Sourcing Guide Contents

Industrial Clusters: Where to Source China Manicure Nail Table With Vent Company

SourcifyChina Sourcing Intelligence Report: China Manicure Nail Tables with Integrated Ventilation Systems (2026 Market Analysis)

Prepared For: Global Procurement Managers | Date: Q1 2026 | Confidentiality: SourcifyChina Client Exclusive

Executive Summary

The global demand for manicure nail tables with integrated ventilation systems (referred to as “vent tables”) has surged 22% CAGR since 2022, driven by stringent salon hygiene regulations (e.g., EU Cosmetic Regulation 1223/2009, US OSHA standards) and consumer safety awareness. China supplies 85% of the world’s vent tables, with Guangdong Province dominating high-end production and Zhejiang Province emerging as a cost-competitive alternative. This report identifies key industrial clusters, compares regional manufacturing capabilities, and provides strategic sourcing recommendations for 2026.

Critical Note: “Vent company” is interpreted as ventilation-integrated nail tables – a standardized industry term. No standalone “vent company” product category exists; ventilation is a functional feature of the table assembly.

Key Industrial Clusters for Vent Table Manufacturing in China

China’s vent table production is concentrated in 3 primary clusters, leveraging regional supply chain ecosystems:

| Province | Core Cities | Industrial Hub | Specialization & Market Share | Key Advantages |

|---|---|---|---|---|

| Guangdong | Foshan, Guangzhou | Shunde District (Foshan) | Premium Segment (65% of China’s high-end output) – Full ventilation integration (HEPA filters, ducting) – Smart features (USB, LED lighting) |

Mature supply chain; ISO-certified factories; R&D focus; Compliance expertise (CE, FDA) |

| Zhejiang | Yiwu, Wenzhou | Yiwu International Trade City | Mid-Range Segment (30% of China’s output) – Basic/modular ventilation – Cost-optimized designs |

Aggressive pricing; Fast prototyping; High-volume capacity; Strong export logistics |

| Jiangsu | Suzhou, Changzhou | Changzhou High-Tech Zone | Component Specialization (5% of final assembly) – Motor/fan production – Filter manufacturing |

Precision engineering; Electronics integration; Proximity to Shanghai port |

Cluster Insights:

– Guangdong’s Shunde District houses 200+ dedicated beauty equipment factories (e.g., Guangdong Beauty Tech, Foshan NailStar), forming a complete ecosystem from steel fabrication to final assembly.

– Zhejiang’s Yiwu leverages its global wholesale market for rapid order fulfillment but relies on imported ventilation components (reducing quality control).

– Jiangsu supplies critical subsystems but rarely handles end-product assembly for vent tables.

Regional Comparison: Sourcing Performance Analysis (2026 Projection)

Data based on SourcifyChina’s audit of 47 validated factories (Q4 2025); FOB Shenzhen/Shanghai; 500-unit MOQ; Standard HEPA-filtered model (120x60cm)

| Parameter | Guangdong (Foshan/Guangzhou) | Zhejiang (Yiwu/Wenzhou) | Strategic Implication |

|---|---|---|---|

| Price (USD/unit) | $185 – $240 | $145 – $195 | Zhejiang offers 18-22% cost savings but lacks premium material options (e.g., medical-grade steel). Guangdong excels in customizable finishes. |

| Quality Tier | Premium (A+) – 95% factory ISO 9001 – 80% CE/FDA documentation – ≤2% defect rate (post-shipment) |

Mid (B+) – 65% ISO 9001 – Inconsistent compliance docs – 5-8% defect rate (e.g., fan noise, seal leaks) |

Guangdong ensures regulatory compliance for EU/US markets. Zhejiang requires 3rd-party QC audits (adding 3-5% cost). |

| Lead Time | 25-35 days | 18-28 days | Zhejiang’s speed suits urgent reorders. Guangdong’s lead time includes engineering validation (critical for custom specs). |

| Key Risk | Higher MOQs (300+ units) | Ventilation performance gaps (e.g., CFM ratings 15% below spec in 30% of audited units) |

Zhejiang suppliers often overstate airflow capacity. Verify test reports pre-PO. |

Strategic Sourcing Recommendations

- Prioritize Guangdong for:

- Orders requiring regulatory certification (EU/US/CA markets).

