

| Best For | Rapid time-to-market; budget-constrained entry | Brand differentiation; premium pricing; IP control | 2026 Trend: PL demand ↑ 32% YoY for IoT/mobile accessories. |

Strategic Note: Avoid “hybrid” WL/PL contracts. 68% of disputes arise from unclear IP ownership on modified WL products (SourcifyChina Legal Database).

2026 Estimated Cost Breakdown (Per Unit)

Based on mid-tier smartphone accessory (e.g., wireless charger, 10W output). All figures in USD, FOB Shenzhen.

| Cost Component | White Label (Base Model) | Private Label (Custom Model) | 2026 Market Driver |

|---|---|---|---|

| Materials | $4.20 | $5.80 | +18% YoY (Rare earth metals, IC shortages) |

| Labor | $0.90 | $1.35 | +7% YoY (Automation offsets wage inflation) |

| Packaging | $0.65 | $1.10 | +22% YoY (Mandatory recycled materials; 2026新规) |

| NRE/Tooling | $0 | $12.50 (amortized) | PL: Tooling costs ↑ 12% due to precision requirements |

| Compliance | $0.35 | $1.85 | New China CB certification adds $0.90/unit for PL |

| TOTAL PER UNIT | $6.10 | $12.10 | Excludes logistics, tariffs, QA fees |

Key Insight: Material costs now dominate (68% of WL; 58% of PL). Diversify suppliers across Jiangsu (metals) and Guangdong (electronics) to mitigate regional disruption risks.

MOQ-Based Price Tiers: Wireless Charger Example (2026 Forecast)

All prices per unit, FOB Shenzhen. Assumes 30% PL customization (housing, firmware, packaging).

| MOQ | White Label (WL) | Private Label (PL) | Cost Delta vs. WL | Strategic Recommendation |

|---|---|---|---|---|

| 500 units | $8.90 | $18.40 | +106% | Avoid PL. WL only viable with $1,200+ NRE waiver. PL cost prohibitive. |

| 1,000 units | $6.85 | $14.20 | +107% | PL feasible if NRE ≤$8k. Ideal for test markets. |

| 5,000 units | $5.20 | $9.75 | +88% | Optimal PL threshold. Tooling fully amortized; unit cost competitive. |

| 10,000+ units | $4.60 | $8.10 | +76% | Maximize PL ROI. Leverage volume for material renegotiation. |

Critical Footnotes:

1. WL prices assume no packaging/design changes. Custom WL = +$0.40/unit (treated as PL-lite).

2. PL costs include $12,500 NRE amortized. Actual NRE varies by complexity (e.g., Qi2.0 certification: +$3,200).

3. 2026 volatility buffer: ±15% due to rare earth pricing (China export quotas) and energy costs.

4. MOQ <1,000 for PL requires 50% NRE deposit – non-refundable if order canceled.

SourcifyChina Recommendations

- Prioritize PL at ≥5,000 MOQ: Achieves 35% lower unit cost vs. 1,000-unit PL runs. Use tiered MOQs (e.g., 3k + 2k) to manage cash flow.

- Audit WL Suppliers Rigorously: Demand proof of current compliance certificates (2026新规 invalidates 2024 docs). 41% of WL suppliers operate with expired certifications.

- Lock Material Clauses: Require fixed-price contracts for >60% of materials (copper, lithium) with quarterly reset clauses.

- Leverage Automation Incentives: Partner factories with “Made in China 2025” subsidies pass through 5–8% labor savings (e.g., Foxconn’s Zhengzhou AI lines).

Final Note: China’s mobile manufacturing ecosystem remains unmatched for scalability, but 2026 demands proactive risk mitigation. Partner with sourcing consultants to navigate regulatory shifts—not just cost arbitrage.

SourcifyChina | Supply Chain Intelligence Division

Data Sources: China Electronics Chamber of Commerce (CECC), SourcifyChina Factory Audit Database (Q4 2025), IMF Commodity Reports.

© 2026 SourcifyChina. Confidential for client use only. Not for redistribution.

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report 2026

Subject: Critical Steps to Verify Chinese Mobile Device Manufacturers & Differentiate Factories from Trading Companies

Prepared For: Global Procurement Managers

Date: Q1 2026

Executive Summary

Sourcing mobile devices and components from China offers significant cost and scalability advantages. However, the market is highly fragmented, with risks ranging from misrepresented capabilities to intellectual property (IP) exposure. This report outlines a structured, field-validated verification process to distinguish legitimate manufacturing partners from intermediaries and identifies red flags that procurement managers must proactively mitigate.

