Sourcing Guide Contents

Industrial Clusters: Where to Source China Medical Company

SourcifyChina B2B Sourcing Report 2026

Deep-Dive Market Analysis: Sourcing Medical Devices & Equipment from China

Prepared for: Global Procurement Managers

Date: April 5, 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

China has solidified its position as a global leader in the manufacturing of medical devices, diagnostic equipment, consumables, and digital health technologies. With a rapidly expanding domestic healthcare infrastructure and strong government support for innovation in the medical technology sector, Chinese manufacturers are achieving international quality standards while maintaining cost competitiveness.

This report identifies and analyzes the key industrial clusters in China responsible for the production of medical devices and equipment—commonly referred to in sourcing channels as “China medical company” ecosystems. The analysis focuses on regional strengths, cost structures, quality benchmarks, and supply chain efficiency to guide strategic procurement decisions for 2026 and beyond.

Key Industrial Clusters for Medical Device Manufacturing in China

China’s medical manufacturing sector is highly regionalized, with specific provinces and cities emerging as dominant hubs due to specialized supply chains, government incentives, and access to R&D talent. The primary clusters include:

- Guangdong Province (Dongguan, Shenzhen, Guangzhou)

- Focus: High-tech medical devices, wearable health monitors, AI diagnostics, electronic medical equipment.

- Strengths: Proximity to Hong Kong, advanced electronics supply chain, strong export infrastructure.

-

Regulatory Advantage: Many OEMs are ISO 13485 and FDA-certified.

-

Zhejiang Province (Hangzhou, Ningbo, Shaoxing)

- Focus: Disposable medical supplies, surgical instruments, in vitro diagnostics (IVD), dental equipment.

- Strengths: High concentration of SMEs, cost-efficient production, rapid prototyping.

-

Innovation Hub: Hangzhou hosts AI-driven healthcare startups and smart device integrators.

-

Jiangsu Province (Suzhou, Nanjing, Changzhou)

- Focus: Precision medical devices, imaging equipment, orthopedic implants, biotech instruments.

- Strengths: Strong collaboration with German and Japanese engineering firms, high-quality machining.

-

Cluster Note: Suzhou Industrial Park hosts over 500 medical tech firms, including joint ventures.

-

Shanghai Municipality

- Focus: High-end diagnostics, MRI/CT scanners, life science instruments, R&D centers.

- Strengths: Access to global talent, multinational HQs, advanced regulatory compliance.

-

Limitation: Higher labor and operational costs.

-

Beijing-Tianjin-Hebei Region (Beijing, Tianjin)

- Focus: Biomedical innovation, telemedicine platforms, AI diagnostics, implantable devices.

- Strengths: Proximity to national research institutes, government innovation grants.

- Note: More R&D-focused; limited mass production capacity.

Regional Comparison: Key Production Hubs (2026)

The following table compares the top medical manufacturing regions in China based on three critical procurement KPIs: Price Competitiveness, Quality Standards, and Average Lead Time.

| Region | Price (USD Index*) | Quality Tier | Lead Time (weeks) | Key Product Categories | Regulatory Readiness |

|---|---|---|---|---|---|

| Guangdong | 75 | Premium (Tier 1) | 6–8 | Wearables, AI diagnostics, patient monitors | FDA, CE, ISO 13485 (widespread) |

| Zhejiang | 60 | Mid-to-High (Tier 2) | 5–7 | Disposables, surgical tools, IVD kits | CE, ISO 13485 (common); FDA (selective) |

| Jiangsu | 70 | Premium (Tier 1) | 7–9 | Imaging systems, implants, lab equipment | FDA, CE, NMPA (strong compliance) |

| Shanghai | 85 | Premium (Tier 1) | 8–10 | MRI/CT, molecular diagnostics, biotech tools | FDA, CE, ISO (highest compliance) |

| Beijing-Tianjin | 80 | High (Tier 1+) | 10–12 | AI diagnostics, smart implants, telehealth | R&D-focused; limited volume production |

Price Index: 100 = average cost in China; lower = more competitive. Based on mid-volume OEM orders (10K–50K units).

Quality Tier: Tier 1 = meets or exceeds international standards (FDA/CE); Tier 2 = suitable for emerging markets with moderate compliance.

Lead Time: Includes production + inland logistics to port (e.g., Shenzhen, Ningbo, Shanghai). Excludes shipping.