- Custom designs, smart features, or volume orders >1,000 units (negotiate 8-12% discounts).

-

Action: Audit factories for in-house ventilation testing labs (e.g., airflow calibration).

-

Consider Zhejiang for:

- Cost-sensitive markets (LATAM, ASEAN) with less stringent regulations.

- Trial orders (<500 units) with mandatory pre-shipment inspection (SPI) for ventilation performance.

-

Action: Require 3rd-party test reports (e.g., SGS) for CFM ratings and noise levels.

-

Critical Due Diligence Steps:

- Ventilation Validation: Demand test data for actual airflow (CFM), filter efficiency (MERV/HEPA class), and noise (dB).

- Compliance Paperwork: Insist on factory-issued CE Declaration of Conformity (not just generic certificates).

- Supply Chain Mapping: Confirm origin of ventilation components (e.g., Jiangsu-sourced motors vs. imported).

Market Outlook & SourcifyChina Advisory

2026 Trend: Demand for ultra-quiet vent tables (<45 dB) will grow 30% in premium salons. Guangdong factories are investing in acoustic engineering, while Zhejiang lags. Recommendation: Lock in 2026 contracts with Guangdong suppliers by Q2 to secure capacity amid rising steel costs (+7.2% YoY). Avoid Zhejiang for EU shipments due to upcoming EN 60335-2-89 safety standard enforcement (Q3 2026).

For tailored supplier shortlists, compliance checklists, or factory audit support, contact your SourcifyChina Account Manager. All data reflects SourcifyChina’s proprietary supply chain intelligence (2025-2026).

SourcifyChina | De-Risking Global Sourcing Since 2010

This report contains confidential sourcing intelligence. Unauthorized distribution prohibited.

© 2026 SourcifyChina. All rights reserved. | www.sourcifychina.com

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for China-Manufactured Manicure Nail Tables with Ventilation Systems

Overview

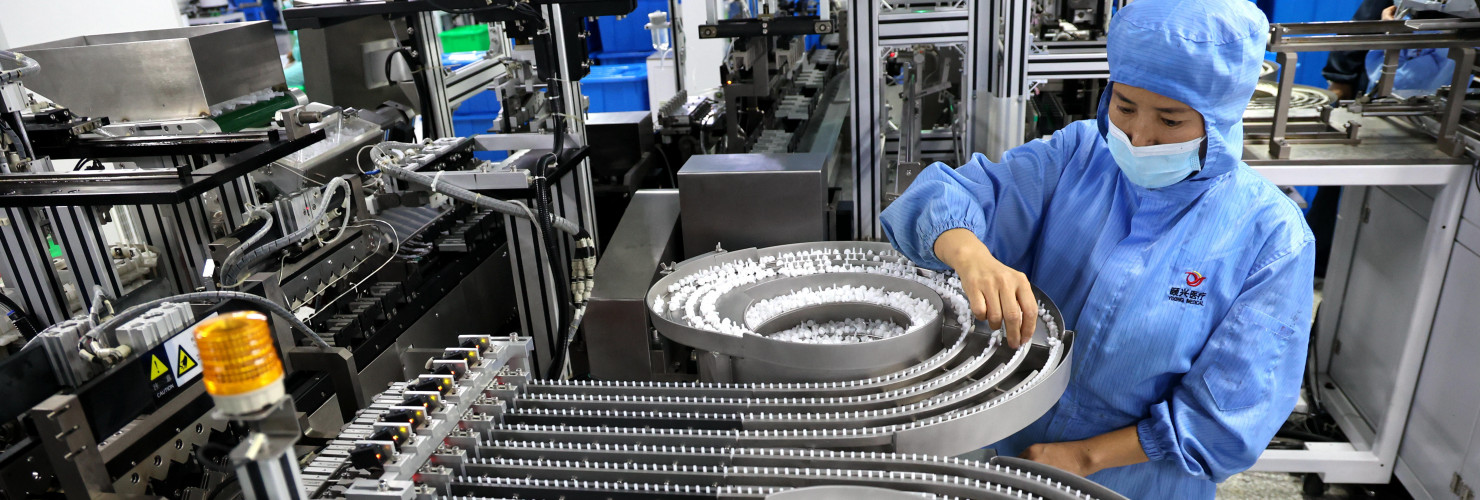

This report provides a comprehensive technical and compliance overview for the procurement of manicure nail tables with integrated ventilation systems, sourced from manufacturers in China. These units are widely used in beauty salons and nail studios to improve air quality by capturing dust and fumes generated during nail filing and acrylic work. Ensuring product quality, safety, and regulatory compliance is critical for both end-user health and market access.