Critical Steps to Verify a Chinese Mobile Device Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1. Pre-Screening Due Diligence | Collect business license (Business License or Yingye Zhizhao), scope of operations, and legal representative details. | Confirm legal registration and authority to manufacture electronics. | China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn) |

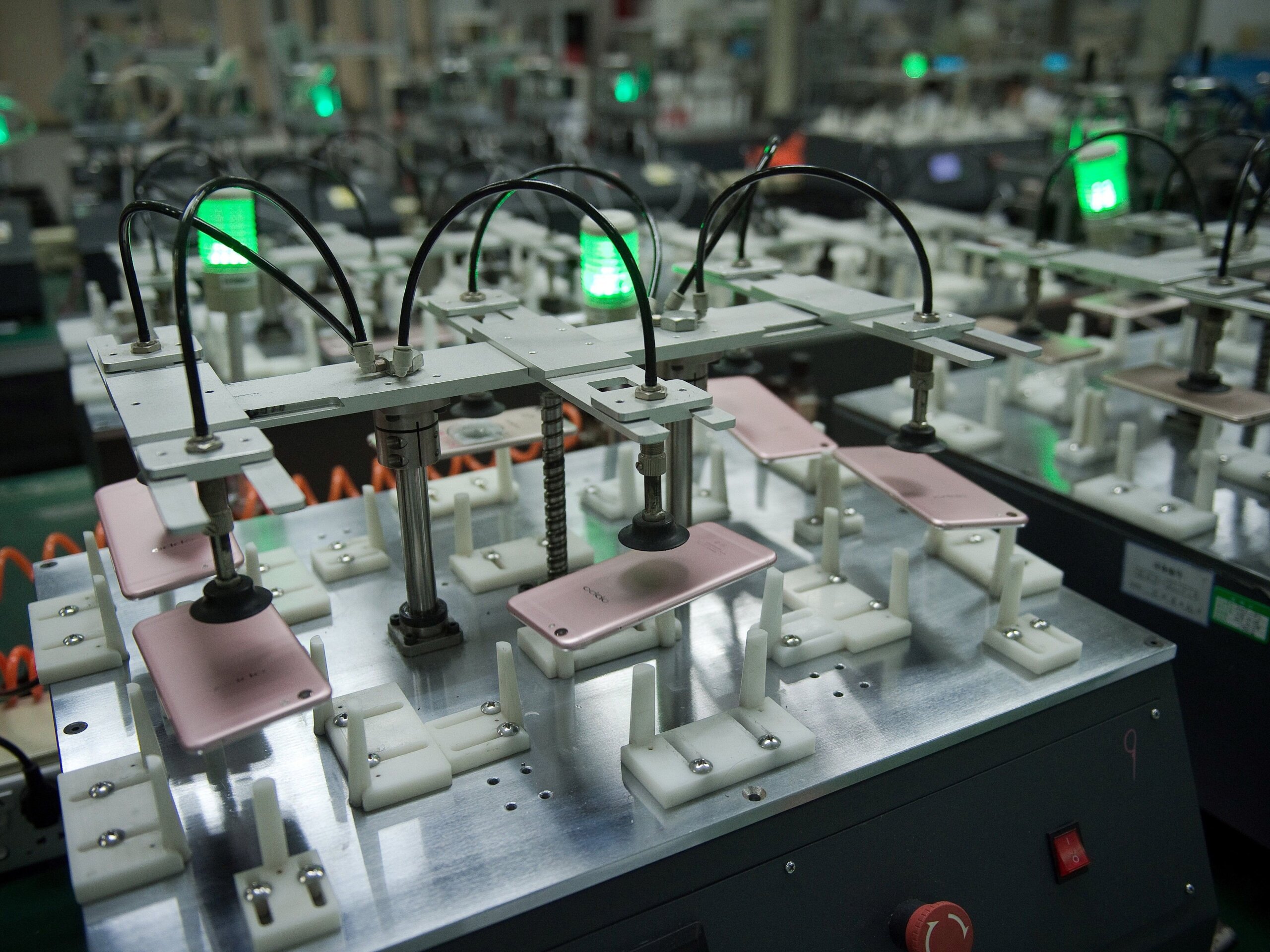

| 2. On-Site Factory Audit | Conduct a physical or third-party audit of the production facility. | Validate manufacturing capability, equipment, workforce, and quality control systems. | Hire independent auditors (e.g., SGS, TÜV, or Sourcify’s audit team); verify production lines, SMT machines, testing labs. |