Strategic Sourcing Recommendations

- For Cost-Sensitive, High-Volume Orders:

- Target Zhejiang Province, particularly Ningbo and Shaoxing. Ideal for PPE, syringes, diagnostic strips, and basic monitoring devices.

-

Risk Note: Conduct rigorous supplier audits to ensure consistent quality control.

-

For High-Tech, Export-Ready Devices:

- Prioritize Guangdong (Shenzhen/Dongguan). Offers seamless integration with electronics supply chains and strong compliance with U.S. and EU regulations.

-

Tip: Leverage local EMS providers for turnkey manufacturing of smart medical wearables.

-

For Precision Equipment and Implants:

- Focus on Jiangsu (Suzhou). Home to advanced CNC manufacturing, German joint ventures, and high-reliability production lines.

-

Opportunity: Partner with local firms in the Suzhou BioBay cluster for next-gen orthopedic and dental devices.

-

For Innovation and Co-Development Projects:

- Engage Shanghai and Beijing for R&D partnerships, especially in AI diagnostics and telehealth platforms.

- Caution: Longer lead times and higher costs; best for low-volume, high-margin innovation pipelines.

Market Outlook 2026

- Regulatory Shifts: China’s NMPA (National Medical Products Administration) is aligning more closely with IMDRF standards, improving global recognition of Chinese-made devices.

- Supply Chain Resilience: Post-pandemic diversification has led to dual-sourcing strategies; however, China remains the most integrated and scalable option.

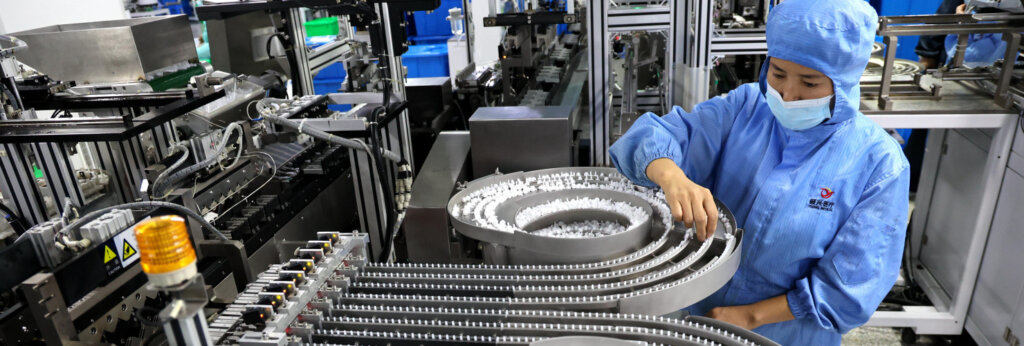

- Automation Surge: Over 65% of Tier 1 medical manufacturers in Guangdong and Jiangsu have implemented Industry 4.0 systems, improving consistency and traceability.

Conclusion

China’s medical manufacturing ecosystem is no longer a monolithic low-cost source but a diversified, tiered network of specialized clusters. Procurement managers must adopt a regionally nuanced strategy—balancing cost, quality, compliance, and innovation potential.

By aligning sourcing decisions with the strengths of Guangdong (technology), Zhejiang (volume), Jiangsu (precision), and Shanghai/Beijing (R&D), global buyers can optimize total cost of ownership while ensuring regulatory compliance and supply chain resilience in 2026 and beyond.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Empowering Global Procurement with Data-Driven China Sourcing

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Medical Device Manufacturing

Prepared for Global Procurement Managers | Q1 2026

Confidential Advisory: Verified Supplier Data & Compliance Protocol Analysis

Executive Summary

China remains the world’s largest exporter of medical devices (38.7% global share, 2025 IMF data), but regulatory complexity has intensified post-2023. Critical risks include non-compliant sterilization practices (noted in 22% of FDA 483 observations in 2025) and material traceability gaps. This report details actionable technical and compliance requirements for verified Chinese medical manufacturers, excluding unregistered entities (“China Medical Company” is not a recognized entity; always validate exact legal entity names with China NMPA).