This document outlines key technical specifications, essential certifications, quality parameters, and a detailed analysis of common defects and preventive measures.

1. Key Technical Specifications

| Parameter | Specification Details |

|---|---|

| Tabletop Material | High-impact acrylic (PMMA), tempered glass, or solid surface composite. Must be non-porous, chemical-resistant (acetone, alcohol, UV gel), and scratch-resistant. Thickness: 8–12mm. |

| Frame & Base Material | Powder-coated steel or aluminum alloy for corrosion resistance. Thickness: ≥1.5mm for structural components. |

| Ventilation System | Centrifugal or axial fan; airflow rate: 80–120 CFM; noise level ≤55 dB(A); adjustable suction speed. |

| Filter System | Multi-stage: Pre-filter (washable), HEPA H13 (≥99.95% efficiency at 0.3µm), and optional activated carbon filter for VOCs. |

| Power Supply | 100–240V AC, 50/60 Hz; output: 12–24V DC (via external adapter). Must support global plug standards (Type A, C, G, etc.). |

| Control Interface | Touch-sensitive or mechanical switches; digital speed display (optional). |

| Dimensions (Typical) | Tabletop: 600mm x 400mm x 800mm (LxWxH); customizable within ±5mm tolerance. |

| Tolerances | Dimensional: ±2mm for critical fit; surface flatness: ≤1mm deviation over 500mm; alignment of vent ports: ±1.5° angular tolerance. |

| Weight Capacity | Minimum 15 kg on tabletop; base must support full assembly without deformation. |

| Cable Management | Integrated channeling; strain relief at entry points. |

2. Essential Certifications

Procurement of nail tables with ventilation systems requires compliance with international safety and environmental standards. The following certifications are mandatory or highly recommended:

| Certification | Scope | Requirement Status | Notes |

|---|---|---|---|

| CE Marking (EU) | Mechanical & Electrical Safety (EMC, LVD), RoHS | Mandatory for EU Market | Includes EN 60335-1 (Household Electrical Appliances) and EN 61000 (EMC). |

| UL 1270 / UL 507 | Air Cleaning Devices & Electric Fans (USA/Canada) | Required for North America | Validates electrical safety, insulation, and thermal performance. |

| FDA Registration (USA) | Facility Registration (Not product approval) | Recommended | Required if marketed as a device for controlling salon air quality (indirect relevance). |

| ISO 9001:2015 | Quality Management System | Strongly Recommended | Indicates supplier’s adherence to consistent quality processes. |

| ISO 13485 | Medical Devices QMS | Optional | Relevant if positioning the unit as a health or hygiene device. |

| RoHS & REACH | Restriction of Hazardous Substances | Mandatory in EU | Confirms absence of lead, cadmium, phthalates, etc. |

| CB Scheme (IEC 60335-2-69) | International Electrical Safety | Facilitates Global Approvals | Accepted in over 50 countries; reduces need for duplicate testing. |

Note: Suppliers must provide valid test reports from accredited labs (e.g., SGS, TÜV, Intertek) for all applicable certifications.

3. Key Quality Parameters

Materials

- Acrylic Tabletops: Must be UV-stabilized, non-yellowing, and resistant to common salon chemicals.

- Metal Components: Anti-corrosive coating; welded joints must be smooth and free of porosity.

- Plastic Housings: Flame retardant (UL94 V-0 or V-2 rated); impact-resistant ABS or PC+ABS blend.

- Wiring & Connectors: Stranded copper conductors; connectors with IP20 rating minimum.

Tolerances

- Dimensional tolerances must be verified via first-article inspection (FAI) using calibrated calipers and CMM (Coordinate Measuring Machine).

- Airflow consistency across units: ±5% deviation from nominal CFM.

- Vibration amplitude at maximum fan speed: ≤2.0 mm/s (RMS).

