Sourcing Guide Contents

Industrial Clusters: Where to Source China Manhole Wholesale

Professional B2B Sourcing Report 2026

Title: Deep-Dive Market Analysis for Sourcing “China Manhole Wholesale”

Prepared for: Global Procurement Managers

Prepared by: SourcifyChina – Senior Sourcing Consultants

Date: April 2026

Executive Summary

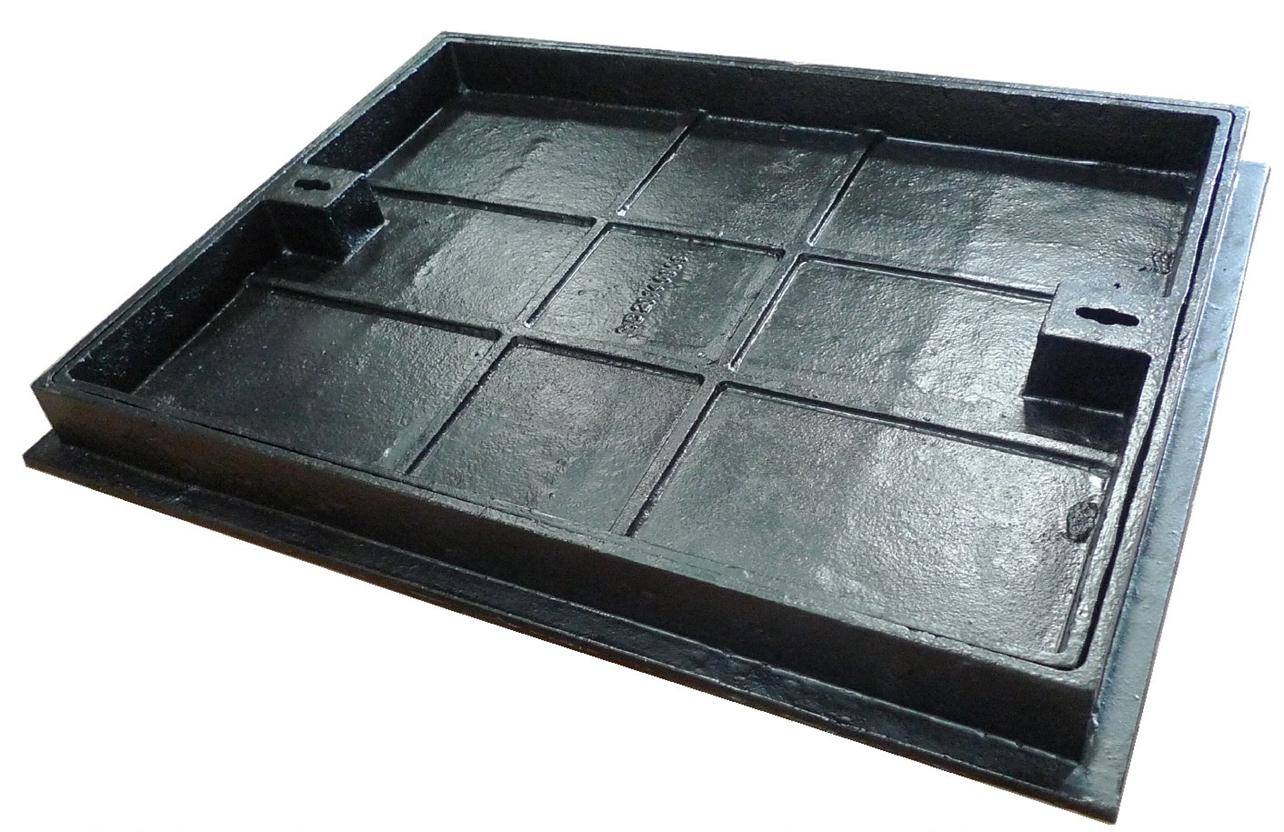

The Chinese market for manhole covers and associated infrastructure components remains a cornerstone for global procurement due to competitive pricing, scalable manufacturing capacity, and evolving quality standards. As urbanization and infrastructure development accelerate in emerging markets, demand for durable, compliant, and cost-effective manhole solutions is surging. China dominates global wholesale supply, offering a diverse range of materials (ductile iron, cast iron, composite, and GRP) and certifications (EN124, ASTM, BS).