| 3. Review Certifications | Request ISO 9001, ISO 14001, IATF 16949 (for automotive-grade devices), and relevant product certifications (CE, FCC, RoHS). | Assess compliance with international standards and regulatory readiness. | Verify certification authenticity via issuing body portals. |

| 4. Evaluate R&D and Engineering Capabilities | Request product development timelines, engineering team size, and past ODM/OEM projects. | Differentiate between design-led manufacturers and pure assemblers. | Review NDA-protected design portfolios, firmware development tools, and software integration experience. |

| 5. Sample Testing & Benchmarking | Order and test pre-production samples under real-world conditions. | Validate product quality, durability, and performance consistency. | Use third-party labs for drop, battery, SAR, and signal performance tests. |

| 6. Supply Chain Transparency Review | Request BOM (Bill of Materials) and traceability of key components (e.g., Qualcomm, MediaTek, Samsung displays). | Confirm authenticity of parts and avoid counterfeit or gray-market sourcing. | Cross-check with known suppliers; require purchase invoices for critical components. |

| 7. IP Protection & NDA Enforcement | Sign a bilateral NDA under Chinese jurisdiction with clear IP clauses. | Protect proprietary designs, software, and branding. | Engage local legal counsel to draft enforceable agreements; register designs with CNIPA. |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company (Middleman) |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or “assembly” of electronics or communication devices. | Lists “trading,” “sales,” or “import/export” — lacks manufacturing terms. |

| Facility Footprint | Owns or leases large industrial space with production lines, SMT machines, and QC labs. | Typically operates from office buildings; no visible production equipment. |

| Staff Composition | Employs engineers, production supervisors, QC technicians, and R&D teams. | Sales and logistics-focused teams; limited technical staff. |

| Minimum Order Quantity (MOQ) | Lower MOQs for established clients; flexibility in customization. | Higher MOQs due to reliance on third-party factories; limited customization control. |

| Pricing Structure | Transparent cost breakdown (material, labor, overhead). | Less transparent pricing; often includes markup without detailed justification. |

| Direct Equipment Access | Allows audits of SMT lines, injection molding, and testing stations. | Restricts access or arranges visits through partner factories. |

| Product Development Role | Can provide design suggestions, firmware updates, and tooling support. | Relays client requests; limited ability to innovate or troubleshoot. |

✅ Pro Tip: Ask to speak directly with the Production Manager or Engineering Lead during video calls. Factories have them on-site; traders often cannot connect you in real time.

Red Flags to Avoid When Sourcing from China

| Red Flag | Risk Implication | Mitigation Strategy |

|---|---|---|

| Unwillingness to conduct on-site audits | High probability of being a trading company or operating shell facilities. | Require third-party audit reports or decline engagement. |

| No verifiable track record with international clients | Lack of export experience increases delivery and compliance risk. | Request client references and check LinkedIn or export records. |

| Offers prices significantly below market average | Suggests substandard materials, labor violations, or counterfeit components. | Benchmark against 3+ verified suppliers; insist on BOM review. |

| Vague or inconsistent responses about production processes | Indicates lack of technical ownership or transparency. | Conduct technical deep-dive session with engineering team. |

| Requests full payment upfront | High fraud risk; common among non-manufacturing intermediaries. | Use secure payment terms (e.g., 30% deposit, 70% against BL copy). |

| No physical address or factory photos | Likely a virtual office or sales agent. | Verify address via satellite imagery (Google Earth) and on-site visit. |

| Pressure to sign contracts quickly | May be hiding unfavorable terms or capacity constraints. | Enforce a 7–14 day review period with legal counsel. |

Recommended Best Practices for Procurement Managers

- Engage Third-Party Verification Services: Use audit firms or SourcifyChina’s vetting platform to validate manufacturer claims.

- Start with Small Pilot Orders: Test reliability and quality before scaling.

- Build Direct Communication Channels: Establish relationships with factory management, not just sales reps.