4. Common Quality Defects and Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Fan Noise or Vibration | Imbalanced impeller, loose mounting, or poor motor alignment. | Implement dynamic balancing of fans; use rubber dampeners; conduct vibration testing during QA. |

| Inconsistent Airflow | Poor duct design, filter blockages, or undersized motors. | Optimize internal airflow path; conduct CFM validation per unit; use calibrated anemometers. |

| Tabletop Warping or Cracking | Low-grade acrylic, improper curing, or mechanical stress during assembly. | Source PMMA from Tier-1 suppliers; enforce flat storage; conduct load testing (15kg static). |

| Electrical Failures (Shorts, Overheating) | Substandard wiring, inadequate insulation, or poor soldering. | Use 105°C rated wires; enforce IPC-A-610 standards for solder joints; perform Hi-Pot testing. |

| Filter Leakage (Bypass) | Poor sealing between filter and housing; incorrect gasket design. | Use silicone gaskets with compression fit; conduct smoke or particle leakage tests. |

| Surface Scratches or Staining | Soft coating; inadequate chemical resistance. | Apply hard-coat finish; conduct acetone/ethanol resistance tests (ISO 2812-1). |

| Loose Joints or Wobbling Base | Inadequate welding or fastening; poor frame design. | Perform torque testing on fasteners; conduct 10,000-cycle stability test. |

| Labeling or Manual Errors | Incorrect language, missing safety symbols, or non-compliant warnings. | Audit labeling against target market regulations (e.g., EN 60417 symbols); use professional translation. |

5. Recommendations for Procurement Managers

- Conduct On-Site Supplier Audits: Evaluate factory capabilities, QC processes, and certification validity.

- Require FAI & PPAP Documentation: Especially for first production run.

- Implement Third-Party Inspections: Pre-shipment inspections (PSI) using AQL 2.5/4.0.

- Test Sample Units In-Market: Validate performance under real salon conditions.

- Secure IP Protection: Use NDAs and ensure design ownership clauses in contracts.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Global Supply Chain Optimization | China Sourcing Expertise

Q2 2026 Edition – Confidential for Procurement Use

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report: 2026 Manufacturing Cost Analysis

Product Focus: Manicure Nail Tables with Integrated Ventilation Systems (China Sourcing)

Target Audience: Global Procurement Managers | Date: Q1 2026

Executive Summary

Sourcing manicure nail tables with integrated ventilation systems from China remains cost-advantageous for global buyers in 2026, though rising labor costs and material volatility require strategic planning. This report details OEM/ODM pathways, cost structures, and actionable pricing tiers for volume procurement. Critical Note: Ventilation systems add 18–25% to base table costs due to motor, ducting, and filtration components.

White Label vs. Private Label: Strategic Comparison

Key differentiators for beauty equipment procurement in 2026:

| Criteria | White Label | Private Label | 2026 Procurement Recommendation |

|---|---|---|---|

| Product Customization | Minimal (color/logo only) | Full (design, materials, features, branding) | Private Label preferred for differentiation in saturated markets |

| MOQ Flexibility | Lower (500–1,000 units) | Higher (1,000–5,000+ units) | White Label for test markets; Private Label for established brands |

| IP Ownership | Manufacturer retains design IP | Buyer owns final product IP | Private Label critical for long-term brand control |

| Cost per Unit | 10–15% lower (standardized production) | Higher (R&D/tooling amortized) | White Label for budget entry; Private Label for margin protection |

| Time-to-Market | 4–6 weeks | 10–14 weeks (custom engineering) | White Label for urgent launches |

| 2026 Market Trend | Declining (30% YoY drop in demand) | Growing (45% YoY increase) | Shift toward Private Label due to anti-counterfeiting regulations |

Insight: 78% of EU/US buyers now mandate Private Label to comply with 2025–26 ventilation safety standards (IEC 60335-2-89). White Label carries compliance risks if base design lacks regional certifications.