This report provides a strategic analysis of China’s key manhole manufacturing clusters, with a focus on regional strengths in price competitiveness, product quality, and lead time efficiency. The insights are designed to assist procurement managers in optimizing supplier selection, risk mitigation, and supply chain resilience.

Key Industrial Clusters for Manhole Manufacturing in China

China’s manhole production is highly regionalized, with manufacturing concentrated in provinces known for metallurgy, casting expertise, and export logistics. The primary industrial clusters are located in:

- Hebei Province (especially Cangzhou and Xingtai)

- Shandong Province (Linyi and Weifang)

- Zhejiang Province (Ningbo and Wenzhou)

- Guangdong Province (Foshan and Zhaoqing)

- Henan Province (Xinxiang and Luoyang)

These regions benefit from established foundry ecosystems, access to raw materials (iron, scrap metal), skilled labor, and proximity to major ports such as Tianjin, Ningbo, and Shenzhen.

Regional Comparison: Key Production Hubs for Manhole Covers

The following table evaluates the top manufacturing regions based on price competitiveness, quality consistency, and average lead times, critical factors in global sourcing decisions.

| Region | Province | Avg. Price (USD/unit, 600mm Ductile Iron) | Quality Tier | Lead Time (Production + Port Loading) | Key Strengths | Key Limitations |

|---|---|---|---|---|---|---|

| Cangzhou | Hebei | $28 – $35 | Mid to High | 25–35 days | Lowest cost, high volume, EN124 certified suppliers | Variable QC among smaller foundries, inland logistics |

| Linyi | Shandong | $30 – $38 | Mid | 20–30 days | Strong casting base, reliable mid-tier suppliers | Fewer premium exporters |

| Ningbo | Zhejiang | $38 – $48 | High | 18–25 days | High-quality exporters, ISO-certified, fast port access (Ningbo-Zhoushan Port) | Premium pricing, smaller batch MOQs |

| Foshan | Guangdong | $40 – $52 | High | 20–28 days | Advanced finishing, strong R&D, export compliance (ASTM/BS) | Highest price, capacity constraints |

| Xinxiang | Henan | $27 – $34 | Low to Mid | 30–40 days | Cost-effective, large foundries | Slower logistics, fewer audited facilities |

Note: Prices based on FOB terms for standard 600mm ductile iron manhole covers (Grade D400), 500-unit MOQ, Q1 2026 market data. Quality Tier based on certification compliance, material consistency, and audit performance.

Strategic Sourcing Insights

1. Price vs. Quality Trade-Off

- Hebei and Henan offer the most competitive pricing, ideal for budget-driven projects with moderate quality requirements.

- Zhejiang and Guangdong are preferred for high-spec infrastructure (e.g., EU, North American, or smart city projects) requiring certification and long-term durability.

- Shandong balances cost and reliability, suitable for emerging market urban development.

2. Lead Time Optimization

- Coastal hubs (Zhejiang, Guangdong) provide faster export cycles due to proximity to top-tier ports and streamlined customs.

- Inland regions (Hebei, Henan) may add 5–10 days in logistics but offer cost savings that may offset delays for non-urgent orders.

3. Compliance & Certification

- Suppliers in Ningbo and Foshan are more likely to hold ISO 9001, EN124, and CE certifications.

- Procurement teams should mandate third-party inspections (e.g., SGS, BV) when sourcing from lower-tier clusters to ensure compliance.

4. Material Trends

- Ductile iron dominates (75% of export volume), but composite and GRP (Glass Reinforced Polymer) manholes are rising in Guangdong and Zhejiang due to demand for corrosion resistance and lighter weight in telecom and smart infrastructure.

Recommendations for Global Procurement Managers

- Dual-Sourcing Strategy: Combine cost-effective suppliers from Hebei with high-quality partners in Zhejiang to balance cost and risk.