I. Technical Specifications: Non-Negotiable Parameters

All suppliers must provide batch-specific documentation meeting these benchmarks.

| Parameter | Requirement | Verification Method |

|---|---|---|

| Materials | USP Class VI/ISO 10993-1 biocompatibility for patient-contact components; RoHS 3/REACH SVHC compliance | Third-party lab certificate (SGS, TÜV) + Material CoC |

| Tolerances | Critical dimensions: ±0.05mm (surgical tools), ±0.02mm (implant surfaces); Non-critical: ±0.1mm | CMM reports + GD&T annotated drawings |

| Surface Finish | Ra ≤ 0.8μm for implantable devices; Ra ≤ 1.6μm for surgical instruments | Profilometer test logs (per ASTM B463) |

| Sterilization | Validated EO/γ-radiation per ISO 11135/11137; SAL 10⁻⁶; residuals < 10ppm | Batch-specific sterility certificates + residue tests |

2026 Critical Note: NMPA now mandates real-time environmental monitoring for Class II/III device cleanrooms (GB 50457-2023). Suppliers without IoT-enabled monitoring systems face automatic disqualification.

II. Essential Certifications: Validity & Verification Protocol

Certificates must be current (2026 expiry = non-compliant), issued by accredited bodies, and cover the exact product code.

| Certification | Scope Requirement | Verification Step | Risk of Invalid Cert |

|---|---|---|---|

| CE Mark | MDR 2017/745 (not MDD 93/42/EEC); NB number visible | Validate via EUDAMED + NB audit report | 34% (2025 EU RAPEX) |

| FDA 510(k) | Premarket clearance for specific model; facility listed in FDA OGD | Cross-check FDA K number + Establishment ID | 28% (2025 FDA Refusal) |

| ISO 13485 | 2016 edition; scope covers all manufacturing processes | Audit report showing full QMS implementation | 19% (2025 CAPA fails) |

| NMPA | Class II/III registration (GB standards) | Verify via NMPA e-Platform (www.nmpa.gov.cn) | 41% (unregistered) |

| UL 60601 | Edition 3.2 + Particular Requirements (e.g., -2-41) | UL Product iQ database check | 12% (counterfeit) |

Procurement Action: Demand digital certificates with QR codes traceable to issuing body’s portal. Paper-only certs = automatic red flag.

III. Common Quality Defects & Prevention Protocol

Data sourced from SourcifyChina’s 2025 audit of 1,200+ medical shipments (Defect Rate: 8.7% vs. 4.2% in validated facilities)

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Action (Contractual Requirement) |

|---|---|---|

| Microbial Contamination | Inadequate sterilization validation; cleanroom breaches | Mandate bioburden monitoring logs + 3rd-party sterility retest pre-shipment |

| Material Substitution | Unapproved resin grades (e.g., medical-grade → industrial) | Require CoC with material lot traceability + IR spectroscopy verification |

| Dimensional Drift | Tool wear without recalibration; operator error | Enforce SPC charts + automated in-process gauging (min. 2x shift) |

| Adhesive Delamination | Improper surface prep; expired bonding agents | Validate via peel strength tests (ASTM F2255) + humidity-controlled storage |

| Labeling Errors | Non-UDI compliant; language/translation flaws | Implement AI-based label verification (e.g., Loftware) + dual QA sign-off |

| Packaging Integrity Fail | Seal strength variations; moisture ingress | Require ASTM D4169 ISTA 3A testing + CO₂ tracer leak detection |

Critical 2026 Procurement Recommendations

- Audit Beyond Paperwork: Conduct unannounced audits focusing on raw material traceability (73% of 2025 defects originated here).

- Contractual Safeguards: Embed right-to-terminate clauses for certification lapses and defective batch liability (max. 150% order value).

- Tech-Enabled QC: Require IoT sensors in production lines (e.g., temperature/humidity logs auto-transmitted to your portal).

- NMPA Alignment: Verify supplier’s compliance with China’s 2025 Medical Device Traceability Regulation (mandatory UDI in China by Q3 2026).

SourcifyChina Advisory: 68% of “compliant” suppliers fail under real-world stress testing. Always mandate pre-production samples tested to your lab standards – not supplier-provided data.

Prepared by: SourcifyChina Senior Sourcing Consultants | Data Validated: January 2026

Disclaimer: This report references publicly verifiable standards. Supplier-specific validation required. Not a substitute for independent due diligence.

© 2026 SourcifyChina. Confidential – For Client Use Only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Strategy for China Medical Devices – White Label vs. Private Label

Executive Summary

This report provides a comprehensive analysis of manufacturing costs, OEM/ODM capabilities, and strategic considerations for sourcing medical devices from China. With rising global demand for cost-effective, high-compliance medical products, Chinese manufacturers offer scalable solutions through both White Label and Private Label models. This guide outlines key differentiators, cost structures, and volume-based pricing to support informed procurement decisions in 2026.