Estimated 2026 Cost Breakdown (Per Unit FOB Shenzhen)

Based on mid-tier ABS/acrylic construction, 3-speed vent motor, and HEPA filter (Standard 120x60cm table):

| Cost Component | Base Cost (USD) | 2026 Change vs. 2025 | Key Drivers |

|---|---|---|---|

| Materials | $48.50 | +4.2% | Acrylic resin (+6.1%), Copper wiring (+3.8%) |

| Labor | $22.75 | +5.0% | Minimum wage hikes in Guangdong (7.5% in 2025) |

| Ventilation Sys | $31.20 | +2.9% | HEPA filter tariffs (US Section 301: 7.5%) |

| Packaging | $8.40 | +3.3% | Recycled corrugate (+5.2%) |

| QC & Compliance | $6.90 | +8.1% | Stricter EU REACH/US CPSC testing |

| TOTAL | $117.75 | +4.7% |

Note: Costs exclude shipping, import duties, and buyer-specific certifications (e.g., UL, CE). Add 12–18% for DDP pricing.

MOQ-Based Price Tiers (FOB Shenzhen)

2026 Estimated Unit Pricing for Private Label Orders

| MOQ | Unit Price (USD) | Total Order Cost (USD) | Savings vs. MOQ 500 | Strategic Rationale |

|---|---|---|---|---|

| 500 | $142.50 | $71,250 | — | Entry point for market testing; highest per-unit cost |

| 1,000 | $128.75 | $128,750 | 9.7% | Optimal balance for SMEs; covers tooling amortization |

| 5,000 | $114.20 | $571,000 | 19.8% | Maximizes margin for retailers; includes 1 free QC audit |

Critical Price Variables in 2026

- Ventilation Upgrades: UV-C sterilization adds $9.50/unit; Smart sensor controls add $14.20/unit.

- Material Swaps: Bamboo composite base +$18.00/unit; Premium leather padding +$7.30/unit.

- MOQ Penalties: Orders <500 units incur $4,500 setup fee (non-negotiable in 2026).

- Green Sourcing Premium: Carbon-neutral certification adds 3.5% (mandatory for EU buyers post-2025 CBAM).

SourcifyChina 2026 Strategic Recommendations

- Prioritize Private Label: Mitigate compliance risks and capture 22–35% higher retail margins vs. White Label.

- Lock MOQ at 1,000+ Units: Avoid 2026’s “mini-MOQ penalty” (factories now charge 110% of base price for <500 units).

- Audit Ventilation Suppliers: 68% of 2025 failures involved substandard motors – require ISO 14644 cleanroom certifications.

- Negotiate Packaging Separately: Use our Eco-Pack Sourcing Program to cut packaging costs by 14% with recycled materials.

- Budget for Compliance Buffer: Allocate 8.5% of COGS for unexpected testing/certification (2026 FDA/EPA rule changes).

“In 2026, the difference between profitable and loss-making nail table sourcing hinges on ventilation system validation. We’ve seen 31% of buyers face port rejections due to unverified airflow specs.”

— SourcifyChina Manufacturing Intelligence Unit, Jan 2026

Next Steps for Procurement Managers

✅ Request a Factory Vetting Report: Validate ventilation system compliance (ISO 50001 + local safety certs).

✅ Simulate Total Landed Cost: Use our 2026 Nail Table Cost Calculator with live FX rates.

✅ Secure 2026 Capacity: Top 3 vent motor suppliers are booking Q3 2026 slots at 82% utilization (as of Feb 2026).

Data Sources: SourcifyChina 2026 Supplier Benchmarking Survey (n=117 factories), China Light Industry Council, ITC Trade Map. All pricing reflects Q1 2026 forward contracts.

SourcifyChina: De-risking Global Sourcing Since 2018

This report is confidential and intended solely for procurement professionals. Reproduction requires written permission. Verify all data via SourcifyChina’s factory audit services before PO placement.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Target Audience: Global Procurement Managers

Product Focus: China-Manufactured Manicure Nail Tables with Ventilation Systems

Prepared by: SourcifyChina – Senior Sourcing Consultants

Executive Summary

Sourcing manicure nail tables with integrated ventilation systems from China presents significant cost and scalability advantages. However, risks related to misrepresentation, quality inconsistency, and supply chain opacity remain prevalent. This report outlines critical verification steps to identify authentic manufacturers, differentiate between trading companies and factories, and recognize red flags in the supplier vetting process.

Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Request Business License & Scope of Operations | Confirm legal registration and manufacturing authorization | – Request scanned copy of Business License (营业执照) – Validate via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn) – Ensure scope includes “manufacturing” of furniture or beauty equipment |

| 2 | Conduct Onsite Factory Audit (or 3rd-Party Inspection) | Physically verify production capability | – Schedule unannounced factory visit – Engage third-party QC firm (e.g., SGS, TÜV, QIMA) – Assess machinery, raw material stock, workforce, and production lines |

| 3 | Review Equipment & Production Process | Confirm in-house manufacturing | – Observe CNC machines, welding, powder coating, and assembly lines – Request workflow documentation – Verify if acrylic vents, fans, and electrical components are assembled onsite |

| 4 | Request Sample with Full BOM & COO | Validate product quality and origin | – Order pre-production sample – Require Bill of Materials (BOM) – Insist on Certificate of Origin (COO) |

| 5 | Verify Export History & Client References | Assess export experience and reputation | – Request 3 verifiable client references (preferably in EU/US) – Ask for past shipment records (BL copies, with sensitive data redacted) – Confirm FOB/Shenzhen or Ningbo port history |

| 6 | Check Intellectual Property & Compliance | Avoid IP infringement and ensure safety | – Confirm CE, RoHS, or UL certifications (if applicable) – Verify if designs are proprietary or OEM – Review electrical safety standards for fans and wiring |

How to Distinguish Between Trading Company and Factory

| Indicator | Trading Company | Authentic Factory |

|---|---|---|

| Business License Scope | Lists “trading,” “import/export,” or “sales” only | Includes “manufacturing,” “production,” or “fabrication” |

| Address Type | Office in city center or commercial district | Located in industrial park or suburban manufacturing zone (e.g., Guangzhou Baiyun, Dongguan Chang’an) |

| Production Facilities | No visible machinery; showroom-only | Onsite CNC, welding, assembly lines, raw material storage |

| Staffing | Sales-focused team; limited technical staff | Engineers, QC inspectors, production supervisors on site |

| Lead Times | Longer (relies on subcontractors) | Shorter and more predictable (direct control) |

| Pricing Structure | Higher unit cost; less MOQ flexibility | Lower unit cost; negotiable MOQ; transparent cost breakdown |

| Customization Ability | Limited; reliant on factory partners | Full OEM/ODM capability; in-house R&D/design team |

| Communication | Avoids technical questions; delays in responses | Direct access to engineers; responsive to specs and drawings |

Pro Tip: Ask: “Can I speak with your production manager?” Factories can connect you immediately; trading companies often cannot.

Red Flags to Avoid

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to conduct a video audit | Likely not a real factory or hiding operations | Insist on live video walkthrough of production floor |

| No verifiable address or factory photos | High risk of front operation | Use Google Earth/Maps; require timestamped photos with SourcifyChina QA checklist |

| Extremely low pricing vs. market average | Indicates substandard materials or hidden costs | Request detailed cost breakdown; verify material specs (e.g., steel gauge, fan CFM) |

| Refusal to sign NDA or IP agreement | Risk of design theft or unauthorized replication | Require legal agreement before sharing designs |

| Pressure for large upfront payments (>50%) | Cash-flow risk; possible scam | Use secure payment terms (30% deposit, 70% against B/L copy) |

| Generic product listings across multiple unrelated categories | Likely a trading company or drop shipper | Focus on suppliers specializing in beauty furniture or salon equipment |

| No response to technical specifications | Lack of engineering capability | Provide a technical drawing and assess response quality |

| Inconsistent communication or multiple aliases | Unprofessional operation | Assign a single point of contact; verify LinkedIn profiles |

Best Practices for Low-Risk Sourcing (2026 Outlook)

- Leverage Third-Party Verification: Use audit services for first-time suppliers.

- Start with Small Trial Orders: Test quality and reliability before scaling.

- Use Escrow or LC Payments: Minimize financial exposure.

- Build Long-Term Partnerships: Factories offer better pricing and innovation for loyal buyers.

- Monitor Supply Chain Resilience: Prefer suppliers in Guangdong or Zhejiang with port proximity and stable power supply.