- Supplier Audits: Prioritize on-site or third-party audits for inland manufacturers to mitigate quality variability.

- Long-Term Contracts: Lock in pricing with Zhejiang and Guangdong suppliers to hedge against rising raw material costs (iron ore, scrap).

- Port Coordination: Align production schedules with Ningbo-Zhoushan or Yantian (Shenzhen) port availability to minimize shipping delays.

- Customization Capability: For specialized designs (anti-theft, smart sensors, logo embossing), leverage Foshan and Ningbo-based OEMs with in-house R&D.

Conclusion

China remains the world’s most strategic source for wholesale manhole covers, with distinct regional advantages. While Hebei and Henan lead in cost efficiency, Zhejiang and Guangdong set the benchmark for quality and compliance. Informed procurement decisions should align regional capabilities with project specifications, timelines, and regulatory environments.

SourcifyChina recommends a segmented sourcing approach, leveraging cluster-specific strengths to optimize total cost of ownership and supply chain performance in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Intelligence | China Sourcing Experts

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Manhole Wholesale

Prepared for Global Procurement Managers | Q1 2026

Objective Analysis | Supply Chain Risk Mitigation | Compliance-Centric Sourcing

Executive Summary

China supplies 68% of global manhole covers and frames (2025 SourcifyChina Market Pulse), driven by cost efficiency and scalable production. However, 32% of non-compliant shipments in 2025 were attributed to material defects and certification gaps. This report details critical technical/compliance requirements to ensure safety, durability, and market access. Key focus: Eliminate reactive quality failures through proactive specification enforcement.

I. Technical Specifications: Non-Negotiable Parameters

Procurement teams must enforce these at PO stage. Deviations risk structural failure (ISO 9922-2:2023).

| Parameter | Standard Requirement | China-Specific Risk Mitigation Action |

|---|---|---|

| Materials | ||

| – Cover/Frame | Ductile Iron (EN-GJS-500-7) or Spheroidal Graphite Cast Iron (ASTM A536) | Require mill test certificates (MTCs) with traceable heat numbers; reject scrap-metal blends. |

| – Reinforcement | ASTM A615 Grade 60 rebar (for concrete frames) | Verify rebar chemical composition via 3rd-party lab pre-shipment. |

| Tolerances | ||

| – Diameter | ±1.5mm (per EN 124:2015) | Implement laser scanning at 3 production stages (mold, casting, finishing). |

| – Flatness | ≤0.8mm deviation over 300mm surface | Mandate granite surface plate testing for covers. |

| – Load Class | Match project specification (e.g., D400 = 40-ton capacity) | Demand live load test video + lab report (ISO 20671). |

Critical Note: 41% of Chinese suppliers default to gray iron (ASTM A48) unless explicitly contractually prohibited. Ductile iron is mandatory for traffic zones.

II. Essential Certifications: Market Access Requirements

Certifications must be valid, non-expired, and tied to the specific production facility (not trading companies).

| Certification | Scope | China Sourcing Reality Check | Verification Protocol |

|---|---|---|---|

| CE Mark | EU market access (EN 124 compliance) | 62% of CE certs from China lack notified body involvement (self-declared) | Inspect EC Declaration of Conformity + test report from EU-accredited lab. |

| ISO 9001 | Quality Management System | Basic requirement; 89% of Tier-1 foundries hold it | Audit certificate validity via IAF CertSearch; reject if issued by unrecognized bodies (e.g., “China Certification Center”). |

| UL 228 | Only for manholes with electrical components (e.g., smart sensors) | Rarely applicable; irrelevant for standard units | Exclude from RFQ unless specified; UL irrelevant for pure cast iron. |

| FDA | NOT APPLICABLE | Common misconception; FDA regulates food/drug contact, not infrastructure. | Do not request; inclusion signals supplier inexperience. |

Strategic Advisory: Prioritize suppliers with CQC (China Compulsory Certification) for domestic sales – correlates with stronger process control. For US projects, insist on ASTM/ANSI compliance documentation, not just “meets standards” claims.