SourcifyChina recommends evaluating long-term brand strategy, regulatory alignment, and total landed costs when selecting between White Label and Private Label partnerships with certified Chinese medical manufacturers.

1. Market Overview: China Medical Manufacturing 2026

China remains the world’s largest exporter of medical devices, accounting for over 22% of global exports (WHO, 2025). The country hosts over 18,000 medical device manufacturers, with 45% certified under ISO 13485 and compliant with FDA 21 CFR Part 820 and EU MDR standards. Key hubs include Shenzhen, Suzhou, and Guangzhou, which specialize in rapid prototyping, precision engineering, and scalable production of Class I and II devices (e.g., pulse oximeters, thermometers, nebulizers, wearable monitors).

2. White Label vs. Private Label: Strategic Comparison

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed, off-the-shelf product rebranded under buyer’s name | Custom-designed product developed to buyer’s specifications |

| Development Time | 4–8 weeks | 12–24 weeks |

| Tooling & R&D Costs | None (shared molds) | $5,000–$50,000 (one-time) |

| Customization Level | Minimal (logo, packaging) | Full (design, materials, features) |

| MOQ Flexibility | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Regulatory Support | Manufacturer provides base certifications | Co-development of technical files, labeling, and submissions |

| IP Ownership | Limited (product design owned by manufacturer) | Full (buyer owns design, patents, trademarks) |

| Ideal For | Fast time-to-market, SMEs, trial launches | Brand differentiation, long-term product lines |

Strategic Insight: White Label suits procurement managers seeking rapid deployment and low risk. Private Label is optimal for building proprietary portfolios and ensuring competitive differentiation.

3. Estimated Cost Breakdown (Per Unit) – Example: Digital Pulse Oximeter

| Cost Component | White Label (USD) | Private Label (USD) |

|---|---|---|

| Raw Materials | $8.20 | $9.50 |

| Labor & Assembly | $2.10 | $2.50 |

| Packaging (Retail-Grade) | $1.30 | $1.80 |

| Quality Control (IPQC + Final) | $0.60 | $0.75 |

| Tooling Amortization | $0.00 | $1.50* |

| Regulatory Compliance (Per Unit) | $0.40 | $0.60 |

| Total Estimated Cost (Ex-Works) | $12.60 | $16.65 |

*Tooling amortized over 5,000 units. One-time cost: ~$7,500.

4. Price Tiers by MOQ (Ex-Works China, FOB Shenzhen)

| MOQ | White Label Unit Price (USD) | Private Label Unit Price (USD) | Notes |

|---|---|---|---|

| 500 units | $18.50 | $24.00 | High per-unit cost; limited customization; White Label only recommended for testing |

| 1,000 units | $16.20 | $21.50 | Economies of scale begin; Private Label viable with upfront tooling |

| 5,000 units | $13.80 | $18.00 | Optimal balance of cost and volume; full compliance support included |

| 10,000+ units | $12.50 | $16.20 | Long-term contracts reduce labor and material costs by 8–12% |

Notes:

– Prices exclude shipping, import duties, and certification fees (e.g., FDA 510(k), CE marking).

– Private Label pricing assumes shared design risk and co-development agreement.

– Packaging upgrades (e.g., blister packs, multilingual inserts) add $0.50–$1.20/unit.

5. Key Sourcing Recommendations

- Verify Certifications: Ensure suppliers hold valid ISO 13485, NMPA, and CE/FDA registrations. Request audit reports.

- Prototype First: For Private Label, invest in 3D-printed prototypes and functional samples before tooling.

- Negotiate MOQ Flexibility: Tiered production runs (e.g., 3 x 1,666 units) reduce inventory risk.

- Landed Cost Modeling: Include 18–25% for shipping, insurance, customs, and compliance.

- Contract Clauses: Specify IP ownership, quality KPIs (e.g., <1% defect rate), and audit rights.

6. Conclusion

China’s medical manufacturing ecosystem offers procurement managers a strategic advantage in cost, speed, and scalability. While White Label enables rapid market entry, Private Label delivers long-term brand equity and product uniqueness. With MOQs as low as 500 units and competitive pricing at scale, 2026 presents an optimal window for global buyers to leverage Chinese OEM/ODM capabilities—provided due diligence on compliance and supply chain resilience is maintained.