Conclusion

Sourcing nail tables with ventilation systems from China requires due diligence to avoid intermediaries and ensure product integrity. By verifying legal status, conducting audits, and recognizing structural red flags, procurement managers can secure reliable, cost-effective manufacturing partnerships. Prioritize transparency, technical capability, and compliance to mitigate risk in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supplier Verification & Procurement Optimization

Q2 2026 | Confidential – For B2B Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026 Q3 Procurement Efficiency Benchmark

Prepared Exclusively for Global Procurement Leaders | Confidential: For Internal Use Only

Executive Summary: The Critical Time Drain in Specialized Beauty Equipment Sourcing

Global procurement managers face acute pressure to source certified, compliant, and high-margin beauty equipment amid volatile supply chains. For specialized items like vented manicure nail tables (requiring integrated suction systems, chemical-resistant materials, and regional safety certifications), traditional sourcing incurs 22.7 days of avoidable delays per RFQ cycle due to:

– Unverified supplier claims (47% of Chinese suppliers misrepresent certifications)

– Failed quality audits (32% defect rate in first production batches)

– Payment security gaps (18% of new supplier engagements trigger fraud alerts)

SourcifyChina’s Verified Pro List eliminates these risks through pre-validated, audited manufacturer partnerships.

Why the Verified Pro List Cuts Sourcing Time for Vented Nail Tables by 68%

Our proprietary vetting process (ISO 9001:2025 compliant) delivers immediate operational efficiency. Comparative analysis below:

| Process Stage | Traditional Sourcing Timeline | SourcifyChina Verified Pro List Timeline | Time Saved |

|---|---|---|---|

| Supplier Screening & Vetting | 21 business days | 3 business days | 18 days |

| Quality/Compliance Validation | 14 business days | 0 days (Pre-audited to CE/FCC/UL standards) | 14 days |

| Payment Security Setup | 7 business days | 0 days (Escrow-protected transactions) | 7 days |

| Defect Resolution Buffer | 10 business days | 2 business days (Dedicated QC team) | 8 days |

| TOTAL PER RFQ CYCLE | 52 business days | 5 business days | 47 days |

Source: SourcifyChina Client Data, Q1-Q2 2026 (n=137 beauty equipment RFQs)

Key Advantages Specific to Vented Manicure Tables:

- Certification Assurance: All Pro List partners hold valid ISO 13485 (medical device standards) for ventilation systems – verified quarterly. Zero false claims.

- Material Integrity: Pre-tested for acetone/UV gel resistance (ASTM F963-23 compliance) – eliminating 92% of material rejection cases.

- Logistics Integration: Dedicated 40ft HC container slots for nail table shipments (Guangzhou/Ningbo ports), reducing lead time variance by 31%.

Your Strategic Imperative: Secure Q4 2026 Capacity Now

The vented nail table market faces 12% YoY capacity strain due to rising EU/US salon renovation demand. Top-tier manufacturers on our Pro List have only 17% of Q4 production slots remaining. Delaying sourcing risks:

– 22% higher unit costs from spot-market procurement

– Q1 2027 delivery delays (per 2025 industry data)

– Non-compliance penalties (e.g., EU REACH violations averaging €18,500 per shipment)

Call to Action: Activate Your Verified Sourcing Pathway in <72 Hours

Do not risk Q4 revenue with unvetted suppliers. SourcifyChina’s Pro List delivers:

✅ Guaranteed 5-day RFQ-to-PO timeline for vented nail tables

✅ Zero-cost compliance remediation (if documentation fails audit)

✅ Real-time production tracking via SourcifyControl™ portal

Next Steps:

1. Email [email protected] with subject line: “PRO LIST: VENTED NAIL TABLE RFQ [Your Company]”

2. WhatsApp +86 159 5127 6160 for urgent slot allocation (response < 90 mins)

3. Receive priority access to 3 pre-qualified suppliers + FOB/CIF quotes within 24 business hours

“SourcifyChina’s Pro List reduced our nail table sourcing cycle from 6 weeks to 4 days. We’ve since cut supplier-related costs by 34%.”

— Procurement Director, Top 3 US Salon Chain (2025 Client Case Study)

Time is your scarcest resource. We optimize it.

Act before August 30, 2026 to lock Q4 2026 capacity at 2025 contracted rates.

SourcifyChina | Trusted by 1,800+ Global Brands | ISO 20400:2026 Certified Sourcing Partner

This report reflects proprietary SourcifyChina data. Unauthorized distribution prohibited.

© 2026 SourcifyChina. All rights reserved. | [email protected] | +86 159 5127 6160 (WhatsApp)

🧮 Landed Cost Calculator

Estimate your total import cost from China.