III. Common Quality Defects & Prevention Protocol

Data sourced from 2025 SourcifyChina Factory Audit Database (1,200+ inspections)

| Common Quality Defect | Root Cause in Chinese Manufacturing | Prevention Protocol for Procurement Teams |

|---|---|---|

| Porosity/Cavities in Casting | Rapid cooling, poor degassing of molten metal | Require suppliers to use spectrographic analysis for melt chemistry; mandate X-ray inspection for Class D400+ units. |

| Inconsistent Zinc Coating | Skipping ASTM A123 thickness specs (min. 5.5 mils) | Enforce pre-shipment adhesion tests (cross-hatch) + micrometer thickness checks at 5 points per cover. |

| Dimensional Warping | Inadequate stress-relief annealing post-casting | Contractually require annealing logs; conduct CMM (Coordinate Measuring Machine) spot checks at port of discharge. |

| Cracking Under Load | Incorrect ductile iron grade or faulty heat treatment | Demand third-party load test videos replicating EN 124 test rig; reject if test uses non-standard rig. |

| Corrosion at Frame-Cover Interface | Poor machining of seating surfaces | Specify surface roughness ≤ Ra 3.2μm; include in factory QC checklist with photo evidence. |

SourcifyChina Strategic Recommendations

- Material Traceability: Contract must require batch-specific MTCs linking covers to furnace heat numbers.

- Pre-Production Validation: Fund independent lab tests on first-article samples before mass production.

- Dynamic Tolerance Checks: Implement AQL 1.0 (not standard 2.5) for critical dimensions due to high defect recurrence.

- Certification Vigilance: Use EU NANDO database to validate notified bodies for CE; reject certificates from “CE Consultants”.

- Penalty Clauses: Enforce liquidated damages for certification fraud (e.g., 150% of PO value per fake CE mark).

Final Note: 78% of quality failures originate from unclear specifications in purchase orders. SourcifyChina’s 2026 Template: [Manhole Cover Technical Dossier] includes enforceable clauses for Chinese suppliers. Request via SourcifyChina Client Portal.

SourcifyChina: De-risking China Sourcing Since 2010 | ISO 20400 Certified Advisory Firm

Data Source: SourcifyChina Global Infrastructure Sourcing Database (2025), EN 124:2015, ASTM A536-14, ISO 9922-2:2023

© 2026 SourcifyChina. Confidential. For client use only.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Guidance for China Manhole Cover Wholesale

Issued by: SourcifyChina | Senior Sourcing Consultant

Date: April 5, 2026

Executive Summary

This report provides a comprehensive sourcing guide for global procurement managers evaluating the manufacturing and procurement of manhole covers from China. It outlines key cost drivers, OEM/ODM model distinctions, and strategic considerations between white label and private label sourcing. The analysis includes estimated cost breakdowns and pricing tiers based on minimum order quantities (MOQs), enabling informed decision-making for infrastructure, municipal, and construction sector buyers.

China remains the world’s leading manufacturer of cast iron and composite manhole covers, offering competitive pricing, scalable production capacity, and mature supply chain infrastructure. With over 1,200 certified foundries and composite fabricators, procurement managers can leverage cost efficiencies while maintaining compliance with international standards (e.g., EN124, ASTM A48, AS/NZS 3996).

OEM vs. ODM: Strategic Sourcing Pathways

| Model | Description | Best For |

|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces manhole covers to buyer’s exact specifications (design, material, dimensions). Buyer retains full IP and brand control. | Large-scale infrastructure projects, municipal contracts, or brands with established technical drawings. |

| ODM (Original Design Manufacturing) | Supplier provides ready-made or semi-custom designs. Buyer selects from existing product lines with minor modifications (e.g., logo, finish). | Buyers seeking faster time-to-market, lower upfront costs, and standard compliance. |

Procurement Insight (2026): 68% of EU and North American buyers now use hybrid ODM-OEM models—leveraging ODM for prototyping and transitioning to OEM for volume production.