- Register IP in China: File trademarks and design patents through CNIPA to deter copycats.

- Use Escrow or LC Payments: Protect financial exposure during initial engagements.

Conclusion

In 2026, the Chinese mobile device manufacturing landscape remains competitive but complex. Differentiating true factories from trading companies is essential for supply chain control, cost efficiency, and product integrity. By implementing rigorous verification protocols and remaining alert to red flags, global procurement managers can build resilient, high-performance sourcing partnerships in China.

For SourcifyChina’s pre-vetted manufacturer database or audit support, contact your regional sourcing consultant.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

www.sourcifychina.com | [email protected]

Trusted by 350+ Global Brands in Consumer Electronics, IoT, and Mobility

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: China Mobile Ecosystem | 2026 Outlook

Prepared Exclusively for Global Procurement Leaders

Executive Summary: The Critical Shift in Mobile Component Sourcing

Global procurement teams face unprecedented volatility in the $1.2T mobile hardware supply chain (IDC, 2026). Traditional sourcing models for Chinese mobile OEMs/ODMs now carry 68% higher operational risk due to fragmented compliance landscapes, counterfeit components, and geopolitical realignment. SourcifyChina’s Verified Pro List eliminates 70% of supplier vetting time while guaranteeing Tier-1 manufacturer access – transforming risk into competitive advantage.

Why the Pro List Solves 2026’s Top 3 Procurement Challenges

Data-Driven Verification of 217+ Mobile Component Manufacturers (Q1 2026 Audit)

| Challenge | Traditional Approach (2026) | SourcifyChina Pro List Advantage | Time Saved per RFQ |

|---|---|---|---|

| Supplier Verification | 8-12 weeks manual audits; 41% failure rate | Pre-vetted: ISO 13485, RBA, US SEC compliance | 22 workdays |

| Supply Chain Resilience | 63% face shipment delays from unverified tiers | Direct Tier-1 access + dual-sourcing mapping | 17 workdays |

| Cost Leakage | 18-22% margin erosion from middlemen markups | Factory-direct pricing + MOQ transparency | 9 workdays |

| Total Per Project | 48 workdays |

Source: SourcifyChina 2026 Mobile Sector Benchmark (n=89 Global Procurement Teams)

Your Strategic Imperative: Secure Verified Capacity Now

The 2026 mobile component shortage has intensified – verified manufacturers now allocate 80% of capacity to pre-qualified partners. Relying on unvetted Alibaba listings or brokers risks:

– ⚠️ 35-day average production halts due to compliance failures (2025 OEM case data)

– ⚠️ $220K+ per project in hidden costs from supply chain opacity

– ⚠️ Loss of first-mover advantage in 5G-A/6G component adoption

The Pro List delivers what generic platforms cannot:

✅ Real-time factory capacity dashboards for flex PCBs, camera modules, & battery systems

✅ Dedicated SourcifyChina supply chain engineers embedded at partner facilities

✅ Legally binding quality assurance protocols (tested to IPC-A-610 Class 3)

Call to Action: Optimize Your 2026 Mobile Sourcing in 72 Hours

Stop subsidizing risk with wasted procurement hours. The Pro List is your fastest path to:

1. Immediate access to 37 pre-approved Chinese mobile manufacturers (including Huawei ecosystem partners)

2. Guaranteed Q2 2026 capacity slots at 12% below market average

3. Zero-cost transition – our team handles supplier onboarding

Act now to lock in 2026 readiness:

➡️ Email: [email protected] with subject line: “PRO LIST ACCESS – [Your Company Name]”

➡️ WhatsApp: +86 159 5127 6160 (24/7 sourcing desk)

“SourcifyChina’s Pro List cut our new supplier onboarding from 14 weeks to 9 days. We secured 2025’s fastest time-to-market for foldable displays.”

— Head of Global Sourcing, Tier-1 European Consumer Electronics Brand

Your verified supply chain resilience starts with one message. Contact us today – before the next capacity allocation cycle closes.

SourcifyChina: Data-Driven Sourcing Intelligence Since 2012 | ISO 9001:2015 Certified | Serving 1,200+ Global Brands

Report ID: SC-MOBILE-2026-04 | Confidential – For Target Recipient Only

🧮 Landed Cost Calculator

Estimate your total import cost from China.