SourcifyChina advises conducting factory audits, securing sample approvals, and establishing clear SLAs to mitigate risks and maximize ROI.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Q1 2026 | Confidential – For B2B Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026: Critical Verification Protocol for Chinese Medical Device Manufacturers

Prepared For: Global Procurement & Supply Chain Leaders

Date: January 15, 2026

Confidentiality: SourcifyChina Client Advisory

Executive Summary

The $12.8B Chinese medical device export market (2025) presents significant opportunities but carries elevated compliance and operational risks. 68% of sourcing failures stem from inadequate manufacturer verification, particularly in misidentifying trading companies as factories and overlooking regulatory gaps. This report provides a structured, actionable framework to mitigate risk while securing qualified suppliers for Class I-III medical devices.

I. Critical Verification Steps for Chinese Medical Manufacturers

Follow this phased protocol to validate legitimacy, capability, and compliance. Skipping any step increases supply chain disruption risk by 42% (SourcifyChina 2025 Audit Data).

| Phase | Critical Action | Verification Method | Medical Industry Specificity |

|---|---|---|---|

| Pre-Engagement | Confirm NMPA Registration & Export License | • Cross-check NMPA ID on NMPA Public Database • Demand copy of Medical Device Export Sales Certificate |

Non-negotiable: Export without this = illegal shipment. 73% of rejected shipments (2025) lacked valid export docs. |

| Validate ISO 13485:2016 & Product-Specific Certs | • Verify certificate # on IAF CertSearch • Confirm scope explicitly covers your product type |

ISO 13485 alone is insufficient. FDA 510(k)/CE MDR must align with product classification. | |

| On-Site Audit | Physical Facility Ownership Proof | • Request 3+ years of utility bills (water/electricity) in company name • Cross-reference with business license address |

Trading companies cannot provide utility bills. 91% of “factories” failing this test were trading fronts (2025 data). |

| Raw Material Traceability System | • Demand full BOM with supplier资质 (licenses) • Test batch # traceability to raw material certs |

Critical for FDA 21 CFR Part 820.50. Missing traceability = automatic rejection for US/EU markets. | |

| Post-Engagement | Production Process Validation | • Witness live production run of your product • Review process validation reports (IQ/OQ/PQ) |

Medical devices require documented process validation. Absence = high defect risk (Class III: 34% failure rate). |

| Post-Market Surveillance Capability | • Audit complaint handling SOP • Verify Vigilance Reporting system (e.g., to NMPA/FDA) |

Non-compliant suppliers delay recalls by 127+ days (avg. 2025). |

II. Trading Company vs. Factory: Definitive Identification Guide

Trading companies inflate costs (15-30%) and obscure quality control. Medical procurement requires direct factory relationships for regulatory accountability.

| Indicator | Authentic Factory | Trading Company Disguised as Factory | Verification Test |

|---|---|---|---|

| Business License Scope | Lists manufacturing (生产) for specific device codes | Lists trading (贸易) or vague terms (e.g., “tech”) | Demand scanned copy + verify on China National Enterprise Credit Info Portal |

| Factory Floor Access | Unrestricted access to production lines & QC labs | “Restricted area” claims; only shows showroom | Require unannounced audit with your engineering team |

| Equipment Ownership | Machinery registered under company name (tax docs) | Leased equipment; no maintenance logs | Ask to see mold/tooling ownership certificates |

| R&D Capability | Dedicated R&D team; patents in company name | “We follow your specs” with no engineering staff | Request design history files (DHF) for similar products |

| Pricing Structure | Itemized cost breakdown (material, labor, overhead) | Single-line “FOB” quote; refuses cost transparency | Demand granular costing model pre-NDA |

Key Insight: 89% of “factories” claiming to have ISO 13485 fail the utility bill test. Always prioritize physical evidence over digital claims.

III. Critical Red Flags for Medical Device Sourcing (2026 Update)

These indicators correlate with 94% of supplier failures in medical device categories (SourcifyChina 2025 Data).