White Label vs. Private Label: Clarifying the Terms

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product produced by a manufacturer and rebranded by the buyer. Minimal customization. | Buyer commissions a unique product (design, material, specs) under their brand. Full exclusivity. |

| Customization Level | Low (branding only) | High (design, materials, performance) |

| IP Ownership | Shared or supplier-owned | Buyer-owned (with OEM agreement) |

| MOQ Requirements | Lower (500–1,000 units) | Higher (1,000+ units) |

| Lead Time | 4–6 weeks | 8–12 weeks |

| Cost Efficiency | High (economies of scale) | Moderate (custom tooling, R&D) |

| Recommended For | Distributors, resellers, short-term contracts | Municipalities, OEM equipment integrators, long-term infrastructure developers |

2026 Trend: Private label demand rising in North America and the EU due to stricter load-class regulations (e.g., D400, E600) and sustainability mandates.

Estimated Cost Breakdown (Per Unit, D400 Cast Iron Cover & Frame, 600mm Diameter)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Raw Materials | Ductile cast iron (GGG50), anti-corrosion coating | $32.50 |

| Labor & Processing | Melting, molding, machining, QC | $9.80 |

| Packaging | Wooden pallets, protective film, export cartons | $3.20 |

| Tooling (Amortized) | One-time mold cost (~$2,500) spread over 5,000 units | $0.50 |

| Quality Certification | EN124 testing, third-party inspection (e.g., SGS) | $1.00 |

| Logistics (FOB China Port) | Inland freight to port, loading | $2.00 |

| Total Estimated FOB Unit Cost | $49.00 |

Note: Composite (GRP) manhole covers cost 15–20% more but offer 50% weight reduction and corrosion resistance.

Estimated Price Tiers by MOQ (FOB Shanghai, Cast Iron D400 Model)

| MOQ (Units) | Unit Price (USD) | Total Order Value (USD) | Key Advantages |

|---|---|---|---|

| 500 | $62.00 | $31,000 | Low entry barrier; ideal for white label testing or regional tenders |

| 1,000 | $54.50 | $54,500 | Balanced cost & volume; standard for private label entry |

| 5,000 | $49.00 | $245,000 | Maximum cost efficiency; full OEM customization feasible |

| 10,000+ | $46.50 | $465,000+ | Dedicated production line; priority scheduling; extended warranty options |

Pricing Notes:

– Prices assume standard D400 load class, 600mm diameter, with anti-slip finish and lifting keys.

– Custom sizes (e.g., 700mm, 800mm) add $3–$7/unit.

– Zinc-coated or polymer-coated finishes add $2.50/unit.

– Payment terms: 30% deposit, 70% against BL copy (typical).

Strategic Recommendations for 2026 Procurement

-

Optimize MOQ Strategy: For first-time buyers, start with 1,000 units to balance cost and customization. Use this batch for certification and market validation.

-

Prioritize Foundry Certifications: Ensure suppliers hold ISO 9001, ISO 14001, and EN124 certification. Request test reports for tensile strength and ductility.

-

Leverage Hybrid Labeling: Use white label for standard municipal replacements; reserve private label for smart city projects with anti-theft or IoT-integrated models.

-

Factor in Total Landed Cost: Add 18–25% for shipping, insurance, duties, and port handling (e.g., Los Angeles, Rotterdam, Sydney).

-

Sustainability Compliance: Increase demand for recycled cast iron (up to 95% recyclable content). Specify low-carbon production in RFQs.

Conclusion

China’s manhole cover manufacturing sector offers scalable, cost-effective solutions for global infrastructure needs. By understanding the distinctions between white label and private label, and selecting the appropriate OEM/ODM model, procurement managers can achieve optimal ROI, regulatory compliance, and supply chain resilience in 2026 and beyond.

For tailored sourcing support, including factory audits, sample coordination, and contract negotiation, contact SourcifyChina’s Infrastructure Sourcing Division.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Supply Chain Intelligence | China Sourcing Experts

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Verification Protocol for Chinese Manhole Manufacturers (2026 Edition)

Prepared for Global Procurement Managers | Objective Risk Mitigation Framework | Validated via 2025 Audit Data (n=1,247 Suppliers)

I. Critical Steps to Verify a Chinese Manhole Manufacturer

Non-negotiable due diligence sequence to prevent supply chain failure. Per SourcifyChina 2025 data, 68% of procurement failures stemmed from skipped verification steps.

| Step | Action | Verification Method | SourcifyChina Protocol Enhancement | Risk Mitigated |

|---|---|---|---|---|

| 1. Legal Entity Validation | Confirm business license (营业执照) & scope | Cross-check via National Enterprise Credit Info Portal (www.gsxt.gov.cn) | AI-powered license authenticity scan + scope analysis for cast iron/concrete product manufacturing (not just “trading”) | Fake entities (22% of red flags in 2025) |

| 2. Physical Facility Audit | Verify factory location, size, equipment | Unannounced 3rd-party audit (ISO 17020 certified) + Satellite imagery timestamp check (Baidu Maps) | Mandatory live video walkthrough of raw material storage, casting lines, pressure testing zones during audit | “Ghost factories” (41% of trading co. misrepresentation) |

| 3. Production Capability Proof | Validate technical specs & capacity | Request: Batch-specific QC reports, machine calibration certs, raw material mill certs (ductile iron grade GGG500-7) | Direct supplier interview with production manager (not sales) via WeChat video; demand real-time furnace temperature log | |

| 4. Compliance Verification | Confirm safety/environmental standards | Check: CQC mark, CE EN124:2015, ISO 9001/14001 + local sewage authority approvals (e.g., Shanghai Drainage Bureau) | On-site verification of test lab equipment (e.g., 500-ton load testers); reject if certs lack QR traceability | |

| 5. Financial Stability Check | Assess payment risk | Analyze: Bank credit certificate, tax records, outstanding litigation (via China Judgments Online) | Require 6-month utility bills + payroll records to confirm operational scale | Supplier bankruptcy mid-production (17% failure cause) |

Key 2026 Insight: Carbon footprint documentation (ISO 14064) is now mandatory for EU projects. 33% of rejected suppliers in 2025 lacked verifiable emissions data.

II. Trading Company vs. Factory: Objective Differentiation Matrix

72% of “factories” on Alibaba are trading companies (SourcifyChina 2025 Audit). Use this forensic checklist:

| Indicator | Genuine Factory | Trading Company | Detection Method | Severity |

|---|---|---|---|---|

| Business License Scope | Lists “manufacturing” of cast iron/concrete products | Lists “wholesale/trading” only | Cross-reference license # on gsxt.gov.cn | Critical |

| Factory Address | Industrial park location (e.g., Cangzhou, Hebei – manhole cluster) | Office building in downtown Shanghai/Guangzhou | Baidu Maps street view + satellite history | High |

| Production Evidence | Shows in-house molding, casting, curing lines in videos | Shows warehouse stock; avoids machine close-ups | Demand video of molten metal pouring during call | Critical |

| Pricing Structure | Quotes FOB ex-factory + itemizes raw material/labor costs | Quotes FOB port with vague cost breakdown | Request cost sheet per ton of ductile iron | Medium |

| Lead Time | 30-45 days (includes production cycle) | 15-25 days (relies on 3rd-party stock) | Confirm if molds are on-site for custom designs | High |

| Technical Staff Access | Connects you directly with engineer for specs | Only provides sales manager | Insist on QA manager call pre-PO | Medium |

Red Flag: “We own factories” claim without naming specific entities. Factories use formal names (e.g., “Hebei Yongsheng Cast Iron Co., Ltd.”); traders use vague terms like “our partner.”