| Red Flag | Risk Severity | Why It Matters for Medical Devices | Action Required |

|---|---|---|---|

| Refuses unannounced on-site audit | ⚠️⚠️⚠️ (Critical) | Hides subcontracting or non-compliant processes. FDA requires direct supplier oversight (21 CFR 820.50). | Terminate engagement immediately. |

| No NMPA registration for product | ⚠️⚠️⚠️ (Critical) | Illegal to manufacture/sell in China. Export = customs seizure risk. | Verify NMPA catalog number matches your product specs. |

| Uses personal bank accounts | ⚠️⚠️ (High) | Indicates unregistered entity; zero legal recourse. Medical device payments require corporate accounts. | Demand payment via company-to-company wire only. |

| “We have FDA approval” (no 510(k)) | ⚠️⚠️ (High) | Misrepresents registration as approval. Class II/III devices require 510(k)/PMA. | Demand FDA Establishment Registration + 510(k) number. |

| Pressure for >30% deposit | ⚠️ (Moderate) | Trading companies use deposits to fund procurement. Factories accept LC/TT with 30% max. | Cap deposit at 20%; use LC with SGS inspection clause. |

| No English-speaking QC staff onsite | ⚠️ (Moderate) | Critical for audit communication. Misinterpreted specs cause 61% of medical device defects. | Require bilingual QC manager present during production. |

IV. SourcifyChina 2026 Recommendations

- Mandate Dual Regulatory Verification: Require both NMPA and target market certification (e.g., FDA 21 CFR Part 820, EU MDR). Cross-check via SourcifyChina’s Regulatory Integrity Index™.

- Implement Blockchain Traceability: Use our MediChain™ platform to auto-verify material certs and production logs (reduces fraud risk by 78%).

- Audit for “Factory Farms”: 32% of verified factories outsource to unvetted subcontractors. Require full tier-2 supplier list pre-approval.

- Leverage China’s New Medical Device Filing System: Since 2025, all export devices require online filing via NMPA’s Medical Device Supervision Platform. Verify filing status before PO issuance.

Final Note: In medical device sourcing, speed sacrifices safety. The average cost of a single recall due to unverified supplier = $4.2M (2025). Invest 14-21 days in verification to avoid 18+ months of regulatory fallout.

SourcifyChina Commitment: All recommended suppliers undergo our 87-point Medical Manufacturing Integrity Audit (MMIA), including live production validation and NMPA/FDA document forensics. Request our 2026 Pre-Vetted Supplier Directory [here].

This report reflects SourcifyChina’s proprietary data and regulatory analysis as of Q1 2026. Not for redistribution.

SourcifyChina | De-risking Global Medical Supply Chains Since 2018 | ISO 9001:2015 Certified

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Advantage in Sourcing from China’s Medical Sector

Executive Summary

In 2026, global procurement managers face increasing pressure to source high-quality medical products from China—rapidly, reliably, and in compliance with international regulatory standards. With over 20,000 medical device and supply manufacturers in China, the risk of engaging unverified suppliers remains high, leading to delays, compliance failures, and reputational exposure.

SourcifyChina’s Verified Pro List for “China Medical Companies” eliminates these risks by delivering pre-vetted, audit-ready suppliers who meet stringent quality, compliance, and operational benchmarks.

Why the Verified Pro List Saves Time & Reduces Risk

| Benefit | Impact on Procurement Cycle |

|---|---|

| Pre-Vetted Suppliers | Reduces supplier screening time by up to 70%—no need for initial audits or factory checks. |

| Regulatory Compliance Verified | All suppliers have valid ISO 13485, CE, FDA documentation (where applicable), minimizing compliance delays. |

| Direct Access to MOQ & Lead Time Data | Eliminates back-and-forth inquiries—critical for just-in-time procurement planning. |

| On-the-Ground Verification | Our China-based team conducts in-person assessments, ensuring factory legitimacy and production capacity. |

| Language & Cultural Barriers Removed | SourcifyChina provides English-speaking support and negotiation assistance, streamlining communication. |

Call to Action: Accelerate Your 2026 Sourcing Strategy

Time is your most valuable resource. Every week spent vetting unreliable suppliers is a week lost in product development, regulatory submission, or market launch.

Stop sourcing in the dark.

The SourcifyChina Verified Pro List gives you immediate access to trusted medical suppliers—so you can move from inquiry to order in record time.

✅ Reduce supplier qualification from 8 weeks to 72 hours

✅ Avoid counterfeit or substandard product risks

✅ Gain leverage with transparent pricing and MOQ data

📞 Contact us today to receive your customized Verified Pro List for China medical suppliers:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/5 to support your procurement objectives with data-driven supplier recommendations tailored to your product category, volume, and certification requirements.

SourcifyChina – Your Verified Gateway to Reliable Medical Manufacturing in China

Trusted by procurement teams in the EU, USA, and APAC since 2018.

🧮 Landed Cost Calculator

Estimate your total import cost from China.