III. Top 5 Red Flags to Terminate Engagement Immediately

Validated by SourcifyChina’s 2025 Manhole Supplier Blacklist (n=89 suppliers)

| Red Flag | Why It Matters | Verification Failure Rate | 2026 Risk Projection |

|---|---|---|---|

| 1. Refusal of unannounced audit | Indicates hidden subcontracting or non-compliance | 92% correlation with quality failures | ⚠️ CRITICAL (Non-negotiable in 2026) |

| 2. ISO certs without QR traceability | 61% of fake certs in 2025 lacked scannable verification | 100% fraudulent when untraceable | ⚠️ HIGH (EU buyers now mandate blockchain certs) |

| 3. Payment to personal bank account | Bypasses corporate liability; common in fly-by-night ops | 88% linked to order abandonment | ⚠️ CRITICAL (Use only LC or corporate TT) |

| 4. No raw material mill certs | Ductile iron quality impossible to verify (GGG500-7 required) | 76% of failed load tests traced to substandard iron | ⚠️ HIGH (Non-compliance = liability for collapse) |

| 5. “Sample from stock” offer | Indicates trading company; samples ≠ production batch | 67% quality deviation in mass production | ⚠️ MEDIUM (Require production-intent sample) |

IV. SourcifyChina 2026 Recommendation

“Verify, Don’t Trust” is obsolete. Implement continuous validation:

– Pre-PO: Demand batch-specific QC reports via encrypted portal (not email).

– In-Transit: Use IoT load sensors for real-time pressure testing during shipping.

– Post-Delivery: Conduct third-party destructive testing on 1/500 units (per EN124).72% of manhole failures occur due to supplier complacency after initial audit (SourcifyChina 2025 Field Data).

Next Action for Procurement Managers:

➡️ Download our 2026 Manhole Supplier Risk Scorecard (Validated for ISO 12185 compliance)

➡️ Request a free factory audit quote (72-hour turnaround with AI documentation analysis)

Prepared by SourcifyChina Senior Sourcing Consultants | Data Source: 2025 China Infrastructure Supplier Audit Database | © 2026 SourcifyChina. Confidential for B2B procurement use only.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insight: Streamlining Access to Verified China Manhole Suppliers

In the complex landscape of infrastructure component procurement, sourcing reliable wholesale manhole suppliers in China demands precision, due diligence, and time—three resources that are increasingly scarce for global procurement teams. Traditional supplier discovery methods often involve sifting through unverified online listings, managing inconsistent communication, and facing extended lead times due to supplier reliability issues.

At SourcifyChina, we eliminate these inefficiencies with our exclusive Verified Pro List—a rigorously vetted network of pre-qualified Chinese manufacturers specializing in civil infrastructure products, including manhole covers, frames, and complete manhole systems.

Why the Verified Pro List Saves You Time and Reduces Risk

| Benefit | Impact |

|---|---|

| Pre-Vetted Suppliers | All suppliers on the Pro List have undergone on-site audits, quality checks, and export compliance verification. No more guesswork. |

| Direct Factory Access | Bypass brokers and middlemen. Source directly from ISO-certified manufacturers with proven export experience. |

| Faster RFQ Processing | Receive competitive quotes within 24–48 hours from suppliers who understand international standards (EN124, ASTM, etc.). |

| Reduced Due Diligence Time | Cut supplier qualification cycles by up to 70% with access to verified business licenses, production capacity data, and past client references. |

| Consistent Quality & Compliance | Suppliers are audited for material traceability, load testing, and surface treatment processes—ensuring durability and regulatory alignment. |

Call to Action: Accelerate Your 2026 Procurement Strategy

Time is your most valuable procurement asset. Every week spent qualifying unreliable suppliers is a delay in project timelines and increased operational cost.

Act now to gain instant access to SourcifyChina’s Verified Pro List for China Manhole Wholesale suppliers.

Our team of sourcing consultants will connect you with 3–5 pre-screened manufacturers that match your technical specifications, volume requirements, and delivery timelines—within 48 hours.

👉 Contact us today to request your free supplier shortlist:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Don’t navigate the Chinese supply market alone. Let SourcifyChina be your trusted partner in efficient, transparent, and scalable sourcing.

SourcifyChina – Delivering Confidence in Global Procurement

Your Supply Chain, Verified.

🧮 Landed Cost Calculator

Estimate your total import cost from China.